Discover the MBT Waste Process for Residual Municipal Waste Treatment

Dealing with waste is a common problem for many communities and agree that the old way of chucking it into a big hole (landfill) isn't a solution. So, you might be wondering how to reduce the amount of rubbish that ends up in landfills. This is where Mechanical Biological Treatment (MBT) has a technology developed since about 2005 in the UK, and Europe.

MBT treats leftover municipal solid waste after all the recyclables have been removed. It uses both mechanical and biological methods. This approach helps separate mixed waste into recyclable materials, refuse-derived fuel (RDF), and biodegradable slurries.

It was hoped that by using the anaerobic digestion process to extract energy it would be a sustainable process, because the MBT process is energy intensive and hard to justify if its energy demand requires the use of non-renewable energy. Unfortunately, many MBT sites have suffered from grit and other non-organic contaminant problems in their anaerobic digeston installations.

In this article, we'll explain how MBT works, its benefits, and the technologies used in these systems. We'll also discuss challenges faced during implementation and case studies from around the world.

Read on to learn more!

Key Takeaways

- MBT (Mechanical Biological Treatment) reduces landfill waste by treating municipal solid waste with mechanical and biological methods.

- Advanced sorting technologies such as magnetic separation and optical sensors improve recycling rates and reduce residual waste.

- The biological phase, including anaerobic digestion, converts organic materials into biogas, which can produce renewable energy.

- Despite high initial costs and complex technologies, MBT systems can support support sustainability goals through reduced greenhouse gas emissions and enhanced resource recovery – but only if in conjunction with anaerobic digestion energy.

- New separation equipment is now available to provide the needed contaminant-free organic pulp for success.

Definition of MBT Waste

MBT stands for Mechanical Biological Treatment. It processes residual waste using mechanical and biological methods.

Explanation of Mechanical Biological Treatment

Mechanical Biological Treatment (MBT) treats residual municipal solid waste by both mechanical and biological methods. The process first separates the waste into dry products, high calorific value refuse-derived fuels (RDF), and wet biodegradable slurries.

Mechanical separation involves sorting mixed municipal solid waste using techniques such as trommels, magnets, and eddy current separators. These tools isolate recyclables like aluminium and other metals from the rest of the waste.

Next comes the biological treatment phase. This stage targets organic components for breakdown through aerobic decomposition or anaerobic digestion. Composting is a key method used here to turn organic matter into soil improvers or fertiliser.

Anaerobic digestion produces biogas which can generate electricity in power plants, contributing to green energy efforts. Both phases significantly reduce landfill dependency while recovering valuable resources from our everyday trash.

Components of MBT Systems

The Mechanical Biological Treatment (MBT) system handles various types of waste. It includes multiple processes that work together for effective waste management.

- Mixing and Shredding: MBT systems first mix and shred waste. This step breaks down large items into smaller pieces, making it easier to sort.

- Separation via Screening: Screens help separate different sizes of waste materials. Small particles fall through holes in the screens, while larger pieces continue on for further sorting.

- Magnetic Separation: Magnets pull out metal objects from the waste stream. This process recycles metals like iron and steel efficiently.

- Eddy Current Separation: An eddy current separator removes non-ferrous metals such as aluminium. It uses a magnetic rotor to create electric currents that repel these metals.

- Optical Separation: Advanced optical sensors identify and sort materials based on colour and type. This technology separates plastics from other recyclables.

- Air Classification: Air classifiers blow light materials, like paper and plastic film, away from heavier items such as glass or stones. This reduces the weight of residual waste sent for disposal.

Each component plays a specific role in improving recycling efficiency and reducing landfill dependency.

Importance of MBT in Waste Management

MBT waste treatment aids in reducing landfill use and preserving natural resources. This system turns waste into valuable materials like compost and refuse-derived fuel (RDF).

Environmental Benefits

MBT plants help lower waste volume and cut down methane emissions. This reduction fights global warming by limiting greenhouse gases. MBT systems also produce refuse-derived fuel (RDF), which can replace fossil fuels in cement kilns.

MBT technologies add value to waste management through organic waste treatment. They convert biodegradable materials into compost or soil conditioner, boosting agriculture while reducing reliance on landfills.

“MTB use transforms waste woes into green gains,” says environmental expert Dr Mary Brown.

Reduction in Landfill Dependency

By treating waste, MBT reduces landfill dependency. It diverts biodegradable municipal solid waste from landfills. This helps decrease greenhouse gas emissions significantly.

The Landfill Directive (EC/31/1999) boosted the use of MBT systems across Europe. Mechanical and biological processes sort and break down waste. These steps produce refuse-derived fuel, composted materials, and recyclables instead of sending them to landfill sites.

Contribution to Circular Economy

MBT waste treatment helps create a circular economy by separating materials for recycling. Recyclables like plastics and metals get new life through reprocessing. The remaining RDF (Refuse Derived Fuel) can generate energy in incineration plants or cement kilns.

Low-quality soil from MBT facilities aids land reclamation projects. By recycling and using RDF, less waste goes to landfills. This reduces the need for raw materials and lowers carbon emissions, supporting sustainability goals.

Process Flow of MBT Waste Treatment

Waste arrives at the MBT plant and goes through initial sorting. Then, mechanical processes separate materials before biological treatment breaks down organic waste.

Waste Reception and Preliminary Sorting

Lorries deliver waste to the MBT plant. Workers then direct the waste into large reception areas. There, machines shred and mix it to create a uniform size and mixture. This helps in sorting out recyclables from non-recyclable materials.

Next, huge screens separate recyclable items by size. Magnetic separation removes metals like iron and steel from other materials. The sorted waste now moves on for further treatment or recycling at the Materials Recovery Facility (MRF).

Mechanical Treatment Phase

The mechanical treatment phase is crucial in MBT waste management. Automated sorting systems handle the bulk, separating materials like metals, plastics, and organic waste. Equipment used includes conveyors, industrial magnets, eddy current separators, trommels, shredders, and hand-picking stations.

A sorting component mirrors a material recovery facility (MRF). It helps recover valuable recyclables from municipal solid waste (MSW) while preparing other fractions for further biological treatment or conversion into refuse-derived fuel (RDF).

This step significantly reduces the volume destined for incineration or landfill sites.

Biological Treatment Phase

Biological treatment in MBT systems involves anaerobic digestion and composting. Anaerobic digestion uses microbes to break down biodegradable waste, producing biogas. Biogas serves as a renewable energy source, reducing reliance on fossil fuels.

Composting transforms organic waste into valuable fertiliser.

In this phase, biodegrading helps reduce the volume of municipal solid waste sent to landfills. Plants use refuse derived fuel (RDF) created during this process for power generation or industrial applications.

This step ensures better management of household waste and supports ecological sustainability.

Technologies Used in MBT Systems

MBT systems utilise different methods to sort and treat waste. These technologies help separate recyclable materials from the rest. They also process organic waste into bioenergy or compost.

Read more to understand how these systems work!

Sorting Technologies

Sorting technologies play a crucial role in MBT systems. They help separate different materials for recycling and energy recovery.

Magnetic Separation

- Uses magnets to extract ferrous metals from waste.

- Removes items like iron and steel cans.

- Reduces contamination in other waste streams.

Optical Separation

- Uses light sensors to sort plastics by type and colour.

- Can process large amounts of waste quickly.

- Improves the quality of recycled plastics.

Eddy Current Separators

- Utilises magnetic fields to eject non-ferrous metals.

- Removes aluminium cans and other metallic items.

- Enhances the purity of remaining materials.

Air Classification

- Employs air currents to separate light materials from heavy ones.

- Can sort paper, plastic films, and other lightweight items.

- Helps in reducing landfill waste.

5. Trommels

– Rotating drums with holes of various sizes.

– Allows small particles to fall through while larger ones continue along the drum.

– Used for initial screening of municipal solid waste (MSW).

6. Ballistic Separators

– Sorting of materials based on shape, size, and density.

– Separates flat items like paper from rolling objects such as bottles.

– Improves efficiency in recycling operations.

7. Near-Infrared (NIR) Scanners

– Uses infrared light to identify different types of plastics and textiles.

– Offers precise sorting capabilities for high-value recyclables.

– Integrates well with automated processing lines.

8. Screens

– Mesh filters are used to sort particles by size at various stages of MBT treatment.

– Efficiently removes fine organic matter from inorganic wastes.

– Reduces wear on downstream machinery.

Each technology plays a specific role in improving the overall efficiency of MBT systems while contributing significantly to environmental sustainability goals.

Biological Processing Techniques

Transitioning from sorting technologies, biological processing techniques play a crucial role in MBT waste management. These techniques help break down organic materials and convert them into useful products.

- Anaerobic Digestion (AD)

- Anaerobic digestion produces biogas and soil improver.

- In AD, microorganisms break down waste in an oxygen-free environment.

- The process generates renewable energy, reducing carbon emissions.

- Digestate, the by-product, can be used as an organic fertiliser on farms.

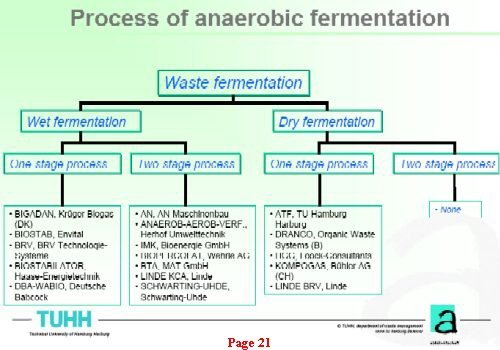

A closely similar but nevertheless biological rather different process often mistakenly called anaerobic digestion is the fermentation of waste as shown in the illustration below:

- Composting

- Composting transforms organic waste into compost but no green energy.

- This aerobic process needs oxygen to decompose materials.

- It improves soil health by adding nutrients and boosting plant growth.

- Municipal solid waste (MSW) often undergoes composting before reaching landfills.

- Biodrying:

- Biodrying reduces the moisture content of waste materials using heat from microbial activity.

- This method makes it easier to handle and transport refuse-derived fuels (RDF).

- Drier waste can be incinerated or gasified for energy production.

- In-vessel Composting:

- In-vessel composting confines the process inside a container, offering better control over conditions like temperature and moisture.

- It results in faster decomposition compared to open-air methods.

- Mechanical Biological Pre-treatment

- Mechanical pre-treatment involves shredding and separating recyclable materials before biological treatment starts.

- These steps enhance the efficiency of subsequent anaerobic digestion or composting processes.

Each technique brings unique benefits, whether through producing renewable fuel or improving soil quality with organic fertilisers. Their integration forms an essential part of modern waste management strategies aiming at sustainability.

Challenges in MBT Implementation

MBT systems face several hurdles, including high initial costs and complex technologies. Read on to find out more about these challenges!

Technological Complexity

Implementing MBT waste treatments poses various technological challenges. Different stages involve many components like shredders, screens, and biological reactors. Each piece of equipment needs regular maintenance to function efficiently.

The integration of sorting technologies such as trommels and eddy current separators can also add to the challenge.

Achieving effective results demands precise calibration and skilled operation. Moreover, ensuring compliance with environmental regulations adds another layer of difficulty. As a result, local authorities often face challenges in adopting these advanced systems without substantial initial investments.

Advanced technology makes mechanical biological treatment both intricate and invaluable.

High Initial Investment Costs

MBT systems require a significant initial investment. The cost to build and equip these facilities can be high due to complex technologies like mechanical separation processes and biological waste treatment techniques.

New infrastructure demands considerable capital, and setting up machines for sorting, composting, or anaerobic digestion adds to the expense.

Many regions face difficulties securing funds for these projects. High upfront costs deter smaller municipalities from adopting MBT plants even though the long-term benefits are clear.

Moreover, producing refuse-derived fuels may necessitate additional investments in combustion facilities, further driving up expenses.

Regulatory and Compliance Issues

All MBT facilities in the UK need permits. These facilities must also follow strict regulatory monitoring. This ensures they operate safely and efficiently. The Integrated Pollution Prevention and Control Directive (IPPC) sets these rules.

Compliance with the IPPC helps reduce pollution from waste treatment plants. It impacts how they manage municipal solid waste (MSW) and refuse-derived fuels (RDF). Following these rules helps protect the environment while ensuring proper treatment of biological waste.

Challenges in Sustainable Anaerobic Digestion

The anaerobic digestion (AD) process has long been viewed as a promising method to extract renewable energy from organic waste streams. By breaking down organic material in the absence of oxygen, AD produces biogas, which can be used for electricity generation, heating, or as a vehicle fuel.

This process aligns well with global sustainability goals, especially when compared to energy-intensive alternatives like the Mechanical Biological Treatment (MBT) process, whose reliance on non-renewable energy unless integrated with biogas production raises questions about its environmental and economic viability.

However, many MBT sites have encountered significant operational challenges when integrating anaerobic digestion into their processes.

Chief among these is the issue of grit and non-organic contaminants entering the AD system. Grit, plastics, and other foreign materials not only reduce the efficiency of biogas production but also lead to increased maintenance costs and downtime. Blockages, wear-and-tear on equipment, and reduced digester capacity are common problems that hinder the performance of AD facilities. This has caused many facilities to fall short of their sustainability objectives, despite the inherent promise of the AD process.

The Drycake Twister: A Proven Solution to Contaminated Organics

To address these persistent challenges, the Drycake Twister depackager and separator emerge as an industry-leading solution.

Designed to handle contaminated organic waste streams, the Drycake Twister effectively removes grit and plastics from the organic pulp output, ensuring that only clean, high-quality material enters the anaerobic digestion system.

This innovation tackles the very problems that have plagued MBT sites, making the AD process more efficient, reliable, and sustainable.

Key Benefits of the Drycake Twister™

The Drycake Twister is equipped with advanced grit separation technology and residual plastic when installed with Drycake Seditank and Plastifloat units as follows:

- Efficient Grit Removal: The combined unit removes fine particles from the organic waste stream. This prevents abrasive materials from damaging downstream equipment and extends the lifespan of digesters by preventing inert material build-up in digester tanks.

- Plastics Separation: Plastics and other non-organic contaminants are effectively separated, ensuring a clean organic pulp output. This not only improves biogas yield but also reduces the environmental impact of AD by minimizing the presence of microplastics in the digestate.

- Enhanced System Performance: By delivering a contaminant-free organic stream, the Drycake Twister optimizes the anaerobic digestion process. Facilities can achieve higher biogas production rates with fewer interruptions, ultimately increasing their energy output and financial returns.

- Cost Savings: The removal of grit and plastics minimizes equipment maintenance and unplanned downtime, resulting in significant operational cost savings. Facilities can allocate resources more efficiently and focus on achieving their sustainability goals.

Revolutionizing Waste Management

The adoption of the Drycake Twister marks a turning point for facilities struggling with contamination issues in anaerobic digestion. By addressing the root causes of inefficiency, the

Twister enables a truly sustainable and economically viable waste-to-energy process. This innovation not only supports the circular economy but also demonstrates the potential for technology to solve long-standing challenges in waste management.

In summary, the Drycake Twister is the ultimate solution for MBT sites aiming to maximize the benefits of anaerobic digestion. By eliminating grit and plastics problems from the organic pulp output, it ensures the process operates at peak efficiency, paving the way for a cleaner, greener future.

Case Studies of MBT Implementation

Many European countries have successfully implemented MBT systems, which have reduced landfill waste. Developing countries are also adopting these methods to manage their municipal solid waste more efficiently.

Success Stories from Europe

Barcelona's Ecoparcs decreased landfill waste and boosted recycling rates. The MBT facilities played a crucial role in handling municipal solid waste (MSW). These plants focused on sorting and processing, achieving higher efficiency levels.

In Germany, larger MBT plants faced odour and bacterial challenges. Yet, they still proved effective in biowaste collection. They helped reduce landfill dependency significantly despite the hurdles.

Such successes highlight Europe's commitment to advanced waste management methods.

Adaptations in Developing Countries

Developing countries can tailor MBT technology to their specific waste management needs. They use it to sort mixed waste streams into different fractions for recycling and energy production.

This approach helps dry and stabilise municipal solid waste effectively.

Successful examples from Europe, such as Germany’s biowaste collection systems, offer a blueprint for these adaptations. Implementing MBT processes reduces landfill dependency while contributing to more sustainable practices.

These adaptations make MBT plants a crucial tool in improving waste management efficiency in developing regions.

Future Trends in MBT Technology

New sorting technologies will make the process faster and more accurate. Researchers are also finding ways to integrate waste treatment with renewable energy sources.

Innovations in Sorting and Processing

MBT systems now use advanced technologies for sorting and processing waste. Optical sorters can identify and separate different types of materials with precision. This increases efficiency in material recovery facilities (MRF).

These innovations reduce the amount of residual waste.

Robotic arms are also becoming common in MBT plants. They help speed up the separation process by picking out recyclable items from mixed waste streams. Anaerobically digested materials produce biogas, which contributes to renewable power sources.

Sorting technologies allow quicker construction and easier design alterations, making MBTs more adaptable to evolving needs.

Integration with Renewable Energy Sources

Innovations in MBT systems pave the way for integrating renewable energy sources. Anaerobic digestion within these setups generates biogas. This biogas serves as a valuable source of renewable energy.

By using biological processes, MBT plants convert waste into usable fuel.

Biomass from refuse-derived fuels (RDF) can also power gasifiers and combustion power plants. These methods reduce reliance on fossil fuels while managing municipal solid waste (MSW).

New technologies continue to enhance efficiency in sorting and processing, supporting the transition to sustainable energy solutions.

Impact of MBT on Waste Reduction Goals

MBT plants significantly lower the amount of waste going to landfills by treating municipal solid waste. This treatment process improves recycling rates and creates valuable outputs like Refuse Derived Fuels (RDF).

Quantitative Reduction in Waste Volume

MBT reduces landfill volume by at least half. This means less land is used for waste disposal. It also prevents the harmful effects of leachate and greenhouse gases.

Moreover, diverting biodegradable municipal solid waste from landfills helps lower carbon dioxide emissions. The process creates refuse-derived fuels which are useful in energy recovery.

Quality of Outputs for Recycling and Energy Recovery

The outputs of Mechanical Biological Treatment (MBT) can vary in quality. Low-quality glass from the process often finds use in road construction rather than traditional recycling streams.

Residual biological material proves ideal for landfill restoration projects.

These materials contribute to both recycling and energy recovery efforts. They help reduce the volume of waste that ends up in landfills. RDF waste or Refuse-Derived Fuel is another significant output, used as a source of energy either through incineration or gasification processes.

This makes MBT an essential part of the circular economy.

Stakeholder Roles in Enhancing MBT Efficiency

Governments play a critical role by setting regulations and providing incentives. Private companies invest in new technologies to improve the systems.

Government Regulations and Incentives

The UK uses MBT systems to meet the Landfill Directive (EC/31/1999) needs. This directive pushes for reduced waste in landfills, promoting recycling and reuse. The U11 exemption allows spreading certain wastes on land for agricultural or ecological benefits.

Government incentives boost private sector investment in MBT plants. Grants and tax breaks make building these facilities cheaper. These steps help reduce municipal solid waste (msw) going to landfills, aiding a zero waste future.

Private Sector Investment

Private companies can greatly improve MBT waste treatment. Their investments provide advanced technologies for sorting and biological processing. This financial support helps reduce landfill dependency and boosts recycling efforts.

For example, businesses investing in MBT plants lead to better soil conditioners from organic waste. By funding these systems, the private sector helps turn municipal solid waste into valuable resources, helping communities achieve their waste reduction goals.

Community Engagement and Education

Communities play a key role in the success of MBT waste management. They must collect biowaste and other fractions separately. Zero Waste municipalities show that effective source separation can reduce the need for more MBT plants and disposal sites.

Education programmes help residents understand what to separate at kerbside collection points. Information on how biological degradation works encourages participation. Government regulations and incentives also support this engagement, lowering volumes heading to landfills.

This results in less landfill gas emission and better soil conditioner production from treated waste.

MBT Waste Conclusion

MBT waste treatment offers a solid solution for residual municipal waste. By using mechanical and biological methods, we can reduce the need for landfills. This process also supports environmental goals and fosters a circular economy.

MBT technology brings promise when integrated with anaerobic digestion but requires high investment and regulation to succeed fully. Together, we can make a big impact on waste management through smart practices and make MBT work.

MBT Waste FAQs

1. What is the Mechanical Biological Treatment of residual waste?

The Mechanical Biological Treatment (MBT) of residual waste involves processing municipal solid waste (MSW) using both mechanical and biological methods to reduce volume before disposal.

2. How do MBT plants manage municipal waste?

MBT plants treat municipal waste through sorting, separating recyclables at Material Recovery Facilities (MRFs), and then biologically treating the remaining organic matter.

3. Can MBT processes produce soil conditioner?

Yes, during the biological treatment process, some organic materials can be converted into a soil conditioner that can be used in agriculture or landscaping.

4. Is incineration involved in MBT waste management?

While MBT itself focuses on reducing and recycling MSW, some residues from this process may still go to incinerators for energy recovery rather than being landfilled.

5. Why is water important in the biological treatment process of MBT?

Water plays a crucial role in facilitating microbial activity during the decomposition phase of biological treatment within MBTs, ensuring efficient breakdown of organic material.