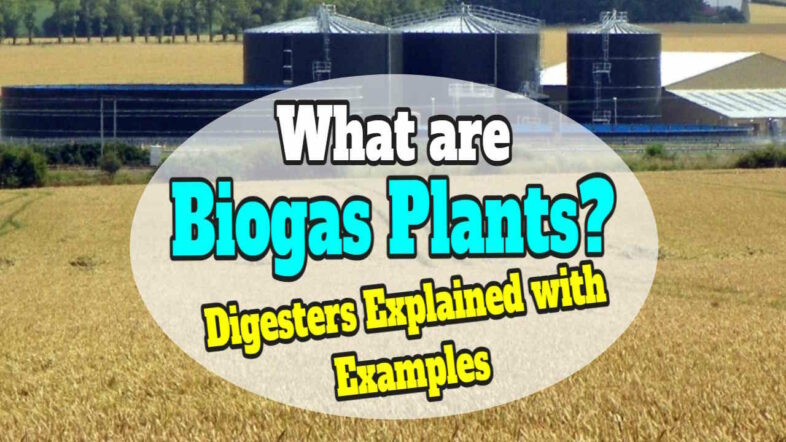

So, what are Biogas Plants?

Biogas plants are systems that use organic waste to generate renewable energy (biogas). Biogas is a gas mixture composed of methane, carbon dioxide, and other gases formed when organic matter decomposes in the absence of oxygen. Anaerobic digestion is the process of producing biogas from organic waste.

1 – An Introduction to Biogas Plants

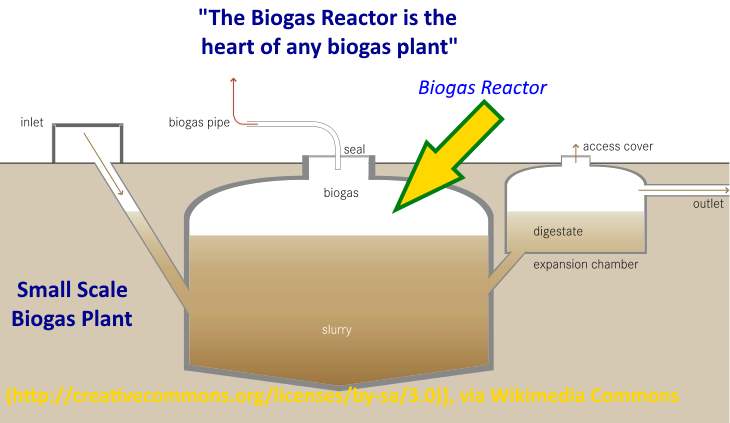

Biogas plants can be built in a variety of sizes, from small-scale household plants to large-scale industrial plants. The plants typically consist of a digester, which is a sealed container or tank into which organic waste is added and allowed to ferment. The biogas produced during the fermentation process is collected and stored for later use in a gas holder or storage tank.

2 – Benefits of Biogas Plants

There are several advantages to producing biogas from organic waste. For starters, it offers a renewable energy source that can be used to power homes, businesses, and industries. Second, it reduces the amount of organic waste that is disposed of in landfills, lowering the environmental impact of waste disposal. Third, anaerobic digestion generates a nutrient-rich slurry that can be used as a fertiliser in agriculture.

3 – Types of Biogas Plants

There are various types of biogas plants, each with its own purpose. Some plants are built to handle specific waste types, such as sewage sludge or agricultural waste, while others are built to handle mixed organic waste. Some plants are built to directly generate electricity from biogas, while others are built to produce biogas for use as a fuel in cooking, heating, or transportation.

4 – How Biogas Plants Work

In this article, we will explore how biogas plants work and the various stages involved in the process.

The first stage of the biogas plant process is the loading of organic waste material into the digester. The digester is a sealed container where organic waste material is added and allowed to ferment. This organic material can be a mixture of agricultural waste, sewage sludge, food waste, and any other organic matter that can be easily broken down.

5 – Fermentation, and Collection of Biogas

The second stage of the process is the fermentation of the organic material in the digester. This process is known as anaerobic digestion, which means that the organic material is broken down in the absence of oxygen. The microorganisms in the digester consume the organic material and produce biogas as a byproduct.

The third stage is the collection and storage of biogas. The biogas is collected from the digester and stored in a gas holder or storage tank for later use. The gas holder or storage tank ensures that the biogas is kept at constant pressure and can be easily accessed for use.

6 – The Five Stages of Biogas Production and Utilization

The fourth stage is the utilization of biogas. Biogas can be used in a variety of ways, depending on the design of the biogas plant. It can be used to generate electricity, heat homes and businesses, and fuel transportation. In some cases, the biogas can also be upgraded to natural gas quality and injected into the natural gas grid.

The final 5th stage is the utilization of the digestate, which is the nutrient-rich slurry produced during the fermentation process. The digestate can be used as a fertilizer in agriculture and horticulture, as it is rich in nutrients such as nitrogen, phosphorus, and potassium.

Conclusion

Finally, biogas plants are systems that convert organic waste into renewable energy in the form of biogas.

Biogas plant technology has been around for several decades and is constantly evolving to improve efficiency and reduce costs. Biogas plants are becoming increasingly popular as a sustainable solution for waste management and energy production in both developed and developing countries.

The process of producing biogas from organic waste has numerous advantages, including:

- the production of renewable energy,

- waste reduction, and

- nutrient-rich fertiliser.

Biogas plants are becoming increasingly popular in both developed and developing countries as a sustainable solution for waste management and energy production.

What now follows is a compilation of Biogas Plant Information for all those new to the anaerobic digestion process, and who need to know exactly what a biogas plant is!

Here are some definitions we found:

and that's the first fact in answer to “What are Biogas Plants” for those seeking the meaning of “biogas plant” and Biogas Plant Information.

And, if you are unsure about what methane is, here is a definition for it:

The process of anaerobic fermentation will then take place in the large tank (biogas reactor), to generate biological gas (biogas).

It will also produce a substrate (called digestate) rich in nutrients which can be used as organic fertiliser or fish feed.

What are Biogas Plants?

We recommend that you SCROLL ON DOWN THE PAGE for more biogas plant information.

The feedstock material type determines strongly the form of the plant and its operational parameters.

During the operation of an industrial biogas plant, it is obligatory, according to the official European guidelines, to adapt a pre-treatment, or post-treatment, thermal stage (for sanitation or pasteurization) of the output from the whole process.

In order to minimise the various disturbances which may arise from the plant’s operation, it is common practice to install the pre-treatment and feeding equipment inside enclosed places (buildings).

Because of the non-constant composition of industrial wastewater and solid waste, those anaerobic digestion process plants require quite sophisticated technology.

Illustrating What are Biogas Plants, and Bringing You the Meaning of “Biogas Plant”, Through Case-Studies Internationally

Information on the First Industrial Size State of the Art Biogas Plant in Armenia

The Danish Industrialisation Fund for Developing Countries ( IFU) has been instrumental in the first industrial size, state-of-the-art, biogas plant. It is based on organic waste from animal farming and will be built (in and known as) the Lusakert Biogas Plant (LBP) (2018)).

Renewable Energy from Poultry Manure

The LBP will process 220 tonnes per day of liquid poultry manure coming from Lusakert Pedigree Poultry Plant LLC. The liquid manure will be processed in a 5,000m³ digester with a process temperature of 38ºC.

Under these conditions biogas with a methane content of around 70% is produced.

The biogas drives a gas motor with a generator.

The yearly electrical generating capacity is 6 GWh of heat from the hot exhaust gas and cooling water to the gas engine is recovered.

GigaWatts of Power Per Hour (GWh)!

This thermal energy in the form of 90°C hot water represents another 8 GWh per year. Total energy production is therefore can amount to up to 14 GWh per year.

LBP thus represents the first serious renewable energy project in Armenia outside of hydroelectricity.

Information on the First Pilot Demonstration and Education Biogas Plant for Lithuania

One AD project was initiated by the Danish Folkecenter for Renewable Energy.

The project is intended as a pilot demonstration and education plant for Lithuania and the surrounding Baltic countries.

Information on a US Biogas Plant…

Synergy Biogas – is an on-farm biogas facility located at the 2,000-head (nominal herd size) cow Synergy Dairy in Wyoming County, NY. It takes 425 tons/day.

Info on an Austrian Biogas Plant…

The village of Strem in Südburgenland makes use of fallow agricultural land in the region, for energy production. The process of solid-state fermentation is used to convert grass and clover together with whole maize plants into biogas.

And the farmers are happy to have a new source of income. Since 2003, Strem has had a biomass heating plant with an integrated district heating grid – a good starting basis for the economically feasible construction of a biogas plant.

Since November 2004, “Biogas Strem Errichtungs und Betriebs GmbH & Co KG” has been operating a biogas plant with an output of 500 kWel next to the biomass plant operated by the agricultural co-operative “Öko Energie Strem”.

Info on an Indian Biogas Plant…

The University of Agricultural Sciences (UAS), Bangalore, is saving Rs. 50,000 a month from its electricity bill by using the power generated from a biogas plant on its campus. The 200m³ capacity plant, which became operational recently (2018), is generating about 300 to 320 units of electricity a day.

The 20kv-biogas generator runs for 16 hours a day.

Info on German Biogas Plants…

In Bavaria, South Germany

Mr Schloetterer is a farmer and owner of a small farm in Bavaria, South Germany. There are about 30 cows on his farm. Additionally, he has got approximately 40 ha of farmland, of which about 12 ha is forest.

For the manure of his cows and the forage from his fields, he decided to build a biogas plant. Compared to other biogas plants in Germany, Mr Schloetterer's biogas plant is fairly small. The digester has a volume of only about 100 m³.

In his old stable Mr Schloetterer located the gas engine with an electrical power output of about 15 kW. That is his plant described in a nutshell.

What are biogas plants good for?

They are good for diversifying small farms to produce renewable energy, in this example.

Mr Kraft has a large farm with about 800 cattle. Additionally, he has got extensive areas of field and a distillery.

“Fats are a good feed material for biogas, and raise the amount of gas produced”

A lot of fat and distillery residues are digested together with the manure from the animals in his biogas plant. There are several companies that deliver these fats to the biogas plant.

Fats deliver much biogas with high methane concentrations. Therefore, all owners of biogas plants appreciate digesting fats within their plants.

This is called co-fermentation. Mr. Kraft's biogas plant has a digester with a volume of 800 m³. In the foundation, there is a heating unit that keeps the temperature inside the digester at approximately 35ºC.

Concrete Ring

Around the digester, there is another concrete ring.

The space between the digester and the ring is used as a storage tank for digested manure, (volume of 1,000 m³). In this manner, the digester has almost perfect insulation.

Only the parts of the digester above the outside ring had to be insulated. Beneath the roof of the digester, there is a gas storage membrane.

So, what are biogas plants good for?

They are good for digesting fats at Kraft!

In Hessian Nidderau-Ostheim, Germany

So far, biogas plants have often been built with open residue storage, to reduce the necessary investment costs. This was also true for the biogas plant of the CPM Biogas GmbH in Hessian Nidderau-Ostheim, which went online in 2006.

During an ongoing discussion in the biogas community, awareness has grown, that roofing the residue storage has two benefits:

- avoiding harmful emissions and

- running a biogas plant more profitably by capturing and using an additional 5% of the biogas yield obtained from biogas collected from above the storage tank.

“The Nidderau Plant is perhaps the most profitable and reliable operating plant in Germany”

Greencon was commissioned to plan the roofing of the residue storage and to add a biomethane gas purification unit with higher performance by using an activated carbon filter.

Due to that unit and to an additionally installed oxidation catalyst for the CHP engines the exhaust gas emission could be reduced and especially the cancer-causing formaldehyde could be reduced to less than 40 mg/m.

“Renewable energy production is an important area for the governments to focus on… All industrial operators should examine their own energy consumption to ensure that energy is used efficiently and that the opportunities to use renewable energy are exploited,”

said Ola Borten Moe, the Minister of Petroleum and Energy, recently.

Better Than Burning

This use is far better than burning for crop residues

These may be:

- aerosols,

- suspended particulates,

- SOx and NOx and

- in some cases dioxins and furans.

Further, burning of the standing crop also leads to volatilization of the soil nutrients, decreasing soil fertility.

Why Making Biogas with Dung Cakes is Better than Using them as a Stove Fuel – Especially Indoors!

Unfortunately, the burning of dung cakes leads to toxic emissions in the form of:

- SPMs,

- PAHs and

- CO.

Studies also associate cow dung cake burning with cases of:

- tuberculosis,

- lung cancer, and other cancers.

Thus, the external costs (environmental damage, soil damage, health damage) associated with the traditional methods are enormous. Using a biogas plant produces no such problems.

Information on a Russian AD Plant

An industrial biogas plant was recently launched in the Belgorod Region in Central Russia. According to the project planning company LLC Engineering Center “Progress”, the new station “Baytsury” is one of the first large-scale industrial AD plants in Russia.

The plant is owned by the Regional Centre for Biotechnology, one of Russia’s largest companies, specialising in projects in the field of biogas energy.

What are biogas plants good for?

They are good for providing much-needed renewable energy in Russia, in this example.

Information on the Biogas Plants of Weltec Biopower

At the beginning of 2012, the German biogas plant manufacturer Weltec Biopower began the construction of a 526 kW biogas plant in France. What are biogas plants good for? They are good for pig slurry treatment in this example. The fermentation substrates to be used for energy production will be pig slurry, waste from the food industry, renewable plant resources and intertillage crops.

The heat produced by the biogas plant will be used to dry the material remaining from the fermentation process and to heat the pig buildings 60 m away. With heat utilisation of 70 % (without fermenter heating), the CHP bonus in France is 4 cents per kWh. That means that the feed-in tariff (FiT) for a 500 kW plant amounts to 17 cents.

In France, the feed-in legislation ensures that the state buys electricity from biogas plants at a guaranteed price for 15 years.

So, what are French biogas plants good for?

They are good for a guaranteed price for 15 years!

Information on a Biogas Plant in Nepal

Nepal has been operating the so-called GGC-2047 biogas plant design for over 20 years. The Nepal Biogas Promotion Association (NBPA) took on the challenge to improve this already well-proven design. To foster the implementation within the Nepalese context, the Nepal Improved Biogas Plant (NBP) orients towards the Biogas Support Programme (BSP) standard design, improving some critical points.

The NIB plant is designed to address the shortcomings of the current GGC-2047 plant design. The R&D activities of NBPA are focusing on the evaluation of usability, performance, price and durability of this new plant design.

What are biogas plants good for? They are good for NIBP in this example. The NIBP can be introduced in the rural- and institutional markets. Its design is much more flexible in terms of space requirements and plant placement than the current system.

The NIBP is designed for more performance (gas production), and for improved usability.

Conclusion to our Biogas Plant Information

We conclude with the words of Wikipedia:

Biogas can be produced from raw materials such as:

- agricultural waste,

- manure,

- municipal waste,

- plant material,

- sewage,

- green waste or food waste.

Biogas is a renewable energy source. via wikipedia.org

Increasing energy prices, more comprehensive regulatory demands, and enhanced competitors in the marketplace are causing lots of in American farming’s livestock sector to consider anaerobic digestion of animal waste for power production by means of biogas.

Nice article

Thank you so much for giving information about what is biogas plant how it works and uses it.

Mervin: It looks OK to me.

I’m compiling my research for a new article for my blog.

I’ve had a good look at your page here, and was having some problems along the way.

Not any more! This page is very comprehensive. Thanks.

I’ll talk more about my article at a later date.

This is the video ever about bio gas digester, kudos to you. I AM realy impressed. I AM a RURAL person with civil engineering back ground.

Hi! This is my initial visit to your blog! I am researching for a group of volunteers and beginning a new task in our community also to build a biogas plant. Your blog site offered us beneficial information to work with. You have done a wonderful task on it!

Hello,

Very Useful blog.

Thanks..

This is very help full informations for biogas plant related and this is very good content .

We are also biogas plant manufacture. We have two types biogas plant first is domestic biogas plant and second is portable biogas.