Fugitive Emissions Testing: A Comprehensive LDAR Handbook for the UK Biogas Sector

Did you know? Up to 3% of valuable biogas can quietly dissipate every year from a typical UK plant as fugitive emissions—enough to damage your bottom line and the environment. This is more than just an operational hiccup; it's a hidden threat to profitability, compliance, and your plant’s green credentials.

This article may be used as a guide offering UK biogas operators a practical roadmap for mastering fugitive emissions testing and turning leak prevention into a competitive advantage.

Unveiling Fugitive Emissions: Why Fugitive Emissions Testing is Critical for UK Biogas Operators

“A single undetected methane leak can cost biogas plants thousands in lost revenue and significantly harm environmental credentials.”

For UK biogas operators, fugitive emissions testing is more than a compliance checkbox—it's an investment in long-term profitability and environmental stewardship. Methane leaks, if unchecked, not only contribute to lost methane sales but also erode your plant’s reputation as a sustainable operation. Rising regulatory scrutiny, increased public awareness of climate change, and the potential for severe financial penalties make it essential that all biogas facilities take leak detection seriously.

Despite robust process controls, fugitive emissions persist in even the best-run anaerobic digestion (AD) sites. Regular emission tests and proven leak detection and repair (LDAR) regimes are now recognised best practices, offering a quick return on investment—often paying for themselves by uncovering leaks invisible to the naked eye. Adopting these measures isn’t just about avoiding fines; it’s about safeguarding revenue, meeting greenhouse gas reduction pledges, and maintaining the green image so critical to the UK biogas sector’s growth.

Startling Statistics: The True Cost of Biogas Leaks and Fugitive Emissions

- Up to 3% of biogas can be lost as fugitive emissions annually

- Methane is 28 times more potent than CO2 as a greenhouse gas

- Regular fugitive emissions testing can reduce leaks by over 70%

These numbers highlight just how vital emissions testing has become. The leak rate from undetected sources translates not only to measurable loss in methane production and sales but also to damaging increases in greenhouse gas emissions. This dual threat pressures operators to act—especially given methane’s capacity to escalate air pollution and its direct links to climate change.

What You'll Learn in This Fugitive Emissions Testing Guide

- Definition and types of fugitive emissions

- The impact of fugitive emissions on biogas profitability and compliance

- Practical steps for effective fugitive emissions testing

- How to select and engage a reliable LDAR service

- The latest technologies for detection and repair

Whether you're new to fugitive emissions testing or seeking to optimise your plant’s leak detection and repair practices, this guide delivers actionable advice. From the basics of emission tests, through best-in-class leak detection, to advanced technology—and real-life UK case studies—you’ll be equipped to minimise methane loss and operate beyond compliance.

What are Fugitive Emissions?

Understanding Fugitive Emissions in the Biogas Sector

Fugitive emissions refer to unintentional and often undetected releases of gases, typically methane, from biogas plants. Unlike planned releases or process vents, fugitive emissions occur due to leaks in equipment such as valves, digesters, pipelines, flanges, and seals. Because methane is odourless and invisible, leak detection requires specialised emission test methods and technology.

In the context of UK biogas operations, fugitive emissions arise from daily wear, poor equipment tightness class, or failures in components like stem seals and control valves. Even minor leaks can accumulate into significant losses over time, leading to both economic and environmental implications. With legislation tightening and stakeholders demanding transparency, understanding, and actively managing fugitive emissions is no longer optional—it's a core responsibility.

How do you Measure Fugitive Emissions?

Emission Test Methods: Practical Approaches for Biogas Plants

Fugitive emission tests use a wide range of methods and technologies for accurate leak detection. Common techniques include visual inspections, advanced optical gas imaging (OGI), Flame Ionisation Detection (FID), and Ultrasonic Leak Detection. OGI cameras allow operators to “see” methane leaks in real time; FID and PID instruments quantify volatile organic compounds and methane levels in the air, crucial for accurate emissions testing as outlined by US Environmental Protection Agency (EPA) and UK environmental protection regulations.

Measuring fugitive emissions requires a site-wide approach—scanning all potential sources using robust protocols similar to those in the oil and gas industries.

A typical emissions test involves equipment assessment, leak detection, quantification of the leak rate or tightness classes (often using helium or methane as tracers), and reporting findings for repair or process improvement.

The frequency and method of testing depend on regulatory guidance, like EA and SEPA guidelines, and internal plant performance standards.

Differences Between Fugitive Emissions and Process Emissions

| Parameter | Fugitive Emissions | Process Emissions |

|---|---|---|

| Source | Leaks, unintended releases | Normal operations/venting |

| Detectability | Requires testing/leak detection | Measured during routine operation |

| Regulatory Controls | Stricter due to unpredictability | Monitored by process protocols |

Understanding the distinction between fugitive and process emissions clarifies the unique challenge fugitive leaks pose. Process emissions occur as part of regular plant activities and are easier to track; fugitive emissions, in contrast, are unpredictable and call for dedicated emissions testing and leak detection strategies, making them a critical focus for biogas operators seeking robust environmental compliance and operational excellence.

Fugitive Emissions vs. Point Source Emissions: Key Differences in Biogas Industry

Emissions Test and Leak Detection Distinctions

In biogas operations, fugitive emissions typically come from multiple dispersed, often invisible leak points—such as flanges, valve seals, or gaskets—while point source emissions are confined to clearly identifiable outlets like stacks or vents. This distinction is vital: point source emissions can usually be monitored through process protocols, but fugitive emissions necessitate comprehensive and regular emission tests with wide coverage and sensitive detection technology.

The key difference is in detectability and control. While process emissions and point source releases can often be predicted and managed as part of standard operating procedures, fugitive leaks slip through unnoticed unless a systematic emission test and leak detection and repair regime is in place. This explains why regulatory controls are often stricter for fugitive emissions, and why their management is a fast-rising priority for compliance and sustainability.

The Economic and Environmental Impact of Fugitive Emissions in Biogas Operations

Methane Losses and Their True Cost to Biogas Plants

- Direct loss of valuable methane

- Increased greenhouse gas emissions

- Potential regulatory fines and reputational risks

The leakage of methane isn’t just an environmental hazard; it’s a matter of lost income. Even a modest leak can translate into thousands of pounds in missed sales annually. With methane being 28 times more potent than CO2 as a greenhouse gas, every escape hastens the pace of climate change and contributes to poor air quality and air pollution. Repeated emissions breaches can result in substantial fines from environmental protection authorities—not to mention potential restrictions on plant operations and long-term reputational damage.

For plant owners, investing in regular emissions testing and prompt leak repairs is a cost-saving strategy as much as an environmental obligation. By choosing robust leak detection and repair protocols, biogas producers can demonstrate leadership in emissions reduction, gain stakeholder trust, and create a culture of operational excellence.

Why Regular Fugitive Emissions Testing is Essential for Compliance

“Consistency in fugitive emissions testing shows commitment to both regulatory compliance and environmental stewardship.”

The UK biogas industry operates under strict national and international regulatory frameworks designed to limit greenhouse gas emissions. Authorities such as the Environmental Agency (EA) and SEPA require plants to actively monitor, report, and reduce fugitive emissions. Regular emission tests not only demonstrate compliance, but offer evidence of proactive environmental management—crucial for public perception and continued plant licensing.

Meeting and exceeding regulatory limits is tied directly to a plant’s ability to quickly identify, document, and repair leaks. With increasing enforcement, transparent emissions testing records serve as both a shield against regulatory action and a badge of credibility in sustainability efforts. Frequent leak detection and transparent reporting—especially when entrusted to external LDAR services—show investors, communities, and regulators that your operation is serious about reducing its environmental impact.

Meeting National and Internal Emissions Targets

National targets to curb greenhouse gas emissions, as well as sector-specific goals for the biogas industry, make routine fugitive emission testing vital. Regular emission tests and data-driven leak detection directly contribute to the UK’s climate policy objectives, and help plants maintain eligibility for green incentives and renewable gas tariffs. The industry’s reputation—and its financial future—now depends on credible, auditable emissions records and actions.

Biogas plants that go beyond minimum regulatory standards not only avoid fines but position themselves as leaders. This leadership builds internal culture and external support, attracting new investment and boosting long-term profitability through stronger plant performance and greater methane yields.

How Fugitive Emissions Testing Works: Proven Methods for Leak Detection and Repair (LDAR)

- Visual inspections

- Optical gas imaging (OGI)

- Flame Ionisation Detection (FID)

- Photoionisation Detection (PID)

- Ultrasonic leak detection

Modern fugitive emission testing combines traditional and cutting-edge approaches. Technicians begin with a thorough visual check for damaged seals, corrosion, or obvious wear. Next, they deploy OGI cameras—an innovation that enables immediate “visualisation” of escaping methane, even in challenging operational environments. For difficult-to-reach zones, ultrasonic detectors or advanced FID/PID devices pick up leaks by measuring trace concentrations of methane and volatile organic compounds.

Every leak detection and repair (LDAR) programme should be supported by detailed reporting. This means cataloguing leak size, source, stem seal conditions, equipment tightness class, and the subsequent repair actions. Today’s best LDAR services offer digital reporting and transparent analytics, so biogas plant managers can visualise leak history, repair trends, and ongoing compliance in one place—supporting both regulatory and strategic management.

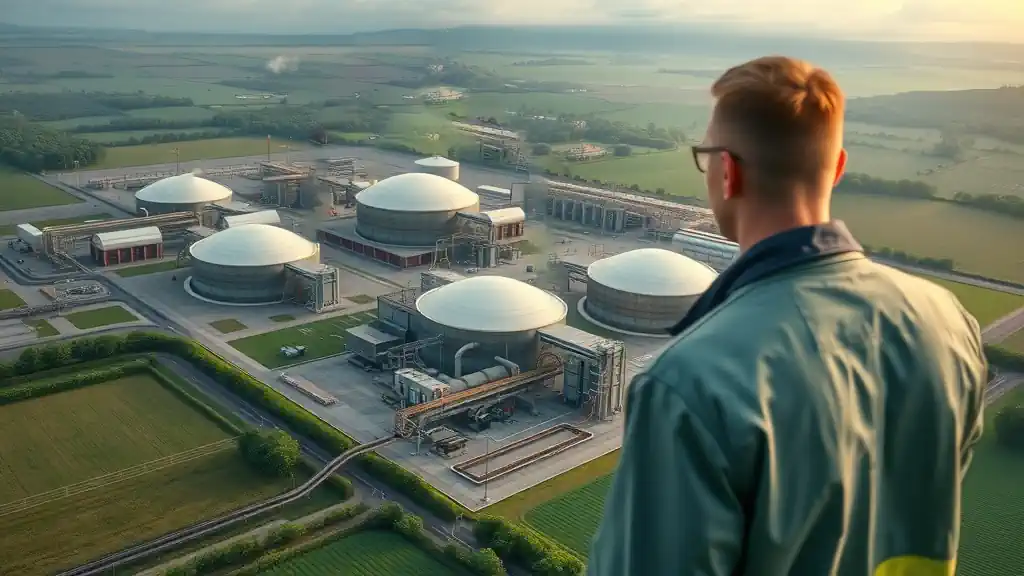

Case Study: Fugitive Emission Test Success Stories in UK Biogas Plants

“Early detection of a critical biogas leak saved one UK plant over £20,000 in lost methane annually.”

Investing in specialist emission tests pays real dividends. In one high-performing UK biogas plant, an annual LDAR survey pinpointed several hidden leaks at pipeline junctions and control valves. Not visible to staff, these fugitive emissions amounted to an annual loss of well over £20,000 worth of methane—more than enough to cover the cost of the leak detection and repair programme many times over.

Beyond immediate financial recovery, the plant’s transparent emissions testing records enabled it to secure further funding and improve stakeholder confidence. Regular emissions testing and repair regimes have since become part of their culture, underscoring the business case for systematic leak detection and repair initiatives.

Selecting the Right LDAR Service for Fugitive Emissions Testing

- Certification and compliance record

- Use of advanced emission test technologies

- Transparency and reporting

- References from other biogas plants

The effectiveness of your fugitive emissions testing program rests on the capabilities of your chosen LDAR partner. Look for service providers with up-to-date certifications, proven history with UK environmental regulations, and a commitment to transparency. They should offer advanced emission test methods (such as OGI and continuous monitoring), strong references from comparable biogas plants, and digital reporting for actionable insights.

Avoid low-cost, low-tech surveyors that rely solely on visual inspections or outdated techniques—especially given the complexity of modern AD facilities and the pace of regulatory change. A robust LDAR partner can help guide compliance strategies, plug knowledge gaps, and ensure that even small leaks are found quickly and addressed before causing financial or reputational harm.

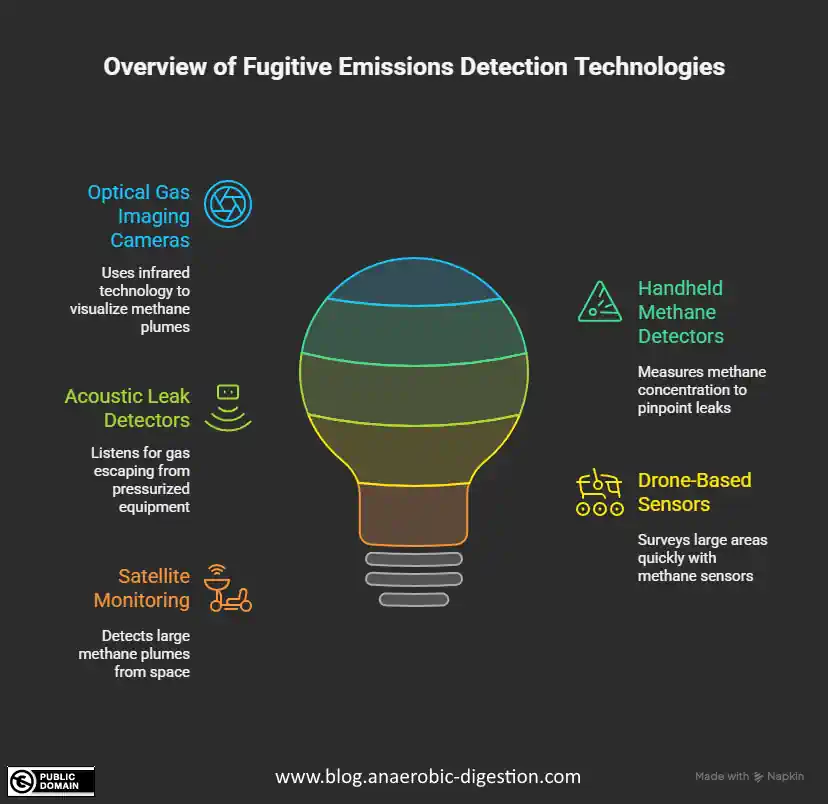

New Technologies in Fugitive Emissions Testing: Enhancing Leak Detection and Repair

Advances in Emissions Testing and Real-Time Monitoring

- AI-powered infrared cameras

- Drone-mounted OGI sensors

- Continuous methane monitoring

- Acoustic emission testing

The technologies supporting emission tests and leak detection have rapidly evolved. AI-enhanced OGI cameras can now instantly highlight the presence and location of methane leaks. Drones fitted with OGI sensors enable comprehensive, hands-off surveys of hard-to-reach areas or complex digesters. Many plants are now adopting continuous methane monitoring systems that provide live alerts when leak rates exceed pre-set thresholds, allowing for fast, targeted repairs.

Acoustic emission testing, already used in oil and gas, is promising for biogas sites: it detects high-frequency sounds produced by escaping gas, adding another layer of precision. Investing in these new emissions testing technologies allows biogas plants to reduce their greenhouse gas emissions faster and bolster the accuracy, efficiency, and transparency of their leak detection and repair programmes.

Best Practices: Minimizing Fugitive Emissions and Optimising Plant Performance

- Schedule routine fugitive emissions testing

- Train staff in leak detection and reporting

- Regularly maintain and upgrade equipment

- Immediately repair identified leaks

- Publicise compliance achievements

Sustainable, profitable plant management means making fugitive emission reduction a core operational priority. Start by integrating regular emission tests into annual maintenance cycles—ideally using a trusted LDAR partner. Build staff capability around leak detection, with practical training and clear reporting lines for rapid issue escalation. Proactively maintaining equipment, and investing in technology upgrades, further lowers fugitive emissions and their associated costs.

Finally, share your successes. Publicising compliance not only boosts your plant’s reputation in a competitive renewable energy market, but also demonstrates leadership in the fight against air pollution and climate change.

Regulatory Framework: Fugitive Emissions Testing Compliance in the UK

- EA and SEPA guidelines

- Industry standards for emissions test frequency

- Consequences of non-compliance

Regulatory oversight of fugitive emissions in the biogas sector is robust and growing more stringent. Plants are subject to Environment Agency (EA) and Scottish Environment Protection Agency (SEPA) directives, requiring documentation of regular emission tests, rapid leak detection, and timely repair. Failing compliance can result in substantial fines, operational limits, or even plant closure.

Keeping abreast of tightening regulations not only ensures uninterrupted production and revenue, but also positions your plant as a leading example in sustainable energy production—an increasingly important consideration for investors, customers, and the public.

Common Questions About Fugitive Emissions Testing

- What equipment is required for a fugitive emission test?

- How often should a biogas plant conduct fugitive emissions testing?

- Does emissions testing disrupt normal plant operations?

- Can small biogas plants benefit from professional leak detection?

What equipment is required for a fugitive emission test?

Modern fugitive emission testing relies on a wide range of tools: OGI cameras, FID/PID analysers, ultrasonic leak detectors, and continuous methane monitors. Most tests require portable, calibrated equipment, with data capture for compliance and reporting.

How often should a plant conduct emissions testing?

At a minimum, annual emission tests are recommended; more frequent testing is advisable for plants with older equipment or a history of leaks. Regulatory bodies may require more regular testing, especially following upgrades or repairs to plant infrastructure.

Does emissions testing disrupt plant operations?

Routine emissions testing is designed to minimise disruption. Professional LDAR teams are trained to work safely around live plant operations, delivering accurate leak detection without stopping production.

Can small biogas plants benefit from professional leak detection?

Absolutely. While cost is a concern, even small-scale operators see payback through recovered methane sales, lower compliance risk, and better stakeholder engagement—often with higher proportional returns compared to larger facilities.

Key Takeaways: Fugitive Emissions Testing for Biogas Plants

- Unchecked fugitive emissions mean lost income and compliance risks

- Regular emissions testing is crucial for profit and reputation

- Modern LDAR services and technologies can drastically cut emissions

- Active leak detection and repair (LDAR) delivers quick ROI

Mastering fugitive emissions testing is not just about compliance—it’s a real business opportunity. Every hidden leak found boosts your revenue, strengthens regulatory standing, and supports a sustainable UK biogas industry.

Frequently Asked Questions (FAQs) on Fugitive Emissions Testing for the Biogas Industry

- Why is methane the primary concern in biogas fugitive emissions?

Methane is both the main energy product of biogas plants and a potent greenhouse gas. Its loss means reduced plant yields and greater environmental harm compared to other gases, making its control and detection a priority. - What regulations must UK biogas plants follow for emissions testing?

Plants are subject to Environment Agency (EA) and SEPA guidelines, including required emissions test frequencies, documentation, and active leak detection and repair regimes. - How can emissions data inform plant management decisions?

Accurate emissions data highlights trends, locates weak points, and supports maintenance and upgrade decisions—boosting both performance and compliance.

Conclusion: Elevate Your Biogas Plant with Proactive Fugitive Emissions Testing

Take charge of your plant’s profitability and green credentials. Start or optimise your fugitive emissions testing today and enjoy improved revenue, compliance, and industry leadership.

Ready to take control of your plant’s methane losses? Engage a certified LDAR service for fugitive emissions testing and publicise your sustainability leadership today.

Follow a concise, instructor-led walkthrough of a real fugitive emission test, showcasing cutting-edge leak detection and repair tools. Perfect for plant managers and on-site teams seeking confidence in best-in-class practices.

Sources

- UK Government AD and Biogas Emissions Mitigation Guidance

- Scottish Environment Protection Agency (SEPA): Pollution Prevention and Control

- US EPA: Leak Detection and Repair (LDAR)

- International Energy Agency: Methane Detection and Measurement

- Anaerobic Digestion and Bioresources Association: Fugitive Methane Emissions Testing

To deepen your understanding of fugitive emissions testing, consider exploring the following authoritative resources:

- The article “Fugitive Emissions Testing and United Valve: Ensuring Environmental and Operational Excellence” provides a comprehensive overview of fugitive emissions, their environmental impact, and the importance of testing for regulatory compliance and operational efficiency.

- The U.S. Environmental Protection Agency’s page on “Next Generation Emission Measurement (NGEM) Research for Fugitive Air Pollution” discusses innovative approaches for detecting and controlling fugitive emissions, including the development of lower-cost, portable air measurement technologies.

If you’re serious about mastering fugitive emissions testing, these resources will provide you with valuable insights and practical guidance.