Learn about biogas digestate side stream ammonia stripping (better known to the uninitiated as “ammonia removal plus return the flow back where it came” and its many advantages. For years this amazing opportunity to raise profitability and bioreactor process stability has seldom been discussed.

We decided to promote this simple technology and to do so in everyday language. Let us know what you think!

Introduction to Side Stream Ammonia Stripping

Biogas digesters are a proven technology for converting organic waste into renewable biogas and a nutrient-rich digestate. However, ammonia, a byproduct of anaerobic digestion, can reach levels that inhibit the methanogenic bacteria responsible for biogas production. Additionally, high ammonia concentrations in digestate can limit its use as a fertilizer due to potential phytotoxicity.

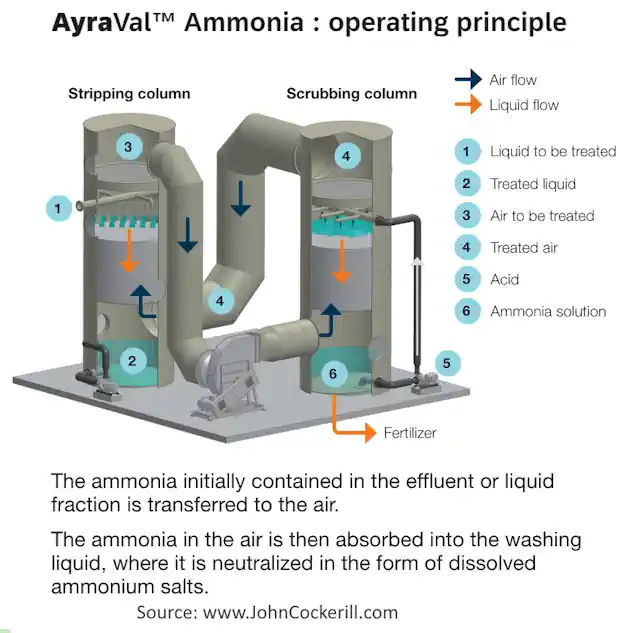

Sidestream ammonia stripping offers a solution to these challenges. This process removes ammonia from the liquid digestate stream using a stripping gas like air or biogas, transferring it to a separate gas stream. This reduces the ammonia load on the digester, improving biogas production efficiency, and creating a concentrated ammonia stream that can be further processed into a valuable fertilizer.

Afterwards, the liquid is recirculated back to where it came from. This is the reason for it being called a sidestream process, with the advantage that if not working for any reason the AD plant will continue to operate.

Side Stream Ammonia Stripping – Key Takeaways

- Side stream ammonia stripping can significantly improve the efficiency of biogas production by removing ammonia, a known inhibitor of methanogenic bacteria.

- The stripped ammonia can be captured and converted into a concentrated fertilizer, reducing reliance on non-renewable resources and creating a potentially revenue-generating product.

- Sidestream ammonia stripping offers a complementary technology that can be integrated with existing anaerobic digestion facilities.

- Don't assume that because you may only have heard about it for the first time here it isn't a powerful tool that the biogas industry won't very soon wake up to!

Benefits of Sidestream Ammonia Stripping

- Improved Biogas Production: By removing ammonia from the digester liquor, (digester tank supernatant) sidestream stripping creates a more favourable environment for methanogenic bacteria, leading to increased biogas production [1].

- Enhanced Digestate Quality: Reduced ammonia levels in the digestate improve its suitability as a fertilizer by minimizing the risk of phytotoxicity in plants [2].

- Sustainable Fertilizer Production: Captured ammonia can be processed into a concentrated, renewable fertilizer, reducing reliance on non-renewable resources for fertilizer production [3].

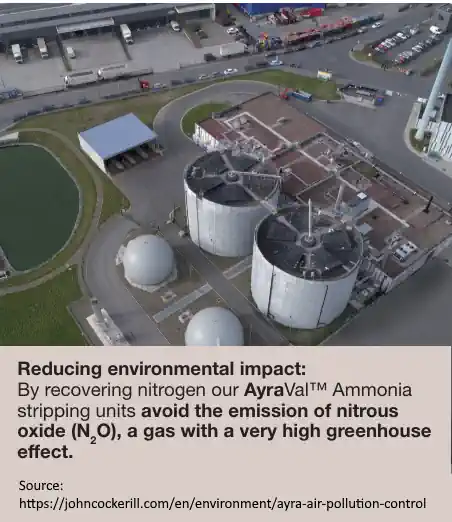

- Nitrous oxide emissions may be avoided, reducing the emissions of this powerful climate-changing greenhouse gas.

Integration with Existing Anaerobic Digestion Systems

Sidestream ammonia stripping can be integrated with existing anaerobic digestion facilities as an add-on process. The ammonia-rich liquid stream, typically the digestate or filtrate from sludge dewatering or the supernatant from the digester itself, is diverted to a stripping column [4]. Here, the stripping gas (air or biogas) removes ammonia, which can then be captured and processed into a usable form, such as ammonium sulfate or urea [5].

Sidestream ammonia stripping can be integrated with existing anaerobic digestion facilities as an add-on process. The ammonia-rich liquid stream, typically the digestate or filtrate from sludge dewatering or the supernatant from the digester itself, is diverted to a stripping column [4]. Here, the stripping gas (air or biogas) removes ammonia, which can then be captured and processed into a usable form, such as ammonium sulfate or urea [5].

Cost vs. Revenue Potential from Side Stream Ammonia Stripping

While a detailed cost analysis would depend on specific factors like plant size and ammonia concentration, sidestream ammonia stripping generally requires additional capital investment for the stripping column and associated equipment. However, the potential revenue generated from selling the recovered ammonia as a fertilizer can offset these costs [6].

The economic viability of recovered ammonia as a fertilizer hinges on several factors, including:

- Market Demand: Local demand for high-quality, renewable fertilizers can significantly impact the selling price.

- Processing Costs: The cost of converting the stripped ammonia into a marketable fertilizer form (e.g., ammonium sulfate or urea) needs to be factored in.

- Transportation Costs: Delivery distance to potential buyers can affect profitability.

While a definitive cost-benefit comparison is challenging without site-specific data, several studies suggest that sidestream ammonia stripping can be economically attractive, particularly when combined with favourable market conditions for renewable fertilizers.

Side Stream Ammonia Stripping FAQs

Q: What are the different types of stripping gas used in sidestream ammonia stripping?

A: Both air and biogas can be used as stripping gas. Biogas offers the advantage of utilizing an existing stream within the anaerobic digestion process.

Q: Can sidestream ammonia stripping be used with any type of anaerobic digester?

A: Sidestream ammonia stripping is particularly applicable to digesters processing feedstocks with high nitrogen content, such as food waste, leading to potentially higher ammonia concentrations. However, the technology can be beneficial for various digester applications depending on the specific ammonia levels and economic considerations.

A: Sidestream ammonia stripping is particularly applicable to digesters processing feedstocks with high nitrogen content, such as food waste, leading to potentially higher ammonia concentrations. However, the technology can be beneficial for various digester applications depending on the specific ammonia levels and economic considerations.

Citation Sources for Side Stream Ammonia Stripping

- Ammonia removal in food waste anaerobic digestion using a side-stream stripping process: Valorgas, University of Southampton

- Methods of ammonia removal in anaerobic digestion: A review Water Science & Technology

- Technical Report – Organics Recycling Group (https://organicsgroup.com/)

- Ammonia removal in anaerobic digestion by biogas stripping: an evaluation of process alternatives using a first-order rate model (CORE: core.ac.uk)

- Side Stream Nutrient Removal US Environmental Protection Agency (.gov)

- Air stripping units for the recovery of nitrogen (N) from industrial and municipal wastewater washing viability of sidestream ammonia stripping: John Cockerill webste