High organic loading rates, acidification from shock loads, or filamentous bacteria are the main causes of anaerobic digester foaming. It can be prevented by modifying operational parameters such as feed rate and temperature, mechanically breaking foam, and carefully adding anti-foam agents, which must be chosen to prevent damage to the digestate.

The key is prevention, which includes cautious substrate management, regular monitoring, headspace-appropriate digester design, and the application of focused operating tactics.

Key Takeaways

- Anaerobic digester foaming requires three key elements: high gas production, surfactants, and floating solids—understanding this trio is essential for effective management.

- Filamentous bacteria aren't direct causes of anaerobic foaming but act as foam stabilisers that can transform minor issues into major operational problems.

- Foaming can cause heat restriction, gas collection blockage, and even solids inversion, potentially compromising the entire treatment process.

If you've ever witnessed a massive foam eruption in your anaerobic digester, you know the immediate panic it creates.

One moment, your operation is running smoothly—the next, you're dealing with foam overflowing from access points, reduced biogas production, and potential equipment damage. Understanding why this happens is the first step to solving it.

Anaerobic digester foaming isn't just an inconvenience—it's a complex issue that can severely impact operational efficiency and treatment performance. I've seen how quickly foaming problems can escalate from minor concerns to system-wide failures.

The good news is that most foaming issues can be effectively managed when you understand the underlying mechanisms and apply the right solutions.

Why Your Anaerobic Digester Produces Foam (And Why It Matters)

Foam formation in anaerobic digesters generally requires three essential elements working in concert:

- high gas production,

- surfactants that reduce surface tension, and

- floating solids that trap gas bubbles.

When these three factors align, foam doesn't just appear—it can rapidly multiply and destabilise your entire operation. The real danger comes not from the foam itself, but from its consequences that can escalate quickly:

- restricted heat transfer,

- blocked gas collection systems, and

- the notorious problem of solids inversion, where your carefully balanced digester contents become mixed up with lumps of crust.

What makes foam particularly troublesome is its self-reinforcing nature. As foam builds up, it traps more gas, which creates more foam, which traps more gas—creating a vicious cycle that can quickly spiral out of control.

Left unchecked, severe foaming can lead to reduced treatment capacity, equipment damage, and even safety hazards from pressure buildup or unexpected releases.

The financial impact shouldn't be underestimated either. When digesters foam, you face increased operational costs from cleaning, reduced biogas production, potential equipment repairs, and possibly even permit violations if untreated material escapes your system.

Understanding the mechanisms behind foaming isn't just technically important—it's economically essential.

“Biogas Plant Foam Control …” from www.picengineering.com.my and used with no modifications.

The 3 Main Causes of Anaerobic Digester Foaming

While foam might look similar regardless of its cause, effective treatment depends on identifying the specific trigger mechanism behind your foaming episode. During my research for this article, I found references to three distinct categories of causes. Unfortunately the majority of the research applies to aerobic process foaming, and each requires a different approach to resolve

To what extent these findings typically apply to anaerobic digester foaming was not clear to me during my research for this article. Be aware that the sections below may only apply to wastewater sludge anaerobic digestion treatment processes – so take care to do your own research before you act on the following.

Your feedback via the comments section below would be very welcome!

Biological Factors: Filamentous Microorganisms and Their Impact

Contrary to common belief, filamentous bacteria like Microthrix parvicella don't directly cause foaming in anaerobic conditions. Instead, they act as powerful foam stabilizers, transforming what might have been a minor foaming incident into a persistent problem.

These filamentous organisms create a structural network that traps gas bubbles and prevents them from escaping, essentially turning your digester into a biological foam factory. Learn more about the role of anaerobic digestion plants in managing these challenges.

The problem often begins upstream in your treatment process. When filament-rich activated sludge enters your digester, it brings this foaming potential with it.

Research by Westlund, Hagland, and Rothman has confirmed that Microthrix parvicella specifically can survive the transition from aerobic to anaerobic environments, continuing to impact foam stability in digesters.

Extracellular polymeric substances (EPS)—the sticky compounds produced by certain bacteria—also contribute significantly to foam stabilisation.

These substances increase viscosity and create the perfect environment for persistent foam. Addressing filamentous bacteria often requires looking at your entire treatment train rather than just the digester itself.

“How to Design for Digester “Foaming” or …” from www.linkedin.com and used with no modifications.

Operational Issues: Feeding Problems and Mixing Inefficiencies

How you operate your digester significantly impacts its tendency to foam. Irregular feeding patterns, especially slug feeding high volumes of substrate, can shock the system and trigger foaming events.

The organic loading rate (OLR) is particularly critical—studies by Ganidi, Tyrrel, and Cartmell have demonstrated that sudden increases in OLR correlate strongly with foam initiation.

Mixing problems represent another operational challenge. Insufficient mixing allows stratification and dead zones where biological activity becomes imbalanced.

Finding the right balance for your specific digester configuration is essential. For an example of innovative solutions, consider Landia's GasMix system, which has been successfully installed at many anaerobic digestion plants.

Temperature variations, particularly rapid changes, can also disrupt the delicate microbial balance in your digester. When temperature shifts stress your methanogen population, acid-forming bacteria can gain the upper hand, leading to volatile acid accumulation and subsequent foaming.

Maintaining stable, appropriate temperatures is crucial for foam prevention. For more insights, explore anaerobic digestion plants and their management techniques.

Chemical Imbalances: Surface Tension Reduction and Surfactant Buildup

At its core, foam formation requires reduced surface tension—and in anaerobic digesters, this often comes from chemical surfactants. A common natural surfactant effect may occur from acetic acid, produced during the acetogenesis phase of digestion. Acetic acid alone is not inherently a surfactant, but it can form surfactants when reacted with certain substances that may also be present in AD substrates.

So, when acetic acid levels rise too quickly for methanogens to process, surface tension drops, and foam becomes likely.

High alkalinity can paradoxically contribute to foaming as well. When operators add alkalinity to increase pH in an acidic digester, they can create a situation where methane and carbon dioxide production resume while volatile acids remain elevated—a perfect recipe for foam formation. This explains why foaming often appears immediately after pH correction efforts.

External surfactants entering your system can compound these problems. Detergents, soaps, and certain industrial chemicals dramatically reduce surface tension and create persistent foams that resist breakdown. Identifying and controlling these inputs may require investigating your collection system and industrial contributors.

Foam Formation Requirements: For problematic foam to develop in anaerobic digesters, three conditions must align simultaneously: high gas production, surfactants that lower surface tension, and floating solids that trap gas bubbles. When troubleshooting, focus on which of these factors you can most easily control in your specific situation.

“5 Anaerobic Digestion Problems to Avoid …” from anaerobic-digestion.com and used with no modifications.

How to Identify Different Types of Digester Foam

Not all foam is created equal. The appearance, persistence, and behaviour of foam can provide valuable diagnostic clues about its underlying cause. Learning to “read” your foam is an essential skill for effective troubleshooting.

Normal vs. Problematic Foam: Visual Indicators

Some foam is actually normal in a healthy anaerobic digester—a thin, light-colored layer that forms and dissipates naturally as part of the digestion process. This normal foam typically appears as a thin layer no more than a few inches thick, has large bubbles that pop easily, and doesn't persist when mixing is temporarily increased. It's essentially a visual sign that gas production is occurring as expected.

Problematic foam, by contrast, tends to be thicker, darker, and more persistent. When foam builds up to more than 1-2 feet in thickness, appears muddy or chocolate-brown in colour, or has a viscous, sticky consistency that resists breakdown, it's signalling an underlying issue.

Particularly concerning is foam that rapidly rebuilds after being broken down, as this indicates active foam production rather than just accumulated gas.

The interface between foam and liquid can also tell you a lot. A sharp, defined boundary with clear liquid underneath typically indicates chemical or surfactant issues, while a gradual, diffuse boundary with turbid liquid suggests biological factors are at play.

Take photos of your foam during different operational states to establish a visual baseline for comparison.

Early Warning Signs of Severe Foaming Events

Most catastrophic foaming episodes don't appear without warning. Vigilant operators can spot several precursors that indicate a major foaming event may be imminent. Increasing volatile acid concentrations, particularly acetic acid, often precede foaming by several days as they reduce surface tension. Regular testing of volatile acid to alkalinity ratios can provide an early alert system.

Changes in gas composition represent another critical warning sign. When the methane percentage in your biogas begins dropping while carbon dioxide rises, it suggests methanogen activity is becoming inhibited—a common precursor to foaming. Modern online gas analyzers make continuous monitoring of this parameter increasingly practical even for smaller facilities.

Operational changes often trigger foaming events, so be especially vigilant after modifications to feeding schedules, mixing patterns, or temperature setpoints. The 3-7 days following such changes are particularly high-risk periods. Implement a formal monitoring protocol during these transition periods to catch potential foaming before it becomes severe.

Monitoring Parameters: What Your Foam Is Telling You

The specific characteristics of your foam provide valuable diagnostic information about the underlying causes. Foam with entrapped solids that appears during or shortly after feeding cycles typically indicates organic overloading or inadequate mixing. If this type of foam coincides with reduced biogas production, your methanogenic bacteria are likely struggling to keep pace with acid production.

Foam with a glossy appearance or that forms rainbow-like patterns suggests surfactant involvement. This is particularly common when receiving industrial waste streams or during periods of high rainfall, when detergents from infiltration may enter your system. Testing influent for surfactants during these periods can help confirm this diagnosis.

Pay special attention to the timing of foaming events. Cyclic foaming that follows a regular pattern often correlates with operational schedules, while random, unpredictable foaming more commonly indicates variable inputs or inconsistent upstream processes. Recording foam observations in relation to operational data points can reveal these patterns and guide your troubleshooting efforts.

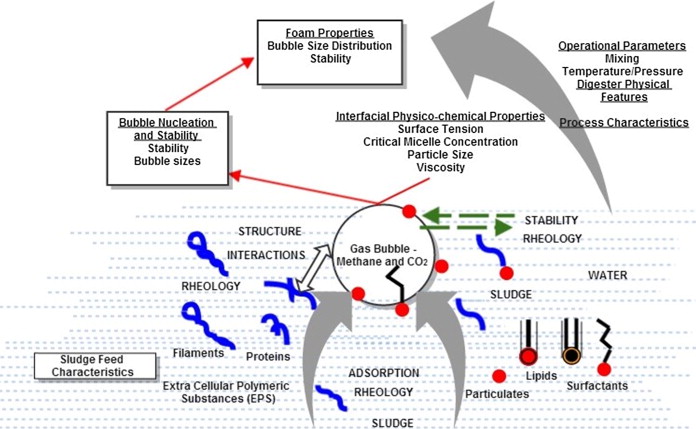

“foam formation in anaerobic digesters …” from www.sciencedirect.com and used with no modifications.

Immediate Actions to Control Active Foaming

When you're facing an active foaming crisis, you need solutions that work quickly. While addressing root causes remains essential for long-term resolution, these immediate interventions can help you regain control of an actively foaming digester before significant operational impacts occur. For more insights on this issue, consider exploring anaerobic digester foaming solutions.

1. Adjust Feeding Rates and Patterns

The first and often most effective emergency response is to modify your feeding approach. Temporarily reducing the organic loading rate by 25-50% can provide immediate relief by lowering gas production and giving your microbial population time to rebalance. Rather than eliminating feeding entirely, which can cause microbial shock, aim for smaller, more frequent feeding events that maintain biological activity without overwhelming the system.

Consider the composition of your feed as well as the quantity. If possible, temporarily divert high-strength or problematic waste streams while maintaining a base level of feeding with more stable substrates. This selective approach maintains treatment capacity while reducing foam-inducing inputs.

Implementing a gradual return to normal feeding rates is crucial once foaming subsides. A stepwise increase of 10-15% every 2-3 days allows your microbial community to adapt without triggering a recurrence of foaming. Document the feeding adjustments that successfully resolved foaming to inform your long-term operational strategy.

2. Optimise Mixing Intensity and Duration

Counter-intuitively, both insufficient and excessive mixing can contribute to foaming problems. During active foaming events, experiment with different mixing patterns to find what works for your specific situation. Intermittent mixing—shorter, less frequent mixing cycles—often proves more effective than continuous mixing during foam control efforts as it allows foam to partially collapse between cycles.

For mechanical mixers, reducing the rotational speed can help break up foam without incorporating additional air. If using gas mixing systems, consider temporarily switching to mechanical mixing if available, as recirculated gas can sometimes exacerbate foaming by introducing more bubble nucleation sites.

Strategic timing of mixing operations can also help manage foam. Mixing immediately before feeding rather than during or after feeding often reduces foam formation by creating space for incoming material and limiting gas entrapment. Document the mixing strategy that proves most effective for your specific digester configuration for future reference.

3. Apply Anti-Foaming Agents Correctly

Chemical anti-foaming agents can provide rapid relief when applied correctly, but product selection and application method significantly impact their effectiveness. Silicon-based defoamers work by destabilising foam bubbles and are most effective for surfactant-related foaming, while polyalcohol-based products typically work better for protein or filament-stabilised foams. Match your anti-foaming agent to your specific foam type for optimal results.

Anti-Foaming Agent Selection Guide: For chemically-induced foaming (glossy appearance, sharp foam-liquid interface), silicon-based defoamers typically work best. For biologically-stabilized foams (brown color, gradual boundary), polyalcohol or enzyme-based products often provide better results. Always perform jar tests with your actual digester content before full-scale application.

Application technique is just as important as product selection. Apply anti-foaming agents directly to the foam rather than to the bulk liquid whenever possible.

For severe foaming, an initial higher dosage followed by smaller maintenance doses often provides better control than consistent moderate dosing. Most anti-foaming agents work best when applied at points of high turbulence where they can disperse effectively.

“Antifoam/Defoamer – AMS …” from www.appliedmaterialsolutions.com and used with no modifications.

Be aware that excessive use of chemical defoamers can potentially impact biological activity or create other operational issues, such as scum formation. Use the minimum effective dose and monitor digester performance closely when applying these products.

Partner with your chemical supplier to determine the optimal product and dosage for your specific situation—many suppliers will conduct on-site testing to help you find the right solution.

When applying anti-foaming agents, safety must remain paramount. Ensure operators wear appropriate personal protective equipment and follow all safety protocols. Some anti-foaming products can create slippery conditions, so take precautions to prevent falls and other accidents during application activities.

4. Implement Temperature and pH Corrections

Temperature Variations with Digester Tanks

Temperature and pH imbalances often contribute to foaming events, so correcting these parameters can help resolve active foaming. For mesophilic digesters, ensure temperatures remain in the 95-100°F (35-38°C) range, as temperatures outside this window can stress methanogens and lead to acid accumulation.

Make any needed temperature adjustments gradually, ideally no faster than 1°F per day, to avoid further microbial stress. Learn more about the role of methane digesters in efficient biogas waste management.

For more insights into mixing to avoid temperature stratification, you can explore the biogas digester tank mixer used in various AD plants.

PH Correction Dosing

pH correction requires careful balance. While low pH often contributes to foaming by allowing acid accumulation, rapid alkalinity addition can trigger immediate foaming by stimulating gas production while acids remain elevated.

Add alkalinity in small, frequent doses rather than large slugs, targeting a gradual return to the optimal 7.0-7.5 pH range. Bicarbonate-based alkalinity sources typically cause less foaming than hydroxide-based alternatives.

5. Modify Gas Collection Systems

During severe foaming events, modifications to your gas handling system may be necessary to maintain operations. Installing or utilising foam traps in gas lines can prevent foam from entering and damaging gas equipment.

These devices create expansion areas where foam can collapse before reaching sensitive components like pressure regulators or gas meters.

Consider temporarily increasing headspace pressure if your system allows it. A slight increase in operating pressure can compress foam and reduce its volume, though this approach requires careful monitoring to stay within equipment design limitations.

Always consult with equipment manufacturers before adjusting operating pressures beyond normal ranges. For more information on related systems, you might be interested in Landia's GasMix system.

Long-Term Strategies to Prevent Recurring Foam Problems

While emergency measures may possibly address active foaming, preventing recurrence requires addressing root causes.

A comprehensive prevention strategy typically combines process modifications, equipment upgrades, and operational adjustments to create a resilient system that resists foaming tendencies even under variable conditions.

The most effective foam prevention approach is holistic, considering your entire treatment process rather than focusing exclusively on the digester itself. Since many foaming causes originate upstream, a system-wide perspective often reveals prevention opportunities that digester-focused approaches might miss.

Implementing these strategies requires initial investment but typically delivers substantial returns through improved reliability and reduced emergency responses.

Upstream Process Modifications for Anaerobic Treatment of Wastewater Sludge

The most effective long-term solution to digester foaming often lies in improving upstream processes when water utility companies carry out Anaerobic Treatment of Wastewater Sludge. Filamentous bacteria control in your activated sludge system can dramatically reduce foam-stabilising organisms entering your digester.

Implementing selector zones in aeration basins, maintaining appropriate dissolved oxygen levels, and ensuring proper nutrient balances during aeration can all help minimise filamentous growth upstream before it becomes a digester problem. For more information on anaerobic digestion processes, explore anaerobic digestion plants.

Pre-digestion treatments can also significantly reduce foaming potential. Thermal hydrolysis processes break down complex materials and lyse cells before they enter the digester, reducing the likelihood of rapid acid formation and subsequent foaming. While these systems require capital investment, they often pay for themselves through increased biogas production and reduced operational issues, including foaming.

Upstream Process Modifications for Industrial Wastewater Treatment

A few anaerobic digestion plants exist that treat organic industrial wastewater. They are rare, but for these plants, there may also be an upstream solution to foaming. In these circumstances, monitoring and controlling industrial contributions to your system can be another critical upstream strategy.

Implementing source control programs that limit surfactant inputs from industrial users can substantially reduce foaming risk.

Regular sampling and analysis of industrial waste streams, particularly during foaming episodes, can help identify problematic inputs that might otherwise go undetected.

Balanced Loading Practices

Developing standardised feeding protocols that prevent organic overloading is fundamental to foam prevention. Calculating your specific digester's optimal organic loading rate based on its design and historical performance provides a crucial baseline.

Generally, maintaining loading rates below 0.15 lbs VS/ft³/day (this rate may not apply to your plant and verify this for your circumstances before any action) for conventional digesters helps prevent foam-inducing acid accumulation while still maintaining efficient treatment.

For more insights on the topic, you can explore anaerobic digestion plants.

Feed equalisation infrastructure represents another valuable investment for foam prevention. Holding tanks with mixing capabilities allow you to blend high-strength wastes with regular feedstock, preventing the shock loading that often triggers foaming events. These systems also provide operational flexibility to adjust feeding during early signs of digester stress, potentially preventing foaming before it begins.

Co-digestion programs require particular attention to maintain balanced loading. While accepting additional waste streams can boost biogas production and provide revenue, improper management of these inputs often leads to foaming problems.

Implementing comprehensive waste characterisation protocols and gradually introducing new substrates at increasing percentages helps minimise these risks while maximising co-digestion benefits.

Proper Micronutrient Supplementation

Micronutrient deficiencies often contribute to digester foaming by limiting methanogen activity and allowing acid accumulation. Regular testing for micronutrients, particularly trace metals like iron, nickel, cobalt, and molybdenum, can identify potential deficiencies before they impact performance.

Establishing a baseline of optimal concentrations for your specific digester provides targets for supplementation programs.

Supplementation should be approached systematically rather than reactively. A scheduled micronutrient addition program based on your specific feedstock characteristics and operational data typically provides better results than intermittent supplementation during problems.

For digesters processing primarily municipal biosolids, iron, nickel, and cobalt often provide the greatest benefit, while those handling food wastes may require a broader spectrum of trace elements.

When implementing micronutrient supplementation, consider bioavailability, not just total concentration. Some micronutrient forms are more readily utilised by microorganisms than others.

Chelated forms of trace metals typically offer superior bioavailability compared to inorganic salts, often allowing for lower dosages while achieving better results. Working with a specialised provider like Aquafix ensures you're getting the most bioavailable forms of essential micronutrients for optimal digester performance.

Specialized Solutions for Different Digester Designs

Egg-Shaped Digesters: Unique Foaming Challenges

Egg-shaped digesters present distinctive foaming challenges due to their narrowing upper section that concentrates foam and can accelerate foam-related problems. The reduced surface area in the upper portion means that even moderate foaming can quickly interfere with gas collection systems. These digesters typically benefit from foam detection systems positioned in the upper cone section that can trigger automatic response measures before foam reaches critical levels.

Mixing strategies must be carefully tailored for egg-shaped digesters experiencing foaming. Research by Subramanian et al. shows that in these digesters, lower intensity mixing concentrated in the lower sections often reduces foam formation compared to full-height mixing.

Egg-Shaped Digester Foam Control: The unique geometry of egg-shaped digesters requires specialized approaches to foam management. Focus on detection in the narrow upper section, implement foam-conscious mixing strategies, and ensure foam-handling gas systems are properly sized for the concentrated foam that can develop in these units. For more insights, explore how Landia's GasMix system is applied in anaerobic digestion plants.

Gas handling systems for egg-shaped digesters should incorporate robust foam separation capacity due to the increased likelihood of foam entering gas lines. Enlarged gas collection pipes with multiple entry points, strategically positioned foam traps, and automated foam detection systems that can temporarily redirect gas flow during foaming events have proven effective in maintaining continuous operation despite foaming challenges.

Cylindrical Digesters: Optimal Foam Management

Cylindrical digesters offer more surface area per volume than egg-shaped alternatives, providing additional foam management flexibility. In these designs, creating dedicated foam management zones can significantly improve control capabilities. Reserving the upper 2-3 feet of operational volume as dedicated foam space rather than active digestion volume provides a buffer that accommodates normal foam production without operational impacts.

Floating covers on cylindrical digesters require particular attention during foaming events. The seal between the floating cover and digester wall often becomes compromised during significant foaming, leading to gas leakage and potential safety hazards.

Regular inspection and maintenance of these seals, combined with proper guide mechanism lubrication, helps minimize these risks. For severe foaming episodes, temporary weight addition to floating covers can help maintain proper sealing despite foam pressure.

| Digester Type | Primary Foaming Challenges | Recommended Control Measures |

|---|---|---|

| Egg-Shaped | Concentrated foam in upper section, rapid gas system fouling | Early detection systems, lower zone mixing, enhanced gas separation |

| Cylindrical (Fixed Cover) | Pressure buildup, internal component fouling | Dedicated foam space, pressure relief optimisation, strategic spray systems |

| Cylindrical (Floating Cover) | Cover lifting, seal compromise, guide damage | Weight management, enhanced seal design, and guide protection systems |

Multiple-tank configurations offer additional foam management options not available in single-tank systems. Distributing loading between tanks during foaming events can help control severe episodes, essentially diluting the problem across a greater volume. In severe cases, temporarily converting the tank configuration from parallel to series operation allows the first tank to act as a buffer, capturing foam-generating components before they reach subsequent tanks.

When to Use Chemical Additives (And Which Ones Work Best)

Chemical interventions play an important role in comprehensive foam management, but their effectiveness depends on selecting the right product for your specific situation and applying it correctly.

Rather than viewing chemical additives as standalone solutions, consider them tools within your broader management strategy, complementing biological, operational, and mechanical approaches to foam control.

Properly timing chemical addition often determines its effectiveness. Preventive application before historical problem periods (such as seasonal industrial changes or known operational transitions) typically provides better results than reactive application once severe foaming has developed.

For facilities with predictable foaming patterns, incorporating preventative chemical application into standard operating procedures can significantly reduce foaming frequency and severity.

pH Adjustment Products: When and How to Apply

pH adjustment remains a fundamental tool for foam management, but it requires careful application to prevent exacerbating the problem. When volatile acid accumulation creates acidic conditions (pH below 6.8), adding alkalinity helps restore methanogen activity—but adding too much too quickly can trigger immediate foaming by stimulating gas production while acids remain elevated.

The most effective approach is gradual alkalinity addition using bicarbonate-based products rather than hydroxide-based alternatives (take care to verify this, as information from papers that describe benefits at laboratory scale may not be applicable in commercial plants), targeting incremental pH increases of no more than 0.1-0.2 units per day until reaching the optimal 7.0-7.5 range.

Enzymatic Solutions for FOG-Related Foaming

When fats, oils, and grease (FOG) contribute to foaming issues, specialised enzymatic products can provide targeted relief by accelerating FOG breakdown. These enzyme formulations typically contain lipases and other enzymes specifically selected to hydrolyse complex lipids into more digestible components, preventing their accumulation at the liquid-gas interface where they contribute to foam formation.

For digesters receiving significant FOG inputs, either directly or through upstream processes, regular enzymatic supplementation can substantially reduce foaming potential while simultaneously improving biogas production from these energy-rich substrates.

Trace Metal Supplements for Improved Methanogen Activity

Trace metal deficiencies frequently contribute to foaming by limiting methanogen activity and allowing acid accumulation. Comprehensive micronutrient supplements containing bioavailable forms of iron, cobalt, nickel, molybdenum, selenium, and tungsten support robust methanogen populations that effectively convert volatile acids to methane before they reach foam-inducing concentrations.

Unlike anti-foaming agents that simply treat symptoms, micronutrient supplementation addresses a root cause of foaming while simultaneously improving overall digester performance and biogas production, making it one of the most cost-effective long-term foam management strategies available.

Foam Prevention Maintenance Scheduling

Preventing foam is always more effective than treating it once established, and a structured maintenance schedule forms the backbone of any successful prevention program.

A comprehensive foam prevention maintenance schedule includes daily visual inspections of foam conditions, weekly testing of key parameters like volatile acid to alkalinity ratios and gas composition, monthly microscopic examination of digester contents for foam-stabilising organisms, and quarterly evaluation of micronutrient levels and supplementation needs.

This systematic approach allows early detection of developing issues before they escalate into operational problems, transforming foam management from reactive crisis response to proactive prevention. For more insights, explore how anaerobic digestion plants manage foam effectively.

Take Control of Your Digester's Foaming Issues Today

Effective foam management in anaerobic digesters requires understanding the complex interaction of biological, chemical, and operational factors that contribute to foam formation.

With the right approach, even persistent foaming problems can be resolved and prevented from recurring. For personalised assistance with your specific digester foaming challenges, Aquafix's team of wastewater specialists can provide targeted solutions based on decades of experience resolving complex operational issues in anaerobic digestion systems.

Frequently Asked Questions

Operators frequently ask questions about specific aspects of digester foaming. The following answers address some of the most common inquiries we receive about foam management and prevention in anaerobic digesters.

Can weather changes trigger foaming in anaerobic digesters?

Yes, weather changes can indirectly trigger foaming in anaerobic digesters through several mechanisms. Heavy rainfall events often introduce increased surfactants from surface runoff and infiltration into collection systems, which can reduce surface tension in digesters and promote foaming. Significant temperature changes can affect wastewater characteristics and microbial activity in upstream processes, potentially altering the composition of material entering digesters.

Additionally, seasonal industrial activities like harvest-time food processing can change influent characteristics in ways that promote foaming.

While digesters themselves are typically insulated from direct weather effects, these indirect impacts make foaming more common than many operators realise. For more insights on managing such impacts, explore anaerobic digestion for food waste.

How quickly should foam subside after applying anti-foaming agents?

Properly selected and applied anti-foaming agents typically begin reducing foam within 30-60 minutes, with significant improvement visible within 2-4 hours. Complete foam collapse may take 6-12 hours, depending on foam severity and the specific anti-foaming agent used.

If no visible improvement occurs within 2 hours of application, either the dosage is insufficient or the product selected is not appropriate for your specific foam type. In these cases, consulting with your chemical supplier about alternative products or increased dosing may be necessary. R

Remember that anti-foaming agents address symptoms rather than causes—if foam rapidly returns after initial collapse, underlying issues are still present and require additional investigation.

Is it normal to have a thin layer of foam in a healthy digester?

Yes, a thin layer of foam (1-3 inches) is completely normal and often indicates healthy gas production in an anaerobic digester.

This normal operational foam typically appears light in colour, consists of relatively large bubbles that pop easily, and doesn't accumulate or persist when mixing is temporarily increased.

Think of this light foam layer as visual confirmation that your digestion process is actively producing biogas.

Only when foam becomes thick (exceeding 6-12 inches), dark in colour, or persistent despite mixing should it be considered problematic and trigger corrective action.

Can foaming problems damage equipment beyond the digester itself?

Absolutely—foam can cause significant damage to equipment throughout your biogas handling system if left unchecked. Gas piping systems are particularly vulnerable, as foam can enter and solidify in pipes, pressure regulators, and flow meters, causing blockages and inaccurate readings.

Foam entering gas compressors can cause mechanical damage and accelerated wear. In combined heat and power (CHP) systems, foam contaminants can foul heat exchangers, damage engine components, and reduce efficiency.

Even minor foaming that doesn't overflow the digester can still impact operations by interfering with level sensors, temperature probes, and sampling equipment, potentially leading to control system issues and inaccurate operational data.

How do I differentiate between foam caused by filamentous bacteria versus surfactants?

Distinguishing between filamentous bacteria-stabilised foam and surfactant-induced foam requires examining both the foam's physical characteristics and its microscopic properties.

Filamentous foam typically appears brown, has a dense, stable structure that resists breakdown, and shows a gradual boundary between foam and liquid phases. Under microscopic examination at 100-400x magnification, you'll see abundant filamentous organisms with characteristic branching or non-branching structures.

Surfactant foam, by contrast, often appears lighter in colour with a glossy or iridescent quality, shows a sharper boundary between foam and liquid, and may form more rapidly but also collapse more quickly when mixing stops.

Microscopic examination shows few filaments but may reveal elevated levels of grease globules or crystal structures. Laboratory testing for surface tension provides additional confirmation—significantly reduced surface tension (below 60 dynes/cm) strongly suggests surfactant involvement.

Caution: We have relied heavily on published papers to write this article, and the recommendations are based largely on this data. However, readers are warned to take special care to verify this article before using this information. Lab-scale results may not work in a large-scale biogas plant.