Recent research conducted at the Agri-Food and Biosciences Institute (AFBI) in Hillsborough, County Down, has revealed groundbreaking findings on reducing emissions from digestate slurry.

They found that digestate emissions of ammonia are higher for digestate spreading than for traditional methods, and suggested a simple solution. This is not in itself a big concern, as the study indicated that more than two-thirds of GHG emissions from untreated manure and digestates were accounted for by CH4 emissions. The contributions from N2O and NH3 are minor negatives when viewed against the methane emissions reduction.

Nevertheless, there is a solution proposed in the AFBI study, and the common use of soil injection spreading machinery means that emissions will be lower.

The study demonstrates that acidification techniques can dramatically cut both ammonia and methane emissions from anaerobic digestion digestate, which typically produces higher atmospheric emissions of these chemicals than conventional slurry management methods.

These findings offer significant implications for the biogas industry and sustainable agricultural practices across the United Kingdom.

Overview of the AFBI Emissions Study

The comprehensive research was conducted in a specialized slurry storage emissions facility at AFBI Hillsborough, representing a collaborative effort between AFBI researchers and Queen's University Belfast. The study's findings have been published in the prestigious Journal of Cleaner Production, adding to the growing body of knowledge on agricultural emission reduction strategies.

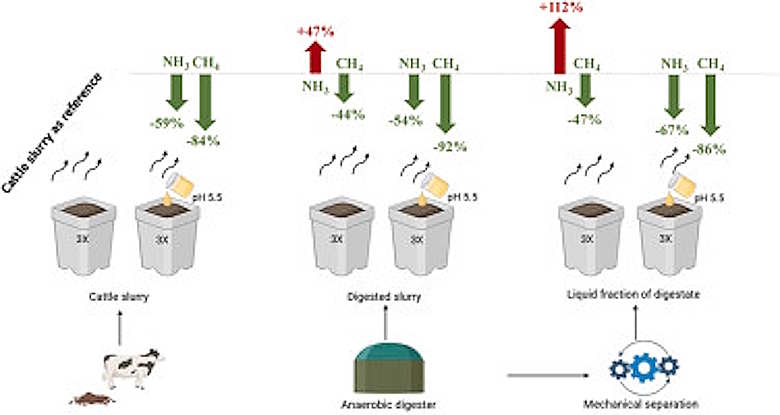

The research team utilized controlled storage tanks with 900-liter capacity to investigate emissions from three distinct sources: cattle slurry, anaerobic digestate, and the liquid fraction of mechanically separated digestate. This comparative approach allowed researchers to quantify emission differences between conventional and processed organic fertilizers.

Research Methodology

The study employed rigorous scientific protocols to measure both ammonia and methane emissions under controlled conditions. Researchers monitored emissions continuously over the storage period, allowing for precise quantification of gas release patterns and total emission volumes. The experimental design included both untreated control samples and acidified treatments to evaluate mitigation effectiveness.

Key Findings on Digestate Emissions

The AFBI study revealed significant differences in emission profiles between conventional cattle slurry and digestate products. When compared to untreated cattle slurry, the research found:

The AFBI study revealed significant differences in emission profiles between conventional cattle slurry and digestate products. When compared to untreated cattle slurry, the research found:Ammonia Emissions

- Anaerobic digestate produced 47% higher ammonia emissions

- Liquid digestate showed 112% higher ammonia emissions

- Higher pH levels in digestate (7.8-8.6) contributed to increased volatilization

- Ammonia losses represent a significant nitrogen value reduction

Methane Emissions

- Digestate produced 44% lower methane emissions than cattle slurry

- Liquid digestate showed 47% lower methane emissions

- Reduced organic carbon content in digestate explains lower methane production

- Methane reduction represents a positive climate impact

These findings highlight a critical trade-off in anaerobic digestion systems. While the process effectively reduces methane emissions compared to untreated slurry, it simultaneously exacerbates ammonia losses if not combined with appropriate mitigation strategies. This presents both a challenge and an opportunity for the biogas industry.

Acid Addition as an Emission Mitigation Strategy

The most significant breakthrough from the AFBI study was the identification of acid addition as a highly effective emission reduction technique. Researchers added sulphuric acid to lower the pH of slurry and digestate samples from their initial range of 7.8-8.6 down to approximately 5.5.

Acidification Results

Lead researcher Dr Khagendra Raj Baral described the results as “dramatic reductions” in both ammonia and methane emissions across all tested materials

Technical Implementation of Acid Addition

The practical implementation of acid addition requires careful consideration of several technical factors. The AFBI study provides valuable insights into the methodology and equipment required for effective acidification of digestate slurry.

Acidification Process

The acidification process involves carefully controlled addition of sulphuric acid to lower the pH of digestate. This can be accomplished through:

- In-tank acidification systems that add acid directly to storage facilities

- In-line acidification during the transfer of digestate

- Field-scale acidification immediately before land application

Each approach offers different advantages in terms of emission reduction, safety, and practical implementation. The AFBI research primarily utilized in-tank acidification under controlled conditions, but they assert that principles can be applied across various system designs.

Understanding Emission Mechanisms

Ammonia Emission Mechanism

Ammonia emissions from digestate are primarily driven by the equilibrium between ammonium (NH₄⁺) and ammonia (NH₃) in solution. This equilibrium is highly pH-dependent, with higher pH values shifting the balance toward volatile ammonia gas. The anaerobic digestion process naturally increases pH and converts organic nitrogen to ammoniacal forms, creating conditions favorable for ammonia volatilization.

By adding acid and lowering pH, the equilibrium shifts strongly toward the non-volatile ammonium form, effectively “locking in” nitrogen and preventing its loss as ammonia gas. This not only reduces environmental impacts but also preserves valuable nitrogen for crop utilization.

Methane Emission Mechanism

Methane emissions from stored digestate occur through continued anaerobic microbial activity. Despite undergoing anaerobic digestion, digestate still contains some residual biodegradable carbon that can be converted to methane by methanogenic bacteria during storage.

Acidification disrupts the activity of these methane-producing microorganisms, which typically function optimally in neutral to slightly alkaline conditions (pH 6.8-8.5). By creating an acidic environment, the metabolic pathways for methane production are inhibited, resulting in significantly reduced emissions.

Feasibility for the Biogas Industry

The implementation of acid addition techniques presents both opportunities and challenges for the biogas industry. Assessing the feasibility requires consideration of economic, practical, and regulatory factors.

The implementation of acid addition techniques presents both opportunities and challenges for the biogas industry. Assessing the feasibility requires consideration of economic, practical, and regulatory factors.Economic Considerations

The economic feasibility of acid addition depends on several factors:

Implementation Costs

- Capital investment for acid storage and dosing equipment

- Ongoing operational costs for acid purchases

- Additional safety measures and training requirements

- Potential modifications to existing storage infrastructure

Economic Benefits

- Preservation of nitrogen fertilizer value (reduced ammonia loss)

- Potential carbon credits or incentives for methane reduction

- Compliance with increasingly stringent emission regulations

- Improved social license to operate through environmental stewardship

Initial calculations suggest that the value of preserved nitrogen and potential emission reduction credits could offset implementation costs, particularly for larger operations or in regions with strict emission regulations.

Practical Implementation Challenges

Several practical considerations must be addressed for successful implementation:

- Safety protocols for handling concentrated acids

- Corrosion-resistant materials for equipment and storage

- Monitoring systems to maintain optimal pH levels

- Integration with existing digestate management systems

- Staff training and operational procedures

The AFBI research provides valuable insights into these challenges, but site-specific assessments would be necessary for individual biogas operations.

Regulatory Context and Compliance

The implementation of acid addition techniques must be considered within the broader regulatory framework governing agricultural emissions and digestate management. Current and emerging regulations in the United Kingdom and European Union increasingly target ammonia and methane emissions from agriculture.

Relevant Regulations

- National Emissions Ceiling Directive (NECD)

- Industrial Emissions Directive (for larger biogas plants)

- Medium Combustion Plant Directive

- Climate change legislation and carbon reduction commitments

- Nitrates Directive and water quality regulations

Acid addition technology offers a pathway to compliance with these regulations while maintaining operational viability. The significant emission reductions demonstrated in the AFBI study could help biogas operators meet increasingly stringent requirements.

Case Studies and Practical Applications

While the AFBI research was conducted under controlled experimental conditions, the principles have been successfully applied in commercial settings. Several case studies demonstrate the practical application of acid addition for emission reduction:

Danish Biogas Experience

Denmark has been at the forefront of implementing slurry acidification technology. Several Danish biogas plants have integrated acid addition systems, reporting emission reductions consistent with the AFBI findings while maintaining digestate quality for agricultural use.

UK Pilot Implementation

A pilot project in the UK implemented in-line acidification during digestate application, achieving over 50% reduction in ammonia emissions while simplifying the handling of acidified materials. The system demonstrated good integration with existing tanker equipment and spreading practices.

These real-world applications provide valuable insights into the practical challenges and benefits of implementing acid addition technology in commercial biogas operations.

Future Research Directions

While the AFBI study provides compelling evidence for the effectiveness of acid addition, several areas warrant further investigation:

- Long-term soil impacts of acidified digestate application

- Alternative acidifying agents that may offer safety or cost advantages

- Optimized dosing strategies to maximize emission reduction while minimizing acid use

- Integration with other emission reduction technologies for synergistic effects

- Life cycle assessment of environmental impacts including acid production

Ongoing research at AFBI and partner institutions continues to address these questions, with the goal of developing comprehensive, practical solutions for the biogas industry.

Implementation Recommendations for the Biogas Industry

Based on the AFBI study findings and broader industry experience, several recommendations emerge for biogas operators considering acid addition implementation:

Phased Implementation Approach

- Conduct site-specific feasibility assessment and emission baseline measurement

- Develop safety protocols and train staff before equipment installation

- Begin with small-scale pilot implementation to refine procedures

- Scale up gradually while monitoring effectiveness and economics

- Integrate with existing environmental management systems

Key Success Factors

- Precise pH monitoring and control systems

- Robust safety protocols and equipment

- Staff training and standard operating procedures

- Regular maintenance of acid storage and dosing equipment

- Documentation for regulatory compliance and potential incentive programs

Our team of specialists can conduct a comprehensive assessment of your biogas operation to determine the potential benefits and implementation requirements for acid addition technology.

Conclusion: The Future of Digestate Management

The AFBI study on digestate slurry emissions and acid addition represents a significant advancement in our understanding of emission reduction strategies for the biogas industry.

The research clearly demonstrates that anaerobic digestion can reduce methane emissions compared to untreated slurry. That's a big gain. A lesser problem is that it may exacerbate ammonia losses without appropriate mitigation measures.

Acid addition emerges as a highly effective technique, capable of reducing ammonia emissions by 54-67% and methane emissions by 84-92% from digestate materials. These dramatic reductions offer a pathway for the biogas industry to enhance its environmental performance while preserving valuable nutrients.

As regulatory pressures increase and the industry continues to mature, technologies like acid addition will likely play an increasingly important role in sustainable digestate management. The economic, practical, and regulatory considerations outlined in this article provide a framework for biogas operators to evaluate this promising approach for their specific circumstances.

By building on the foundation of rigorous research exemplified by the AFBI study, the biogas industry can continue to improve its environmental performance while maintaining operational and economic viability.