A biogas generator uses the process of anaerobic digestion to break down organic waste like animal manure, crop waste, or kitchen scraps, producing biogas (a mixture of methane and carbon dioxide) that can be used to generate renewable electricity and heat. This energy source is an environmentally friendly alternative to fossil fuels, and it produces a nutrient-rich fertiliser as a byproduct. These generators have a great and growing future as the planet warms up.

Key Takeaways

- Biogas generators transform organic waste into renewable energy through anaerobic digestion, providing a sustainable solution to waste management challenges.

- Implementing biogas systems can reduce greenhouse gas emissions by up to 90% compared to traditional waste management methods while producing valuable byproducts like natural fertilizer.

- The technology scales from small home digesters processing 20-100kg daily to industrial systems handling tons of waste, making it accessible for various applications.

- Converting waste to energy with biogas generators can significantly lower energy costs, with some farms cutting fossil fuel dependence by thousands of gallons annually.

- HomeBiogas offers innovative systems that empower individuals and organizations to participate in the sustainable energy revolution through efficient waste-to-energy conversion.

Biogas generators represent one of the most elegant solutions in our renewable energy toolkit. They take what would otherwise be waste and transform it into valuable energy resources while solving multiple environmental problems at once.

The concept is remarkably elegant: organic materials that would typically end up in landfills or treatment facilities are instead channeled into a productive energy generation cycle. This waste-to-energy approach is gaining momentum worldwide as communities and businesses seek more sustainable alternatives to fossil fuels while tackling waste management challenges.

What Are Biogas Generators and Why They Matter

Biogas generators are specialized systems that capture and utilize the natural gas produced when organic matter breaks down in oxygen-free environments. Unlike fossil fuels that take millions of years to form, biogas represents a renewable energy source that can be continuously produced as long as organic waste materials are available. These generators form a crucial link in the circular economy by recapturing energy that would otherwise be lost.

As global waste production continues to rise and conventional disposal methods face increasing scrutiny, biogas technology offers a practical solution that addresses multiple challenges simultaneously. By converting waste into energy, these systems help reduce landfill volumes, cut greenhouse gas emissions, and provide a sustainable energy alternative that can be produced locally, reducing dependence on imported fuels.

“Small Biogas Generator Gas Engine …” from pulitaenergy.en.made-in-china.com and used with no modifications.

How Biogas Transforms Organic Waste into Energy

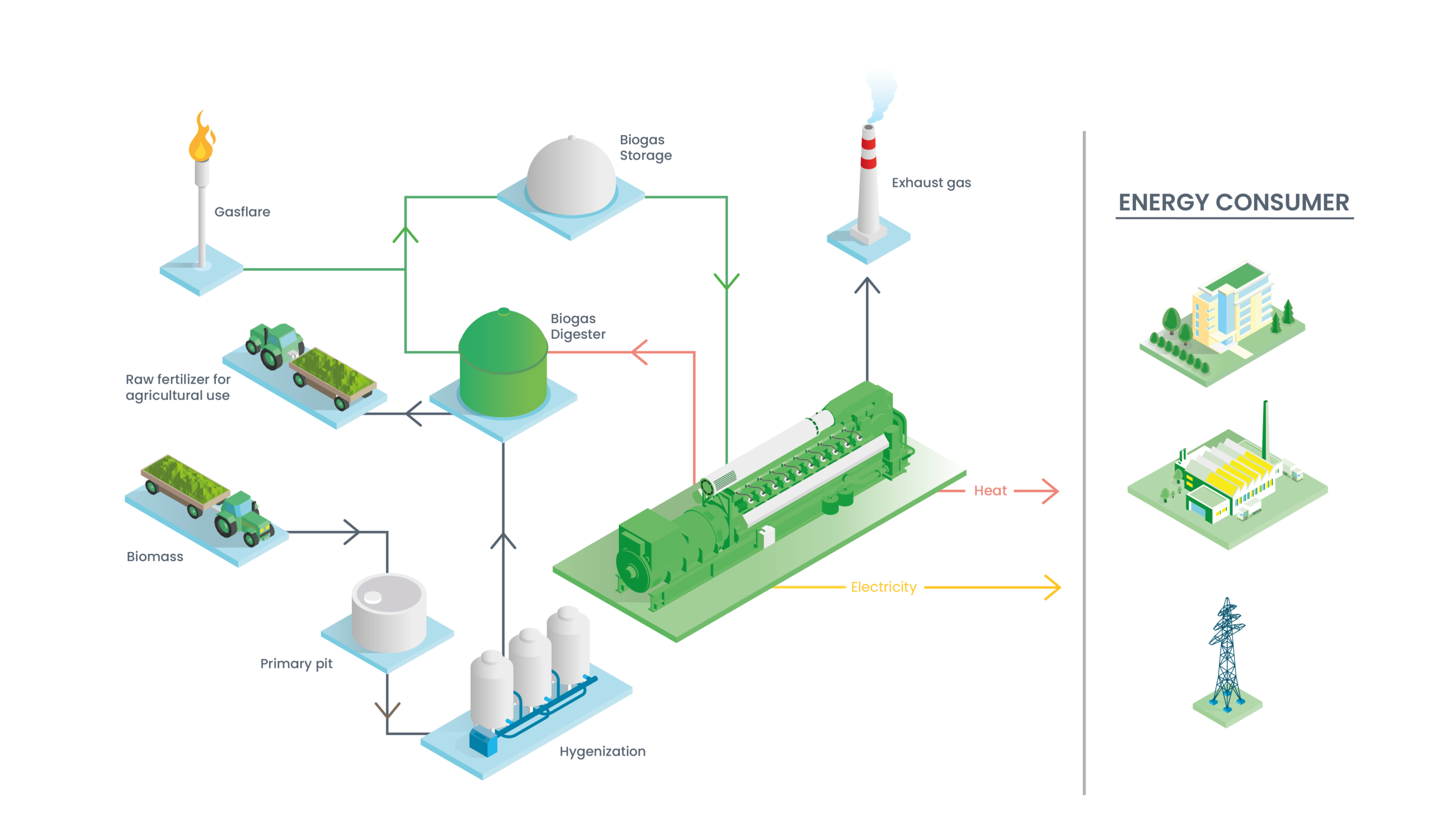

The transformation process begins when organic materials—ranging from food scraps and agricultural residues to animal manure and sewage—are collected and fed into a sealed digester tank. Within this oxygen-free environment, specialized bacteria break down these materials through a process called anaerobic digestion. This biological process naturally occurs in environments like swamps and landfills, but biogas generators optimize and accelerate it under controlled conditions.

As the bacteria decompose the organic matter, they release a gas mixture primarily composed of methane (CH₄) and carbon dioxide (CO₂), along with smaller amounts of other gases. This biogas is captured, typically stored, and then can be used directly for cooking or heating, or further processed to generate electricity through specialized engines paired with alternators. HomeBiogas has pioneered systems that make this process accessible even for individual households, allowing more people to participate in this sustainable energy revolution.

The Environmental Impact of Traditional Waste Management

Conventional waste management methods come with significant environmental costs. When organic materials decompose in landfills, they release methane directly into the atmosphere—a greenhouse gas approximately 25 times more potent than carbon dioxide in terms of global warming potential. Meanwhile, the energy potential of these materials is completely wasted. Sewage treatment facilities consume substantial amounts of energy to process waste, creating a net energy loss rather than gain.

Main Components of a Biogas System

A complete biogas system consists of several key components working together. The digester tank forms the heart of the system—an airtight container where the anaerobic digestion occurs. This is complemented by a feeding mechanism for introducing organic matter, gas collection and storage systems to capture and hold the biogas until needed, and gas utilization equipment such as stoves, heaters, or generators. More sophisticated systems include gas purification units to remove impurities like hydrogen sulfide and moisture, maximizing efficiency and extending the life of downstream equipment.

“Biogas Generator Sets | Energy …” from www.jenbacher.com and used with no modifications.

How Biogas Generators Actually Work

The functionality of biogas generators relies on carefully orchestrated biological processes combined with mechanical systems. Understanding this workflow helps appreciate how these systems effectively convert what was once considered waste into valuable energy resources that can power homes, farms, and even entire communities.

The Science of Anaerobic Digestion

Anaerobic digestion unfolds through four distinct biological phases, each carried out by different groups of microorganisms working in harmony. The process begins with hydrolysis, where complex organic compounds are broken down into simpler molecules like sugars and amino acids. Next comes acidogenesis, converting these simpler molecules into volatile fatty acids, alcohols, carbon dioxide, and hydrogen. The third phase, acetogenesis, transforms these products into acetic acid, carbon dioxide, and hydrogen. Finally, methanogenesis occurs when methanogenic archaea convert these compounds into methane and carbon dioxide—the primary components of biogas.

From Waste to Watts: The Energy Conversion Process

Once biogas is produced, it must be converted into usable energy forms. The simplest application is direct combustion for cooking or heating, which requires minimal processing. For electricity generation, the biogas flows into specially designed engines that drive electrical generators. These engines are typically modified natural gas engines or purpose-built biogas engines that can handle the specific composition of biogas. The efficiency of this conversion typically ranges from 25% to 40%, with waste heat often captured for additional applications in more sophisticated systems.

Modern biogas systems often incorporate combined heat and power (CHP) units that maximize overall efficiency by utilizing both the electrical output and the thermal energy produced during generation. This approach can achieve total system efficiencies of up to 80-90%, making biogas one of the most efficient renewable energy technologies available when properly implemented.

Types of Waste That Make the Best Biogas

Not all organic materials are created equal when it comes to biogas production potential. Animal manures provide excellent feedstock due to their high bacterial content and consistent composition, with cow and pig manure being particularly effective. But gas yields are low. Food waste delivers impressive gas yields, especially from fats and oils, which can produce up to five times more biogas than typical vegetable matter. Agricultural residues like crop stalks and processing byproducts work well when combined with more nitrogen-rich materials to achieve the optimal carbon-to-nitrogen ratio.

Wastewater sludge from sewage treatment facilities contains concentrated organic material that produces consistent biogas yields, making it ideal for municipal applications. Yield can be improved by pre-treatment of the sludge to break down the tough cell walls in much of this feedstock. Dedicated energy crops such as corn silage or high-growth-rate grasses can be grown specifically for biogas production in larger operations, though this approach raises questions about land use priorities that must be carefully considered.

Biogas plant developers would soon become unpopular throughout the world if they were to grow energy crops instead of food.

Biogas Composition and Energy Content

The composition of biogas directly affects its energy value and potential applications. Typically, biogas contains 50-70% methane, 30-40% carbon dioxide, and trace amounts of other gases, including hydrogen sulfide, nitrogen, and water vapour. The methane component determines its energy content, with higher methane concentrations yielding greater energy value. Raw biogas has a lower heating value of approximately 18-26 MJ/m³, compared to natural gas at about 36 MJ/m³.

For advanced applications like vehicle fuel or grid injection, biogas must be upgraded to biomethane by removing carbon dioxide and other impurities, increasing the methane concentration to over 95%. This purification process, while adding cost, dramatically expands the potential applications and value of the gas produced.

5 Major Benefits of Biogas Generation

Biogas systems deliver multiple overlapping benefits that extend well beyond simple energy production. This multi-benefit approach explains why the technology continues to gain traction across diverse applications from household systems to industrial-scale operations around the world.

1. Renewable Energy Production

Unlike fossil fuels, which deplete finite resources, biogas represents a truly renewable energy source that can be produced indefinitely as long as organic waste is available. This continuous production capability makes biogas a reliable energy option that can contribute to energy security while reducing dependence on imported or fossil-based fuels. The energy produced can be stored and used on demand, addressing one of the key challenges associated with intermittent renewable sources like solar or wind.

The flexibility of biogas is particularly valuable – it can be used for cooking, heating, electricity generation, or even purified for use as vehicle fuel or natural gas grid injection. This versatility allows biogas systems to be customized to meet specific local needs and integrate with existing infrastructure.

2. Waste Management Solutions

Biogas technology transforms waste management from a cost center into a value-generating opportunity. By diverting organic materials from landfills or wastewater treatment facilities, biogas systems significantly reduce waste volumes while capturing valuable resources. This approach aligns perfectly with circular economy principles, where “waste” becomes simply another resource input.

The process stabilizes and reduces the volume of organic waste, making any remaining material easier and less expensive to handle. For farms dealing with large volumes of manure or food processors managing organic byproducts, this waste reduction benefit alone can justify biogas system implementation.

3. Reduced Greenhouse Gas Emissions

The climate benefits of biogas systems are substantial and multifaceted. By capturing methane that would otherwise be released during natural decomposition, these systems prevent a potent greenhouse gas from entering the atmosphere. When this captured biogas displaces fossil fuels, a second layer of emissions reduction occurs. Together, these effects can reduce greenhouse gas emissions by up to 85-90% compared to conventional waste management and energy generation methods.

Properly managed biogas systems can actually become carbon-negative, meaning they remove more greenhouse gases from the atmosphere than they emit throughout their lifecycle. This exceptional environmental performance makes biogas technology one of the most effective climate mitigation strategies available today.

4. Production of Natural Fertilizer

The often-overlooked byproduct of biogas production – digestate – represents a valuable resource in its own right. This nutrient-rich material makes an excellent natural fertilizer that can replace synthetic alternatives. The digestion process breaks down complex organic compounds into forms more readily available to plants while preserving key nutrients like nitrogen, phosphorus, and potassium. Learn more about dry anaerobic digestion plants and their role in sustainable agriculture.

“Canadian Digestate Management Guide …” from biogasassociation.ca and used with no modifications.

Unlike raw manure or compost, digestate typically contains fewer weed seeds and pathogens due to the anaerobic treatment process. Its improved consistency and reduced odor make application easier and more neighbor-friendly. For agricultural operations, this closed-loop system where waste becomes fuel and then returns to the land as fertilizer represents a model of sustainable resource management.

5. Energy Independence and Cost Savings

Biogas systems create opportunities for energy self-sufficiency at scales ranging from individual households to entire communities. By generating energy on-site from locally available waste materials, users can insulate themselves from energy price volatility and supply disruptions. The economic value of this energy production typically increases over time as conventional energy costs rise.

For commercial operations, the financial benefits extend beyond direct energy savings to include reduced waste disposal costs, potential carbon credits or renewable energy certificates, and fertilizer production value. When all these benefits are properly accounted for, many biogas systems deliver attractive returns on investment with payback periods of 3-7 years depending on scale and local conditions.

Different Types of Biogas Systems for Various Needs

Biogas technology has evolved to address diverse applications across multiple scales. From backyard digesters processing household food scraps to industrial facilities handling thousands of tons of organic waste daily, the underlying biological principles remain similar while the engineering approaches vary considerably to meet different needs. For instance, dry anaerobic digestion plants are an example of how technology adapts to specific waste processing requirements.

The appropriate system design depends on factors including available feedstock types and quantities, desired end-uses for the biogas, climate conditions, available space, and budget constraints. Matching system type to specific requirements is essential for technical and financial success.

Small-Scale Home Digesters

“Anaerobic Digestion: What about small …” from waste-management-world.com and used with no modifications.

Home biogas systems provide an excellent starting point for households wanting to convert kitchen scraps, garden waste, and even small amounts of animal manure into usable energy. These compact systems typically process between 20-100 kg of organic waste daily, producing enough gas for 2-3 hours of cooking time. Modern home systems like those from HomeBiogas feature user-friendly designs that simplify feeding and maintenance while maximizing gas production efficiency.

The investment for residential systems generally ranges from $500 to $3,000 depending on capacity and features, making them accessible to environmentally conscious homeowners. These systems work best in moderate to warm climates but can be adapted for colder regions with proper insulation or heating provisions. The compact footprint means even suburban properties can accommodate them, typically requiring only about 2-4 square meters of outdoor space.

Farm-Based Biogas Systems

“Manure Digester Biogas | Agricultural …” from www.agmrc.org and used with no modifications.

Agricultural operations represent ideal candidates for biogas implementation due to their consistent supply of organic waste materials, particularly animal manures. Farm-scale systems typically handle daily waste volumes from 20-500 animals, producing enough energy to power farm operations and sometimes generating surplus electricity for sale to the grid. These systems often incorporate complete nutrient management solutions, capturing both the energy value and the fertilizer potential of agricultural wastes.

The economics of farm biogas systems improve with scale, with medium-sized livestock operations often achieving payback periods of 5-7 years through energy savings, waste management cost reductions, and potential revenue from energy sales. These systems help farms reduce odour issues, improve waste handling compliance, and enhance overall sustainability profiles—increasingly important in modern agricultural marketing.

Commercial and Industrial Generators

“Biogas plants utilizing food waste …” from www.host-bioenergy.com and used with no modifications.

Commercial biogas systems serve food processors, breweries, municipal facilities, and other operations generating substantial organic waste streams. These sophisticated systems can handle tons of waste daily while producing megawatt-scale electricity. They typically incorporate advanced monitoring systems, automated feeding mechanisms, and optimized biological processes to maximize gas production and system stability. For those interested in learning more about the potential of biogas, biogas sector challenges provide valuable insights.

The capital investment for commercial systems often runs into millions of dollars, but their ability to solve waste management challenges while generating renewable energy makes them increasingly attractive as environmental regulations tighten and energy costs rise. Many food processors find particular value in these systems as they can close the loop on their production cycle, turning processing byproducts into energy that powers their facilities.

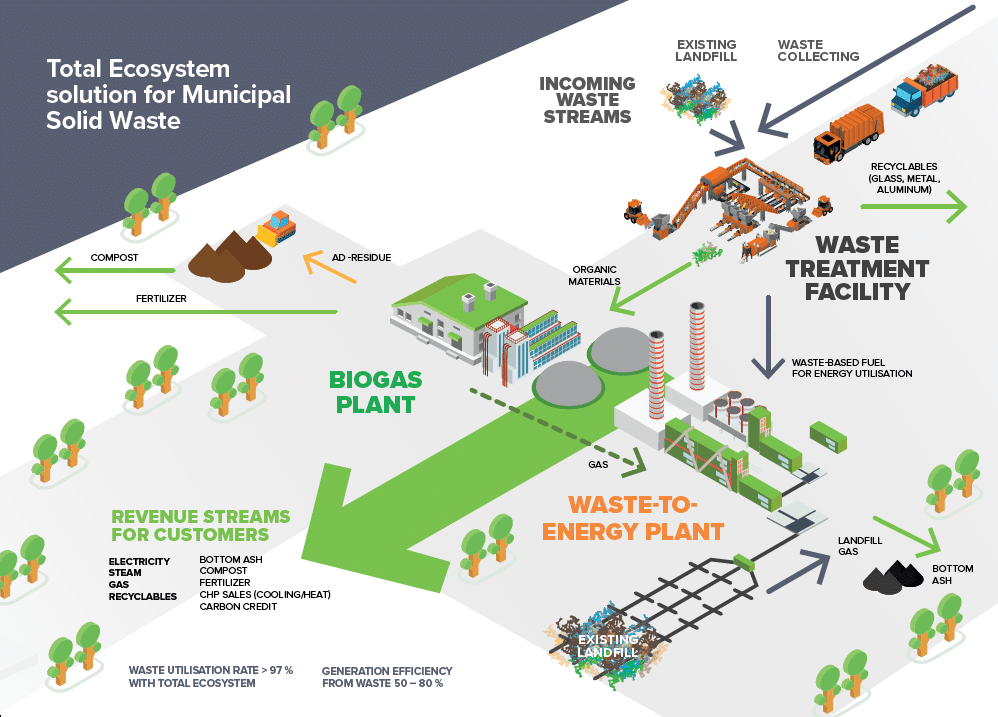

Municipal Waste-to-Energy Plants

“Energy-From-Waste | The WOIMA Ecosystem” from www.woimacorporation.com and used with no modifications.

The largest scale applications of biogas technology occur at municipal waste-to-energy facilities that process urban organic waste streams including sewage sludge and the organic fraction of municipal solid waste. These industrial-scale plants can process hundreds or thousands of tons daily, generating enough electricity to power thousands of homes. Modern facilities often combine anaerobic digestion with complementary technologies like composting to create integrated organic waste management solutions.

Beyond their environmental benefits, these facilities create local jobs and can generate revenue streams from tipping fees, energy sales, and fertilizer products. Some advanced municipal biogas plants in Europe and North America have achieved virtual zero-waste operations, where essentially all incoming organic materials are transformed into useful products including energy, fertilizers, and process water.

Setting Up Your Own Biogas System: A Practical Guide

Implementing a biogas system requires careful planning and consideration of multiple factors to ensure optimal performance and return on investment. Whether you're considering a small home system or a larger commercial installation, following a structured approach will help maximize your success and minimize potential challenges.

Assessing Your Waste Resources

The foundation of any successful biogas project begins with understanding your available feedstock. Conduct a thorough audit of the organic materials you can consistently access, noting both quantities and characteristics. Kitchen scraps, garden waste, and animal manures work well for home systems, while farms might focus on livestock waste and crop residues. Food processing operations should evaluate production byproducts and expired inventory.

Beyond quantity, consider the quality aspects that affect biogas potential. Materials high in fats, oils, and proteins generally produce more methane than fibrous plant materials. The moisture content, seasonal availability patterns, and any potential contaminants should also be documented. This comprehensive feedstock assessment allows you to accurately size your system and establish realistic performance expectations.

Choosing the Right System Size

Sizing a biogas system involves balancing your waste volume, energy needs, available space, and budget considerations. A common mistake is oversizing based on optimistic waste estimates or energy requirements, resulting in underutilized capacity and diminished returns. Conversely, an undersized system may become overloaded or fail to meet energy production goals.

As a general guideline, home systems processing 5-10 kg of kitchen waste daily can produce 1-2 hours of cooking gas, while systems handling 50 kg might generate enough gas for cooking, water heating, and some lighting needs. For farm or commercial applications, detailed engineering calculations based on specific waste characteristics and energy requirements should guide system sizing decisions. Consider starting with a modular design that allows for future expansion as you gain experience and confidence in the technology.

Essential Components You'll Need

A complete biogas system requires several core components working in harmony. The digester tank forms the heart of the system and should be sized according to your daily feedstock volume multiplied by the desired retention time (typically 20-40 days). This tank must be airtight, corrosion-resistant, and designed to maintain optimal temperature conditions.

Additional essential elements include a reliable feeding mechanism, gas collection and storage system, pressure regulation devices, moisture traps, and appropriate end-use equipment such as modified stoves, heaters, or generators. Larger systems benefit from automated monitoring systems that track parameters like temperature, pH, gas production rates, and pressure. Safety features including pressure relief valves, flame arrestors, and gas detectors are critical for all installations regardless of size. For a deeper understanding, you can explore this guide to gas generators.

Safety Considerations for Biogas Operation

Biogas contains methane which is both flammable and an asphyxiant in confined spaces, requiring careful attention to safety. All systems should incorporate flame arrestors to prevent flashback, pressure relief valves to prevent over-pressurization, and appropriate ventilation where gas is used. Electrical components must be properly rated for use in potentially explosive atmospheres, particularly in larger installations.

Operating procedures should include regular leak checks using soapy water or electronic detectors, clear protocols for system maintenance, and emergency response plans. Larger installations should implement formal safety training programs for all personnel involved with system operation. While properly designed and maintained biogas systems pose minimal risk, respect for the flammable nature of biogas must inform all aspects of system design and operation.

Maintenance Requirements and Schedule

Consistent maintenance ensures optimal performance and longevity of biogas systems. Daily tasks for all systems include proper feeding with appropriate materials, monitoring gas production levels, and basic operational checks. Weekly activities should include inspecting pipes and connections for leaks, checking pressure levels, and removing any accumulated condensate from gas lines.

Monthly maintenance typically involves checking pH levels in the digester, inspecting valves and safety devices, and cleaning gas filters. Annually, plan for more thorough inspections of all components, calibration of monitoring instruments, and potential removal of accumulated sediment from the digester bottom. Establishing a maintenance logbook helps track system performance over time, identify potential issues before they become problems, and optimize operational parameters for maximum efficiency.

Real Success Stories: Biogas in Action

Examining successful implementations provides valuable insights into the practical benefits and operational realities of biogas systems. These case studies demonstrate how diverse organizations have leveraged this technology to address specific challenges while creating environmental and economic value.

How Fair Oaks Dairy Cuts Diesel Use by 1.5 Million Gallons

Fair Oaks Farms in Indiana transformed their waste management approach with one of North America's most innovative biogas operations. By processing manure from 36,000 dairy cows through a series of anaerobic digesters, the farm produces enough renewable natural gas (RNG) to displace approximately 1.5 million gallons of diesel fuel annually. This purified biogas powers a fleet of milk delivery trucks that travel to processing facilities and retail distribution centers.

Beyond the impressive fuel savings, the system reduces greenhouse gas emissions by over 19,000 tons of CO₂ equivalent per year, nearly eliminates manure odor issues, and produces high-quality fertilizer that the farm applies to its fields. The project's success has made Fair Oaks a destination for educational tours, demonstrating how modern agriculture can implement circular economy principles while enhancing profitability and sustainability.

Community Biogas Projects Transforming Villages

In rural communities across developing nations, village-scale biogas projects have created remarkable transformations in energy access and waste management. In India, the village of Chhotkei implemented a system processing agricultural residues and cow manure to power micro-grids serving over 140 households previously lacking reliable electricity. The project provides lighting, phone charging, and energy for small businesses while reducing the health impacts of traditional biomass cooking fires.

Similar community-scale biogas initiatives in Ghana, Nepal, and Bangladesh have dramatically improved quality of life through clean cooking fuel, reliable electricity for basic needs, and the associated health and economic benefits. These projects often incorporate cooperative management structures that build community capacity while ensuring equitable distribution of benefits. The social impact extends beyond energy to include improved sanitation, reduced indoor air pollution, and enhanced economic opportunities, particularly for women who traditionally spend significant time collecting cooking fuel.

From Food Waste to Power: Restaurant Chain Case Study

A regional restaurant chain with 12 locations implemented an innovative centralized biogas system to process food waste from all its establishments. The system, located at their distribution center, converts approximately 2 tons of food waste daily into biogas that powers a combined heat and power unit. This generates electricity for the distribution center while providing thermal energy for water heating and warehouse climate control.

The project achieved a 4.5-year payback period through combined savings in waste disposal fees, energy costs, and hot water production. Additional benefits included significant reduction in the chain's carbon footprint, positive publicity that attracted environmentally conscious customers, and improved staff engagement through participation in the company's sustainability initiatives. The success of this implementation demonstrates how food service operations can close the loop on organic waste while creating multiple streams of value.

Common Challenges and How to Overcome Them

While biogas systems offer compelling benefits, they also present operational challenges that must be addressed for successful implementation. Understanding these common issues and their solutions helps ensure your biogas project delivers its full potential.

Temperature Control Issues

Maintaining optimal temperature ranges represents one of the most common challenges in biogas operation. The microorganisms responsible for biogas production work most efficiently in either mesophilic (95-105°F/35-41°C) or thermophilic (125-135°F/52-57°C) temperature ranges. In colder climates or seasons, digesters may require insulation, greenhouse-style enclosures, or active heating systems to maintain productive conditions. Some systems recirculate a portion of the biogas to heat the digester, creating a self-sustaining process once initial operation is established.

Dealing with Varying Waste Composition

Inconsistent feedstock characteristics can disrupt the biological processes in anaerobic digesters, leading to reduced gas production or even system failure. The microorganisms adapt to specific input materials, and sudden changes in composition or feeding rates can shock the system. Establishing a feeding regimen that gradually introduces new materials while maintaining a base of consistent inputs helps preserve microbial stability.

For systems processing diverse waste streams, implementing a pre-mixing tank allows for blending different materials to achieve more consistent composition before introduction to the main digester. Monitoring indicators like pH and gas production helps identify potential issues early, allowing for adjustments before significant problems develop. Some larger operations benefit from laboratory analysis of feedstock to optimize mixing ratios for maximum methane production.

Biogas Storage Solutions

Matching biogas production with utilization patterns presents challenges since generation typically occurs continuously while usage often follows daily patterns. Effective storage solutions bridge this gap, allowing accumulated gas to be available when needed. Options range from simple flexible membranes that expand and contract with gas volume to more sophisticated high-pressure storage systems for applications requiring concentrated energy delivery. For more insights on biogas, check out the Northern Ireland biogas moment.

Overcoming Seasonal Performance Fluctuations

Many biogas operations experience seasonal variations in both feedstock availability and system performance. Agricultural operations may have harvest-related surges in crop residues, while temperature fluctuations affect digestion efficiency throughout the year. Developing seasonal feeding strategies that adjust inputs based on availability while maintaining consistent organic loading rates helps maintain stability.

Implementing co-digestion approaches, where multiple feedstock types are combined to balance characteristics and availability patterns, provides another effective strategy for smoothing seasonal variations. Some operations incorporate feedstock preservation methods such as ensiling crop residues to extend availability beyond harvest periods. System design should account for these seasonal patterns, potentially incorporating flexible capacity or modular components that can be adjusted to match changing conditions.

The Future of Biogas Technology

The biogas sector continues to evolve rapidly, with emerging innovations expanding both the efficiency and application scope of this versatile technology. From enhanced biological processes to sophisticated digital integration, these developments are positioning biogas to play an increasingly significant role in our future energy landscape.

Integration with Smart Energy Grids

Modern biogas systems are increasingly designed to interface with smart energy infrastructure, allowing for optimized production and utilization patterns. Unlike intermittent renewable sources such as solar or wind, biogas can be produced and stored for on-demand use, making it valuable for grid balancing applications. Advanced systems incorporate real-time monitoring and automated controls that adjust production or utilization based on grid conditions, energy prices, or integrated renewable generation from other sources.

This intelligent integration enables biogas facilities to participate in demand response programs or energy markets, potentially generating additional revenue streams beyond basic energy production. Some cutting-edge installations combine biogas with hydrogen production capabilities, using excess renewable electricity to produce hydrogen that enhances the methane content of biogas through biological or catalytic processes. These hybrid approaches maximize the flexibility and value of biogas within increasingly complex energy ecosystems.

Advancements in Biogas Purification

Significant technological progress continues in the field of biogas upgrading, where raw biogas is refined into biomethane with natural gas equivalent properties. Newer purification methods deliver higher efficiency while reducing both capital and operational costs, making biomethane increasingly competitive with conventional natural gas. These advances expand market opportunities by enabling biogas to serve applications requiring higher purity, including vehicle fuel and natural gas grid injection.

- Membrane separation technologies using advanced materials that selectively filter gas components

- Cryogenic upgrading processes that separate gases through controlled cooling and phase changes

- Biological upgrading methods where specialized microorganisms convert CO₂ and hydrogen into additional methane

- Water scrubbing systems with enhanced efficiency and reduced water consumption

- Pressure swing adsorption technologies with improved energy efficiency and methane recovery rates

These purification technologies not only improve the energy value of biogas but also create opportunities for carbon capture and utilization, where separated CO₂ can be used in industrial applications or sequestered. This dual benefit enhances the climate mitigation potential of biogas systems beyond their already substantial contribution.

The continuing reduction in purification costs is gradually opening biomethane markets to smaller producers, allowing more distributed biogas operations to access premium energy markets previously viable only for larger installations.

Emerging Uses for Biogas Beyond Electricity

While electricity generation remains a common application for biogas, innovative new use cases are expanding its potential impact. The transportation sector represents a rapidly growing market, with biomethane increasingly used as compressed natural gas (CNG) or liquefied natural gas (LNG) for vehicles ranging from passenger cars to heavy-duty trucks. This application offers particularly compelling climate benefits when replacing diesel in commercial fleets or agricultural equipment, reducing both carbon emissions and particulate pollution.

Taking Action: Next Steps for Biogas Adoption

Whether you're considering biogas for your home, farm, business, or community, the path to implementation follows similar principles. Begin by assessing your specific waste streams, energy needs, and available resources. Research applicable technologies and system designs that match your scale and objectives, remembering that many successful implementations start modestly and expand as experience grows. Connect with existing biogas operators in similar contexts who can provide practical insights beyond what's available in technical literature.

Explore available incentives, grants, or financing options specific to your region, as these can significantly improve project economics. Many areas offer renewable energy credits, carbon offset programs, or specialized funding for agricultural or waste management improvements that biogas systems can qualify for. Consider partnering with experienced system designers or consultants for initial planning, but aim to develop in-house expertise for long-term operation. Remember that successful biogas implementation is as much about consistent operation and maintenance as it is about initial system design—commit to developing the routines and skills necessary for long-term success. Through thoughtful planning and dedicated operation, your biogas system can deliver substantial environmental and economic benefits for years to come. HomeBiogas can help you take the first step toward sustainable waste-to-energy conversion with solutions designed for various scales and applications.

Frequently Asked Questions

As biogas technology enters the mainstream, potential adopters frequently raise similar questions about practical implementation aspects. These common queries reflect the considerations most relevant to successful system selection and operation.

Understanding these fundamentals helps establish realistic expectations and informs better decision-making throughout the biogas adoption process. The answers provided here represent general guidelines that may require adjustment based on your specific circumstances and local conditions.

How much organic waste is needed to power a home with biogas?

A typical household requiring gas for cooking needs approximately 2-3 cubic meters of biogas daily, which can be produced from 5-10 kg of food waste or 20-25 kg of animal manure. This amount provides enough energy for 3-4 hours of cooking on a standard biogas stove. For broader energy needs including some electricity generation, the requirement increases substantially—a household seeking modest electrical self-sufficiency might need 8-12 cubic meters of biogas daily, requiring 20-40 kg of mixed organic waste.

The exact quantities depend significantly on the specific waste materials available, as high-energy food waste produces considerably more biogas per kilogram than fibrous plant materials. Climate factors also influence production efficiency, with warmer conditions generally yielding faster and more complete digestion. Most home systems incorporate some storage capacity to balance daily production with usage patterns.

For practical planning purposes, a family of four typically generates enough kitchen waste to produce cooking gas for 1-2 hours daily, meaning supplemental feedstocks like garden waste or small animal manures may be necessary to achieve full cooking self-sufficiency. Adding just two to four farm animals (goats, pigs, etc.) generally provides sufficient additional material to meet complete cooking needs.

What's the typical payback period for a biogas generator investment?

Payback periods vary widely based on system scale, local energy costs, available feedstocks, and applicable incentives. Small household systems typically achieve financial breakeven in 3-5 years when replacing purchased cooking fuel, faster in areas with high energy prices or where organic waste disposal carries significant costs. Farm-scale systems often see payback within 4-7 years, particularly when they capture multiple value streams including electricity generation, heat utilization, waste management cost reduction, and fertilizer production.

Can biogas systems operate in cold climates?

Yes, biogas systems can function effectively in cold regions, though they require specific design adaptations. In colder climates, digesters need proper insulation and often incorporate heating systems that use a portion of the biogas produced or integrate with other heat sources. Underground installation provides natural insulation, while greenhouse-style enclosures create solar heating benefits. Some cold-climate designs employ heat exchangers to warm incoming feedstock and maintain optimal internal temperatures despite external conditions.

Is biogas production smell-free or does it create odors?

Properly designed and operated biogas systems actually reduce odors compared to conventional organic waste management. The sealed anaerobic digestion process contains odors that would normally be released during decomposition in open air. When feeding or maintaining the system, some temporary odors may occur, but these are typically less intense than those from traditional composting or waste storage. The digestate produced as a byproduct has significantly less odor than raw organic waste, making land application as fertilizer much more neighbor-friendly than spreading untreated manure. For more insights, check out this fact sheet on biogas by the Environmental and Energy Study Institute.

How does biogas compare to natural gas in terms of energy output?

Raw biogas contains approximately 50-70% methane, giving it about 60% of the energy content of natural gas, which typically contains 90%+ methane. In practical terms, one cubic meter of biogas provides roughly 6-6.5 kWh of energy compared to natural gas at 10-11 kWh per cubic meter. This lower energy density means biogas requires larger storage volumes and slightly modified equipment for equivalent performance.

When biogas undergoes purification to biomethane (removing CO₂ and trace compounds), its energy content becomes nearly identical to natural gas, allowing direct substitution in all applications. This upgraded biomethane can be used in any natural gas appliance without modification, injected into natural gas grids, or used as vehicle fuel with the same performance characteristics as conventional natural gas. For those interested in the broader implications, the biogas sector challenges offer further insights into the potential of this renewable energy source.

For most small to medium applications, the slightly lower energy density of raw biogas is easily accommodated with minor equipment adjustments, while still delivering significant environmental and economic benefits compared to fossil alternatives. HomeBiogas continues to lead innovation in making these systems more accessible to homes and communities worldwide, helping transform waste challenges into energy opportunities.