Biogas Engines For Ships: The Trend Toward Biogas In Maritime Transport

Finding greener options for fuel in ships is a big challenge today. The International Maritime Organisation aims to cut ship emissions by half by 2050. Our article explores the latest developments and how biogas can offer a solution, providing cleaner energy for ships.

Keep reading to learn more!

Key Takeaways

- Ships are using biogas to reduce pollution and meet the International Maritime Organization’s goal to cut emissions in half by 2050. Biogas is made from organic waste.

- The maritime industry sees biogas as a renewable energy source that can help make shipping fossil-free. Using both biogas and traditional fuels in engines lowers harmful emissions.

- Companies like Gasum are working to increase the supply of biogas, supporting Europe’s green energy goals. By 2030, Europe wants to produce 35 billion cubic metres of biomethane annually.

- Ships powered by biogas could significantly lower their carbon footprints, making maritime transport more sustainable. This aligns with global efforts against climate change.

- Dual-fuel engines that run on both liquified natural gas (LNG) and biomethane show promising results in reducing pollutants compared to conventional fuels, marking progress towards cleaner shipping practices.

Understanding Biogas in Maritime Transport

Ships are starting to use upgraded biogas as a cleaner fuel. This shift helps the maritime industry cut down on pollution and meet global targets for reducing greenhouse gas emissions. The International Maritime Organization (IMO) aims to slash these emissions by at least 50% by 2050 compared with 2008 levels.

Biogas, made from organic waste like food scraps and agricultural residue, is key to achieving this goal.

Using biogas in ships makes sense because it’s renewable and produces low CO2 emissions when burnt, but most importantly the CO2 is biogenic and does not cause global warming.

Liquefied biogas (LBG), which is mostly methane, can be mixed with LNG in ship engines, further lowering carbon emissions.

However, there are challenges like ensuring enough supply and dealing with higher costs than natural gas. Despite these hurdles, adopting biogas is a step forward towards greener maritime travel that relies less on fossil fuels.

Biogas: The Road to Fossil-Free Shipping?

Is biogas the key to fossil-free shipping? Its potential as a renewable energy source, large-scale usage possibilities, and ability to address methane slip make it an intriguing prospect for the maritime industry to participate in the circular economy.

Renewable Energy Potential

So, by utilizing biogas to fuel their engines, ships can significantly reduce their carbon footprint, supporting global efforts to combat climate change.

As we have said before, the International Maritime Organization (IMO) has set ambitious targets to cut greenhouse gas emissions from international shipping by more than half by 2050. This goal underlines the urgent need for renewable energy sources like biogas to achieve decarbonisation in the sector.

With the European Commission planning to increase biomethane production to 35 billion cubic metres annually by 2030, there is clear momentum behind renewable fuel shipping as a feasible path forward.

Transitioning into large-scale usage possibilities showcases how preparedness can meet rising demand while adhering to stricter environmental regulations.

By adopting dual-fuel technologies, ships can operate using both biogas and traditional fuels, improving combustion and cutting harmful emissions further.

Addressing Methane Slip

Moving from the potential for large-scale biogas use in shipping, the industry will have to face the challenge of methane slip. Methane slip is when unburned methane escapes from the engine into the atmosphere.

Any unburnt LNG (methane) will act as a potent greenhouse gas, so tackling this issue is vital for making biogas a truly green maritime fuel.

Several solutions exist to reduce methane slip. The first point is that biomethane will be used. Biomethane is made by upgrading biogas to biomethane through techniques like pressure swing adsorption. This process removes impurities and increases methane content, making it burn more completely in engines.

Furthermore, modern engines designed for low emissions also contribute significantly to solving this problem by ensuring more efficient combustion of the upgraded biogas (biomethane).

Increasing the Supply of Biogas

Companies like Gasum are taking big steps to boost biogas production. They plan to grow their biogas portfolio through 2024 and beyond. This effort meets the growing demand for cleaner fuels in maritime transport and supports Europe’s green energy goals.

The European Commission wants biomethane production to hit massively higher production rates than 2020 levels. The shift to sustainable shipping solutions has advanced thanks to EU incentives for investors to push for much higher investment in biogas plants.

Application of Biogas as Maritime Fuel: An Overview

To fully appreciate this sector, we explain the regulations and legislation governing its use and offer a PESTEL and SWOT analysis below, providing insights into biogas and biomethane’s applicability for the industry.

PESTLE: (political, economic, social, technological, legal and environmental) analysis

SWOT: (strengths, weaknesses, opportunities, threats) analysis.

Regulations and Legislation

The ambitious goal that has been set to push the maritime industry towards finding cleaner fuel options, is putting pressure on ship owners and operators to adopt greener fuels.

In Europe, the “Fit for 55” package introduces several directives, including FuelEU Maritime and the revised Renewable Energy Directive (RED II). These regulations aim to make shipping more eco-friendly by encouraging the use of alternative fuels.

The EU is leading with strict policies that require ships to lower emissions or face penalties. This legislative environment makes biogas an attractive option for companies aiming to meet these stringent standards while also benefiting from potential incentives for reducing their environmental footprint.

PESTEL and SWOT Analysis of Biogas and Biomethane

Exploring the significance of biogas and biomethane in maritime transport requires a strategic analysis to understand both the opportunities and challenges involved. A PESTEL and SWOT analysis can shed light on these aspects, offering insights into the external and internal factors impacting their adoption.

| PESTEL Analysis | SWOT Analysis |

|---|---|

|

|

This analysis highlights that while biogas and biomethane have the potential to transform the maritime sector towards more sustainable practices, careful consideration of technological, economic, and regulatory factors is crucial.

Availability, Supply Chain, and Cost Breakdown

Let’s delve into the world of biogas and biomethane to understand their availability, supply chain, and cost breakdown.

| Aspect | Details |

|---|---|

| Production Increase | A projected rapid rise in production by 2030 and 2050. |

| Well-to-Wake Chain | Includes upgrade, transportation, and distribution of biomethane/biogas. |

| Infrastructure Needs | Essential for biomethane production and liquification. |

| Engine Compatibility | Direct use in existing engines is viable, with some treatments needed. |

| Market Potential | Based on LBM data from the IHS Market database. |

| Challenges | Includes production costs and the need for compressed natural gas infrastructure. |

| RTDI Focus | Future research on supply chain and carbon capture integration. |

The insights offer a clear vision of the path ahead for the maritime industry in embracing biogas and biomethane. The next stage of discussion in this article will revolve around the applicability of these green fuels in maritime operations.

Applicability for the Maritime Industry

Moving on from understanding the logistics of biogas supply and cost implications, it’s essential to explore its applicability in the maritime industry. Biogas has gained traction as a potential renewable fuel alternative due to its low sulfur levels and limited CO2 emissions, aligning with the industry’s low-sulfur fuel requirements.

Despite being more expensive than natural gas, this advanced biofuel presents a technically viable solution for sustainable maritime operations. The market shift towards liquefied and compressed biomethane and biogas signals their relevance for the shipping sector.

Concerns about meeting production demand persist, especially concerning oceanic traffic responsible for 80% of global maritime CO2 emissions. However, major gas suppliers like Gasum investing in new biogas plants underscore substantial potential for applicability within the maritime industry.

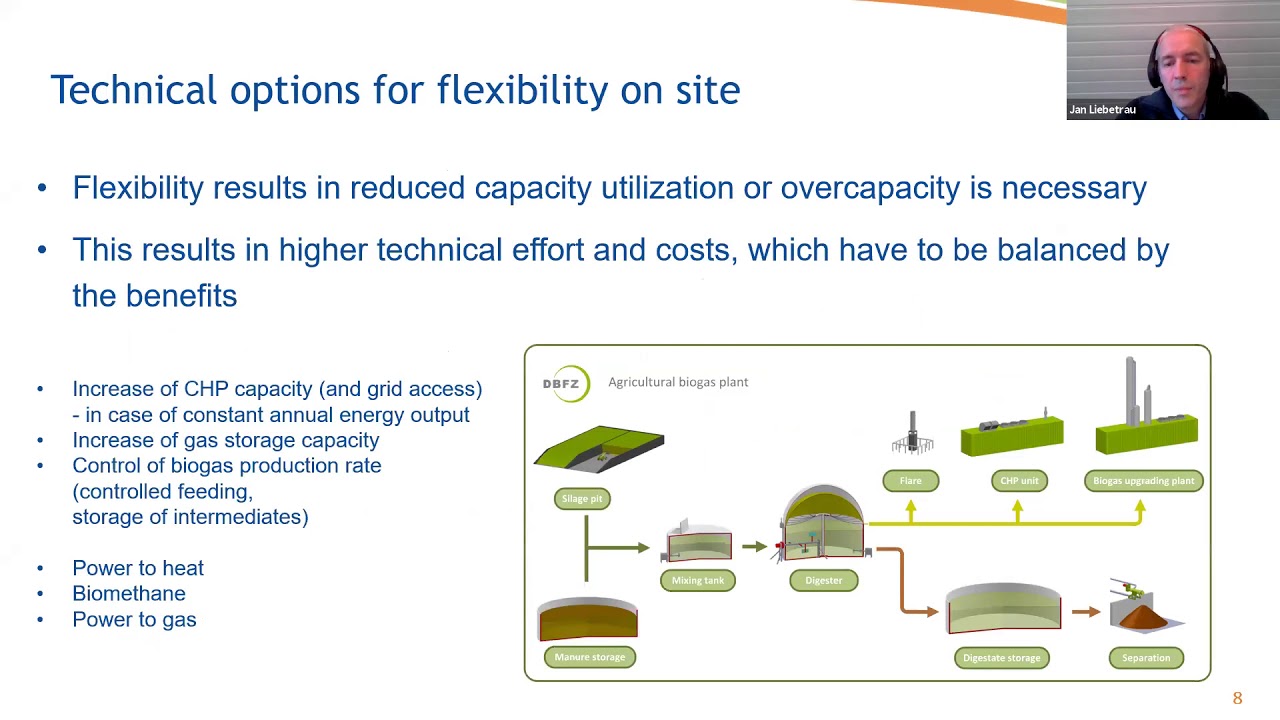

Dual-Fuel Biogas and Biomethane Engines in Maritime Transport

Dual-Fuel LNG and Biomethane Gas Engines are gaining traction in maritime transport.

Read more to understand their pollutant emission performance, and the benefits of biogas upgrading to biomethane for a greener shipping industry.

Pollutant Emission Performance

Biogas engines offer low emission performance, contributing to reduced environmental impact. When used as maritime fuel, biogas significantly lowers CO2 and nitrogen oxide emissions compared to traditional fossil fuels.

Moreover, Liquefied Biomethane (LBM) presents an environmentally friendly alternative for maritime transport by providing substantial reductions in pollutants like sulphur oxides and particulate matter.

Benefits of Biogas Upgrade to Biomethane

Upgrading biogas to biomethane enhances its quality for use as a sustainable maritime fuel. Biomethane, with its higher methane content and lower impurities, significantly reduces emissions in compression-ignition engines.

This upgrade inhibits harmful emissions while improving combustion efficiency, aligning with the global focus on greener shipping solutions.

Considering these advantages, biomethane stands out as a pivotal player in driving sustainable energy practices in the maritime industry.

Advantages of LNG as a Marine Fuel

LNG, as a marine fuel, offers significant advantages. It helps in reducing CO2 emissions by at least 20% and cuts the existing sulfur oxides (SOx) and nitrogen oxides (NOx) emissions, from the current use of oil, by up to 85%.

Additionally, it provides competitive pricing and portfolio management services for sourcing liquefied gas. Going further, Gasum’s provision of LNG and LBG for ships also makes it an attractive option with its potential to produce up to 90% less carbon dioxide emissions than conventional fuels.

Renewable liquefied biogas (LBG), when compared with traditional fuels, yields multiple environmental benefits. It significantly lowers carbon dioxide emissions by 67%, while also substantially decreasing sulfur oxide emissions by 99%, fine particle emissions by 91%, and nitrogen oxide emissions by 92%.

Services for Shipping Companies

Shipping companies can benefit from specialised services that support the adoption of alternative fuels like biogas.

Consultancy firms offer tailored advice on integrating biogas as a sustainable solution, addressing complexities in storage and transportation. Providers deliver efficient bunkering operations, enhancing accessibility to liquefied biogas (LBG) for ships.

Shipping companies exploring alternative fuels require support in navigating regulatory requirements and identifying viable supply chains. Industry experts offer comprehensive analyses of PESTEL and SWOT factors specific to biogas applications in maritime transport.

Biogas-Powered Ships’ Impact on Emission Reduction

Biogas-powered ships have a significant impact on emission reduction. Biogas, being a renewable energy source, contributes to lowering the carbon footprint of maritime transport. It is an effective solution for reducing greenhouse gas emissions and mitigating air pollution from ship operations.

DNV’s report “Maritime Forecast 2050” highlights that bio-LNG, bio-MGO, and bio-methanol are preferred fuels due to their net zero carbon potential in the maritime sector.

Understanding Bunkering Operations

Bunkering operations involve supplying fuel to ships. This process includes the transfer of liquefied natural gas or other marine fuels from storage tanks or terminals to the ship’s fuel tanks.

The bunkering procedures must adhere to strict safety and environmental regulations, ensuring that vessels are supplied with clean, compliant, and sufficient fuel before embarking on their voyages.

The bunkering process involves various operational elements such as risk assessments for safe transfer, quantity measurement accuracy, compliance documentation checks, and adherence to international standards for bunker delivery notes (BDNs).

These ensure that the ship receives the correct type and amount of fuel while maintaining safety protocols. Shippers and suppliers alike need to prioritise these aspects during bunkering operations in order to meet emission reduction goals effectively.

Future of Biogas Engines in Maritime Transport

Having delved into the intricacies of bunkering operations, it is vital to gaze toward the future of biogas engines in maritime transport. The potential for biogas and biomethane is poised to grow substantially in the coming decade, solidifying their position as key forces in decarbonising shipping.

With an expected increase in LNG and LPG usage by vessels, there’s a promising indication for a surge in biomethane adoption. However, this progress hinges on dedicated infrastructure development and streamlined value chains for efficient production and liquefaction of biomethane.

The cost breakdown from production source to vessel journey encompasses various pathways without adjusting for regional cost dynamics, offering insight into potential market opportunities for liquefied biomethane (LBM), according to data from IHS Markit database.

The ever-evolving narrative regarding marine internal combustion engines (ICEs) holds significant implications; with their high reliability and efficiency, they currently hold a dominant 98% market penetration across global vessel fleets.

This underscores the importance of integrating eco-friendly fuel alternatives like biogas and biomethane—vital players steering maritime transport towards sustainability within the upcoming years while simultaneously tackling carbon emissions effectively.

Conclusion

In the race for fossil-free shipping, biogas engines offer a promising solution. With the IMO’s commitment to reducing greenhouse gas emissions, liquefied biogas presents an opportunity for significant CO2 reduction in maritime transport.

Although challenges exist, such as methane slip and production capacity concerns, investments in new biogas plants show potential for meeting future demands. As the world navigates towards sustainable energy sources, exploring and embracing biogas could be a vital step towards greener maritime transport.

Biogas Engines for Shipping FAQs

1. What are biogas engines for ships?

Biogas engines for ships use bio-gas produced through anaerobic digestion or gasification of biomass, including advanced biofuels and green electricity, to power vessels in a more environmentally friendly way.

2. Why is using liquefied natural gas (LNG) and liquefied biogas (LBG) better for the environment?

Using LNG and LBG in maritime transport reduces pollution from ships by cutting down emissions of sulphur, carbon monoxide, and smoke. These fuels help make shipping cleaner.

3. How do biogas engines support social responsibility in shipping?

By meeting high environmental, social, and governance (ESG) criteria, companies using biogas engines show they care about reducing their environmental impact while supporting socially responsible practices.

4. Can switching to biogas help with compliance under international regulations?

Yes! Switching to biogas helps ships meet stricter rules set by the International Convention for the Prevention of Pollution from Ships (MARPOL), EU ETS, and NECA zones by lowering harmful emissions.

5. Are there any technological advancements making biogas more effective for shipping?

Recent advances include improvements in compression ignition technology and exhaust gas recirculation systems, which enhance energy efficiency and reduce greenhouse gases emitted by ships running on biofuels.

6. What role does corporate social responsibility play in adopting biogas engines for container ships?

Adopting biogas technology reflects a company’s commitment to corporate social responsibility (CSR) by actively choosing solutions that lead to lower carbon emissions and promote sustainability within the maritime industry.

Text in panel

Original article from May 2021:

The most recent and welcome development in 2021 for biogas engines is that the first application in shipping for renewable biogas energy is underway. Biogas will be used to power a green shipping fleet.

The shipping company Hurtigruten will use the biogas as fuel for its fleet of ships.

First Biogas Engines to Power Shipping Announced

In Skogn, outside of Trondheim, Scandinavian Biogas Fuels is investing 170 million kroner (€17 million) in a liquid biogas facility. On the site in Norway, the company already has the world’s largest liquid biogas facility.

The plant is expected to start producing 35 GWh of biogas in the third quarter of 2022.

Ever since 2018, Skogn has been supplying liquid biogas.

“The operations at Skogn have been well received, and customers are waiting in line,”

said Skogn’s, business area manager in Norway:

“As a result, it feels very rewarding to be able to reveal that we are now increasing our liquid biogas capability”.

The company also received a grant from Klimatklivet, the Swedish government, earlier this year.

It was granted for the expansion of their liquid biogas facilities in the Stockholm region.

Biogas is a sustainable energy technology available today.

It is unique because it is produced using a process that handles waste and transforms it into energy.

Biogas can be used to fuel existing internal combustion engines without requiring significant modifications. Not only will the renewable source of this fuel reduce net carbon emissions, but it will also replace the poor quality air-polluting standard oil grade used by the shipping industry.

The following is the original article as posted in October 2013:

Developments in Biogas Engines for Shipping

In 2013, when this page was first uploaded, Clarke Energy was already well known to anyone looking out for news and developments in biogas engines. Clarke Energy had the monopoly in online news releases in this market that year. And it has been a strong company in the sector ever since.

In 2013, it was all about biogas engines supplied for sites in the UK, and Kenya, as we said in our October 2013 article.

— End of original article —

[Article first published in May 2021.]

I wanted to express my appreciation for the recent content you shared regarding the latest news and developments in biogas engines for shipping. It is evident that this technology has significant potential to contribute to the reduction of greenhouse gas emissions and improve overall environmental sustainability. If ever you have upcoming projects that needs smart reliable solutions I suggest CHP Plant By choosing CHP Plant, you are not only investing in a high-quality energy source but also contributing to a greener future for us all. Visit their website at https://www.evoet.com.au/ to know more about their services.