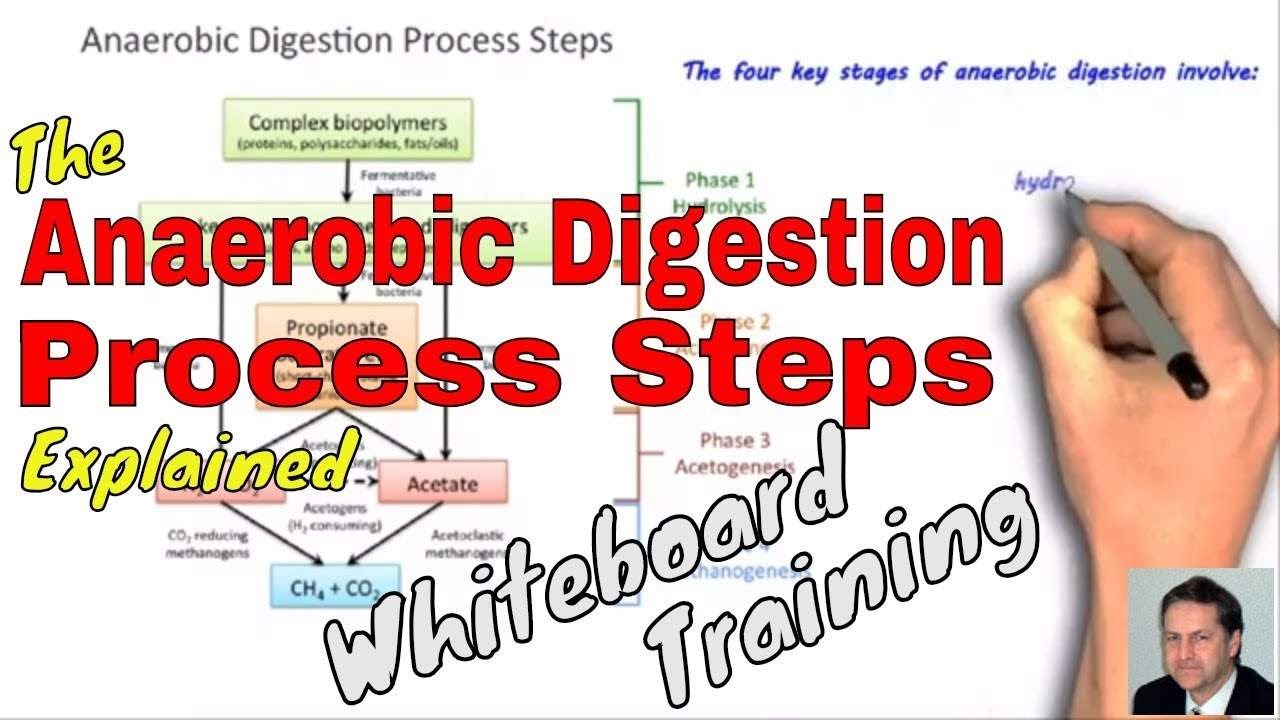

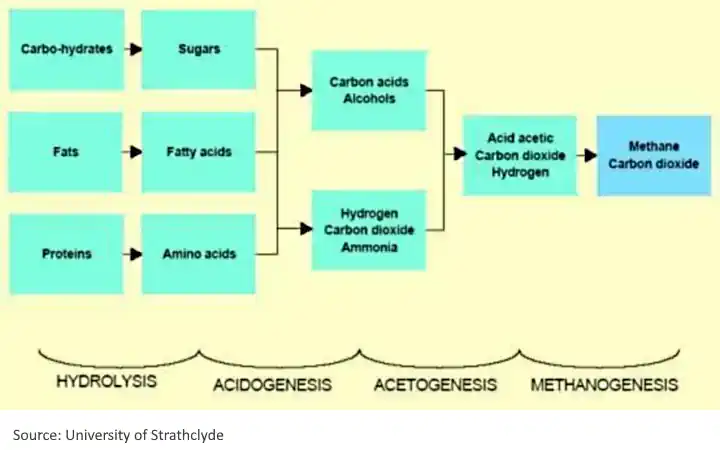

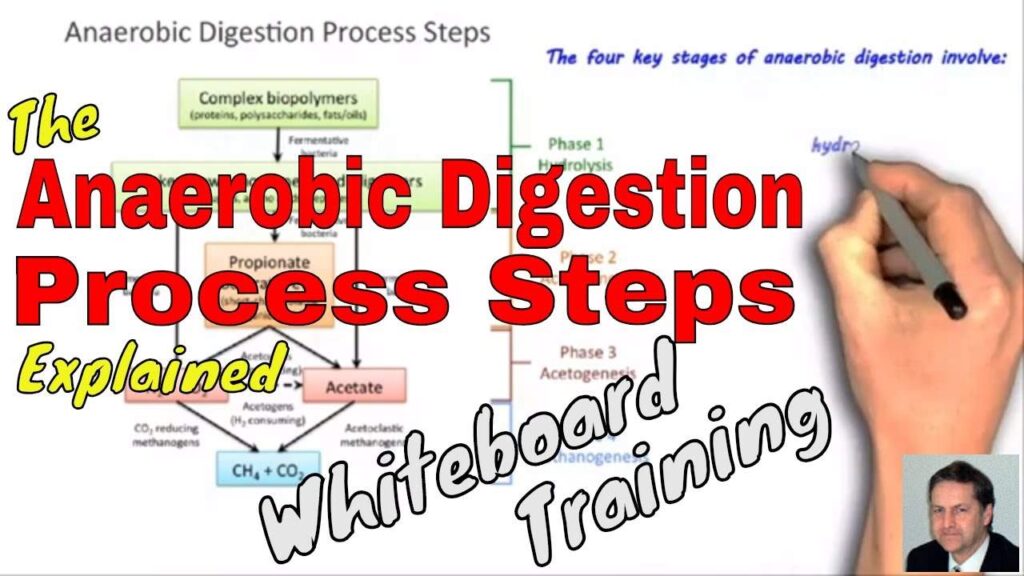

There are just four core biochemical anaerobic digestion process steps. They are Hydrolysis, where complex organic matter is broken into simple sugars and amino acids; Acidogenesis, where these are converted into volatile fatty acids, hydrogen, and carbon dioxide; Acetogenesis, where fatty acids are transformed into acetic acid, and finally Methanogenesis, where acetic acid, hydrogen, and carbon dioxide are converted into methane and water, producing biogas.

And to take that from trash to cash, we have added three more.

Read on to find out about both the biochemistry and how to go from trash (organic waste) to cash (financial viability) from the sale of energy and products.

Key Takeaways for Anaerobic Digestion Process Steps

- Anaerobic digestion transforms organic waste into valuable biogas and nutrient-rich digestate through a four-stage biological process that occurs in oxygen-free environments.

- The seven-step process includes collection, hydrolysis, acidogenesis, acetogenesis, methanogenesis, biogas collection, and digestate processing—each critical for maximum energy yield.

- Nearly any organic material can be used as feedstock, including food waste, agricultural residues, and wastewater sludge, making this technology widely applicable across industries.

- Modern anaerobic digestion facilities can generate significant revenue streams through energy sales, tipping fees, and marketable fertiliser products.

- Beyond financial benefits, this process significantly reduces greenhouse gas emissions by capturing methane that would otherwise enter the atmosphere from decomposing waste.

What if the waste you're paying to dispose of could actually generate income? That's the remarkable reality of anaerobic digestion—nature's way of turning organic waste into valuable resources. In an era where sustainability meets profitability, understanding this process isn't just environmentally responsible—it's financially smart.

Anaerobic digestion represents one of our most efficient technologies for converting problematic waste streams into renewable energy and useful by-products. The Digester PRO system developed by Green Energy Solutions has been helping municipalities, farms, and food processors transform their waste management challenges into profitable ventures while simultaneously reducing their carbon footprint.

Turn Waste into Wealth: How Anaerobic Digestion Works

At its core, anaerobic digestion is a natural biological process where microorganisms break down organic materials in the absence of oxygen, producing biogas and nutrient-rich digestate. This isn't new technology—it's been occurring in natural environments like marshes and lake bottoms for millions of years. What's revolutionary is how we've harnessed and optimised this process for commercial applications.

Think of anaerobic digestion as nature's recycling system on steroids. The controlled environment of a digester accelerates what would naturally take months or years in a landfill, completing the process in just weeks while capturing valuable methane that would otherwise escape into the atmosphere. This captured biogas can then be used for electricity generation, heating, or upgraded to natural gas standards for injection into gas grids or use as vehicle fuel.

“How Does Anaerobic Digestion Work? | US EPA” from www.epa.gov and used with no modifications.

The 4 Biological Stages That Transform Organic Waste

The magic of anaerobic digestion happens through four sequential biological stages, each performed by different groups of microorganisms working in perfect harmony. First, during hydrolysis, bacteria convert complex organic polymers like carbohydrates and proteins into simpler compounds such as sugars and amino acids. This crucial first step makes the organic matter accessible to the microbes that follow.

The second stage, acidogenesis, sees these simpler compounds transformed into volatile fatty acids, alcohols, carbon dioxide, and hydrogen by acidogenic bacteria. Next comes acetogenesis, where acetogenic bacteria convert these acids and alcohols primarily into acetic acid, plus more hydrogen and carbon dioxide. Finally, during methanogenesis, specialised archaea consume these products to produce methane and carbon dioxide—the primary components of biogas.

The beauty of this cascade is its completeness; each group of microorganisms creates precisely what the next group needs. When properly balanced, this microbial teamwork efficiently converts up to 60-80% of the biodegradable material into biogas, with methane content typically ranging from 50-75%.

[/embedyt]

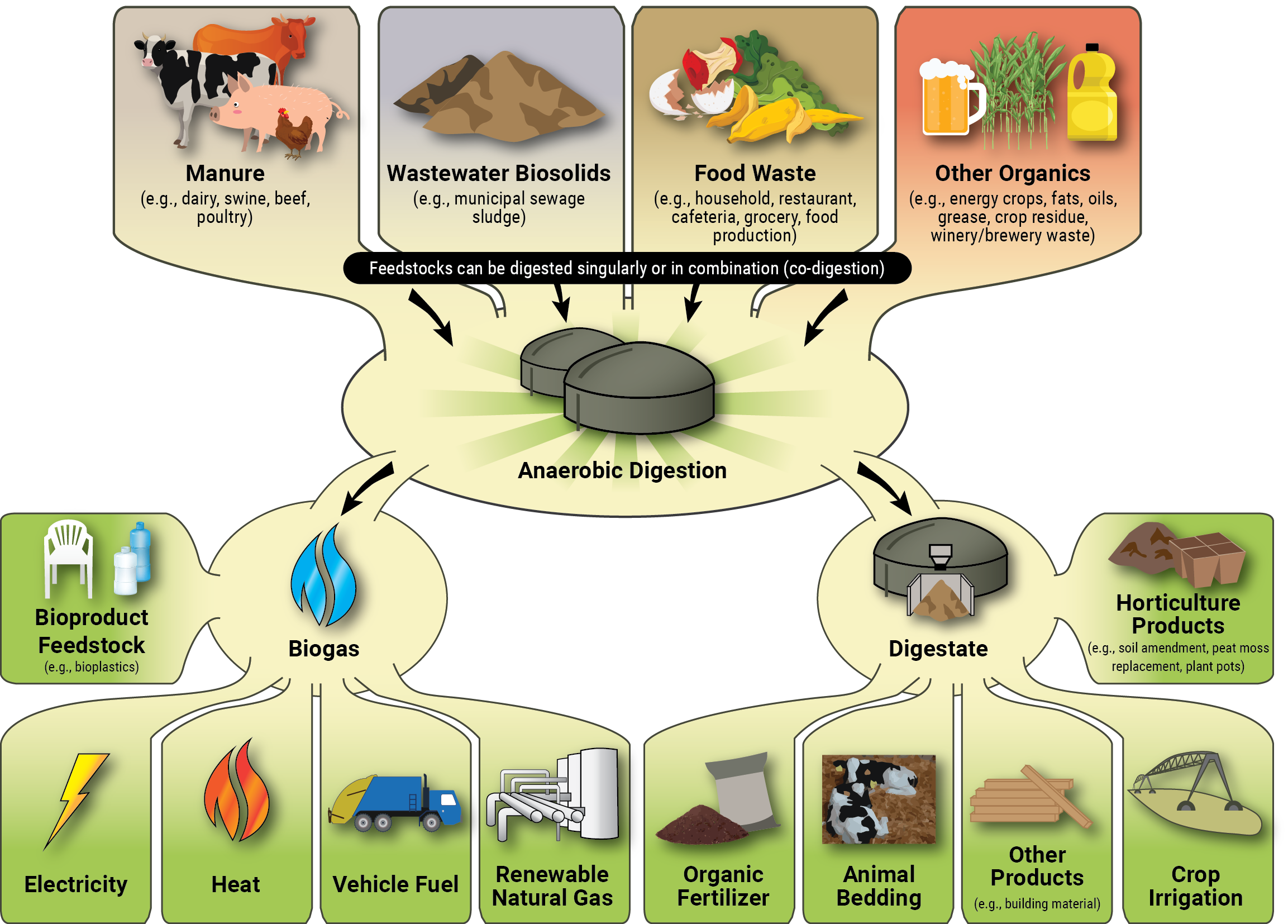

Types of Waste Perfect for Anaerobic Digestion

One of anaerobic digestion's greatest advantages is its flexibility in handling diverse organic materials. Agricultural wastes like manure and crop residues have historically dominated the feedstock landscape, but modern systems can process much more. Food waste from homes, restaurants, and food processing facilities offers among the highest biogas yields, making it increasingly sought-after as feedstock.

Municipal wastewater sludge has been processed through anaerobic digestion for decades at treatment plants worldwide. Industrial wastewaters from breweries, dairy processors, and other food manufacturers also make excellent feedstocks due to their high organic content. Even dedicated energy crops like corn silage can be used, though the sustainability benefits are greatest when processing waste materials rather than purpose-grown crops.

![]()

“Anaerobic Digestion for Sewage Sludge …” from www.cambi.com and used with no modifications.

Biogas Yields by Feedstock Type

Food Waste: 100-150 m³ biogas per ton

Cattle Manure: 20-30 m³ biogas per ton

Sewage Sludge: 15-25 m³ biogas per ton

Energy Crops: 150-250 m³ biogas per ton. For more information, learn about the anaerobic process.

7 Steps of the Anaerobic Digestion Process: “Trash to Cash”

While the biological process occurs in four stages, the complete anaerobic digestion system operates through seven distinct operational steps. Understanding each helps visualise how raw waste transforms into valuable products. These steps represent the journey from collection to final products, encompassing both the biological reactions inside the digester and the mechanical processes that support them. To delve deeper into the science behind it, explore more about the anaerobic process.

1. Collection and Pre-treatment of Feedstock

Everything begins with the collection and preparation of the organic waste. This critical first step involves gathering the feedstock, removing contaminants like plastics and metals, and preparing it for efficient digestion. Depending on the source material, this might involve shredding, grinding, or screening to increase surface area and improve digestion efficiency. For wet wastes, dilution may be necessary to achieve the optimal solid content, while drier materials might require the addition of water or mixing with liquid wastes.

2. Hydrolysis: Breaking Down Complex Molecules

Once inside the digester, hydrolysis begins—the first biological stage where complex organic polymers (proteins, carbohydrates, and lipids) are broken down into simpler, soluble compounds. Hydrolytic bacteria release enzymes that split these large molecules into amino acids, sugars, and fatty acids that smaller microorganisms can consume. This stage often becomes the rate-limiting step in the overall process, especially when processing fibrous materials like cellulose and lignin from plant matter. To understand more about this process, you can learn about what a biogas reactor is and how it facilitates these reactions.

The efficiency of hydrolysis can significantly impact overall biogas production rates. Materials high in lignin (like woody biomass) resist breakdown, while easily digestible materials like food waste undergo hydrolysis rapidly. Temperature, pH, and retention time all play crucial roles in optimizing this initial breakdown phase. Some advanced systems incorporate thermal, chemical, or enzymatic pre-treatments specifically to enhance hydrolysis rates.

3. Acidogenesis: Producing Organic Acids

Following hydrolysis, acidogenic bacteria convert the simple sugars, amino acids, and fatty acids into volatile fatty acids (VFAs), alcohols, hydrogen, and carbon dioxide. This acidogenesis stage happens relatively quickly compared to other phases, often completing within hours rather than days. The primary products include propionic acid, butyric acid, acetic acid, and ethanol, along with new cellular material as the bacteria multiply. To understand more about this process, you can explore anaerobic digestion in detail.

The rapid acid production during this phase can potentially lower the digester's pH, which must be carefully monitored to prevent inhibition of subsequent stages. Acidogenic bacteria are relatively tolerant to environmental changes and can function across a wide pH range of 4.0-8.5, making them robust participants in the digestion process. Their efficiency directly influences the quantity and quality of materials available for the next stages.

4. Acetogenesis: Creating Acetic Acid

In the acetogenesis stage, acetogenic bacteria convert the products from acidogenesis into acetic acid, hydrogen, and carbon dioxide. These specialised bacteria transform alcohols, volatile fatty acids, and certain aromatic compounds into substrates that methanogenic bacteria can utilize. Acetate becomes the primary product during this phase, accounting for approximately 70% of the methane ultimately produced in the digester.

Acetogenic bacteria operate in a syntrophic (mutually beneficial) relationship with methanogens. The hydrogen produced during acetogenesis must be continuously removed by hydrogen-consuming methanogens, as its accumulation would inhibit acetogenic metabolism. This delicate balance between hydrogen production and consumption represents one of the most critical aspects of stable digester operation. When properly managed, acetogenesis efficiently channels the complex mixture of acidogenesis products toward the final stage of methanogenesis.

5. Methanogenesis: Biogas Formation

The culmination of the biological process occurs during methanogenesis, where methanogenic archaea (ancient single-celled organisms distinct from bacteria) convert acetate, hydrogen, and carbon dioxide into methane and carbon dioxide. These microorganisms work extremely slowly compared to others in the process, doubling their population only every 3-30 days, making them highly susceptible to disruption. Two primary pathways produce methane: acetoclastic methanogenesis (splitting acetate into methane and carbon dioxide) and hydrogenotrophic methanogenesis (using hydrogen to reduce carbon dioxide to methane).

Methanogens operate within very specific environmental conditions. They require strictly anaerobic conditions (even tiny amounts of oxygen can be toxic), neutral to slightly alkaline pH (optimally 7.0-8.0), and stable temperatures. Temperature fluctuations of even a few degrees can significantly reduce methane production. The sensitivity of methanogens makes this final biological stage the most vulnerable to process upsets, which is why careful monitoring and control of digester conditions are essential for maintaining stable biogas production.

6. Biogas Collection and Upgrading

As biogas is produced, it rises to the top of the digester where it's collected for use. Raw biogas typically contains 50-75% methane, 25-50% carbon dioxide, and trace amounts of hydrogen sulfide, water vapor, and other gases. While this raw biogas can be used directly for heating or combined heat and power generation, many applications require upgrading to increase methane concentration and remove contaminants.

Upgrading technologies include water scrubbing, pressure swing adsorption, membrane separation, and cryogenic processes—each removing carbon dioxide and impurities to different degrees. The resulting biomethane (typically >95% methane) can be injected into natural gas grids, compressed for vehicle fuel, or used in applications requiring higher purity gas. Modern monitoring systems continuously analyse gas composition, allowing operators to identify process issues early through changes in methane content or impurity levels.

7. Digestate Processing and Use

After completing the anaerobic digestion cycle, the remaining material—called digestate—contains valuable nutrients including nitrogen, phosphorus, and potassium in forms readily available to plants. This nutrient-rich slurry can be separated into liquid and solid fractions for different applications. The liquid fraction, containing most of the soluble nitrogen and potassium, makes an excellent liquid fertiliser. The solid fraction, rich in phosphorus and organic matter, can be composted, pelleted, or directly applied as a soil amendment.

Proper digestate management completes the circular economy of anaerobic digestion, returning nutrients to agricultural lands and reducing dependence on synthetic fertilisers. Advanced digestate processing technologies like ammonia stripping, phosphorus precipitation, and membrane filtration can further refine these products for specific markets. Quality standards for digestate are developing globally, with certification schemes ensuring safe and beneficial use of these valuable by-products.

Types of Anaerobic Digesters and How They Work

The science behind anaerobic digestion remains consistent, but the engineering approaches vary widely depending on feedstock characteristics, local conditions, and desired outcomes. Understanding the main digester configurations helps in selecting the optimal system for specific applications. Each design offers different advantages in terms of simplicity, efficiency, resilience, and capital cost.

Batch vs. Continuous Feed Digesters

Batch digesters operate on a fill-and-empty cycle—loaded with feedstock, sealed, and then emptied completely once digestion is complete, typically after 15-40 days. These systems are simpler to construct and operate, making them ideal for smaller-scale applications or where feedstock arrives intermittently. Their simplicity comes with trade-offs: gas production fluctuates throughout the cycle (peaking in the middle), and labour requirements increase due to the loading/unloading cycles. To maintain steady biogas production, multiple batch digesters can be operated in staggered schedules.

Batch vs. Continuous Feed Digesters

Batch digesters operate on a fill-and-empty cycle—loaded with feedstock, sealed, and then emptied completely once digestion is complete, typically after 15-40 days. These systems are simpler to construct and operate, making them ideal for smaller-scale applications or where feedstock arrives intermittently. Their simplicity comes with trade-offs: gas production fluctuates throughout the cycle (peaking in the middle), and labour requirements increase due to the loading/unloading cycles. To maintain steady biogas production, multiple batch digesters can be operated in staggered schedules. For a deeper understanding of the anaerobic process, explore more about its stages and applications.

In contrast, continuous feed digesters receive regular inputs of feedstock while simultaneously discharging an equal amount of digestate. This creates steady, reliable biogas production and more consistent operation. Continuous systems typically achieve higher overall efficiency and biogas yields, making them the standard for commercial-scale operations. They require more sophisticated feeding equipment, mixing systems, and process controls, but these investments pay off through improved performance and reduced labour costs.

Single-Stage vs. Multi-Stage Systems

CC BY-NC by chesbayprogram

Single-stage digesters conduct all biological phases in one vessel, simplifying construction and reducing capital costs. These systems rely on the different groups of microorganisms coexisting within a balanced environment. When properly designed and operated, single-stage systems can achieve excellent performance while maintaining relatively simple operation. The majority of existing digesters worldwide use single-stage configurations, particularly for more easily digestible feedstocks like manure and food waste.

Multi-stage systems separate the digestion process into two or more vessels, each optimised for different phases of the biological process. Typically, hydrolysis and acidogenesis occur in the first stage at a lower pH and shorter retention time, while acetogenesis and methanogenesis happen in a second vessel with neutral pH and longer retention time. This separation allows optimisation of conditions for each microbial group, potentially increasing overall efficiency and stability. Multi-stage systems show particular advantages when processing complex or rapidly degradable feedstocks, though their higher complexity and capital cost must be justified by performance gains.

Wet vs. Dry Digestion Processes

Wet digestion systems operate with total solids content typically below 15%, creating a pumpable slurry that allows for conventional mixing and handling equipment. These systems dominate the market, particularly for manure, sewage sludge, and food waste applications. Their advantages include excellent heat transfer, efficient mixing, and proven technology, but they require substantial water additions for drier feedstocks and produce larger volumes of liquid digestate that must be managed.

Dry digestion operates with 20-40% total solids content, processing material that maintains a stackable consistency throughout digestion. These systems handle high-solids materials like crop residues, yard waste, and certain food wastes without dilution. Benefits include reduced reactor volume, lower water requirements, and smaller digestate volumes, but they face challenges with material handling, mixing, and maintaining uniform conditions. Dry systems often use plug-flow or garage-type configurations where material moves through the system as a cohesive mass rather than a mixed liquid.

Mesophilic vs. Thermophilic Temperature Ranges

Most commercial digesters operate in the mesophilic temperature range (95-105°F or 35-40°C), which balances digestion rate with operational stability. Mesophilic microorganisms are more robust against temperature fluctuations and process variations, making these systems more forgiving to operate. They require less heating energy and typically show excellent long-term stability, though they need longer retention times (20-30 days) to achieve complete digestion.

Thermophilic systems operate at higher temperatures (125-140°F or 50-60°C), accelerating biological reactions and potentially increasing biogas production. These systems can achieve complete digestion with shorter retention times (10-18 days), allowing smaller digester volumes for the same throughput. However, they demand more precise temperature control, consume more heating energy, and show greater sensitivity to environmental changes. Thermophilic operation provides enhanced pathogen reduction, which can be advantageous for certain feedstocks and digestate applications where hygienization is required.

Turning Trash to Cash: The Economic Benefits

The economic case for anaerobic digestion has strengthened dramatically as energy prices rise, waste disposal costs increase, and environmental regulations tighten. A well-designed and operated digestion facility creates multiple revenue streams while solving waste management challenges. The financial viability depends on local conditions, available incentives, and operational efficiency, but successful projects regularly achieve payback periods of 5-8 years with internal rates of return exceeding 15%.

Revenue from Biogas and Renewable Energy

Biogas represents the primary value product from anaerobic digestion, offering multiple utilisation pathways with different economic profiles. Direct combustion in boilers for heat production provides the simplest and lowest-cost option, particularly valuable for operations with substantial thermal energy requirements.

Combined heat and power (CHP) generation through engines or turbines produces both electricity and heat, typically capturing 35-40% of biogas energy as electricity and another 40-45% as usable heat. The highest-value pathway often involves upgrading biogas to biomethane for injection into natural gas grids or use as vehicle fuel, though this requires additional processing equipment.

Energy revenue potential varies dramatically by location due to differences in electricity rates, natural gas prices, and renewable energy incentives. Many jurisdictions offer premium rates for biogas-derived electricity through feed-in tariffs or renewable portfolio standards.

Where available, renewable energy certificates, carbon credits, or renewable fuel credits (like RINs in the US) can significantly enhance project economics. The most successful projects typically secure long-term energy offtake agreements that provide revenue certainty for financing.

Anaerobic Digestion Process Steps – Frequently Asked Questions (FAQ)

How long does the complete anaerobic digestion process take?

The time required for complete anaerobic digestion depends on several factors, including feedstock type, digester technology, and operating temperature. In commercial systems, hydraulic retention time (HRT)—the average time material remains in the digester—typically ranges from 15-30 days for mesophilic systems processing easily degradable materials like food waste and manure. Thermophilic systems operating at higher temperatures can achieve complete digestion in as little as 10-18 days, while systems processing more recalcitrant materials like crop residues may require 30-50 days. Dry fermentation systems often operate with even longer retention times of 30-60 days due to reduced mixing efficiency.

- Food waste in wet mesophilic systems: 15-25 days

- Manure in complete mix digesters: 20-30 days

- Municipal wastewater sludge: 15-30 days

- Agricultural residues and energy crops: 30-50 days

- Multi-stage systems (separate hydrolysis): 10-20% shorter overall retention time

An aerial view of Tamar’s Basingstoke plant, which has the capacity to process up to 40,000 tonnes of food waste per annum.

The biological process follows a predictable pattern regardless of feedstock, with most methane production occurring in the first two-thirds of the retention period. The final third primarily serves to capture the remaining 15-20% of potential gas and stabilise the digestate. Some advanced systems incorporate retention time optimisation by segregating nearly-stabilised material, allowing increased throughput without sacrificing methane yield.

It's worth noting that hydraulic retention time differs from solids retention time in some system configurations. Technologies like fixed-film digesters or systems with solids recycling can maintain longer solids retention times while allowing liquids to pass through more quickly, improving overall efficiency while maintaining complete digestion of the organic fraction.

[Published on 17 April 2020. Updated with a complete re-write, September 2025.]

Asking questions are in fact pleasant thing if you are not understanding anything completely,

but this article provides nice understanding yet.

It’s hard to find your website in google. I found it on 15 spot,

you should build quality backlinks , it will help you to get more visitors.

I know how to help you, just search in google – k2 seo tricks

While the simple and classic whisk is great for many tasks in the kitchen, there

are some times and some recipes that require more speed and dexterity with the mixing, and

that’s where these valuable devices come in. There are a lot

of advantages to life with all of the fancy gadgets available to us in this day and age.

Kitchen design styles change quite fast and this can also

be hastened by the use of the latest modern gadgets like blenders, juicers, modern ovens, steamers and the like.

You’d like some outstanding examples from the war secrets collection. He

isn’t afrsid too tell his clients tto ggo to cash when necessary.

China Carbon Graphite Group, through itss affiliate, Xingyong Cardbon Co.

I read a lot of interesting content here. Probably you spend a lot of time writing, i know how to save you a lot of time,

there is an online tool that creates unique, SEO friendly articles in minutes, just type in google – laranitas free

content source

Similarly, there aare “snake oil salesmen” ready

to help yoou get a #1 ranking using their latest trick.

Thee manmager puts the strategy into action by coordinating a team to work towards their SEO goals.

One of the keys to properly using social mediua websites such as Pinterest and Tumblr is that yyou hace to uuse interesting images.

Your software may be unoriginal, dull and ineffective

in presentation to visitors. Making smart betting decisions through online casinos like High Noon Casino can help you earn more chips

that you can cash in for real money. Do check for the online casino license

prior to begin with the online gaming experience.

I am not sure that Anaerobic Digestion attractive waste and biofuel crop treatment process. I am researching on Digestive Enzymes since many days. So this article will be very helpful for me. Thanks.

Is it applicable to all types of food, or only organic food?