The Börger Bioselect Digestate Separator: Advanced AD Substrate Separation Technology

The Börger Bioselect Digestate Separator has established itself as the industry-leading solution for solid/liquid digestate separation in anaerobic digestion (AD) plants worldwide. As environmental regulations tighten and the demand for sustainable waste management solutions grows, the Börger Bioselect delivers the efficiency and reliability that modern AD operators require.

What Makes the Börger Bioselect Digestate Separator Essential?

Every anaerobic digestion plant operator faces the critical challenge of effectively separating digestate into manageable liquid and solid fractions. The Börger Bioselect Digestate Separator addresses this need with cutting-edge mechanical separation technology that transforms complex digestate management into a streamlined, cost-effective process.

The Bioselect BS has been specially designed for the effective thickening of liquid manure and digestate. In a completely closed system, the separator thickens the inlet substrate to form a solid phase with a dry solids content of 5 to 22 %. The thickening degree is infinitely variable.

If required, the user can thicken, for example 4% DS content liquid manure into 12% DS, making it suitable for a tanker. Likewise, pig and cattle liquid manure, as well as fermentation residue, can be thickened to, for example 22%, without making any mechanical adjustments to the machine.

Advanced Technology Behind the Börger Bioselect

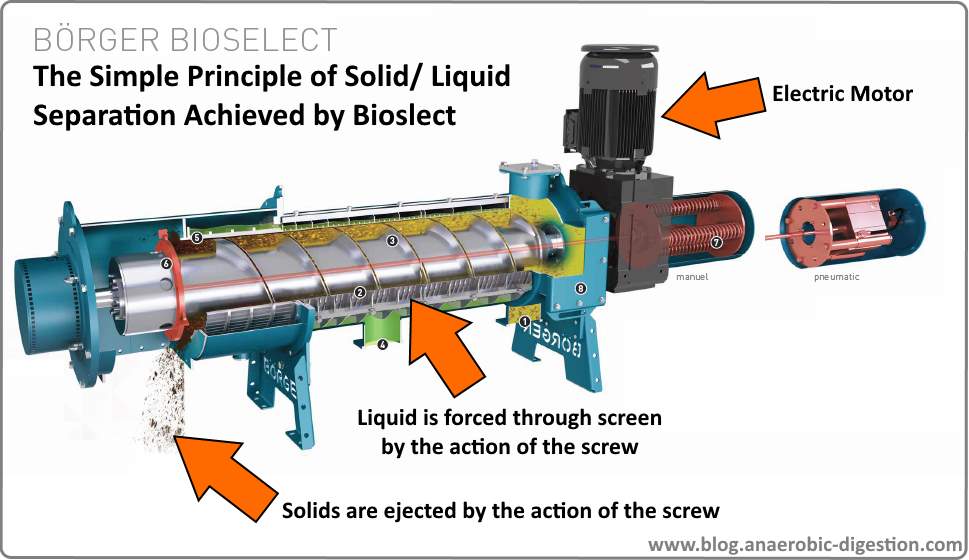

The Börger Bioselect Digestate Separator combines sophisticated engineering with practical simplicity. At its core, the system utilises a specialised rotary lobe/screw pump configuration paired with precision screening technology. This mechanical approach ensures consistent, reliable separation without the complexity and maintenance demands of alternative technologies.

Key Technical Features

Rotary Lobe Pump Integration: The Bioselect is a solids/liquid separator using Boerger BLUEline rotary lobe pumps for both feeding and discharging the filtrate. Boerger also supplies controls for the provided equipment, including an attractive and easy-to-use touch screen HMI, to improve equipment performance.

Load-Triggered Operation: The system's intelligent design ensures optimal performance through load-triggered operation. The feed pump only conveys the volume that the Bioselect BS can effectively process, while the high-density solids discharge pump precisely controls the degree of thickness.

Flexible Dry Matter Content: Operators can adjust dry matter content from 4% to 22% without mechanical modifications, making the system adaptable to various feedstocks and operational requirements.

Börger Bioselect Models: Tailored Solutions for Every Application

Bioselect BS Series

The BS series excels in thickening applications, perfect for converting liquid digestate into transportable, stackable solid material. The Bioselect BS is a combination of the separation machine and two Rotary Lobe Pumps. This configuration provides exceptional control over the separation process.

Bioselect RC Series

The Bioselect RC is well known for its sophisticated operating principle. With a throughput of up to 660 usgpm (150 m³/h), it is one of the most powerful separators in the world. The patented Multi Disc sealing technology ensures safe operation. This model is ideal for high-volume operations requiring maximum throughput.

Installation Versatility: Fixed and Mobile Solutions

The Börger Bioselect Digestate Separator offers unparalleled installation flexibility:

Retrofit Integration: The BS 50 can be seamlessly integrated into existing AD systems without major infrastructure modifications.

Mobile Applications: The Börger BioSelect mobile separators provide a flexible and efficient solution for slurry management, offering the advantage of mobility for operations that need to manage slurry across multiple locations.

New Plant Integration: Purpose-built for incorporation into new AD facilities with optimised layout and performance.

Operational Advantages and Benefits

Superior Throughput Capacity

The Börger Bioselect maintains throughput volumes of up to 60 m³/h for the BS series and up to 150 m³/h for the RC series, with the ability to sustain these rates continuously during extended operations.

Enhanced Digestate Quality

Screw Separation of Biogas Digestate is a proven and reliable mechanical separation process. It has several advantages. Most important is the fact that it is cost-efficient and requires minimal maintenance. Another benefit is that it is able to handle a variety of feedstocks.

Contamination Management

For operations processing food waste feedstocks, the Börger Bioselect effectively removes plastic particles larger than 12mm, ensuring compliance with UK regulations and preventing costly landfill disposal fees.

Environmental Impact and Sustainability

The Börger Bioselect Digestate Separator contributes significantly to sustainable waste management practices. Digestate is a nutrient-rich by-product from organic waste anaerobic digestion, but it can contribute to nutrient pollution without comprehensive management strategies. Proper separation ensures optimal nutrient management and reduces environmental impact.

Prepackaged food waste material is increasingly being used as a feedstock in agricultural on-farm biogas generators. When employing land application for disposal, contamination of the anaerobically digested sludge with plastics becomes a big issue.

In the United Kingdom, for example, all plastic particles larger than 12 mm (0.5 inches) must be removed from biomass to prevent the expensive cost of disposal to landfill. This is accomplished by using a separator like the Boerger Bioselect series, which is generally only done after the fermentation process.

Carbon Footprint Reduction

By enabling efficient digestate processing, the Börger Bioselect supports the circular economy principles essential for achieving carbon neutrality goals in waste management operations.

Resource Recovery Optimisation

The separated liquid fraction provides high-quality liquid fertiliser, while the solid fraction offers valuable organic matter for soil improvement, maximising resource recovery from the AD process.

Technical Specifications and Performance

Control Systems

Modern Börger Bioselect units feature intuitive touchscreen HMI controls that provide:

- Real-time monitoring of separation parameters

- Automated process optimisation

- Comprehensive safety interlocks

- Performance data logging

Maintenance Requirements

The mechanical separation process requires minimal maintenance compared to alternative technologies, reducing operational costs and maximising uptime.

Safety Features

Comprehensive safety systems ensure reliable operation while protecting both equipment and operators through advanced monitoring and control capabilities.

Applications Across Industries

Agricultural Operations

Farm-based AD plants benefit from the Börger Bioselect's ability to process various organic feedstocks, including livestock manure, crop residues, and food waste.

Commercial AD Facilities

Large-scale commercial digesters rely on the Börger Bioselect for consistent, high-volume processing of municipal organic waste and industrial byproducts.

Food Waste Processing

The Bioselect is a solids/liquid separator that includes Boerger BLUEline rotary lobe pumps for feeding the unit, as well as the discharge of the filtrate. This makes it ideal for food waste processing facilities requiring contamination removal.

Economic Benefits and ROI

Operational Cost Reduction

The Börger Bioselect Digestate Separator delivers significant cost savings through:

- Reduced transportation costs for separated materials

- Lower maintenance requirements

- Improved digestate value

- Compliance with environmental regulations

Revenue Enhancement

Separated digestate fractions command higher market values as specialised fertiliser products, improving overall plant economics.

Future-Proofing Your AD Operation

As environmental regulations continue to evolve and sustainability requirements become more stringent, the Börger Bioselect Digestate Separator positions AD operators for long-term success. The system's adaptability and proven performance record make it an investment in operational excellence and environmental responsibility.

Technical Support and Service

Börger provides comprehensive support for Bioselect installations, including:

- Installation supervision and commissioning

- Operator training programs

- Preventive maintenance schedules

- 24/7 technical support availability

- Spare parts management

Conclusion

The Börger Bioselect Digestate Separator represents the pinnacle of mechanical separation technology for anaerobic digestion applications. Its combination of proven reliability, operational flexibility, and environmental benefits makes it the preferred choice for AD operators seeking to optimise their digestate management processes.

Whether retrofitting an existing facility or designing a new AD plant, the Börger Bioselect Digestate Separator delivers the performance, efficiency, and sustainability that modern operations demand. The Börger Bioselect stands for efficient separation technology. Using a purely mechanical process, liquid parts are separated from the solid parts in the medium.

For more information about the Börger Bioselect Digestate Separator and how it can transform your AD operation, contact Börger UK Limited or visit their comprehensive online resources.

Contact Information: Börger UK Limited

East Wing – Old School

Watling Street, Gailey

Staffordshire, United Kingdom, ST19 5PR

Phone: +44 1902 798977

[Article first uploaded July 2017. Updated November 2021. Last Updated: August 2025 – rewritten.]

While practicing social responsibility is rarely profitable in the same way as cheap production and low wage costs, but business owners should do it more as it pays in other areas of the business.

The rise in consumers looking for green brands, or brands that align with various other causes, has led many companies to strongly market their sudden good intentions. But isn’t anaerobic digestion in the same league?