It's very unlikely that even waste management professionals have thought much about the anaerobic digestion of pre-consumer food waste because it all happens behind closed doors.

It is out of sight and out of mind!

So, why should you care?

Our planet is grappling with the mounting issue of food waste, climate change is romping on, and you may be wondering how societies will ever effectively manage it. But there is one beacon of hope: anaerobic digestion (AD). And AD is the best way to dispose of inedible Pre-Consumer Food Waste.

Currently, the UK throws out approximately 9.5 million tonnes of food per year. CIWEM 2020

According to Winnow: “…it is a common misconception that most of the food waste in the hospitality sector comes from the customer’s plate. In an analysis of more than 450 kitchens using Winnow, we have found that pre-consumer food waste makes up 70% of kitchen waste.”

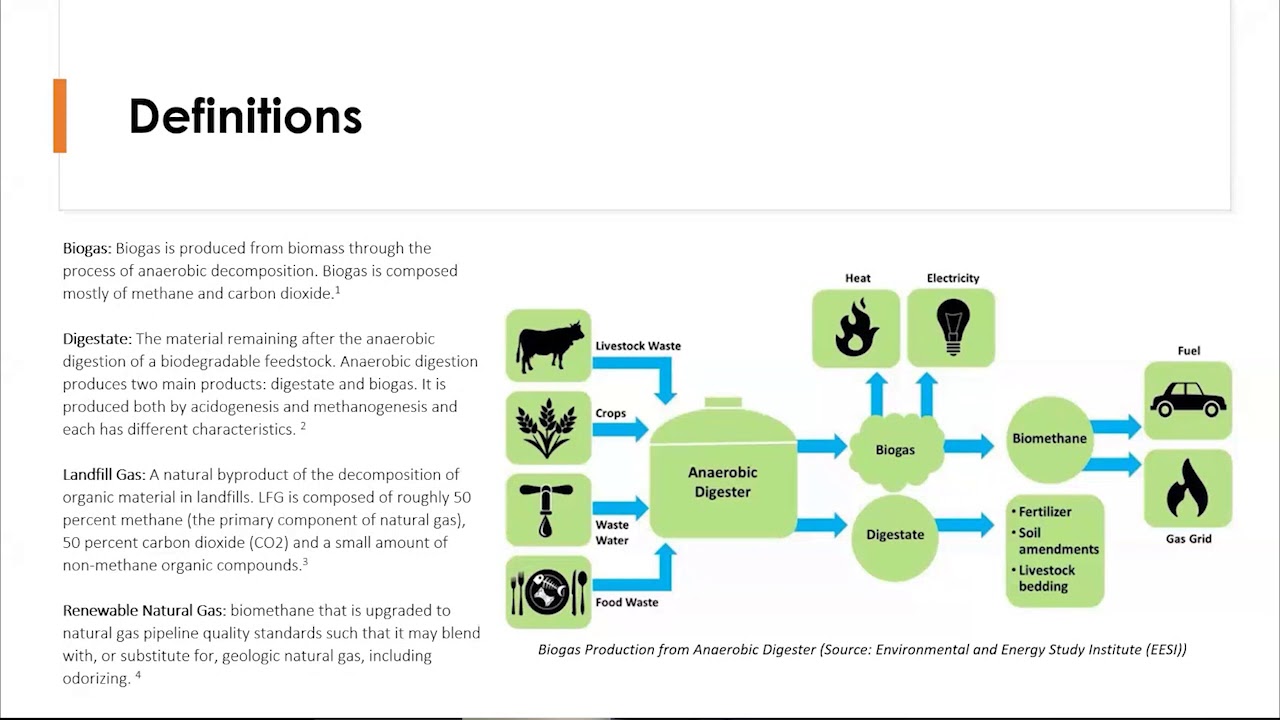

So, this form of food waste needs attention. But did you know that anaerobic digestion can cut down all food waste organic materials into compost-ready matter plus methane gas in a matter of weeks? It can be profitable as well when the renewable gas is purified and sold to power low-emission trucks and even trains.

This post unravels the intricacies behind the anaerobic digestion of pre-consumer food waste, and how the biogas plants where this is done are offering the first truly sustainable solutions for pre-consumer food waste.

Let's dive in, shall we?

Key Takeaways

- Anaerobic digestion (AD) if combined with effective organics separation is the most sustainable solution for managing pre-consumer food waste.

- Before AD can be effectively achieved the process involves:

- depackaging,

- separating the organic and non-organic matter

- sending the organic matter to an AD digester tank where it is broken down in a special air-sealed tank, with the help of microorganisms, into biogas and “the rest” (known as “digestate”)

- producing methane gas that can be used for clean power and heat

- sorting the rejected waste (plastic bags and containers, bottles, cans, tins etc.) and either recycling them for their materials or for extraction of their embodied heat (e.g. incineration).

- Anaerobic digestion can play a crucial role in reducing climate-changing emissions after depackaging and separating the “organics”, using the organic pulp for digester feedstock, and recycling pre-consumer food waste into biogas.

[boomdevs_toc]

What is Pre-consumer Food Waste?

Definition of Pre-consumer Food Waste

Pre-consumer food waste, also known as upstream food waste, refers to food that is discarded or wasted at various stages of the supply chain before it reaches the consumer. This type of food waste occurs primarily in the production, processing, distribution, and retailing stages of the food supply chain.

Pre-consumer Food Waste Examples

Examples of pre-consumer food waste include:

1. Agricultural surplus: Crops that are left unharvested or are discarded because they do not meet quality standards or market demands.

2. Food processing waste: Food processing facilities generate a remarkably large amount of waste during the preparation, packaging, or processing of food products. This can include trimmings, peels, or parts of food items that are not used in the final product.

3. Damaged or spoiled goods: Food products that become damaged or spoiled during processing, packaging, transportation, storage, or display in retail stores.

4. Excess inventory: Retailers and restaurants may over-order or over-produce food items, leading to surplus inventory that eventually goes to waste. An example is the preparation of salads and barbeque food that remains unsold when the weather turns unexpectedly cold or wet.

5. Expired products: Food items with expired shelf lives or “best before” dates that are removed from store shelves and disposed of before they are sold to consumers.

Efforts to reduce pre-consumer food waste rightly focus on optimizing supply chain management, improving food processing efficiency, and implementing better inventory management practices to minimize the amount of food wasted before it reaches consumers.

Reducing pre-consumer food waste is a significant step toward reducing overall food waste tonnages and its associated environmental and economic impacts. It also complies with good waste management practices which prioritize waste reduction. Next in the sustainable waste management hierarchy comes reuse, and wherever possible producers sell on their pre-consumer food waste as animal feed.

The Sustainable Role of Anaerobic Digestion of Pre-Consumer Food Waste

Anaerobic Digestion of pre-consumer food waste is sustainable when all other opportunities more favoured within the waste management hierarchy have been exhausted.

The first part of the sustainability equation is the high degree of avoidance of greenhouse gas emissions by not disposing of this food waste to landfill. Similarly, to incinerate food waste makes no sense either. Food waste with its generally high moisture content contributes little to the energy output from incineration, so incineration is not a good option and the high cost of incineration of food waste reflects this.

First and foremost, of course, the food should be given to the needy whenever possible!

But, for the food waste that still needs to be disposed of it is not a simple matter to depackage and separate cleanly any type of pre-consumer organic waste.

The food waste must be pre-treated before it can become the food for the microorganisms in a biogas digester. It's not too bad for solely dry per-consumer food waste, but much more challenging when the organic pulp fed into the digester is wet and mushy. Before it is fed into a digester it must be virtually free from plastic, otherwise, the microplastic will flow out in the digestate after a month or more, and if spread on the fields it will pollute the land.

All other matter that would settle and build up in the digester must also be removed as well, and as much as possible of what is removed must be recycled in some form. That's no easy trick! But is essential if pre-treatment costs are to be offset by selling recyclates for income.

Until recently with the advent of 3rd generation depackaging equipment, progress in the depackaging and separation of food waste has been disappointing and most pre-treatment currently results in a reject stream that is a dirty mess of damp shredded plastic, grit and other sediment and all tangled up with bits of plastic film. A stodgy cake that's too low a calorific content to even be used as incinerator fuel (known as RDF – or refuse-derived fuel).

How can pre-treatment be done better? That's the next part of this story.

The Process of Pre-Treatment and Management of Food Industry Source Separated Organic Feedstock

The treatment and control of food waste is a big task. Here is how they do it:

- First, sort the waste. Pre-consumer waste is called “source-separated” but in truth, it contains a huge variety of organic materials and other things. The first challenge is to remove all packaging and separate the organic content of food waste from other types of waste (e.g. metal and mineral content, dirt, and unexpected objects of all sorts!).

- Sorting results in two outputs the organic output is either dry (as say crushed date-expired biscuits) or as a pulp (like a disgusting soup!) plus the rest.

- The depackaging and separation treatment takes place in a “depackager machine” also called “turbo” “paddle” and most commonly “shredder” separators. These machines all have two principal functions to output:

- a clean organic stream at a controlled low moisture content, and

- a similarly clean and low moisture content/ high calorific value “reject stream” – a (packaging and everything else!) stream.

- The organic material (if not suitable as animal feed) will go to anaerobic digestion where tiny living things called microorganisms help out. They eat up the organic stuff and produce a gas named methane plus a natural fertiliser of fibre and a liquid portion.

- Methane is a good thing! We can use this renewable methane for clean power and heat.

- The leftover material after anaerobic digestion is not useless. It's called “digestate” and it can be put on the soil to help plants grow better. In many ways, it is a better fertilizer than commercial chemical fertilizers and above all it is renewable

- But be careful with this digestate. Most times, with older generations of the pre-treatment equipment, there will be parts that should not be in there like plastic pieces and other harmful substances, because what goes into the digester that isn't organic must come out.

- The steps in the digester take time — two to six weeks at least. Wait for another few weeks to compost the digestate fibre.

3 Generations of Improvements in Food Waste Depackagers/ Separators

Food waste separation technology has been improved since the first pioneering local authorities began to introduce food waste processing as long ago as 40 years ago.

Generation 1 – Rebranded Shredding and Milling Machines

In the 1980s, when food waste processing began in Europe, and to a limited extent also in the US, there was no existing dedicated technology, and no commercial incentive to drive the development of purpose-built machines. Consequently, the waste industry adapted existing machines for food waste. Those machines were shredding and milling machines designed to chop and crush everything in food waste to small particles, before processing.

It was before the days of any awareness of the hazards of plastic once it gets into the environment. It was only after the plastic packaging used for snack and drink options was similar to that highlighted in the images of marine plastic pollution shown in Blue Planet II, Episode 7, on 11 Sept 2020, that the public and the waste industry began to recognise the danger of microplastic pollution.

Until then it was assumed that size reduction was perfectly acceptable. As long as the plastic spread on land did not contain sharp pieces to cause injury, was not chemically contaminated such as with heavy metals, nor placed an excess of nutrients, no limit would be placed upon the amount of tiny plastic pieces present as long as they were too small to be obviously visible. (See UK WRAP PAS110 for compost suitable for land-spreading.)

These first-generation machines, although most still remain in use, create microplastics in bulk and give recycling a bad name due to the fact that microplastics are actively created during waste processing.

Generation 2 – Low Impact Paddle and Turbo “Depackagers”

The second generation is what for the purpose of this article we call low-impact paddle and turbo depackagers/ separators, in which developers moved on from the philosophy of particle size reduction as the main mechanism for handling the plastic content of food waste.

Instead, the physical forces of squeezing using paddles and/ or centrifugal force are used to open all the containers and separate packaging from the food. The abandonment of size reduction has been a very positive move forward. But with these systems confined to operating in the liquid and slurry phase on a plug flow or pumped basis, little attention is paid to cleaning the reject output.

Other than the possibility of adding the likes of vortex separators, and washing stages as downstream add-on processes, the output is high moisture content and below the industry's best organic content on the surface of the rejects.

Generation 3 – 3rd Gen Food Waste Depackaging and Separation Equipment

Pure fantasy! We asked the AI image creator “MidJourney” to imagine what a perfect 3rd generation food waste separation machine would look like and it gave us this!

Third-generation food waste depackaging and separation machines are great. These machines tear open and remove the packing from food waste while keeping bottles and cans more or less intact. Films such as plastic bags are rejected in torn pieces but little if any microplastic is created.

The new patented 3rd generation Twister Depackaging and Separation Equipment offered by Drycake helps us keep plastic out of our soil.

These machines make food waste recycling cleaner too. They sort out the organic pulp more quickly than old models could, use less energy while doing so and can be run dry (for bakery and biscuit wastes) as well as with the addition of water for optimum pulp consistency.

Innovative machines like these can play a big role in creating clean, plastic-free organic pulp for use as a digester feedstock.

They also help to boost biogas production. More biogas means we have more energy that comes from natural sources, instead of fossil fuels like coal or oil. With this tech, we can better manage our planet's resources!

Avoiding microplastics produced by shredding and other size-reduction equipment

Small bits of plastic called microplastics can get into food waste, but the vast majority is caused when shredding or milling is used. They come from items like bags or bottles, and it's not only plastic which gets smashed into tiny pieces. The metal from tins and cans, including heavy metals such as zinc also get into the compost that way. The key to keeping them out is not to use shredding and other size-reduction steps.

3rd generation depackaging equipment as developed by Drycake for their Twister range of machines uses bats (not paddles) to knock and pluck the packaging into the rejects bin with the air vortex induced by a vertical impeller. Plastic films, cartons and pots are also rattled fiercely around and shaken clean on the inside of the cylindrical chamber, before being blown out as rejects. While, all the time the organic content drops to the bottom where it is ejected through screens which ensures a consistently clean pulp.

Anaerobic Digestion of Pre-Consumer Food Waste Conclusion: The Future of Pre-Consumer Food Waste Management

A lot more pre-consumer food waste is generated and disposed of each year than is generally appreciated. So much is produced, that food waste is burdening the globe with enormous penalties for the contribution that this waste, is adding to climate change.

Anaerobic digestion is recognised to be the preferred most sustainable method of disposal of the organic content of food waste within the waste hierarchy. It can play a crucial role in managing Pre-Consumer Food Waste not only sustainably but also by providing high-demand premium value methane fuel in the form of renewable natural gas (RNG) (also known as biomethane).

The waste management (recycling) industry does this through:

- the depackaging and separation of organics,

- using organic pulp for digester feedstock,

- recycling the rejected non-organic materials

and, through a chain of ensuing benefits, reducing climate-changing emissions.

With careful steps, we can turn this waste into rich soil and green energy. This way, our earth wins! Let's stand up for 3rd gen organics separation and anaerobic digestion today.

This means recycling pre-consumer food waste fights against global warming and gives us natural fertiliser and renewable power at the same time!

For these reasons, anaerobic digestion will play a key role in future waste plans.

Anaerobic Digestion of Pre-Consumer Food Waste FAQs

1. What does the term “Anaerobic Digestion of Pre-Consumer Food Waste” refer to?

This process changes food waste from industries such as catering, hospitality and bakery into energy-rich biogas like methane (CH4) and carbon dioxide (CO2).

2. How does anaerobic digestion aid in generating electricity and heat?

The energy-rich biogas produced by anaerobic digestion can get used for making electricity or producing heat.

3. Can Anaerobic Digestion help reduce landfilling and incineration?

Yes! By turning pre-consumer food waste into useful products, it lessens the burden on landfills and cuts down on burning rubbish.

4. Why should we separate organic material before anaerobic digestion?

Organic separation gets rid of plastic contamination, which increases the quality of the feedstock and helps produce cleaner biomethane fuel for transport vehicles.

5. Can this method contribute to climate change prevention?

Yes, it reduces the emission of non-renewable carbon dioxide leading to fewer greenhouse gases in the atmosphere that cause climate change.

The ultimate goal is to enhance the efficiency and effectiveness of pre-consumer organics separation and anaerobic digestion, consequently promoting sustainable waste management practices with a significant positive impact on global climate change reduction.

6. What happens to the solid leftovers from anaerobic digestion?

Liquid fuels are not all that remain after this treatment; solids known as digestate also result which later serve as soil amendments boosting plant growth.

7. In Simple Language: What are the Basic Principles Behind Depackaging and Organics Separation

Depackaging is the action of taking off the wrapping from food waste.

It is a key part of waste handling in the food business. This step makes sure, as far as possible, that no unwanted stuff gets in with the food waste.

After depackaging, we move on to organics separation.

At its best, his process drops out all the organic bits, separating them from all the other sorts of waste for subsequent anaerobic digestion in a biogas digester tank.

In a perfect scenario, it would pull out everything but the organic content in a perfectly dry and clean “reject” output stream.

These steps, if perfectly done, make sure pre-consumer food waste can be treated better and reused more easily.

These methods pave the way for anaerobic digestion, using nature's own helpers: microorganisms! The work these tiny life forms do turns our sorted-out organic pulp into useful products such as natural fertilisers and soil amendments plus valuable energy-rich biogas.

Source URLs

- https://www.nrdc.org/bio/darby-hoover/evaluating-anaerobic-digestion-municipal-organics-recycling

2. https://www.waterrf.org/research/projects/evaluation-existing-source-separated-organic-feedstock-pre-treatment-and