Key Takeaways

- Biodigester toilet systems convert human waste into usable biogas through anaerobic digestion, offering a sustainable solution for waste management without requiring connection to municipal systems.

- These systems can reduce your carbon footprint by producing clean-burning biogas for cooking, heating, and lighting while generating nutrient-rich fertilizer as a byproduct.

- Proper site selection with well-draining soil and adequate space is crucial for optimal biodigester performance and longevity.

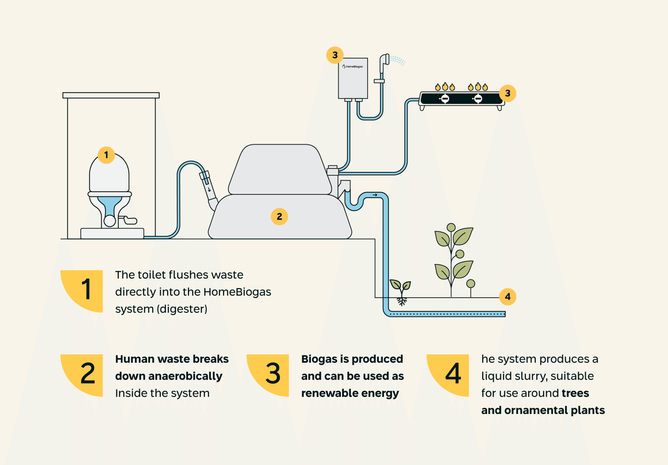

- HomeBiogas offers integrated bio-toilet solutions that seamlessly connect to their biodigester systems, providing a complete waste-to-energy solution for eco-conscious homeowners.

- Biodigester toilets require minimal maintenance compared to traditional septic systems while offering significant long-term cost savings and environmental benefits.

What Are Biodigester Toilet Systems and Why They Matter

Biodigester toilet systems represent a revolutionary approach to handling human waste in an environmentally responsible manner. Unlike conventional toilets that require water-intensive flushing and connection to municipal sewage systems, biodigester toilets process waste on-site through natural biological processes. At their core, these systems harness anaerobic digestion—a process where microorganisms break down organic matter in the absence of oxygen—to transform human waste into valuable resources: biogas and nutrient-rich fertilizer. HomeBiogas has pioneered integrated bio-toilet solutions that make this sustainable technology accessible to homeowners seeking self-sufficient waste management options.

The significance of biodigester toilets extends far beyond mere waste disposal. As water scarcity becomes an increasingly pressing global concern, these systems offer a practical solution that dramatically reduces water consumption compared to conventional flush toilets. Moreover, they provide a complete waste management facility that operates independently of municipal infrastructure—making them ideal for rural settings, off-grid homes, and areas with limited access to centralized sewage systems.

What truly sets biodigester toilets apart is their ability to transform a problem—human waste—into a solution. Rather than treating waste as something to dispose of, these systems view it as a valuable resource. The biogas produced can be used for cooking, heating, and lighting, replacing fossil fuels or wood with a renewable, clean-burning alternative. This dual benefit of waste management and energy production makes biodigester toilets a compelling option for environmentally conscious individuals looking to reduce their ecological footprint while gaining greater self-sufficiency.

“What is a Biodigester Toilet? A …” from riseadapt.co.uk and used with no modifications.

The Science Behind Biodigester Toilets

The magic of biodigester toilets lies in their harnessing of natural biological processes that have occurred on Earth for billions of years. These systems create controlled environments where specific microorganisms can efficiently break down organic matter in the absence of oxygen. Understanding this science helps appreciate why biodigester toilets represent such an elegant solution to human waste management.

How Anaerobic Digestion Breaks Down Waste

Anaerobic digestion occurs in four key stages, each facilitated by different groups of microorganisms working in harmony. First, during hydrolysis, complex organic molecules like proteins and carbohydrates are broken down into simpler compounds such as amino acids and sugars. Next, acidogenic bacteria convert these simple compounds into volatile fatty acids, alcohols, carbon dioxide, and hydrogen. The third stage, acetogenesis, transforms these intermediate products into acetic acid, carbon dioxide, and hydrogen. Finally, methanogenic archaea convert these substances into methane and carbon dioxide—the primary components of biogas. This entire process takes place in an oxygen-free environment carefully maintained within the biodigester chamber, with optimal temperature conditions promoting efficient microbial activity.

Types of Biodigester Systems Available

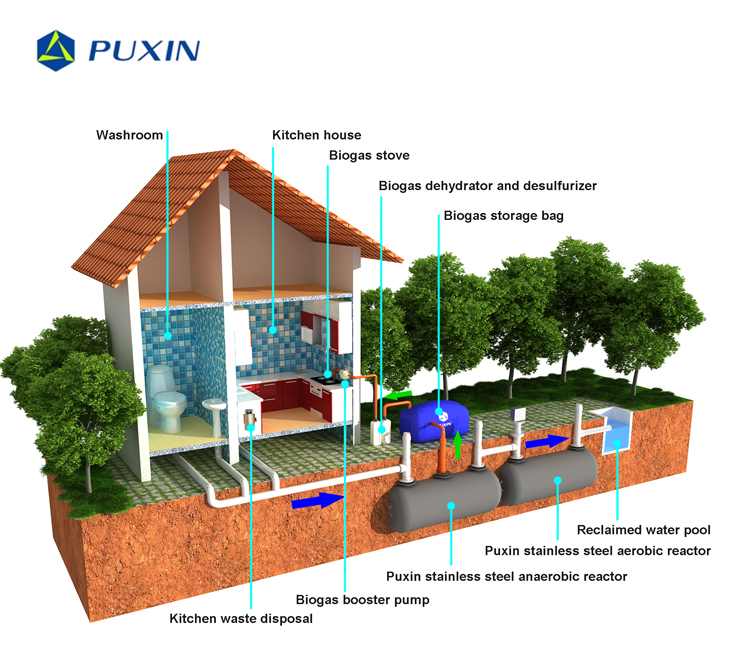

Biodigester toilet systems come in several variations, each suited to different contexts and needs. Fixed-dome digesters feature a permanent underground chamber with a fixed, non-movable dome for gas collection—offering durability and low maintenance but requiring professional installation. Floating-drum digesters utilize a movable gas holder that rises and falls depending on the amount of gas stored, providing visual feedback on gas production but requiring more maintenance due to moving parts. Bag or balloon digesters consist of flexible materials like PVC or polyethylene, offering portability and easy installation at lower costs, though with shorter lifespans. Prefabricated systems, like those offered by HomeBiogas, provide complete plug-and-play solutions with standardized components designed for residential use, balancing convenience and performance. Each system type presents different advantages in terms of cost, space requirements, and complexity, allowing users to select the option best aligned with their specific circumstances.

![]()

“solar-assisted biodigester …” from www.sciencedirect.com and used with no modifications.

Key Components and Their Functions

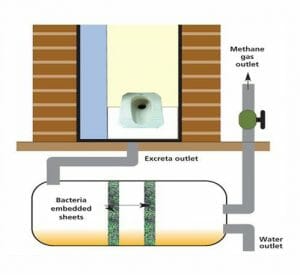

A complete biodigester toilet system comprises several essential components working together to ensure efficient waste processing. The toilet fixture serves as the user interface, designed to minimize water usage while effectively channeling waste into the system. An inlet pipe transfers waste from the toilet to the digestion chamber, sometimes incorporating a mixing mechanism to combine waste with water at appropriate ratios. The digestion chamber itself serves as the heart of the system—a sealed container where anaerobic digestion occurs, typically constructed from concrete, fiberglass, or high-density polyethylene to ensure durability and gas-tightness.

Gas storage mechanisms collect and hold the produced biogas until needed, either integrated into the digester design or as separate components. Outlet systems manage the effluent (liquid discharge) after digestion, directing it to secondary treatment or safe disposal areas. Finally, gas utilization components—such as pressure regulators, filters, and specialized biogas appliances—enable the practical application of the produced biogas for cooking, heating, or lighting. These components must work in harmony to create an efficient, safe, and user-friendly system that effectively manages waste while maximizing resource recovery.

7 Major Benefits of Installing a Biodigester Toilet

Biodigester toilet systems offer numerous advantages that extend beyond basic waste management, making them increasingly popular among environmentally conscious homeowners and off-grid enthusiasts. These benefits represent a holistic approach to sustainability that addresses multiple ecological challenges simultaneously.

1. Eco-Friendly Waste Management Without Chemicals

Biodigester toilets exemplify truly sustainable waste management by eliminating the need for harmful chemicals commonly used in conventional systems. Unlike traditional septic systems or chemical toilets that rely on toxic additives to control odors and break down waste, biodigesters employ beneficial microorganisms that naturally process human waste through anaerobic digestion. This biological approach prevents potentially harmful substances from entering groundwater or local ecosystems. The process significantly reduces pathogen levels naturally, with the digestion process killing up to 95% of harmful bacteria without requiring disinfectants or sanitizing agents.

The environmental impact extends beyond chemical avoidance—biodigesters prevent untreated sewage from contaminating water sources, a common problem in areas with inadequate sanitation infrastructure. By keeping waste contained and processed on-site, these systems help protect local watersheds and aquatic ecosystems from nutrient pollution and bacterial contamination. This closed-loop approach to waste management represents one of the most environmentally responsible sanitation solutions available today, particularly valuable in ecologically sensitive areas or locations with high water tables.

2. Water Conservation Compared to Conventional Toilets

Biodigester toilet systems dramatically reduce water consumption compared to traditional flush toilets. While conventional toilets use between 1.6 to 7 gallons per flush, biodigester toilets typically require only 0.5 to 1 gallon or sometimes no water at all, depending on the specific design. This water efficiency can translate to savings of up to 35,000 gallons annually for an average household, a substantial contribution to water conservation efforts.

The reduced water dependency makes biodigester systems particularly valuable in water-scarce regions or during drought conditions. By minimizing water usage for waste disposal, these systems help preserve precious freshwater resources for drinking, agriculture, and other essential purposes. For homeowners in areas with water restrictions or high water costs, the savings can be significant both environmentally and financially.

3. Energy Production Through Biogas Generation

One of the most compelling benefits of biodigester toilets is their ability to transform waste into usable energy. A typical family-sized biodigester can produce between 1-2 cubic meters of biogas daily, depending on input volume and system efficiency. This biogas consists primarily of methane (50-70%) and carbon dioxide (30-50%), creating a clean-burning fuel comparable to natural gas but produced from waste materials that would otherwise be discarded.

This biogas can be directly utilized for cooking, heating water, or even generating electricity with appropriate equipment. A family of four can generate enough biogas to cook 1-3 meals daily or power a gas lamp for 3-6 hours, creating tangible energy independence. The energy production aspect transforms these systems from mere waste management solutions into renewable energy generators, providing a continuous supply of fuel as long as the biodigester receives regular inputs.

![]()

“Biogas: Converting Waste to Energy …” from www.eesi.org and used with no modifications.

4. Reduced Carbon Footprint and Emissions

Biodigester toilets significantly lower greenhouse gas emissions compared to conventional waste management systems. Traditional sewage treatment processes release methane—a potent greenhouse gas—directly into the atmosphere, while septic systems can also contribute to methane emissions through incomplete decomposition. Biodigester systems capture this methane for useful purposes, preventing its release while simultaneously reducing reliance on fossil fuels. To learn more about the environmental benefits, you can explore how anaerobic digestion is good for the environment.

By producing renewable energy from waste, these systems displace the use of fossil fuels, further reducing carbon emissions. When biogas replaces firewood or charcoal for cooking, it also eliminates the black carbon and particulate emissions associated with solid fuel combustion. The combined impact of proper waste management, methane capture, and fossil fuel displacement can reduce a household's carbon footprint by several tons of CO₂ equivalent annually, making biodigester toilets a meaningful climate action at the individual level.

“reducing carbon emissions” from capitalise.com and used with no modifications.

5. Cost Savings Over Traditional Septic Systems

While the initial investment in a biodigester toilet system may be comparable to or slightly higher than conventional septic systems, the long-term economic benefits are substantial. Traditional septic systems require regular pumping every 3-5 years, costing $300-$600 per service, while biodigesters typically need only minimal maintenance with significantly lower ongoing costs. The energy value of the biogas produced can offset household fuel expenses, providing additional financial returns on the initial investment.

The reduced water consumption translates directly to lower water bills, particularly significant in areas with metered water supply. For off-grid locations, biodigester systems eliminate the substantial costs of installing and maintaining connections to municipal sewage infrastructure. When factoring in these ongoing savings and the value of energy production, biodigester toilet systems typically achieve payback periods of 3-7 years, after which they continue to generate economic benefits throughout their 15-20 year lifespan.

Designing Your Perfect Biodigester Toilet System

Creating an effective biodigester toilet system requires thoughtful planning and design considerations tailored to your specific location, needs, and constraints. This process involves evaluating several critical factors that will determine the system's performance, efficiency, and longevity. By addressing these design elements systematically, you can develop a biodigester solution that provides reliable waste management while maximizing resource recovery for years to come.

Site Selection Factors for Optimal Performance

Choosing the right location for your biodigester is perhaps the most crucial design decision you'll make. The ideal site should feature well-draining soil to prevent waterlogging around the digester, which can compromise structural integrity and reduce system efficiency. Proximity to groundwater is another critical consideration—maintaining at least 50 feet (15 meters) distance from wells and water sources prevents potential contamination while ensuring regulatory compliance in most jurisdictions. For more insights, learn about what an anaerobic digester is and how it functions.

Sun exposure significantly impacts system performance, particularly in colder climates where solar heat can help maintain optimal digestion temperatures. Position your biodigester where it receives maximum sunlight, preferably on the south-facing side of your property in the northern hemisphere. Accessibility for maintenance and servicing must also be considered, with enough space to allow for periodic inspections, cleaning, and repairs without major disruption.

Consider the topography of your land, ideally selecting a slightly sloped area that facilitates gravity flow from the toilet to the digester and from the digester to effluent disposal areas. This natural flow reduces or eliminates the need for pumps, creating a more resilient, energy-efficient system. Finally, evaluate the area for potential hazards like flooding, erosion, or tree roots that could damage underground components over time. For more on how anaerobic digesters work, visit our detailed guide.

Calculating the Right Size Based on User Numbers

Accurate sizing is essential for biodigester effectiveness, with capacity directly linked to the number of regular users and their expected waste production. The average person produces approximately 0.5-1.5 liters of waste (combined urine and feces) daily, which serves as the baseline calculation for system sizing. For residential applications, engineers typically recommend a minimum digester capacity of 1 cubic meter (1,000 liters) for every 4-6 daily users, with additional capacity providing better performance and gas production.

Beyond basic capacity calculations, consider usage patterns that might affect system loading. Seasonal variations, visitor frequency, and special events can create temporary increases in system demand that should be accommodated in your design. For systems serving multiple households or community installations, a safety factor of 15-20% additional capacity is advisable to handle peak loads and ensure consistent performance.

Biodigester Sizing Guidelines

Number of Users

Minimum Digester Volume

Biogas Production (approx.)

Recommended Application

1-4 people

1,000 liters

0.5-1 m³/day

Single family homes

5-10 people

2,000 liters

1-2 m³/day

Large households

11-20 people

4,000 liters

2-4 m³/day

Small communities

21-50 people

8,000-10,000 liters

4-10 m³/day

Community facilities

The digester's hydraulic retention time (HRT)—the average time waste remains in the digestion chamber—is another critical sizing factor. For optimal anaerobic digestion of human waste, an HRT of 20-30 days is typically recommended. This means your system volume should be at least 20-30 times the daily input volume to ensure proper treatment and pathogen reduction. In colder climates, longer retention times of up to 60 days may be necessary to compensate for slower microbial activity at lower temperatures.

When calculating system size, don't overlook the gas storage requirements. The biogas production will fluctuate based on temperature, input volume, and other factors, while gas usage often follows different patterns. Sufficient gas storage capacity—typically 40-60% of daily gas production—ensures you can effectively utilize the biogas when needed rather than wasting this valuable resource.

Space Requirements for Different Models

Different biodigester designs have varying footprints and installation requirements that must be accommodated in your site planning. Fixed-dome digesters typically require the most space due to their permanent underground construction, needing excavation areas approximately 30-50% larger than the actual digester volume to allow for proper installation. Floating-drum designs have similar space requirements but need additional clearance above for the vertical movement of the gas drum. Bag or balloon digesters are generally more space-efficient in terms of installation but require level ground and protection from physical damage, often necessitating a protective enclosure or dedicated housing that adds to the overall footprint.

Water Supply Considerations

While biodigester toilets are far more water-efficient than conventional systems, they still require some water for optimal operation. Most systems function best with a water-to-waste ratio between 1:1 and 3:1, depending on the specific design and local conditions. This translates to approximately 1-3 liters of water per toilet use, which must be reliably available throughout the system's lifetime.

The water source should be easily accessible to toilet users, whether through manual addition or automated systems connected to existing plumbing. In water-scarce regions, consider incorporating greywater recovery from sinks, showers, or rainwater harvesting systems to meet the biodigester's water needs without taxing precious drinking water supplies. Remember that water quality affects digester performance—chlorinated water can inhibit microbial activity, so settling or aeration may be necessary when using treated municipal water.

Effluent Disposal Options and Requirements

The liquid effluent from biodigester toilets requires proper management as part of your overall system design. Though significantly reduced in pathogen content compared to raw sewage, this nutrient-rich liquid still needs appropriate handling. Common disposal options include leach fields (similar to septic systems but smaller), constructed wetlands that provide additional biological treatment, or controlled agricultural application as fertilizer for non-food crops. Regulations regarding effluent disposal vary widely by location, so consult local authorities early in your design process to ensure compliance with health and environmental requirements. For more insights, you might explore why anaerobic digestion is good for the environment.

“Bio-Toilets for Off-Grid Clean Energy …” from energydigital.com and used with no modifications.

Step-by-Step Installation Guide

Installing a biodigester toilet system requires careful planning and execution to ensure safety, functionality, and compliance with local regulations. While specific steps may vary depending on your chosen system design and local conditions, this general guide outlines the core installation process that applies to most biodigester toilet implementations. For prefabricated systems like those offered by HomeBiogas, always follow the manufacturer's specific instructions while adapting these general principles to your situation.

Site Preparation and Excavation

Begin by marking the installation area according to your design specifications, ensuring proper clearance around the biodigester for maintenance access. Excavate the site to the required depth—typically 3-6 feet depending on system size and local frost line considerations. The excavation should be approximately 12-18 inches wider than the actual digester dimensions on all sides to allow for proper backfilling and insulation. Ensure the bottom of the excavation is level and compacted to provide a stable foundation for the digester.

Remove any sharp rocks or debris that could potentially damage the digester structure, and install a 4-6 inch layer of sand or fine gravel as a base layer. This foundation layer helps with drainage, prevents settling, and protects the digester from punctures. In areas with high water tables, consider installing a drainage system around the excavation perimeter to prevent water accumulation around the biodigester, which could affect structural integrity and insulation properties.

Building the Digester Chamber

For prefabricated systems, carefully lower the digester unit into the prepared excavation using appropriate lifting equipment to avoid damage. Ensure the unit is level and properly oriented with inlet and outlet pipes aligned with planned connections. For site-built digesters using concrete or masonry, construct the chamber according to engineered plans, ensuring proper reinforcement and watertight construction. Apply appropriate waterproofing treatments to concrete surfaces to prevent groundwater infiltration and potential contamination.

Once positioned, begin careful backfilling around the digester with sand or fine soil free from rocks and debris. Backfill in layers of 6-8 inches, compacting each layer before adding the next to prevent future settling that could stress or damage the system. In colder climates, consider adding insulation materials like foam boards around the digester to maintain optimal internal temperatures for microbial activity year-round.

![]()

“2.3.1 Fixed Dome Digester …” from sanihub.info and used with no modifications.

Connecting Plumbing and Ventilation

Install the inlet pipe from the toilet location to the digester at a minimum slope of 1/4 inch per foot to ensure proper waste flow. Use appropriate diameter piping (typically 3-4 inches) with watertight connections to prevent leaks and odors. The outlet pipe should be installed at the opposite end of the digester, leading to your designated effluent disposal area, maintaining similar slope requirements for gravity flow.

Install the biogas collection system according to manufacturer specifications or design plans, ensuring all gas lines are pressure-tested for leaks before operation. Proper gas venting is critical for safety—install a methane release valve and consider a secondary vent pipe that extends above roof level to disperse any excess gas safely. For systems with direct gas utilization, install appropriate filtration components to remove hydrogen sulfide and moisture from the biogas before it reaches appliances.

Installing the Toilet Fixtures

Mount the toilet fixture securely according to manufacturer guidelines, ensuring a stable and comfortable user experience. Connect the toilet to the inlet pipe using appropriate seals and fittings to create an airtight connection that prevents odor backflow. Depending on your system design, install any water supply connections needed for flushing or waste transport, ensuring accessible shutoff valves for maintenance. For more information, you can refer to the Bio-Digester Construction Manual.

For optimal user experience, properly ventilate the toilet area with a fan or passive ventilation system that directs any potential odors away from living spaces. Complete the installation with appropriate flooring that can be easily cleaned and maintained, as well as adequate lighting and privacy considerations. Finally, install clear user instructions near the toilet explaining proper use and any specific guidelines for your system. For more information on integrating biodigesters into your setup, consider these biogas plant integration tips.

Maintenance Essentials for Long-Term Performance

Proper maintenance is the key to ensuring your biodigester toilet system operates efficiently for its full expected lifespan of 15-20 years. While these systems require significantly less maintenance than conventional septic systems, consistent attention to a few essential tasks will optimize performance and prevent potential issues. Establishing a regular maintenance routine protects your investment while maximizing both waste processing efficiency and biogas production.

Regular Monitoring Practices

Implement a monitoring schedule to track system performance indicators including gas production rates, effluent clarity, and digestion efficiency. Keep a simple logbook recording the approximate daily waste input, water usage, gas production, and any observed changes in system behavior. Regularly check the pH level of the digester content, aiming for a neutral range between 6.8-7.2, which provides optimal conditions for methane-producing microorganisms. pH testing kits are inexpensive and provide valuable insight into digester health.

Monitor the temperature within the digestion chamber, particularly in colder seasons, as anaerobic digestion slows considerably below 68°F (20°C) and becomes virtually inactive below 50°F (10°C). If you notice decreased gas production during colder periods, consider additional insulation or supplemental heating methods to maintain optimal digestion temperatures. Finally, regularly inspect all connections, pipes, and valves for signs of leakage, corrosion, or damage, addressing any issues promptly to prevent system failure.

Cleaning and Service Schedule

While biodigesters continuously process waste, some non-digestible materials and slowly decomposing solids will accumulate over time. Every 2-5 years, depending on usage and system design, arrange for removal of accumulated solids from the digestion chamber. This service is far less frequent than septic tank pumping and typically involves removing only a portion of the digester content to maintain active microbial populations.

Clean gas filters every 3-6 months to remove hydrogen sulfide and moisture that can corrode equipment and reduce gas quality. Regularly clear the inlet and outlet pipes of any blockages using gentle methods that won't damage the pipes or introduce harmful chemicals into the digester. For the toilet fixture itself, use mild, biodegradable cleaners that won't harm the beneficial bacteria in the digestion system—avoid bleach, antibacterial products, and harsh chemicals that could disrupt the microbial ecosystem.

Troubleshooting Common Issues

Reduced gas production is among the most common issues and typically stems from temperature fluctuations, pH imbalance, or insufficient feeding. Check digester temperature first, then test pH levels—if acidic (below 6.5), add small amounts of agricultural lime or wood ash to neutralize; if alkaline (above 7.5), increase organic inputs to restore balance. Ensure consistent feeding patterns, as irregular usage can disrupt the microbial ecosystem. For more insights on maintaining balance, learn about anaerobic digesters and their operation.

Odor problems generally indicate either a leak in the gas system or improper digestion. Inspect all connections for leaks using soapy water to identify bubbling at leak points. If the digestion process is causing odors, check for overloading, temperature issues, or the presence of antibiotics or chemicals that might be killing beneficial bacteria. Toilet backups or slow drainage typically result from blockages in the inlet pipe—clear these using mechanical methods rather than chemical drain cleaners that could harm the digester ecosystem.

If effluent appears unusually dark or odorous, this suggests incomplete digestion or system overloading. Reduce inputs temporarily and ensure adequate retention time within the digester. For systems experiencing freezing issues in cold climates, add additional insulation around pipes and the digester chamber, or consider installing heating elements specifically designed for biodigester applications.

Real-World Applications and Success Stories

Biodigester toilet systems have proven their versatility and effectiveness across diverse settings worldwide, from individual households to large community installations. These real-world applications demonstrate the practical benefits of biodigester technology while providing valuable insights for those considering similar implementations. The growing adoption of these systems reflects their ability to address multiple challenges simultaneously—waste management, energy production, and environmental protection—in a sustainable, cost-effective manner.

Off-Grid Homes Using Biodigester Systems

The Johnson family in rural Colorado installed a HomeBiogas bio-toilet system when building their off-grid mountain home, eliminating the need for costly septic installation on their rocky property. Their 2,000-liter biodigester not only processes all household waste but produces sufficient biogas to handle approximately 70% of their cooking needs, significantly reducing their propane consumption. The system has performed reliably through winter temperatures as low as 15°F (-9°C) thanks to strategic placement in a south-facing location with additional insulation and periodic warm water additions during extreme cold snaps.

In Australia's remote Kimberley region, architect Sarah Wilson designed a completely self-sufficient home featuring an integrated biodigester toilet system that processes waste from two bathrooms. The system's effluent irrigates native landscaping through a subsurface drip system, conserving precious water in this arid environment while producing enough biogas to power the home's hot water heater. Sarah reports that the initial investment of $4,800 was recovered within four years through savings on propane deliveries and water costs, with the added benefit of complete independence from municipal infrastructure.

“Underground Biodigester Septic Tank …” from www.alibaba.com and used with no modifications.

Community and Commercial Implementations

The village of Nyabigega in Rwanda implemented a community-scale biodigester toilet system serving 120 residents, replacing unsafe pit latrines that were contaminating local water sources. The 12,000-liter centralized biodigester collects waste from six toilet blocks strategically placed throughout the village. The system produces approximately 8-10 cubic meters of biogas daily, which powers a community kitchen where meals are prepared for schoolchildren and provides lighting for evening educational programs. Beyond the sanitation and energy benefits, the project has created two permanent maintenance jobs and significantly reduced respiratory illness from traditional wood cooking fires.

Eco-tourism resort Jungle Bay in Dominica installed multiple biodigester toilet systems across their property, processing waste from 35 guest cabins and common facilities. The resulting biogas fuels the resort kitchen and water heating, while treated effluent nourishes tropical landscaping through carefully designed leach fields. Resort owner Sam Raphael reports that beyond the operational savings, the visible sustainability features have become a marketing advantage, with guests specifically choosing the resort for its environmental practices. The biodigester system has continued performing effectively through several tropical storms, proving more resilient than conventional infrastructure in extreme weather events.

Getting Started: Your Action Plan

Implementing a biodigester toilet system requires careful planning and systematic execution to ensure successful integration with your property and needs. This action plan outlines key steps to move from initial consideration to functional installation, helping you navigate the process efficiently while avoiding common pitfalls. By following these guidelines and adapting them to your specific circumstances, you can create a roadmap for successfully incorporating this sustainable technology into your home or property.

Budget Planning and Cost Breakdown

A comprehensive budget for a biodigester toilet system should account for all components and services required for complete installation. For a typical residential system serving 4-6 people, expect total costs between $2,500-$7,000 depending on system complexity and location factors. The biodigester unit itself represents approximately 40-50% of total costs, ranging from $1,000 for basic models to $3,500 for advanced prefabricated systems with integrated gas collection and utilization features. Plumbing components, including specialized toilet fixtures, inlet/outlet pipes, and gas lines, typically add $300-$800 to the project budget.

Installation expenses vary significantly based on site conditions and whether professional services are employed, ranging from $500 for straightforward DIY installations to $2,500 for complex sites requiring extensive excavation or specialized equipment. Additional components such as gas appliances (stoves, water heaters), effluent management systems, or monitoring equipment can add $300-$1,000 to the total investment. When budgeting, also allocate funds for permits and inspections ($100-$500 depending on local requirements) and include a 10-15% contingency for unexpected challenges during installation.

Finding Qualified Installers vs. DIY Options

The decision between professional installation and DIY approaches depends on your skills, available time, and system complexity. Professional installers bring specialized knowledge of local regulations, soil conditions, and technical requirements that can prevent costly mistakes. Look for contractors with specific experience in alternative waste systems, biogas technologies, or at minimum, extensive septic system installation background. Ask potential installers for references from previous biodigester projects, photos of completed installations, and their familiarity with any specific system you're considering.

DIY vs. Professional Installation Comparison

Consideration

DIY Approach

Professional Installation

Cost

$500-$1,000 (materials only)

$1,500-$3,000 (labor + materials)

Time Requirement

3-7 days of active work

1-3 days typically

Equipment Needed

Excavator rental, specialized tools

Included in service

Permitting Assistance

Self-managed

Often included

Warranty Coverage

Materials only

Materials + installation

Best For

Experienced builders, simple sites

Complex sites, time-constrained owners

For those pursuing DIY installation, prefabricated systems like those from HomeBiogas offer the most straightforward approach, with comprehensive instructions and support. Many manufacturers provide installation videos, detailed manuals, and customer support to guide first-time installers. Consider participating in workshops or online courses focused on biodigester installation to build confidence and skills before beginning your project. Even with a DIY approach, certain aspects like final gas connections may require professional certification in many jurisdictions for safety and insurance reasons.

A hybrid approach often represents the best value—handling site preparation and basic installation yourself while bringing in specialists for critical components like gas systems or final connections. This approach can significantly reduce costs while ensuring safety and compliance in the most technical aspects of the system. Regardless of your chosen approach, thoroughly research your specific system requirements and local regulations before beginning work.

Permits and Regulations You Need to Know

Regulatory requirements for biodigester toilet systems vary widely by location, with some jurisdictions embracing these sustainable technologies while others have limited specific provisions. Start by contacting your local health department or building permit office to inquire about alternative waste treatment systems. Many areas regulate biodigester toilets under existing septic system codes or alternative treatment system provisions, though specific requirements for design, setbacks from property lines and water sources, and effluent management will apply. Some jurisdictions may require engineered designs or professional installation certification, particularly for the gas production aspects of the system.

Beyond local building and health codes, consider other regulatory factors including homeowner's association restrictions, insurance implications, and potential resale considerations. Maintain thorough documentation of your system's design, permitting process, and installation details for future reference. Proactively engaging with regulatory authorities early in your planning process typically leads to smoother approval processes and can help identify potential compliance challenges before significant investments are made. For a comprehensive guide, you can refer to the Bio-Digester Construction Manual.

Frequently Asked Questions

As biodigester toilet systems become more mainstream, prospective users typically share common questions about their implementation, operation, and benefits. These frequently asked questions address the most common concerns and misconceptions about biodigester toilets, providing clear, factual information to help inform your decision-making process. Understanding these fundamental aspects can help you determine whether a biodigester toilet system is right for your specific situation.

The following questions represent those most commonly received from homeowners, builders, and property developers considering biodigester toilet implementation. The answers reflect current best practices and technical understanding of these systems, though specific details may vary based on local conditions and chosen system designs.

How much does a biodigester toilet system typically cost?

Complete biodigester toilet systems typically cost between $2,500 and $7,000 for residential applications, with variables including system size, features, and installation complexity. Basic systems serving 1-4 people start around $2,000-$3,000 including the digester, toilet fixture, and basic plumbing components. Mid-range systems with enhanced features like integrated gas collection, prefabricated components, and moderate capacity (4-8 users) generally fall in the $3,500-$5,000 range. Premium systems with larger capacity, advanced monitoring features, automated operation, and comprehensive gas utilization equipment can range from $5,000-$7,000 or more. These costs typically include primary components but may not include excavation, site preparation, or specialized gas appliances, which can add $500-$2,000 depending on specific requirements. For more detailed information, you can refer to this Bio-Digester Construction Manual.

Can biodigester toilets work in cold climates?

Biodigester toilets can function effectively in cold climates with proper design adaptations. Anaerobic digestion naturally slows at lower temperatures, with optimal activity occurring between 95-105°F (35-40°C) for mesophilic bacteria and significant reduction below 68°F (20°C). In cold regions, successful implementations typically include strategic placement in sunny locations, additional insulation around the digester chamber, and sometimes supplemental heating systems during extreme cold periods.

Effective cold-climate designs often incorporate the digester inside or adjacent to heated structures, utilizing passive solar gain or waste heat from buildings. Some advanced systems include heating elements powered by the produced biogas itself, creating a self-sustaining cycle. In extremely cold locations like Alaska and northern Canada, biodigester systems have been successfully operated year-round by housing them in insulated structures or partially burying them below the frost line with adequate insulation. While additional measures increase initial cost, the operational benefits of biodigester toilets often still outweigh alternatives in remote cold regions where conventional septic systems face freezing challenges and regular maintenance difficulties.

What happens to the waste after digestion?

The anaerobic digestion process transforms waste into three primary outputs: biogas, liquid effluent, and a small amount of remaining solids. The biogas, consisting primarily of methane (50-70%) and carbon dioxide (30-50%), can be captured and used for cooking, heating, or other energy applications. This renewable energy source represents one of the most valuable byproducts of the system.

The liquid effluent, which makes up the majority of the volume, contains significantly reduced pathogen levels (typically 95-99% reduction) and concentrated nutrients like nitrogen, phosphorus, and potassium. This liquid can be safely managed through various methods including leach fields, constructed wetlands, or controlled application as fertilizer for non-food crops and ornamental plants. The nutrient content makes it particularly valuable for landscaping applications when properly managed. The remaining solids, which accumulate very slowly compared to conventional septic systems, require removal only every 2-5 years depending on usage patterns. These solids can be safely composted with additional processing or removed by service providers familiar with biodigester maintenance.

Do biodigester toilets smell?

Properly designed and maintained biodigester toilet systems should produce minimal to no odor during normal operation. The anaerobic digestion process occurs in a sealed chamber, preventing the escape of odorous gases. Modern systems incorporate multiple odor control mechanisms including water traps, one-way valves, and ventilation systems that direct any potential odors away from living spaces. The toilet fixtures themselves typically include features like airtight seals and small water volumes that create effective barriers between the user and the digestion system.

Occasional odors may occur during maintenance activities or if the system experiences imbalances like improper feeding, pH disruption, or temperature fluctuations that affect microbial activity. These situations are typically temporary and resolve with proper system management. Many users report that biodigester toilet systems actually produce less odor than conventional toilets, particularly in comparison to chemical toilets or poorly maintained septic systems. The microbial digestion process effectively breaks down odor-causing compounds when operating under optimal conditions.

How much maintenance is required for a biodigester toilet?

Biodigester toilet systems require relatively minimal maintenance compared to conventional alternatives. Routine maintenance typically includes a visual inspection of the system components every 3-6 months, checking for leaks, proper gas flow, and normal effluent appearance. Users should monitor basic indicators like gas production rates and effluent clarity to ensure the system is functioning properly. Gas filters and lines should be checked and cleaned every 6-12 months to remove accumulated moisture and hydrogen sulfide that could affect appliance performance.

The most significant maintenance task involves removing accumulated solids from the digestion chamber, typically required only every 3-5 years for residential systems under normal use. This service is far less frequent than septic tank pumping and generally less costly. Daily operation requires no special attention beyond normal toilet use, though users should be mindful to avoid introducing harmful chemicals, antibiotics, or non-biodegradable materials that could disrupt the microbial ecosystem. With these basic maintenance practices, biodigester toilet systems typically provide reliable service for 15-20 years before major components require replacement.

Biodigester toilet systems represent a practical, sustainable solution for waste management that offers significant environmental and economic benefits compared to conventional alternatives. Their ability to transform waste into valuable resources while reducing water consumption and environmental impact makes them increasingly attractive for both off-grid and connected properties. As climate concerns grow and resource conservation becomes increasingly important, these systems provide a tangible way for households to reduce their ecological footprint while gaining greater self-sufficiency.

If you're ready to explore sustainable waste management options for your property, HomeBiogas offers complete biodigester toilet solutions designed for easy installation and reliable performance in various settings. To understand more about how these systems work, you can learn about anaerobic digesters and their role in waste management.