Enhancing Anaerobic Digestion of Corn Stover: Unlocking Higher Methane Yields through Freeze–Thaw Pretreatment

Anaerobic digestion (AD) technology has evolved significantly over the past decades, becoming a vital solution for renewable energy generation by converting organic waste into valuable methane-rich biogas. A recent advancement involves using freeze–thaw (FT) pretreatment—particularly effective in colder climates—to increase the digestibility of corn stover, an abundant agricultural residue. Combining physical (FT) and chemical pretreatments (water or sodium hydroxide, NaOH) dramatically boosts biogas yields, significantly impacting both sustainability and economic feasibility for biogas producers.

Key Takeaways:

- Freeze–Thaw (FT) pretreatment significantly enhances anaerobic digestion by physically disrupting biomass.

- Combining FT with chemical pretreatments (especially water or NaOH) further improves methane yields.

- Introducing water into FT pretreatment is economically superior to NaOH despite NaOH’s higher methane yields.

- Utilizing corn stover more effectively could dramatically scale up biogas production, transforming AD into a major renewable energy source.

Understanding Corn Stover and Its Potential

Understanding Corn Stover and Its Potential

Corn stover refers to the leftover stalks, leaves, husks, and cobs from corn harvesting. Typically seen as a waste product, this lignocellulosic biomass is both abundant and renewable, offering massive untapped potential as a feedstock for renewable energy.

Globally, corn stover production is immense. For example, China alone generates approximately 240 million tons of corn stover annually. However, less than 30% of this is currently utilized effectively, with the rest often burned in fields or discarded, causing environmental harm and wasting potential energy resources.

The Global Significance of Corn Stover Utilization

Considering just China's annual production:

| Statistic | Quantity |

|---|---|

| Annual corn stover production (China) | ~240 million tons/year |

| Currently utilized | <72 million tons/year (<30%) |

| Potential additional resource | ~168 million tons/year (>70%) |

If fully utilized in anaerobic digestion, this untapped 168 million tons could dramatically boost global biogas output, reshaping the renewable energy landscape. Such massive increases would challenge longstanding skepticism among net-zero pessimists who argue that anaerobic digestion is too small-scale to significantly contribute to global renewable energy needs.

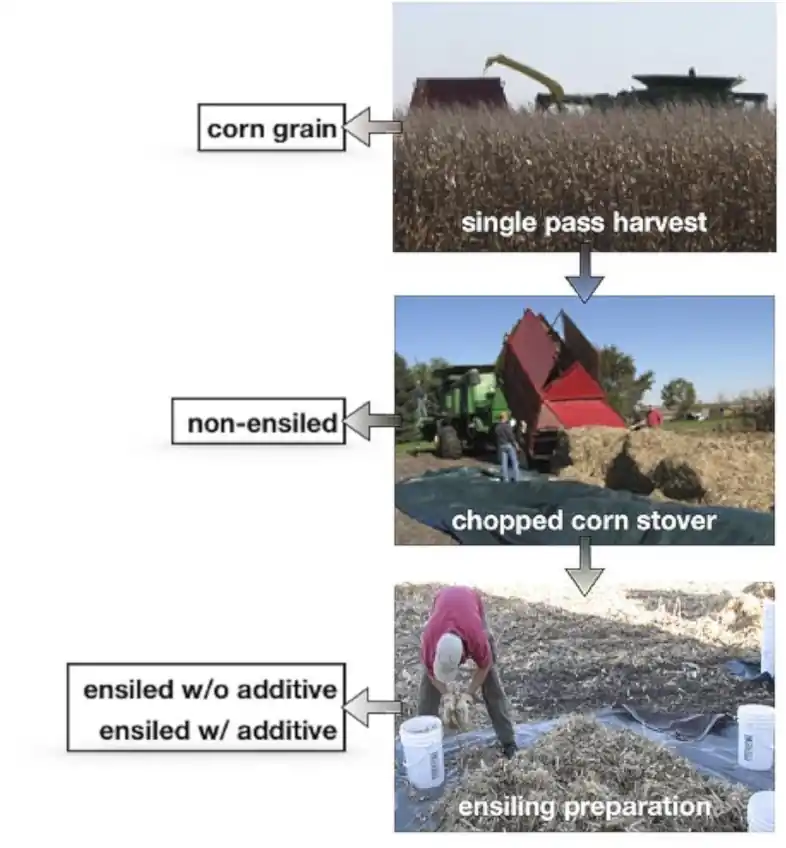

“Corn Stover into Natural Gas …” from www.extension.iastate.edu and used with no modifications.

Environmental and Health Benefits of Avoiding Corn Stover Burning

Traditionally, leftover corn stover (straw) has often been disposed of by open-field burning, a practice that generates significant air pollution. This burning releases dense smoke and particulate matter, significantly deteriorating air quality and visibility.

The environmental and health impacts include:

- Respiratory illnesses: Smoke inhalation can cause or exacerbate respiratory conditions like asthma, bronchitis, and other chronic lung diseases.

- Carbon black emissions: Burning corn stubble releases carbon black particles, tiny dust-like particles that rise into the atmosphere and contribute significantly to the greenhouse heating effect, accelerating climate change.

- Reduced soil fertility: Burning stubble removes organic matter beneficial for soil health, leading to increased dependency on chemical fertilizers.

By converting corn stover into biomethane through enhanced anaerobic digestion, we eliminate harmful burning practices, significantly reducing both greenhouse gas emissions and improving public health outcomes.

Evolution of Anaerobic Digestion Pretreatments

Historically, the complex structural composition of corn stover—particularly its high lignin content—has hindered its effective digestion. This limitation prompted significant research into pretreatment methods designed to make lignocellulosic biomass more digestible by microbes, thus improving methane yields. Common pretreatment methods previously explored include:

- Thermal methods (high energy costs)

- Chemical methods (environmental and economic concerns)

- Biological methods (slow and often inefficient)

However, many methods proved either too costly or energy-intensive, limiting widespread adoption.

Why Freeze–Thaw Pretreatment is Revolutionary

The newly researched freeze–thaw (FT) method effectively utilizes naturally occurring low temperatures, common in many major agricultural regions, significantly reducing the energy input required compared to other pretreatments.

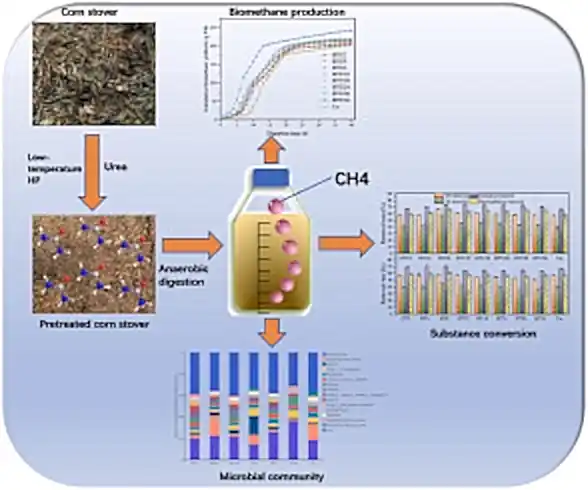

This pretreatment process involves repeatedly freezing and thawing biomass, creating internal ice crystals that physically disrupt biomass cell walls, greatly enhancing microbial access during digestion. When combined with chemicals like water or NaOH, structural disruption is amplified, further improving the biomass’s digestibility.

Detailed Findings from Recent Research

The recent study highlighted the significant benefits of FT pretreatment. Key findings included:

- The highest methane yield (326.8 mL/g VS) was achieved with NaOH/FT pretreatment, marking up to a 96.3% increase over untreated controls.

- Pretreatment efficacy improved with increased FT cycles (1, 2, and 4 cycles studied).

- FT combined with water alone also improved yields significantly (287.4 mL/g VS, a 76.3% increase over untreated controls).

Comparative Methane Yield Results:

| Pretreatment Type | Methane Yield (mL/g VS) | Yield Increase vs. Untreated |

|---|---|---|

| Untreated (CK) | 166–257 | – |

| FT + Water | 271–287 | 11.9%–76.3% |

| FT + NaOH | 302–327 | 27.3%–96.3% |

“corn stover anaerobic digestion …” from www.sciencedirect.com and used with no modifications.

Economic Analysis: Water vs. NaOH

Although NaOH pretreatment consistently produced higher methane yields, detailed economic analysis revealed a different story. When considering chemical costs, the superior yields from NaOH did not justify its additional expense.

Detailed economic assessment:

- NaOH cost: approximately 333 USD/ton

- Methane market price: approximately 3 RMB/m³ (~0.42 USD/m³)

Economic Comparison Table:

| Pretreatment Method | Methane Yield (m³/ton VS) | Methane Income (USD/ton VS) | Chemical Cost (USD/ton VS) | Net Economic Benefit (USD/ton VS) |

|---|---|---|---|---|

| Untreated (CK4) | 256.8 | 108.00 | 0 | 108.00 |

| Water + FT (W-FT4) | 287.4 | 120.85 | 0 | 120.85 (highest benefit) |

| NaOH + FT (N-FT4) | 326.8 | 137.42 | 42.15 | 95.27 (lowest benefit) |

This demonstrates that while NaOH enhances methane yield, the increased chemical cost significantly diminishes its economic advantage compared to using water alone.

Implications for the Biogas Industry and Circular Economy

Improving the digestibility of corn stover through economically feasible FT pretreatment can transform anaerobic digestion into a major renewable energy contributor:

- Boosting Renewable Fuel Production: Greater methane yields from abundant corn stover could significantly increase renewable biomethane production, displacing fossil fuels and driving the renewable energy sector forward.

- Circular Economy Advancement: Utilizing corn stover more effectively aligns directly with circular economy principles, transforming waste into energy, reducing environmental pollution, and promoting resource efficiency.

- Job Creation: Enhanced biogas production would create numerous job opportunities across collection, logistics, processing, operation, and management of anaerobic digestion facilities, especially in rural communities.

“Corn Stover …” from www.frontiersin.org and used with no modifications.

FAQs Section

Q1: What is Freeze–Thaw (FT) pretreatment?

FT pretreatment involves repeatedly freezing and thawing biomass to physically disrupt its structure, improving microbial access during anaerobic digestion.

Q2: Why focus on corn stover as an anaerobic digestion feedstock?

Corn stover is an abundant yet underutilized agricultural residue. Effectively digesting this biomass significantly increases renewable energy output and reduces agricultural waste problems.

Q3: Why is water more economically beneficial than NaOH for FT pretreatment?

Though NaOH generates higher methane yields, its chemical cost reduces net economic benefits. Water provides a more cost-effective balance between increased yields and low pretreatment costs.

Q4: Could anaerobic digestion using corn stover significantly contribute to renewable energy targets?

Absolutely. Utilizing the currently wasted corn stover resource could dramatically scale biomethane production, making anaerobic digestion a substantial contributor to renewable energy goals.

Q5: Is FT pretreatment practically feasible for large-scale commercial anaerobic digestion?

Yes, especially in colder climates where natural freezing temperatures can be leveraged economically, although ongoing optimization and scalability assessments are necessary.

Reference: Read the original research article published in BioEnergy Research (2025).