Recent developments in CO₂ separation membrane technology mean that there are big improvements in these selective barriers (often hollow fibre or spiral-wound) that allow carbon dioxide to pass through faster than other gases. This technology uses the solution-diffusion mechanism, driven by partial pressure differences, to purify gas streams for applications like biogas upgrading, natural gas processing, and carbon capture, offering advantages

CO2 Separation Membrane Technology – Key Takeaways

- CO2 separation membrane technology can reduce biogas purification costs by up to 70% compared to traditional methods, making renewable natural gas production more economically viable.

- Leading membrane technologies from Toray, Evonik, and MTR offer superior performance with methane recovery rates of up to 98% and significantly lower energy consumption.

- The most advanced membranes are moisture-resistant, eliminating costly pre-treatment steps that plague conventional purification systems.

- Real-world applications demonstrate that membrane technology scales effectively from small farm digesters to industrial-sized plants.

- Strategic membrane selection based on feedstock composition and output requirements can dramatically improve ROI timelines for biogas upgrading projects.

The biogas industry stands at a crossroads. While renewable natural gas (RNG) production continues to gain momentum, many facilities struggle with the economics of traditional CO2 separation processes. The good news? Advanced membrane technology is changing the game entirely.

Membrane-based separation systems are rapidly becoming the gold standard for biogas upgrading, delivering unprecedented efficiency while slashing operational costs. A recent one-year trial by Toray demonstrated a 70% reduction in moisture removal costs at a sewage treatment plant in Osaka, signalling a major breakthrough for the industry. Biogas Solutions International has been tracking these developments closely, recognising that membrane technology represents the future of cost-effective biogas purification.

But not all membrane systems deliver equal results. Understanding the critical differences between available technologies is essential for operators looking to maximise their return on investment while meeting increasingly stringent pipeline specifications.

“porous carbon fiber …” from www.compositesworld.com and used with no modifications.

Revolutionary CO2 Separation Membranes Transform Biogas Economics

The economics of biogas upgrading has historically been challenging. Traditional purification methods require substantial energy inputs, complex multi-stage processing, and expensive pretreatment systems—all eating into profit margins. Membrane technology changes this equation dramatically by simplifying the process while delivering superior results.

Modern CO2 separation membranes leverage advanced material science to selectively remove carbon dioxide while retaining valuable methane. The most efficient systems can achieve methane recovery rates exceeding 98%, a remarkable improvement over conventional technologies that typically top out around 85-90%. This increase in recovery alone can improve project economics by 10-15% over the lifetime of a facility.

What makes these membranes truly revolutionary is their resilience. Unlike polymer and zeolite membranes used in conventional systems that degrade when exposed to moisture, newer carbon fibre and advanced polymer membranes maintain structural integrity and performance even in high-moisture environments. This eliminates expensive pretreatment steps and reduces downtime, creating a compounding economic advantage. For further insights into biogas applications, explore how food waste pumps prove their effectiveness at large biogas plants.

Why Traditional Biogas Purification Methods Fall Short

To appreciate the advancement that membrane technology represents, it's important to understand the limitations of traditional purification methods. Pressure Swing Adsorption (PSA), water scrubbing, and amine scrubbing have dominated the industry for decades, but each comes with significant drawbacks that impact operational efficiency and profitability.

High Energy Consumption Cuts Into Profits

Traditional biogas upgrading systems are notorious energy consumers. Water scrubbing, for instance, requires continuous water circulation and repressurization, while PSA systems demand multiple pressure cycles to achieve adequate gas separation. These energy requirements can consume 0.2-0.3 kWh per cubic meter of raw biogas—representing up to 30% of the energy value in smaller systems. Learn more about biogas plant efficiency and how innovative solutions are being implemented.

By contrast, membrane systems typically operate with energy demands of 0.1-0.15 kWh per cubic meter, effectively doubling the net energy yield of the upgrading process. For a medium-sized plant processing 500 Nm³/hr of biogas, these energy savings alone can translate to over $100,000 annually in reduced operating costs. Learn more about biomethane success stories and their impact on the industry.

Moisture Sensitivity Creates Costly Pretreatment Steps

Traditional separation technologies fail spectacularly when exposed to moisture—an inevitable component of raw biogas. To protect these sensitive systems, operators must install elaborate dehumidification equipment, adding capital expense and creating another energy-intensive process step. These moisture removal systems typically account for 15-25% of total plant energy consumption. Learn more about the challenges faced by engineers in biogas facilities in this insightful article.

The moisture-resistant properties of advanced membrane materials eliminate this requirement entirely. Toray's carbon fiber membranes, for example, maintain performance even with significant moisture content, eliminating an entire process step and its associated costs.

- Water scrubbing requires complete moisture saturation, consuming water resources

- PSA systems require moisture removal to <0.1%, adding significant pretreatment costs

- Amine systems are corrosion-prone when moisture combines with CO2

- Advanced membranes operate effectively with moisture present, eliminating the need for pretreatment

Scaling Difficulties Limit Growth Potential

“Traditional biogas upgrading technologies simply don't scale efficiently. What works for a 100 Nm³/hr plant becomes prohibitively expensive at 1,000 Nm³/hr. Membrane technology changes this equation entirely, with nearly linear scaling economics.” — Biogas Technology Assessment Report, 2022

The modular nature of membrane systems represents perhaps their greatest advantage over traditional technologies. Adding capacity is as simple as installing additional membrane modules—no redesign required. This scalability makes membrane systems ideal for growing operations or those with seasonal fluctuations in feedstock availability.

3 Game-Changing Membrane Technologies Reshaping The Industry

When evaluating membrane technologies for biogas applications, three manufacturers stand out for their innovative approaches and proven performance. Each offers a distinct CO2 Separation Membrane technology platform with specific advantages depending on project requirements and operating conditions.

Toray's Carbon Fibre Membrane: 70% Lower Moisture Removal Costs

“Toray shows carbon fiber CO₂ …” from www.compositesworld.com and used with no modifications.

Toray's revolutionary carbon fibre membrane technology represents a fundamental shift in biogas purification. Unlike conventional membranes, Toray's system uses carbon fibre as the structural foundation, creating exceptional chemical resistance and thermal stability. This design innovation allows the membranes to operate effectively even in high-moisture environments, eliminating the need for extensive pre-drying systems that plague traditional technologies.

The results from Toray's year-long trial at an Osaka sewage treatment plant demonstrate the real-world impact: 70% reduction in moisture removal costs compared to conventional systems. This single improvement dramatically shifts the economics of biogas upgrading, particularly for wastewater treatment facilities where biogas typically contains high moisture content.

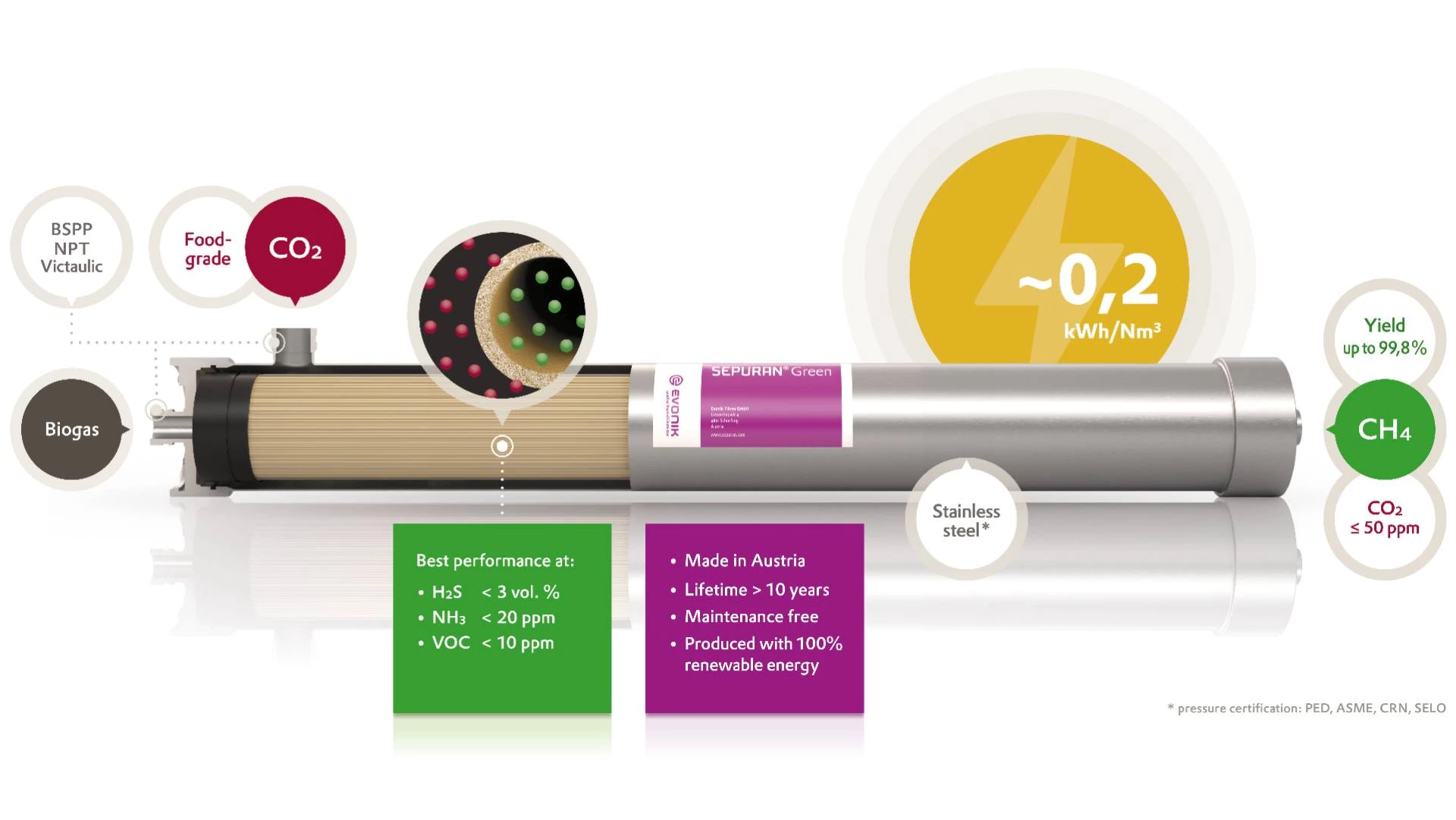

Evonik's SEPURAN® Green: Multi-Stage Hollow Fibre Process

“SEPURAN® Green I Membranes for CO2 separation from methane in biogas to yield high value biomethane…” from www.membrane-separation.com and used with no modifications.

Evonik's SEPURAN® Green technology takes a different approach, utilising specially developed hollow fibre membranes arranged in a patented three-stage configuration. This unique design maximises both methane recovery and CO2 removal in a single process, achieving biomethane purities up to 99% with methane recovery rates exceeding 95%.

What sets SEPURAN® Green apart is its exceptional selectivity—the ability to precisely separate methane from CO2 molecules—combined with impressive resistance to common biogas contaminants. Since entering the market in 2011, Evonik has installed over 100 SEPURAN® systems worldwide, accumulating more than one million operating hours and establishing a proven track record across diverse operating conditions. For more insights into biogas applications, check out these success stories of biomethane in public transport.

MTR's Polymer Chemistry: 98% Hydrocarbon Recovery

“Polaris Membrane – an overview …” from www.sciencedirect.com and used with no modifications.

Membrane Technology & Research (MTR) has developed a proprietary polymer chemistry specifically designed to withstand the challenging components found in biogas. Their membranes feature a unique molecular structure that allows for exceptional selectivity while maintaining structural integrity even when exposed to hydrogen sulfide, siloxanes, and other problematic compounds.

The most impressive feature of MTR's system is its hydrocarbon recovery rate—up to 98% of available methane is captured and preserved through the purification process. For facility operators, this translates directly to increased RNG production and revenue. MTR's systems also offer remarkably compact footprints, requiring up to 70% less space than equivalent PSA or water scrubbing installations.

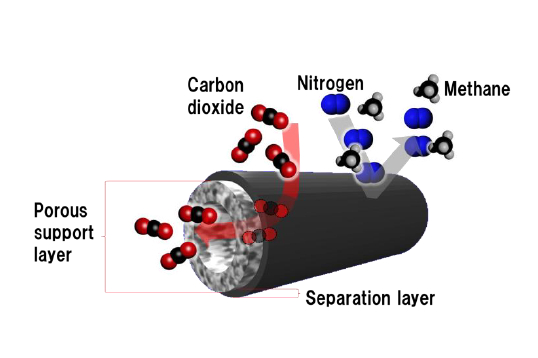

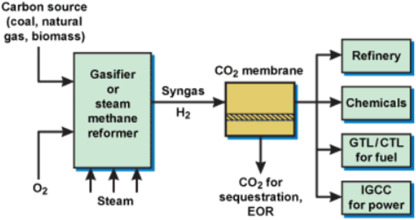

How Advanced Membranes Actually Work

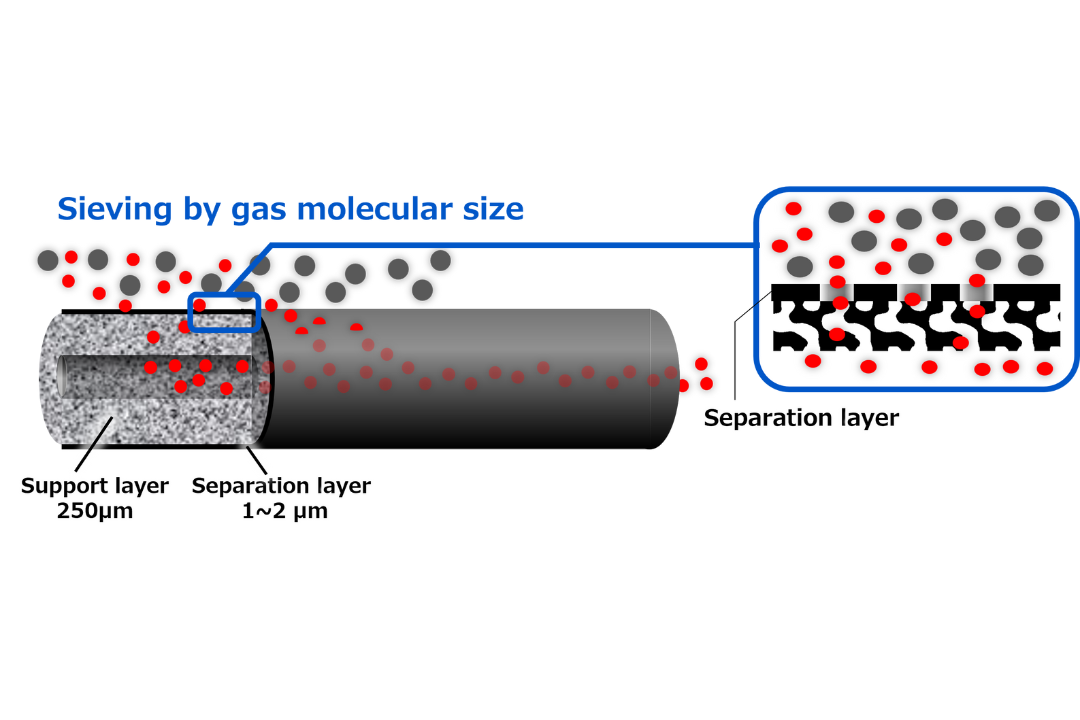

Understanding the fundamental mechanisms behind membrane separation helps operators make informed decisions when selecting technology. At their core, all membrane systems rely on selective permeation—allowing certain gas molecules to pass through while blocking others—but significant differences exist in how this selectivity is achieved.

Selective Permeation Mechanics

Gas separation membranes function on a simple principle: different gas molecules move through membrane materials at different rates. This selectivity occurs because CO2 molecules are more soluble in the membrane material than methane molecules, creating a natural separation mechanism. As biogas flows across the membrane surface under pressure, CO2 preferentially dissolves into the membrane and diffuses through to the permeate side, while methane molecules are largely retained on the feed side. For further insights on the biogas industry, you can explore The American Biogas Council.

Modern membrane systems typically operate in a counter-flow configuration, where the gas mixture flows in the opposite direction to the permeate flow, maximising the concentration gradient and improving separation efficiency. Multiple membrane stages are often employed, with each stage optimised for a specific aspect of the separation process—some focused on maximising methane retention while others prioritise CO2 removal.

The most advanced systems incorporate pressure and temperature management to optimise molecular behaviour, creating ideal conditions for selective permeation based on the specific membrane chemistry employed. This allows for fine-tuning of performance to match the unique characteristics of each biogas source.

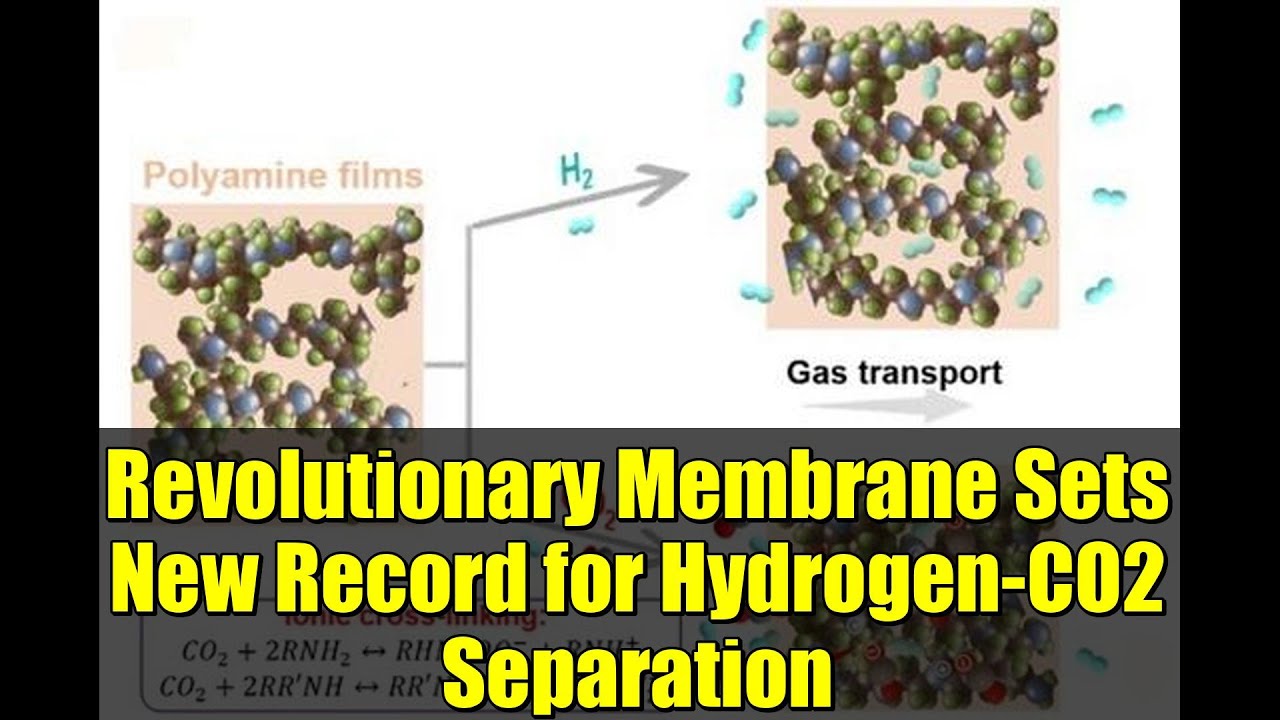

Material Science Breakthroughs

Watch the video below for an explanation of the concept behind CO2 Separation Membrane Technology efficiency gains:

Recent breakthroughs in materials science have dramatically enhanced membrane performance. Traditional polymer membranes suffered from a fundamental tradeoff between selectivity and permeability—improvements in one typically came at the expense of the other. Modern membrane materials have shattered this limitation through nanoscale engineering of membrane structures.

Toray's carbon fibre membranes are said to represent one such breakthrough, utilising graphene-like carbon structures that create molecular-sized channels perfect for gas separation. Evonik's hollow fibre approach creates an enormous surface area within a compact module, maximising separation efficiency while minimising footprint. MTR's proprietary polymer blends incorporate specialised functional groups that preferentially interact with CO2 molecules while repelling methane.

5 Critical Performance Metrics That Matter When Choosing CO2 Separation Membrane Tech

When evaluating membrane technologies for biogas applications, five key performance metrics should guide decision-making. These factors directly impact operational efficiency, economic performance, and the long-term viability of upgrading systems.

1. Methane Recovery Rate

Methane recovery represents the percentage of available methane that's successfully retained during the separation process. This single metric often has the greatest impact on economic performance, as methane losses directly reduce potential revenue. Modern membrane systems achieve recovery rates between 95-98%, compared to 85-90% for traditional technologies, representing a significant economic advantage. For more insights on the benefits of biomethane, explore these success stories of biomethane in public transport decarbonization.

2. CO2 Removal Efficiency

CO2 removal efficiency determines whether the upgraded biomethane can meet pipeline specifications, which typically require 97-99% methane purity. The best membrane systems can achieve over 99% CO2 removal in a properly configured multi-stage setup. This high-efficiency removal eliminates the need for secondary polishing steps required by some traditional technologies.

The efficiency of CO2 removal directly impacts system sizing as well. Higher efficiency means fewer membrane modules are needed, reducing both capital costs and physical footprint. This becomes particularly important in space-constrained installations like wastewater treatment plants or urban facilities.

3. Moisture Tolerance

Moisture tolerance represents a critical advantage for modern membrane systems. Traditional purification methods require extensive moisture removal before gas can be processed, adding significant complexity and cost. Advanced membranes like Toray's carbon fiber technology can handle biogas with high moisture content without performance degradation.

This tolerance eliminates the need for dedicated dehumidification systems, reducing capital costs by 15-20% and decreasing energy consumption by a similar margin. For operators, this translates to simpler system architecture, lower maintenance requirements, and improved overall reliability.

4. Energy Consumption

Energy consumption directly impacts operational economics and determines the net energy yield of the biogas upgrading process. Membrane systems typically require 0.1-0.25 kWh per cubic meter of raw biogas processed, with newer systems trending toward the lower end of this range. This represents a substantial improvement over water scrubbing (0.25-0.3 kWh/m³) and PSA systems (0.2-0.3 kWh/m³).

The energy advantage becomes particularly significant for smaller facilities where parasitic loads can consume a substantial portion of overall energy production. Membrane systems can increase net energy output by 10-20% compared to traditional technologies, directly improving project economics.

5. Membrane Longevity

Membrane longevity determines maintenance requirements and lifetime costs. Early membrane systems suffered from relatively short operational lifespans of 3-5 years, creating significant replacement costs. Modern membranes have dramatically improved durability, with expected lifespans of 7-10 years under proper operating conditions.

This extended lifespan reduces lifetime costs and minimises operational disruptions from membrane replacements. Manufacturers like Evonik and Toray now offer performance guarantees, providing operators with greater financial certainty when projecting operational costs.

Real-World Performance: Sewage Plants to Farm Digesters

Membrane technology has proven its versatility across diverse applications, from municipal sewage plants to agricultural digesters and landfill gas recovery systems. This adaptability stems from the inherent flexibility of membrane systems, which can be configured to match specific feedstock characteristics and desired output specifications.

Osaka Prefecture Case Study: Toray's Year-Long Trial

Toray's landmark trial at an Osaka sewage treatment plant provides compelling evidence of membrane performance in challenging real-world conditions. Over a full year of operation, their carbon fiber membrane system achieved consistent biomethane purity exceeding 98% while reducing moisture removal costs by 70% compared to conventional systems.

The Osaka installation processes biogas with unusually high moisture content—typical of sewage digesters—yet maintains stable performance without the extensive pretreatment systems required by traditional technologies. System uptime exceeded 98.5%, demonstrating exceptional reliability even with variable feedstock conditions.

Perhaps most importantly, the simplified system architecture reduced maintenance requirements by approximately 40% compared to the facility's previous PSA system. This reduction in maintenance translated to lower operational costs and simplified staffing requirements, which can be further explored through advancements in CO2 removal technology.

Scale Flexibility of CO2 Separation Membrane Technology: From Small Farms to Industrial Plants

One of membrane technology's most significant advantages is its exceptional scalability. The modular nature of membrane systems allows for precise sizing to match project requirements, from small farm digesters processing 50 Nm³/hr to industrial installations handling over 3,000 Nm³/hr.

Small-scale agricultural installations benefit particularly from membrane technology's simplified architecture and reduced maintenance requirements. These systems can often be operated with minimal specialised training, making them ideal for on-farm biogas upgrading where dedicated technical staff isn't available.

At the industrial scale, the compact footprint of membrane systems provides significant advantages. A membrane installation typically requires 50-70% less space than equivalent water scrubbing or PSA systems, reducing construction costs and allowing for installation in space-constrained environments.

Economic Analysis: When Membrane Tech Pays For Itself

The economic advantage of membrane technology stems from a combination of lower capital costs, reduced operational expenses, and improved gas recovery. While specific economics vary by project, membrane systems typically demonstrate payback periods 15-30% shorter than traditional technologies.

Capital Expenditure vs. Operational Savings

Initial capital expenditure for membrane systems is competitive with or slightly lower than traditional technologies, primarily due to simplified system architecture and reduced pretreatment requirements. For a 500 Nm³/hr system, capital costs typically range from $1.2-1.8 million, compared to $1.5-2.1 million for equivalent water scrubbing systems.

The true economic advantage emerges in operational expenses, where membrane systems demonstrate substantial savings. Reduced energy consumption, lower maintenance requirements, and minimal consumables translate to operational cost reductions of 25-40% compared to traditional systems. For a medium-sized installation, these savings typically amount to $150,000-250,000 annually.

Higher methane recovery rates further improve economics by increasing revenue from RNG sales. A 5% improvement in recovery rate—typical when comparing advanced membranes to traditional technologies—can increase annual revenue by $100,000-300,000, depending on gas pricing and facility size.

ROI Timeline Based on Plant Size

Return on investment timelines vary significantly based on facility size, with larger installations generally demonstrating faster payback due to economies of scale. Small installations (50-200 Nm³/hr) typically achieve payback in 4-6 years, medium installations (200-1,000 Nm³/hr) in 3-5 years, and large installations (>1,000 Nm³/hr) in 2-4 years when utilising membrane technology. These timelines are typically 1-2 years shorter than equivalent projects using traditional purification methods.

Implementation Guide: Selecting The Right Membrane System

Selecting the optimal membrane system requires careful consideration of project-specific factors, including feedstock characteristics, desired output specifications, and operational constraints. While membrane technology offers advantages across nearly all applications, the specific membrane system and configuration should be matched to project requirements.

Feedstock Considerations

Feedstock composition significantly impacts CO2 Separation Membrane selection and system configuration. Biogas from different sources contains varying levels of contaminants that can affect membrane performance and longevity. Agricultural digesters typically produce biogas with higher hydrogen sulfide content, while landfill gas often contains siloxanes and volatile organic compounds that require consideration.

Hydrogen sulfide (H2S) represents a particular challenge, as it can damage membrane materials and downstream equipment if not properly managed. For applications with high H2S levels, pretreatment with iron oxide media or activated carbon may still be necessary, though some advanced membranes demonstrate improved resistance to H2S exposure.

Moisture content also influences system design, with sewage digesters and food waste facilities typically producing biogas with higher moisture levels. While modern membranes offer improved moisture tolerance, extremely high moisture content may still require some degree of dehumidification to optimize performance and prevent condensation issues.

| Feedstock Source | Typical Challenges | Recommended Membrane Type |

|---|---|---|

| Wastewater Treatment | High moisture, moderate H2S | Carbon fibre (Toray) |

| Agricultural Digester | High H2S, variable composition | Chemical-resistant polymer (MTR) |

| Landfill Gas | Siloxanes, VOCs, nitrogen | Multi-stage hollow fibre (Evonik) |

| Food Waste | High CO2 content, organic acids | High-selectivity hollow fibre (Evonik) |

Output Requirements (Pipeline vs. Vehicle Fuel)

Output requirements fundamentally influence system design and membrane selection. Pipeline injection typically requires biomethane with 97-98% methane content, while vehicle fuel applications often demand 99%+ purity and additional compression. Membrane systems can be configured to meet either requirement, but optimising for specific output specifications improves efficiency and economics. For more insights, explore the success stories of biomethane in public transport decarbonization.

Plant Size and Throughput Matching

“The beauty of membrane technology lies in its modularity. You can precisely match system capacity to project requirements without the significant cost penalties associated with scaled-down versions of traditional technologies.” – CO2 Separation Membranes Biogas Engineering Handbook, 2023

Proper sizing of membrane systems is critical for optimising both performance and economics. Undersized systems create throughput bottlenecks, while oversized systems represent unnecessary capital expenditure. Most manufacturers offer standardised modules that can be combined to achieve the desired capacity, allowing for precise sizing with minimal cost premium.

Future expansion should also be considered during initial system design. The modular nature of membrane systems allows for straightforward capacity increases, but adequate space for additional modules and appropriate sizing of ancillary equipment (compressors, controls, piping) is required to facilitate seamless expansion.

For projects with seasonal variation in biogas production, membrane systems offer advantages through turndown capability. Most membrane installations can efficiently operate at 30-100% of rated capacity without significant performance degradation, allowing for adaptation to changing production rates without compromising efficiency.

Future-Proof Your Investment: Where Membrane Tech Is Headed

The rapid evolution of membrane technology promises continued improvements in performance, durability, and economics. Current research focuses on developing membranes with even higher selectivity, improved chemical resistance, and extended operational lifespans.

Next-generation membranes incorporating nanomaterials like graphene and carbon nanotubes demonstrate potential for 25-40% improvements in separation efficiency while reducing energy requirements.

For operators investing in membrane technology today, modular architecture ensures systems can be upgraded as new membrane materials become commercially available, protecting the initial investment while allowing access to future performance improvements.

CO2 Separation Membranes – Frequently Asked Questions

Biogas operators considering membrane technology often share common questions about performance, maintenance, and economics. The following responses address the most frequent inquiries based on current field experience and manufacturer data.

While membrane technology has matured significantly over the past decade, misconceptions still persist about reliability, performance, and applicability across different operating conditions. The following clarifications aim to address these questions with current, field-verified information. For a deeper understanding, you might find it interesting to read about a day in the life of an engineer at a biogas facility.

How do CO2 separation membranes compare to traditional PSA or water scrubbing systems?

Membrane systems offer several fundamental advantages over traditional technologies. They typically require 40-60% less energy than water scrubbing, eliminate water consumption entirely, and occupy 50-70% less space than PSA systems. Modern membranes also achieve methane recovery rates of 95-98%, compared to 85-90% for traditional technologies, directly increasing biomethane production and revenue.

The simplified architecture of membrane systems eliminates moving parts associated with PSA valve systems and water circulation equipment, reducing maintenance requirements by 30-50%. This translates to higher reliability, with modern membrane installations routinely achieving 98%+ uptime compared to 90-95% for traditional technologies.

Can membranes handle H2S and other biogas contaminants?

Modern membranes demonstrate improved tolerance to common biogas contaminants, but limitations still exist. Most membrane materials can handle H2S levels up to 300-500 ppm without significant performance degradation, but higher concentrations typically require pretreatment to prevent accelerated membrane ageing. Siloxanes and volatile organic compounds (VOCs) present in landfill gas may also require pretreatment depending on concentration levels.

The most advanced membrane materials, particularly MTR's proprietary polymer formulations, offer enhanced resistance to contaminants, but economic analysis should include appropriate pretreatment systems when processing biogas with high contaminant levels. Manufacturer specifications should be consulted for specific tolerance thresholds based on the membrane chemistry employed.

What's the typical lifespan of modern CO2 separation membranes?

Modern membranes demonstrate significantly improved longevity compared to early generations. Under proper operating conditions with appropriate pretreatment, current-generation membranes typically achieve operational lifespans of 7-10 years before replacement is required. This represents a substantial improvement over early membranes with 3-5 year lifespans. For a deeper understanding of biogas facilities and their operations, explore a day in the life of an engineer at a biogas facility.

Several factors influence membrane longevity, with contaminant exposure and operating temperature being particularly significant. Exceeding recommended temperature limits can accelerate aging, while exposure to high concentrations of hydrogen sulfide, siloxanes, or VOCs may reduce lifespan if not properly managed through pretreatment. Most manufacturers now offer performance guarantees with specific warranty periods, providing financial protection against premature failure. For more information on membrane-based separation technology, visit Membrane Separation.

Do membrane systems require specialised maintenance staff?

Membrane systems generally require less specialised maintenance than traditional technologies due to their simplified architecture and reduced mechanical complexity. Routine maintenance primarily involves filter replacement, compressor maintenance, and periodic performance monitoring, all of which can be performed with basic mechanical skills and manufacturer training.

Are there government incentives for upgrading to membrane-based biogas purification?

Numerous government incentives support biogas upgrading projects, though most are technology-neutral rather than specific to membrane systems. In the United States, the Renewable Fuel Standard (RFS) provides significant value through RIN credits for renewable natural gas, while the Inflation Reduction Act offers tax incentives for biogas upgrading equipment. The California Low Carbon Fuel Standard (LCFS) provides additional value for RNG used as transportation fuel, with credit values determined by carbon intensity scoring.

Several states have implemented clean fuel standards similar to California's program, creating additional value streams for biomethane producers. Though these incentives are not membrane-specific, the higher efficiency and methane recovery rates of membrane systems often result in improved carbon intensity scores, potentially increasing credit values under these programs.

While specific incentives vary by region, the trend toward more aggressive decarbonization targets suggests continued policy support for biogas upgrading technologies. Consulting with regional renewable energy associations can provide up-to-date information on applicable incentives and emerging opportunities.

Biogas technology is rapidly advancing, providing sustainable energy solutions worldwide. One of the critical components of this technology is the effective management of by-products such as digestate. For instance, understanding digestate slurry emissions and acid addition can significantly enhance the efficiency of biogas plants. By optimising these processes, biogas facilities can not only reduce environmental impact but also improve overall energy production.