Bennamann is the biomethane upgrading equipment systems supplier that, for the first time, supplies affordable upgrader units to the average cash-strapped UK farmer‘s agricultural biogas plant.

Until now, most UK farm biogas plant owners have faced a frustrating challenge: their plants are too small for the new high-efficiency biomethane upgrading equipment. Major suppliers have typically required minimum biogas outputs that exceed what the average farm can produce. This leaves many farmers unable to tap into valuable biomethane markets despite having functional anaerobic digestion systems.

Bennamann stands out as a biomethane upgrading supplier with a solution designed specifically for smaller operations. Their new CAPCH4 Biogas Upgrader®, launched in the summer of 2025, can process the modest biogas volumes common on UK farms.

This technology transforms standard biogas into high-quality biomethane suitable for vehicle fuel or portable power systems.

This article explores how the CAPCH4® system works, what makes it different from other options, and why it might be the perfect fit for your farm's biogas plant. We'll compare it with other market offerings and outline key factors to consider when selecting biogas upgrading equipment.

The right choice could free the farm from the tyranny of poor rates from local electricity grid operators, and even without a gas grid connection, use the CNG to power the farm vehicles, and with enough output, sell your compressed biomethane to local transport businesses. Do this via your own CNG (LNG equivalent) Truck Fuelling Station, gain a far better return for your output and transform your farm waste into a profitable energy resource.

There is an opportunity to use self-contained portable trailer-mounted biomethane upgraders that can tour a group of digesters while each farm draws off biomethane via the CNG fuelling station mounted on the trailer itself.

Key Takeaways on the subject of Bennamann – Biomethane Upgrading Supplier For The Average-Poor UK Farm Biogas Plant

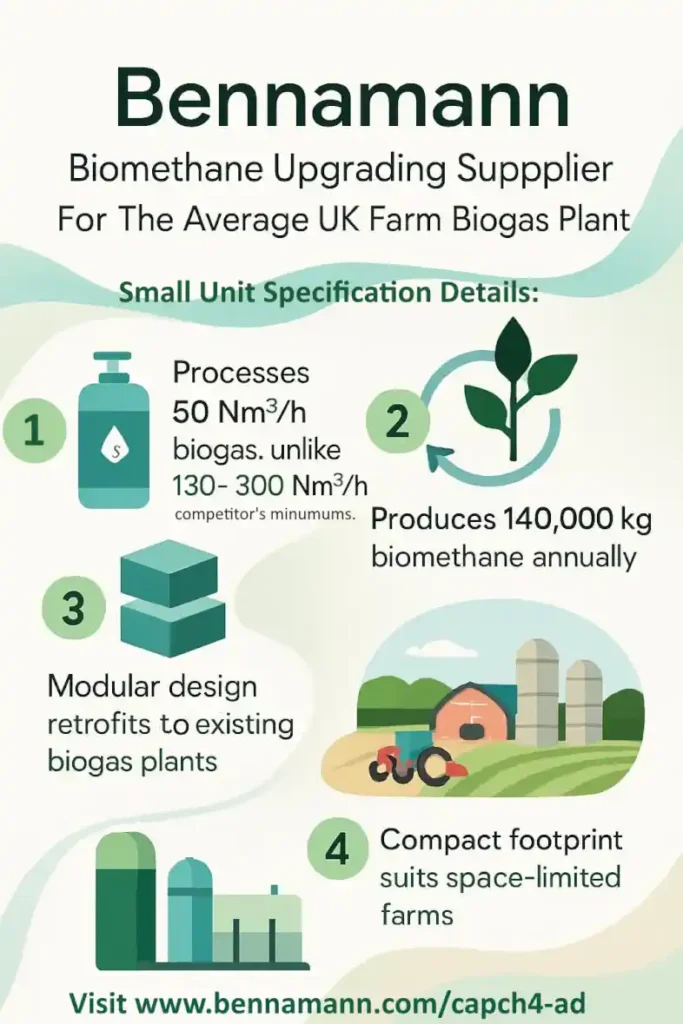

- Bennamann's CAPCH4® Biogas Upgrader processes just 50 Nm³/h of biogas, making it ideal for small UK farms, while competitors require 180-300 Nm³/h minimum.

- Set to launch in 2025, the CAPCH4® system can produce 140,000 kg of biomethane annually from farm waste, creating a new revenue stream for farmers.

- The upgrader features a modular design that easily retrofits to existing biogas plants without major modifications, saving farmers time and money.

- Unlike industrial-scale equipment, CAPCH4® has a compact footprint with simple electrical integration requirements, making it practical for space-limited farm operations.

- The system includes advanced membrane separation technology, built-in odorisation, and high-pressure storage at 250 bar that meets all safety standards.

- Get into the renewable energy market and gain additional income, as a biomethane producer, from Renewable Gas Guarantees of Origin (RGGOs) and Renewable Transport Fuel Certificates (RTFCs).

Comparison of minimum biogas output from major biomethane upgrading equipment suppliers

Many farm biogas plant owners face challenges in finding suitable upgrading equipment for smaller operations. Large industrial upgraders often require high minimum gas flows that small farms simply cannot produce. This creates a barrier for many UK agricultural biogas plants wanting to convert their biogas to biomethane.

| Supplier | Minimum Biogas Input (Nm³/h) | Technology Type | Best Suited For |

|---|---|---|---|

| Greenlane Renewables | 250 | Water Wash System | Medium to large operations |

| Clarke Energy | 200 | Membrane/Selective Solvent | Industrial and larger agricultural sites |

| EnviTec Biogas | 300 | Pressurised Water Scrubbing | Customised larger installations |

| Air Liquide | 180 | Modular Units | Mid-sized agricultural projects and large |

| Bennamann CAPCH4 | 50 | Proprietary Technology | Small, mid-sized and large farm operations |

The data shows a clear gap in the market. Most upgrading systems require at least 180-300 cubic metres per hour of biogas input. The CAPCH4 system stands out with its ability to process as little as 50 cubic metres per hour, making biomethane production practical for typical UK farm-scale anaerobic digestion plants. Farm owners with smaller operations can now access the biomethane market without scaling up their entire production system.

Why the Bennaman CAPCH4 Biogas Upgrader is ideal for smaller biogas plants

While most biogas upgrading equipment requires large-scale operations, many UK farms produce smaller amounts of biogas that still deserve to be used. The Bennamann CAPCH4 Biogas Upgrader fills this gap perfectly.

This system can transform modest biogas outputs into valuable fuel-grade biomethane, with a yearly production of 140,000 kg. Its modular design allows for quick setup on existing farm biogas plants without major changes to your current setup.

The CAPCH4 stands out for small farm operations because it was built with retrofitting in mind. Farmers can add this technology to their current biogas systems without costly rebuilds.

Set to launch in 2025, this upgrader turns what might be wasted gas into a useful energy source that can power farm vehicles or be sold as renewable natural gas. The system helps reduce greenhouse gas emissions while creating a new income stream from agricultural waste, making it a smart choice for farms looking to boost their renewable energy production.

Overview of the CAPCH4® Biogas Upgrader

The CAPCH4 Biogas Upgrader from Bennamann turns farm waste into clean energy with its compact design and low running costs – perfect for small to medium UK farms looking to cut carbon and boost profits…

Read on to learn about its key features from this biomethane upgrading supplier and how it fits into your existing biogas setup.

What are the benefits of the CAPCH4® biogas upgrader?

The CAPCH4 biogas upgrader offers farm owners a range of benefits that boost profits and support green energy goals. This compact system from Bennamann turns farm waste into valuable biomethane with less hassle than larger systems.

- Increased farm revenue through the sale of upgraded biomethane to the gas grid or as vehicle fuel.

- Extended asset lifespan for existing farm equipment by adding value to current biogas operations.

- Quick installation process that causes minimal disruption to daily farm activities.

- Lower capital costs compared to larger industrial biomethane systems from other suppliers.

- Reduced carbon footprint that helps farms meet sustainability targets and access green incentives.

- Efficient conversion of biogas to high-purity biomethane with minimal methane loss.

- Compact design that fits into small farm spaces without major site modifications.

- Simple operation that doesn’t require specialist staff, making it ideal for family-run farms.

- Flexible output options for compressed natural gas or grid injection depending on farm needs.

- Contribution to energy transition goals by creating renewable fuels from organic waste.

- Lower greenhouse gas emissions through the capture of methane that might otherwise escape.

- Potential for decentralised energy production, reducing reliance on external power sources.

- Compatible with various biogas sources including animal manure, crop residues and green waste.

- Automated monitoring systems that alert operators to any issues before they become problems.

What features does the CAPCH4® include?

The CAPCH4 Biogas Upgrader comes packed with features that make it perfect both for small farm operations and large. Bennamann has designed this system to help you turn farm waste into valuable renewable energy with minimal fuss.

- Advanced membrane separation technology that cleans biogas to fuel-grade quality without complex chemicals or processes

- Annual production capacity of 140,000 kg of biomethane, giving farms a steady income stream from renewable energy

- Modular design allowing for quick installation and easy integration with existing biogas plants

- Built-in odorisation system that meets all OEM manufacturer specifications for safety and compliance

- High-pressure cylinder bundles that store biomethane at 250 bar for maximum energy density

- Fast dispense capability that works just like normal fuel pumps at petrol stations

- Compact footprint that fits well on farms with limited space

- Low carbon footprint operation that helps reduce greenhouse gas emissions from farm waste

- Compatible with various organic waste sources, including manure and crop residues

- Integration options for combined heat and power systems to maximise energy efficiency

- Ability to produce vehicle fuel directly on the farm, cutting transport costs

- Support for carbon capture from the upgrading process, creating additional value streams

How is the CAPCH4 integrated into a biogas plant?

Integrating the CAPCH4 biogas upgrader into your farm's existing setup is straightforward and causes minimal disruption. The system connects to your biogas feed line before your CHP unit, with return lines for recirculation going back to your biogas storage. A highly innovative Biomethane Upgrading Supplier.

Your plant needs only basic electrical integration with the AD control system, plus a LAN or WiFi connection for remote monitoring capabilities. The CAPCH4 runs on standard three-phase power, making it compatible with most UK farm setups without requiring major electrical upgrades.

Smart integration means maximum efficiency with minimum hassle for farm operators.

The physical footprint remains small compared to larger industrial upgrading systems, making it ideal for space-limited farm operations. Many renewable energy technologies require complex installation processes, but the CAPCH4 focuses on simplicity while still delivering effective methane capture and greenhouse gas reduction.

Next, let's explore who the key players are in the biomethane upgrading market.

Biomethane Upgrading Suppliers

Biomethane upgrading suppliers offer a range of technologies to transform raw biogas into pipeline-quality biomethane. Each supplier brings unique solutions to the market, from membrane systems to water scrubbing methods, with varying capacities suited to different farm sizes.

Who are the key players in biomethane upgrading?

The biomethane upgrading market has several major players who serve farm biogas plants across the UK. These companies offer various technologies to transform raw biogas into pipeline-quality biomethane for multiple uses.

- Greenlane Renewables offers water wash technology that works well for medium-sized farm operations with consistent gas production.

- Clarke Energy provides combined heat and power solutions that integrate with upgrading systems for farms looking to maximise energy output.

- EnviTec Biogas specialises in complete biogas plant solutions including upgrading units that handle varying gas qualities from different farm waste types.

- Air Liquide delivers membrane-based upgrading systems that require less space, making them suitable for farms with limited area.

- Malmberg Water focuses on water scrubbing technology that achieves high methane recovery rates from farm biogas.

- Xebec Adsorption uses pressure swing adsorption that works efficiently for smaller farm operations with lower gas volumes.

- Carbotech Gas Systems provides systems that can handle biogas with higher levels of contaminants, common in varied farm waste streams.

- Biogas Products Ltd offers UK-based support and parts for upgrading systems, reducing downtime for farm operators.

- Gruppo AB specialises in solutions that integrate with existing farm energy systems for smooth operation.

- Bennamann's CAPCH4 stands out for small farm biogas plants with its ability to process lower gas volumes cost-effectively.

- Neuman und Esser provides high-quality compression systems essential for biomethane storage and transport from farm sites.

- Nippon Gases offers expertise in gas purification for farms aiming to produce vehicle-grade biomethane.

- Ammongas specialises in carbon dioxide removal systems that achieve very high methane purity for farms targeting gas grid injection.

How does the biogas upgrading process work?

Biogas upgrading turns raw farm gas into pure biomethane through several key steps. First, pre-treatment removes harmful impurities like hydrogen sulphide, VOCs, and moisture that could damage equipment or reduce quality.

Next comes the purification stage where carbon dioxide is separated from methane using special technology. The final separation process employs either membrane systems or selective solvents to achieve high-purity biomethane.

This clean gas can then be injected into the national grid or used as vehicle fuel.

Farm operators should know that modern upgrading systems are designed for maximum methane recovery while minimising energy use. The process transforms what was once waste gas into a valuable renewable energy source that helps cut greenhouse gas emissions.

Most systems now feature automated controls that need minimal daily attention, making them practical for busy farm operations. The resulting biomethane serves as a carbon-neutral fuel that can replace fossil fuels in many applications.

What are the key considerations when choosing a supplier?

Choosing the right biomethane upgrading supplier for your farm biogas plant impacts your long-term success. Several key factors should guide your decision to ensure you get the most suitable system for your needs.

- Minimum biogas input requirements – Many suppliers design systems for large operations, making them unsuitable for average UK farms. Check if the supplier can handle your plant's output volume.

- Intended use of biomethane – Your plans for the upgraded gas (grid injection, vehicle fuel, or on-site use) affect which technology works best for your farm.

- Required purity levels – Different applications need different methane purity standards. Grid injection typically requires 97-99% methane content.

- Technology type – Compare membrane separation, water scrubbing, and other methods based on your farm size and budget. Each has different costs and maintenance needs.

- Scale flexibility – Look for systems that can grow with your operation or handle seasonal output changes common in farm settings.

- Energy efficiency – The upgrading process uses energy, so check how much power the system needs to run compared to the biomethane it produces.

- Carbon emission reduction – Calculate the total greenhouse gas savings to see how the system helps meet your sustainability goals.

- Installation space requirements – Farm space is valuable, so consider how much room the upgrading equipment needs.

- Maintenance support – Check if the supplier offers training, spare parts, and service contracts with quick response times for rural locations.

- Track record with similar farms – Ask for references from other farms of similar size to yours that use their equipment.

- Total cost of ownership – Look beyond the purchase price to include installation, operation, maintenance, and expected lifespan costs.

- Compliance with renewable energy schemes – Ensure the system meets requirements for any state subsidies or incentive programmes you plan to use.

Next, we'll examine how these considerations apply specifically to the CAPCH4® Biogas Upgrader and its integration into existing farm biogas operations.

Conclusion

Bennamann's CAPCH4 Biogas Upgrader fills a crucial gap for smaller UK farm biogas plants. This innovative system turns farm waste into valuable fuel-grade biomethane with minimal fuss.

Farm owners gain a new revenue stream while cutting carbon emissions and extending the life of their existing assets. The modular design fits neatly into current AD plant setups, making adoption straightforward for most operations.

With its 2025 launch, the CAPCH4 represents a practical step toward energy independence for British farms facing economic pressures.

FAQs

1. What is Bennamann, and how does it help UK farms?

Bennamann is a supplier of biomethane upgrading systems for average UK farm biogas plants. They help farmers turn organic waste into renewable energy, reducing greenhouse gas emissions while creating useful carbon-neutral fuels.

2. How does the biogas upgrading process work?

The process separates methane (CH4) from carbon dioxide (CO2) and other gases found in raw biogas. Using membrane technology, the system purifies biogas from farm waste into biomethane that can be used as vehicle fuel or for power generation.

3. What are the benefits of upgrading biogas on farms?

Upgrading biogas creates new income streams for farmers while supporting the UK's transition to renewable energy. It turns a waste problem into storable energy that can replace diesel or be used in combined heat and power (CHP) systems.

4. Can the upgraded biomethane be used in vehicles?

Yes. Once upgraded, the biomethane can be compressed (CNG) or liquefied (LNG) for use in vehicles. This provides a sustainable transport option that helps lower CO2 emissions compared to traditional fuels.

5. Is biomethane better than other renewable energy sources?

Biomethane has a key advantage over some renewable energies: it's storable. Unlike solar or wind power, biomethane can be saved for when it's needed, making it valuable in the energy market alongside nuclear power plants and other renewable sources.

6. What happens to the waste from sewage treatment plants?

Sewage gas from treatment plants can also be upgraded using Bennamann's technology. This turns a problematic waste product into useful energy for electricity generation, creating macroeconomic benefits while reducing GHG emissions.