In this article, we look at how Veolia and anaerobic digestion (AD) are progressing together, as an example of how one global waste company is building their investment in biogas technology as it embraces circularity across the business. This post is a compilation of our research, based upon the information provided by the company across the web.

On This Page:

- Anaerobic digestion in Veolia

- AD: why and for whom?

- What does AD mean to Veolia?

- Examples of Veolia's Research on Biogas and Biomass

- AD Offers a Solution For Food Waste

- Just how is Veolia reducing food going to waste?

- How the City of Toronto uses AD

- Organic waste recovery challenge

- Dedicated solutions for organic waste recovery

- AD wet or dry

- Transforming Wastewater to Green Energy.

- AD of Wastewater

- Increase in biogas production

- Other Waste Streams to Energy

- Concluding Embracing Circularity at Veolia

Anaerobic Digestion in Veolia

Biogas is a valuable renewable energy source. Anaerobic purification of industrial wastewater, anaerobic digestion (AD) of sewage sludge and other organic waste (biowaste), and fermentation of organic material in covered landfills all contribute to its production. After that, biogas can be converted into electricity, heat, or biomethane.

Veolia is a global leader in the recovery of organic materials. They assist municipalities in efficiently and effectively processing food-waste and converting these materials into renewable energy and valuable soil products for agricultural and other land-based applications. Veolia operates 126 AD and composting facilities in seven countries, processing over 3 million tonnes of materials annually, producing over 1.0 million tonnes of fertiliser, and generating over 44,000 MWh of electricity.

Veolia owns and operates landfills. These generate a lot of biogas. This biogas, produced by the digestion of biowaste in the absence of oxygen (AD), is composed primarily of methane (65% – 7%) and CO2. It is a renewable energy source that can be captured and recovered as electricity, heat for district heating networks or biofuel.

Veolia invests heavily in landfill gas collection and extraction systems, which deliver the landfill gas (biogas) to energy from waste (EfW) plants most of which generate electricity. Increasing numbers of their EfW plants now go one step further to purify (upgrade) the raw biogas to become very nearly pure methane, known as biomethane. Biomethane has advantages over direct electricity generation both financially and for the planet.

AD: Why and for Whom?

Veolia believes that biological waste treatment – through the management of aerobic composting units and anaerobic centres – will prove to be the best approach for these materials over time. The use of biological methods replaces essential nutrients in the soil for the good of future generations.

With over 100 composting units around the world, Veolia helps to revitalise soil with composts and organic fertilisers while also recovering energy through a biological waste treatment infrastructure that includes both aerobic composting and AD suitable for efficient and sustainable waste disposal.

This viewpoint is based on the fact that:

- the level of sophistication of the technology in these sectors is rising and

- there are many more examples of proven performance in advanced economies around the world, according to a report.

The Australian National Waste report 2018 showed that the policy is consistently working as landfill gas, processed engineered fuels, and AD is still the most common form of renewable energy recovery in Australia after ten years.

Biogas is a valuable renewable energy source. It is created by the company through the:

- anaerobic purification of commercial and industrial waste

- as a by-product of wastewater treatment in the AD of sewage sludge and other biowaste, and

- by fermentation of the biowaste in landfills that are covered. After production in an anaerobic digester, biogas is converted into electricity, heat, or biomethane.

What does AD mean to Veolia?

For Veolia Anaerobic Digestion is an area as a waste management company that, with a massive and guaranteed in-house organic materials supply, can research and implement new energy technologies to maintain its leading position in municipal waste. At the same time, the company can build and maintain a technical lead, ultimately to the benefit of national and international targets for:

- Net Zero global carbon emissions by 2050

- Efficiency in raw materials use, and

- Eliminating waste by implementing the “circular economy” in which the great majority of waste materials collected will be avoided, minimized, reused, recycled or, if that's not possible, used as a renewable energy source.

Examples of Veolia's Research on Biogas and Biomass

Veolia is investing in leading research in using nutrients from its own waste stream combined with sunlight to grow microalgae. The microalgae reproduce by absorbing the sunlight and CO2 from the environment or industrial processes. They will then be converted into low-carbon-intensity next-generation biofuels once they reach maturity. The focus on microalgae will eventually help Veolia North America's efforts to develop sustainable biofuel innovations like wood-to-energy biomass operations and food-to-fuel AD.

Veolia Water Technologies works with its internal technology centre, Biothane

Veolia is developing leading-edge solutions to raise the efficiency of AD processes. One recent innovation was developed by Biothane™, a wholly-owned subsidiary of Veolia that has recently made significant strides in its Asian business. Memthane™ is a low-carbon anaerobic digestion technology that allows for the efficient treatment of high-strength waste streams.

Biothane™ has been a leading brand in the field of anaerobic industrial wastewater and biogas treatment solutions for over 40 years. They cater to food and beverage, pulp and paper, biobased and chemical, and municipal markets. Their mission is to “resource the world” through the production of green energy (biogas, biomethane) and clean water.

Kruger, a subsidiary of Veolia Water Solutions & Technology (VWS), has designed a benchmark plant at Grindsted Kommune, a cooperative in a primarily agricultural area with local food processing industries. It is a Danish plant that co-digests household waste, sewage sludge, food waste, and organic industrial wastewater in order to generate biogas for power generation.

AD Offers a Solution For Food Waste

Veolia is achieving energy recovery from food waste. It uses AD as an alternative method of disposing of food waste. The process decomposes waste and converts it into biogas, which can then be used to generate green energy for electricity or heat.

Because the power generated can be used on-site or fed back into the grid, AD can contribute to a circular solution.

They are a Valorgas partner in research. The addition of sewage sludge digestate as a co-substrate with food waste has provided the company with a novel and effective solution to better biogas yields.

For example, Veolia is using the AD process to treat segregated domestic food waste while avoiding ammonia inhibition problems (side-stream stripping). It is also involved in research on making compostable bioplastics from residual municipal solid waste.

Ref: Banks, C. , and Rintala, J. , 2014. AD of autoclaved and untreated food waste. Waste Manag, 34 (2),. 370-377. 27. Valorgas, 2013. Technical solutions to allow digesters operating on high. Nitrogen food waste to achieve the maximum energy yield.

Just how is Veolia reducing food going to waste?

Veolia provides curbside food waste collections for municipalities and for businesses. It applies sustainable and circular solutions to process and disposes responsibly of all the food waste collected.

They explain to their customers that by segregating their food waste, they can help them reduce the environmental impact of their businesses and meet their sustainability targets.

To quote Veolia:

“It’s better for the environment, simple to do and doesn’t cost the earth. First, we’ll perform a waste audit to assess your needs and the space you have available at your premises.”

As a result, existing plants dedicated to the treatment of wastewaters, animal manures, or food wastes are being transformed into specialised centres for the production of bio-energy and green chemicals. They are achieving this in a UK industry subject to unreliable government support with high installation costs, wide feedstock dispersion, and market distortions..

How is biogas used?

In a hot-off-the-press announcement a few days before we wrote this post, Veolia provided details of the future it sees for its biogas use. Read on to find out more:

TotalEnergies and Veolia Join Forces to Accelerate Biomethane Development

TotalEnergies™ and Veolia™ announced in February 2022 that they had signed an agreement to produce biomethane from Veolia waste and water treatment facilities in more than 15 countries.

The partners plan to develop and co-invest in a portfolio of international projects that will produce up to 1.5 terawatt-hours (TWh) of biomethane per year by 2025. This renewable gas production from biowaste will be equivalent to the average annual natural gas consumption of 500,000 residents, saving approximately 200,000 tonnes of CO2 per year. TotalEnergies will market the resulting biomethane as a renewable fuel for mobility or as a natural gas substitute in other applications.

The partners will pool their industrial know-how in biomethane production as part of this agreement. Veolia will contribute its expertise in the production and processing of biogas from its facilities, while Totalenergies will contribute its comprehensive understanding of the entire biomethane value chain.

Totalenergies™ added that the resulting biomethane would be marketed as a renewable fuel for mobility or as a substitute for natural gas in other applications. They also said that:

“Anaerobic treatment is a tried-and-true, low-energy method of treating industrial wastewater.”

In an oxygen-free environment, it uses anaerobic bacteria (biomass) to convert organic pollutants or COD (Chemical Oxygen Demand) into biogas.

Anaerobic microorganisms (those that thrive in oxygen-free environments) are chosen for their ability to degrade organic matter in industrial effluents, converting organic pollutants into biogas (methane + carbon dioxide) and a relatively smaller quantity of biosolids.

Estelle Brachlianoff, Veolia's chief operating officer, added;

“Our partnership with Totalenergies is in line with Veolia's strategy to develop solutions for decarbonizing the energy mix, particularly with biogas, as part of an ecological transition.”

“The biogas resources at our sites provide more than 6 TWh of primary energy on a global scale.”

La Chauvinière Sewage Sludge

From 2018, a number of innovations were implemented at La Chauvinière in order to reduce energy consumption as much as possible and become part of a circular model. Veolia built an anaerobic digestion unit at the site, which produces biogas from the La Chauvinière sewage sludge. This unit generates the same amount of biogas as the Le Mans bus network.

How the City of Toronto uses AD

Since 2014, Veolia has collaborated with Toronto facility technology provider CCI BioEnergy Inc. to operate, manage, and maintain the City of Toronto Disco Road Organics Anaerobic Digestion Plant Organics Processing Facility.

By doing so, the company ensures that 75,000 metric tonnes, which is nearly 45% of the bin programme, including food scraps, soiled paper, disposable diapers, feminine hygiene products, and pet waste, is recycled.

BIOMET™ Sludge Co-digestion

Veolia BioMet™ is a practical, modular approach for removing or co-digesting sewage sludge, agricultural wastes, and biogas from sewage.

The system extracts the maximum amount of energy from biogas to generate power and heat while also ensuring maximum stability.

Co-digestion is the process of combining sewage wastewater and other solid wastes from the home or workplace to produce anaerobically digestible end products or biogases.

Organic waste recovery challenge

When biowaste decomposes in storage facilities or wastewater treatment plants, it emits biogas, which operators capture for sustainable energy recovery. The biowaste recovery challenge is for the global community to develop this technology and achieve a high level of organic waste recovery. This in turn will reduce methane emissions and start to slow down climate change.

Veolia is a major producer of biogas, which is now mostly recovered as electricity. The challenge is to maximise its conversion into biomethane in order to meet a demand from municipal and industrial customers to reduce their carbon footprint.

Clients who have been helped with their waste recovery by Veolia are already expressing heartfelt gratitude to the Veolia group for its belief in and commitment to assisting its partners in addressing climate change. These clients appreciate that it is the most serious challenge confronting our generation.

The highly innovative Wagabox project reflects French industrial excellence in gas engineering as well as that country's pioneering role in waste processing and recovery.

A new AD plant will be operational in February 2022, producing biomethane from waste and supplying renewable gas to 20,000 homes in the Paris region. Wagabox is a game-changing technology for recovering biogas from landfilled waste. It separates methane from the other components of biogas produced by organic matter decomposition to produce biomethane.

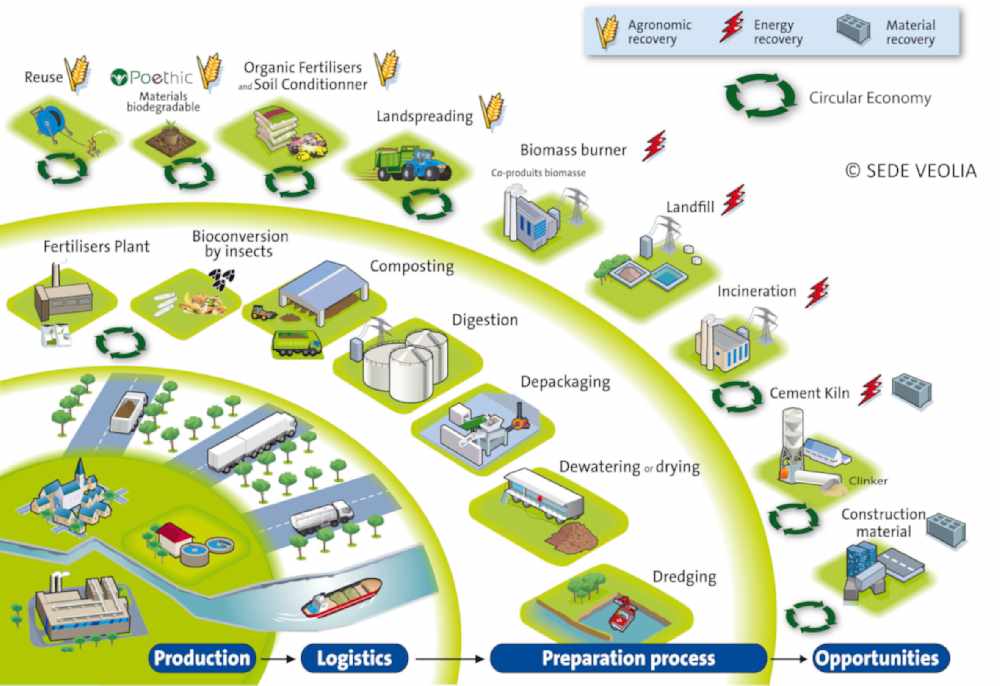

Dedicated solutions for organic waste recovery

Veolia processes waste from hazardous waste to commercial waste like fluorescent lamps and batteries.

They provide responsible waste solutions, emphasizing the recovery of products from waste to help preserve diminishing resources.

At the company, it is justifiable to say that they are more than just the world’s leading provider of environmental solutions. They are also dedicated to customized, cost-effective solutions that reflect best practices, environmental protection and a better quality of life.

AD Wet or Dry

Some service providers like Veolia provide their own batch process dry-AD systems for solids machine handled materials. However, European biogas companies also offer fully mixed and stirred (CSTR) “wet process” AD technologies for the higher water content organic feedstocks.

The size of these biogas companies based in Europe ranges from having completed hundreds of AD plants to much smaller businesses with no more than a half-dozen reference AD plant projects.

The important point is the choice of either a wet or a dry process, is always to consider whether wet or dry AD is the best suited for each feedstock.

Transforming Wastewater to Green Energy.

Montpellier Agglomération (now Montpellier Méditerranée Métropole) decided in 2009, as part of its sustainable development and renewable energy policy, to initiate “a comprehensive approach to saving energy and reducing greenhouse gas emissions”.

They did this for the Maera Wastewater Treatment Plant. As a result, the city asked Veolia to recover the biogas generated by sewage waste by constructing a cogeneration plant that would generate energy in the form of electricity and heat.

Anaerobic Digestion of Wastewater

When treated anaerobically, organic material in wastewater can be used to generate energy. The produced methane-rich biogas can be used as a renewable, storable source of supplemental. power.

It can generate biosolids of Class A, which are bio-safe and can be applied to land without restriction.

Separating the acid and methane-forming phases improves digestion efficiency and effectiveness. Aeration is not required, so energy costs are low.

Increase in biogas production

The company delivers increases in biogas production year on year. Bio Thelys™, which is a company owned by Veolia, complements other Veolia sludge treatment processes like Athos™ (hydrothermal oxidation), Pyrofluid™ (incineration), BioCon™ (thermal drying), and Solia™ (solar drying) to provide even more sustainable solutions.

Bio thelys™ handles all kinds of organic, industrial or municipal sludge and can also handle grease.

Using Bio thelys™ process allows to:

- Reduce sludge volume.

- Increase biogas production.

Bio thelys™ Features and benefits

Bio thelys™ is a flexible and safe solution that produces a pasteurised digestate that is compliant with international standards.

Other Waste Streams to Energy

The enormous potential for bioenergy derived from forestry and timber, agricultural raw and residual materials, and organic waste streams available today can make a significant contribution to greenhouse gas emission reductions.

Biogas and biomethane from these sources, in particular, are essentially sustainably produced renewable natural gas from organic (residual) recyclables with significant energy potential.

SEDE's perfectly integrated waste treatment solution enables users to achieve a variety of community goals, including:

- Adapting collection logistics to meet the needs of the customer.

- Treating category 3 animal by-products, treat all bio-waste streams in collaboration with an approved partner.

- Proposing waste recovery that is both agronomic and energy-efficient.

Concluding Embracing Circularity at Veolia with AD and Biogas

The vision for the future is of Veolia serving the circular economy. Part of that will be that the company will become a significant renewable power company producing biogas from biomass and sewage farm sludges.

The energy will be produced through a large number of highly efficient anaerobic digestion and thermal recovery, facilities.

Biogas will be the main source of this energy as it is produced by the fermentation of organic substances of animal and vegetal origin in absence of oxygen (anaerobic process).