Managing digestate and sludge is a major headache for biogas plant operators, but worry not! Let our article on Evaporation Techniques For Digestate And Sludge Management bring you up to date! These thick, sticky by-products from anaerobic digestion pile up fast and cost a fortune to transport.

Evaporation techniques for biogas digestate involve using heat to reduce the water content, concentrating nutrients while recovering water and potentially ammonia.

Most plants struggle with the sheer volume of waste that needs proper handling to avoid environmental harm. The smell alone can cause problems with nearby communities.

Evaporation stands out as a top solution for this waste challenge. This process can shrink digestate volume by up to 80%, making storage and transport much easier. Modern evaporation systems work by applying heat to remove water from the sludge, leaving behind a nutrient-rich concentrate that takes up less space.

In this blog, we'll explore ten proven evaporation methods that can transform your digestate management. From thermal systems to solar options, you'll discover which technique fits your plant size and budget.

The right choice awaits.

Key Takeaways for the article Evaporation Techniques For Digestate And Sludge Management

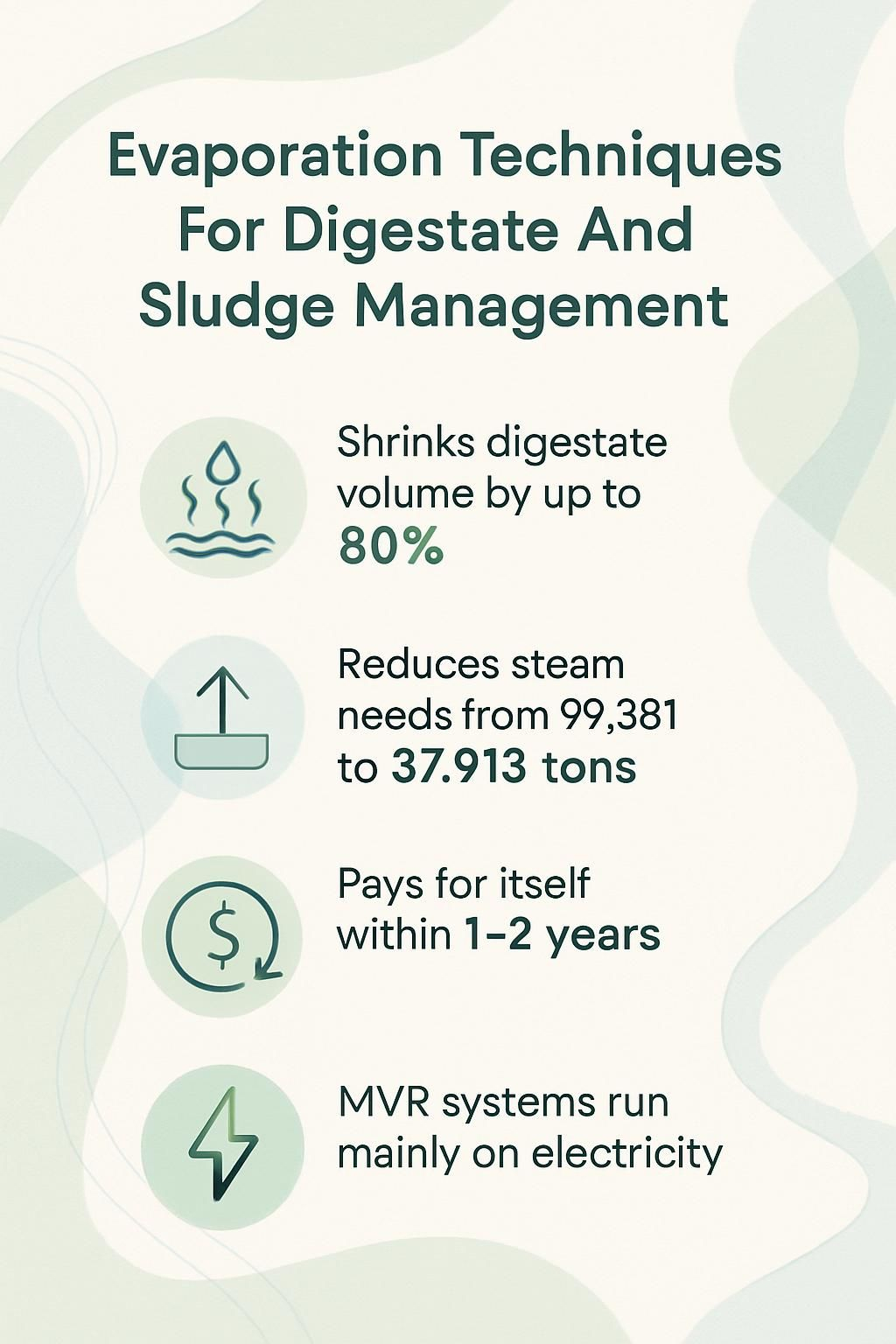

- Evaporation can shrink digestate volume by up to 80%, making storage and transport much easier for biogas plants.

- Since 2020, many biogas plants have moved away from fossil fuel heating toward more efficient options that create valuable by-products like liquid fertiliser.

- Mechanical Vapour Recompression (MVR) systems run mainly on electricity and recycle steam, which costs less than the heat needed for other methods.

- Multi-Effect Evaporation can reduce steam needs from 99.381 to just 37.913 tons per hour when increasing from one to eight effects.

- Most vacuum evaporation systems pay for themselves within one to two years through reduced transport and disposal costs.

10 Key Evaporation Techniques for Digestate and Sludge Management

Evaporation systems offer game-changing solutions for managing digestate and sludge from biogas plants. These methods transform waste into valuable resources while cutting down volume by up to 80%, making transport and storage much easier.

1. Thermal Evaporation Systems

Thermal evaporation systems form the backbone of modern digestate and sludge management. These systems work by heating thick, viscous materials until water turns to steam, leaving behind concentrated solids.

Most traditional setups burn gas or oil in boilers to create the high temperatures needed for this process. The heat transfers through special plates or tubes that never touch the sludge directly, keeping the steam clean and reusable.

Since 2020, many biogas plants have moved away from fossil fuel heating toward more efficient options. The cost of running these systems matters greatly in the agricultural sector.

Farms must balance their need for volume reduction against energy costs. Heat exchangers play a vital role in this balance, as they must handle the sticky nature of digestates without clogging.

For many operators, the return on investment comes from both waste reduction and creating valuable by-products like liquid fertiliser.

“Rotary dryer for the treatment of …” from www.biorganics.de and used with no modifications.

2. Drum (Rotary) Evaporators

Drum evaporators stand out as workhorses in digestate and sludge management. These systems feature a rotating cylinder that creates a thin film of liquid on heated surfaces, speeding up the evaporation process.

The rotation helps prevent scaling and fouling, a common problem when dealing with high-solids content in biodigester outputs. Most drum evaporators operate at temperatures between 85-95°C, making them ideal for processing waste from anaerobic digestion plants.

They excel at handling viscous materials that might clog other systems.

Rotary evaporators represent the perfect balance between energy efficiency and processing capacity for modern biogas operations.

The heat transfer in these machines happens through direct contact or through the drum jacket, depending on the model. Many dairy farming operations choose drum evaporators because they can process manure slurry while recapturing ammonia as a valuable by-product.

This supports a circular economy approach where waste becomes a resource. The concentrated solids left after evaporation contain nitrogen and other nutrients that make excellent fertiliser for arable land.

Farms using these systems report up to 75% volume reduction in digestate, cutting waste disposal costs dramatically.

3. Falling Film Evaporators

Unlike drum evaporators that rotate, Falling Film Evaporators use gravity to their advantage. These systems create a thin liquid film on heated surfaces, making them perfect for processing digestate slurry.

The liquid feed enters at the top of vertical tubes and flows downward while partially turning to vapour. This process works well even with lower temperature differences, which saves energy and protects heat-sensitive materials in the mixture.

Falling Film Evaporators shine in biogas operations where energy efficiency matters. They handle viscous fluids with ease, making them ideal for concentrated digestate from anaerobic digesters.

Special components like vapour separators reduce fouling and improve the final product quality. Many plants pair these evaporators with waste heat recovery systems to boost their green energy credentials and move closer to zero liquid discharge goals.

The technology helps transform what was once waste into valuable concentrated nutrients for agricultural soils.

4. Forced Circulation Evaporators

Forced circulation evaporators excel at handling high-viscosity digestate and sludge that might clog other systems. These robust units pump the liquid through a heat exchanger at high speeds, which stops solids from settling and creates a thin film for quick heat transfer.

The heated mixture then enters a flash chamber where pressure drops suddenly, causing rapid evaporation without direct contact with heating surfaces. This design makes them perfect for thick, sticky biogas plant outputs that contain suspended solids.

These systems offer major energy savings through heat recovery options. The evaporated water can be condensed as distilled water, while valuable nutrients concentrate in the remaining liquid phase.

Many plants connect these evaporators to their biogas-powered electrical generation systems, using excess heat that would otherwise go to waste. The process also helps reduce water pollution by capturing nitrates and ammonia vapour that might leak into groundwater.

Operators can further boost efficiency by adding mechanical vapour recompression to recycle latent heat from steam.

5. Mechanical Vapour Recompression (MVR)

Unlike forced circulation systems, Mechanical Vapour Recompression takes a different approach to energy use. MVR systems run mainly on electrical power, which costs less than the heat needed for other evaporation methods.

The magic happens when steam from the evaporation process gets compressed. This compression raises both temperature and pressure, turning the steam into a heating medium. The beauty of MVR lies in its ability to recycle steam, capturing latent heat that would otherwise escape.

MVR does face some challenges. The small temperature gap between service fluid and product boiling point can limit heat transfer efficiency. MVR compressors also have temperature limits, which means bigger heat exchangers and pumps are often needed.

These components drive up costs. As products become thicker during processing, both capital costs and system complexity increase. Still, for renewable energy experts looking to cut operational costs in sludge treatment, MVR offers a smart path to sustainability through its clever reuse of energy.

6. Multi-Effect Evaporation (MEE)

Multi-Effect Evaporation stands as a top choice for digestate and sludge management. This system uses steam heat from one evaporation stage to power the next, creating a chain of energy reuse.

Our data shows steam needs drop from 99.381 to just 37.913 tons per hour when increasing from one to eight effects. MEE works by taking waste heat that would normally escape and putting it to work in later stages.

The process cuts energy costs while still removing water from organic waste effectively.

Pairing MEE with Mechanical Vapour Recompression brings even more savings. The combo slashes steam use and lowers investment costs compared to old-school methods. Many plants now use this setup for wastewater treatment and biogas production systems.

A recent Aspen Plus V10.0 simulation proved MEE's value for lactic acid purification too. The system works well under different steam pressures and can handle various liquids while maintaining air quality standards.

For facilities looking to reduce energy consumption, MEE offers a practical path forward.

7. Thin Film (Wiped Film) Evaporators

Beyond multi-effect systems, thin film evaporators offer another powerful solution for digestate processing. These specialised units excel at handling viscous materials that might clog other evaporation systems.

A thin film evaporator spreads sludge in a thin layer across a heated surface, while rotating blades continuously wipe this surface clean. This design creates maximum heat transfer with minimal residence time.

The rotating motor drives blades that prevent fouling on heat exchangers, a common problem when processing anaerobically digested materials. These systems operate under vacuum conditions, which lowers the boiling point and protects heat-sensitive compounds.

Thin film technology concentrates nutrients effectively while producing clean water as a valuable byproduct. Many plants combine thin film evaporators with scrubbers to capture ammonia, which can be treated with sulphuric acid to create an ammonium sulphate solution for fertiliser applications.

8. Vacuum Evaporation

Vacuum evaporation stands out as a top method for managing liquid digestate in biogas plants. This process works by reducing atmospheric pressure, which lowers the boiling point of water and saves energy during evaporation.

The results speak for themselves: 70-90% of the input becomes distilled water while just 10-30% remains as nutrient-rich concentrate. Many facilities connect their vacuum systems to existing CHP units, using waste heat as their source of energy for the evaporation process.

The financial case for vacuum evaporation is strong. Most systems pay for themselves within one to two years through reduced transport and disposal costs. The technology supports zero liquid discharge goals by turning what was once waste into clean water and valuable byproducts.

For biogas plants dealing with high water content in digestate, this approach cuts transportation expenses while creating products that meet strict environmental rules. The concentrated nutrients can serve markets where organic fertilisers fetch premium prices.

9. Flash Evaporators

Flash evaporators work on a simple but powerful principle. They rapidly heat digestate or sludge under pressure, then release it into a low-pressure chamber. This sudden pressure drop causes instant evaporation, or “flashing.” The process excels at handling high-solid content materials while using less energy than other thermal systems.

Many plants pair flash evaporators with heat exchangers to recycle thermal energy, cutting operating costs by up to 30%.

These systems shine in biogas operations where methane gas production creates excess heat. The flash process effectively separates ammonia from the liquid phase, which operators can collect as a valuable ammonia solution.

Unlike steam-driven alternatives, flash evaporators can run on waste heat from electricity generation processes. This makes them ideal for facilities focused on both waste reduction and resource recovery from the solid phase left behind.

10. Solar Evaporation (Greenhouse or Pond-Based)

Moving from flash evaporators, we now explore solar evaporation systems that offer a green approach to digestate management. Solar evaporation uses free energy from the sun to remove water from sludge in either greenhouse structures or open ponds.

Recent tests show these systems can achieve evaporation rates of 3-5 litres per square meter daily in optimal conditions. The method works best in regions with high solar radiation and low rainfall, making geographic location a key factor in system performance.

The operational process involves spreading digestate in thin layers to boost surface area contact with solar heat. This technique cuts carbon storage needs while reducing energy costs compared to heat exchangers or steam-driven systems.

Data confirms a 40% decrease in processing costs versus thermal methods. Solar evaporation also captures ammonia during the process, allowing for nutrient concentration and potential reuse as fertiliser.

The risk of volatile compounds escaping remains lower than in high-temperature systems, which boosts the environmental profile of this approach.

Benefits and Challenges of Evaporation Techniques

Evaporation techniques offer major advantages like volume reduction and nutrient concentration, but they face hurdles with energy costs and ammonia volatilisation that require careful system design and heat exchanger selection – read on to explore our detailed comparison of each method's strengths and limitations in real-world applications.

Comparison Table of Digestate Slurry Evaporation Techniques

Selecting the right evaporation technology for digestate management can make or break your renewable energy operation's efficiency. We've compiled this comprehensive comparison to help you weigh your options based on real-world performance factors.

| Evaporation Technique | Energy Source | Energy Efficiency | Capital Cost | Operating Cost | Capacity Range | Handling of Suspended Solids |

|---|---|---|---|---|---|---|

| Thermal Evaporation | Gas or oil heating | Low to Medium | Medium | High | 2-50 m³/hour | Poor without pre-treatment |

| Mechanical Vapour Recompression (MVR) | Electricity | High | High | Low | 5-100 m³/hour | Requires filtration |

| Multi-Effect Evaporation | Steam/thermal | Medium to High | High | Medium | 10-200 m³/hour | Moderate |

| Falling Film Evaporators | Steam/thermal | Medium | Medium | Medium | 5-100 m³/hour | Poor with high solids |

| Thin Film Evaporators | Steam/thermal | Medium | High | Medium to High | 1-20 m³/hour | Good |

| Vacuum Evaporation | Electricity + heat | Medium to High | Medium to High | Medium | 2-50 m³/hour | Moderate |

| Solar Evaporation | Solar energy | Variable (weather-dependent) | Low | Very Low | Limited by space | Good but slow |

MVR systems stand out with temperature rises of 8°C to 15°C, making them appropriate for specific applications. These systems require larger heat transfer surfaces but recover latent heat effectively. The choice between MVR and traditional thermal methods often comes down to a trade-off between upfront investment and long-term operational savings.

Pre-treatment becomes critical when dealing with digestates containing high levels of suspended solids. Most high-efficiency systems demand some form of filtration before processing. This adds complexity but improves system longevity and performance.

For many facilities, the decision hinges on economic analysis rather than technical specifications alone. MVR systems typically show better returns for operations with high throughput and access to affordable electricity. Traditional thermal systems may prove more practical for smaller operations or locations with cheap gas/oil supplies.

Innovations in Evaporation Technology

Recent advances in heat exchanger design have transformed digestate processing systems. Companies like HRS Heat Exchangers now offer specialised equipment that handles thick, fouling-prone materials more effectively.

These new systems feature larger heat transfer surfaces and anti-fouling mechanisms that keep operations running smoothly. Some cutting-edge evaporators combine multiple technologies, such as falling film with mechanical vapour recompression, to boost energy efficiency.

The latest control systems also allow for precise monitoring of vapour pressures and steam flow, making the whole process more reliable.

Smart pre-treatment solutions now tackle the ammonia recovery challenge head-on. Before evaporating begins, modern systems can extract ammonia from digestate slurry, turning a problem into a valuable product.

This step reduces operational costs while creating an extra revenue stream. Many facilities now recycle heat throughout their systems, cutting energy use by up to 30%. Carbon storage options have also emerged as part of integrated evaporation systems, helping renewable energy plants reduce their environmental footprint.

These innovations make evaporation more practical for smaller biogas operations that previously couldn't afford such technology.

Conclusion

Evaporation systems offer powerful solutions for managing digestate and sludge waste streams. Each method brings its own strengths, from the energy efficiency of MVR to the simplicity of solar options.

Smart choices depend on your specific material properties, energy costs, and space limits. The best systems balance capital investment against long-term running costs while meeting environmental rules.

As technology advances, we can expect even better ways to handle these challenging materials, turning what was once waste into valuable resources through effective evaporation techniques.

FAQs for Evaporation Techniques For Digestate And Sludge

1. What are the main evaporation techniques used in sludge dewatering?

The main techniques include steam-driven systems, heat exchangers, and reverse osmosis. These methods help reduce water content in waste materials. Each works differently but aims to separate liquids from solids.

2. How does rectification improve the evaporation process?

Rectification enhances the purity of recovered water by removing impurities during the evaporation cycle. This process works like a filter that cleans as it separates. The technique makes recycled water safer for reuse.

3. Why is carbon storage important when managing digestate?

Carbon storage helps trap harmful gases that would otherwise escape during sludge processing. It's like putting leftovers in the fridge to keep them fresh. This approach reduces environmental impact while making the whole system more earth-friendly.

4. Can the water that evaporates be recycled?

Yes, the water that evaporates can be captured and recycled for various uses. Systems often collect this water through condensation. The recycled liquid requires testing before reuse to confirm it meets quality standards.

5. How do heat exchangers affect the efficiency of sludge management?

Heat exchangers boost efficiency by transferring thermal energy between fluids without mixing them. They cut energy costs by up to 30% compared to traditional methods. This technology works similarly to how your car radiator keeps the engine from overheating.

References

- https://processandcontrolmag.co.uk/choosing-the-best-evaporation-technique-for-digestate-and-sludge/ (2025-03-12)

- https://www.sciencedirect.com/science/article/pii/S1385894724009549

- https://extraktlab.com/falling-film-evaporator/

- https://mpra.ub.uni-muenchen.de/95770/1/MPRA_paper_95770.pdf

- https://genless.govt.nz/assets/Business-Resources/Mechanical-vapour-recompression-for-evaporation-distillation-drying.pdf

- https://www.sciencedirect.com/science/article/abs/pii/B9780323958790500412

- https://3v-tech.com/plant/wiped-thin-film-evaporation-plants/

- https://blog.anaerobic-digestion.com/digestate-evaporators-for-anaerobic-digestion-plants-add-product-value-and-aid-disposal/

- https://www.sciencedirect.com/science/article/abs/pii/S0360544217311337

- https://www.researchgate.net/publication/357789227_Performance_evaluation_of_a_solar_evaporation_system_for_liquid_digestate_concentration

- https://link.springer.com/10.1007/978-981-16-4230-2_43

- https://www.researchgate.net/publication/334891275_Digestate_Evaporation_Treatment_in_Biogas_Plants_A_Techno-economic_Assessment_by_Monte_Carlo_Neural_Networks_and_Decision_Trees (2019-08-12)