A biogas plant project involves using anaerobic digestion to break down organic waste (manure, food scraps, sewage) into biogas (methane and CO2) for renewable energy (electricity, heat, vehicle fuel) and nutrient-rich biofertilizer, scalable from small DIY units to large commercial facilities, supporting waste management and energy autonomy.

Biogas Plant Project Basics

- The cost of a biogas plant usually falls in the ballpark of $75-100 per cubic meter of capacity, and the cost per unit volume decreases as the size of the system increases

- Small agricultural biogas projects generally cost between $5,000-10,000 per kilowatt of electrical capacity installed

- The digester makes up 35-40% of the total installation costs, with additional costs for operation and maintenance

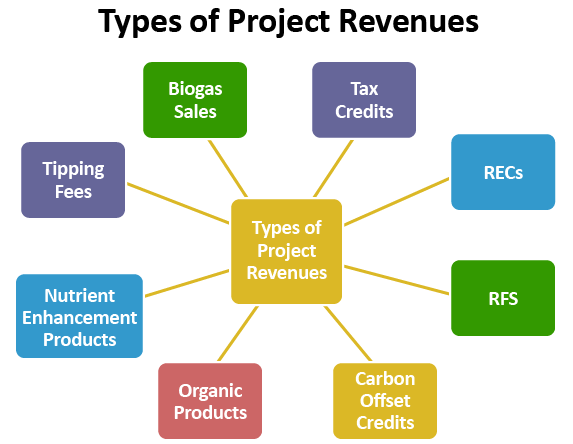

- Revenue streams include treatment fees, energy production, and fertilizer by-products that can offset initial investments

- Proper sizing based on feedstock availability is crucial for optimal financial returns, with ROI typically achieved in 2-7 years

Note: All the figures we give in this article are no more than a generalised guess! There are so many factors at play in every biogas plant project that you will only know the real cost of any biogas project when you complete project design, itemise each component and obtain quotes.

All successful biogas plant projects are an impressive combination of waste management and renewable energy production. By turning organic waste into clean energy and nutrient-rich fertiliser, these systems offer multiple revenue streams while solving environmental challenges. Whether you're considering a small residential unit or a large commercial installation,

understanding the true costs involved is essential for project success.

What is the Actual Cost of a Biogas Plant?

Setting up a biogas plant requires an investment that can vary widely based on the size, technology, and application of the plant. If you're looking at a basic unheated biogas system, you can expect costs to range from $75-100 per cubic meter of digester capacity, not including the cost of land. This is the price range for simple systems. More complex systems with advanced features will require a larger investment. However, there's a silver lining. The cost per cubic meter decreases significantly as the size of the system increases, which means larger projects benefit from economies of scale.

The cost of a biogas plant can be broken down into several categories. The digester, which is the main component of the system, makes up about 35-40% of the total cost.

The rest of the budget is used for gas collection systems, piping, biogas utilization equipment, construction labour, and control systems. In North America, a complete system for agricultural use typically costs between $5,000-10,000 per kilowatt of electrical capacity installed. This makes biogas plants one of the most affordable renewable energy solutions available.

Usual Investment Range: $5,000-$1M+ Based on Size

Small residential biogas digesters that serve 1-2 people generally cost $1,500-$5,000 and generate enough gas for cooking needs. Medium-sized systems that serve families or small farms range from $5,000-$15,000 and can produce enough energy for cooking, water heating, and some electrical production.

Large-scale systems for entire properties or commercial operations start around $15,000 and can exceed $1 million for industrial applications, but offer comprehensive energy solutions including electricity generation, heating, and vehicle fuel.

Location plays a crucial role in these costs. Developing regions might have lower material and labour costs, but they may face higher costs for importing equipment. Islands and remote areas usually have higher installation costs because of the challenges in transportation.

However, they often see faster returns on investment because their energy prices are traditionally high. Many island nations currently generate electricity using diesel at costs that are more than $0.50/kWh. For a deeper understanding of how biogas can be a sustainable energy solution in these regions, explore more about biogas generators.

Return on Investment: 2-7 Years for Most Home Systems

The amount of time it takes for a biogas system to pay for itself can vary greatly depending on a number of factors, but most well-planned home systems will pay for themselves within 2-7 years.

Farming applications will normally see a longer return on investment despite the double benefit of saving money on waste management and creating energy. When you factor in the money saved on waste disposal for food processing facilities that would otherwise have to pay for organic waste removal, the financials look a lot better.

The most obvious financial advantage comes from energy savings, particularly in areas where energy costs are high.

However, the fertiliser byproduct (digestate) is another valuable benefit that many project evaluations fail to consider. This nutrient-dense material can be used instead of commercial fertilisers, potentially saving agricultural operations thousands of dollars each year, while also enhancing soil health and crop productivity.

“How To Make Biogas at Home – A Step-by …” from www.homebiogas.com and used with no modifications.

Overlooked Expenses That Many Project Engineers Forget

Aside from the initial setup, comprehensive financial planning should also include continuous operational costs.

Maintenance has been suggested to cost 1.5-3% of the capital costs per year from year 1, and includes component replacement, system cleaning, and performance monitoring. The labour requirements depend on the size and complexity of the system, ranging from a few hours per month for small systems to full-time positions for industrial installations.

There are several project plans that tend to ignore crucial infrastructure enhancements such as access roads, grid interconnection costs for systems that generate electricity, or specialised equipment for handling specific feedstocks.

Another potentially huge expense is permitting and regulatory compliance, particularly in regions that are heavily regulated. Environmental impact assessments, air quality permits, and waste handling licenses can increase project costs by thousands and implementation timelines by many months.

The Advantages of Biogas Energy for Your Home

There are many reasons to consider a residential biogas system beyond just the potential cost savings. They can make your home more energy independent, help to solve waste management problems, and create a closed-loop system of sustainability where waste becomes a valuable resource.

For homeowners who are environmentally conscious, biogas generators are a practical way to significantly decrease the carbon footprint of your household while providing daily benefits that you can see and feel.

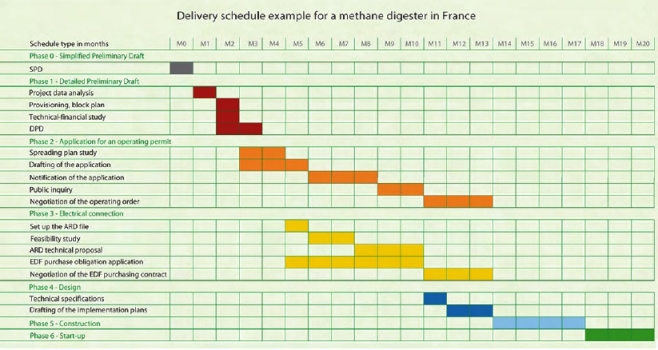

“Planning of a biogas plant” from www.biogas-renewable-energy.info and used with no modifications.

Turn Your Food Scraps Into Your Own Supply of Cooking Gas

Did you know that the average household throws away 20-30% of the food they buy? This constant supply of waste is perfect for creating biogas.

A home system that's the right size can turn this waste into 1-3 hours of cooking gas every day, depending on the size of your household and how much gas you use. This direct conversion from waste to energy gets rid of disposal costs and gives you a cooking fuel that burns cleanly. It has similar properties to natural gas, but it's made from renewable resources.

Biogas is a more versatile energy source than solar or wind, as it can be used with most existing natural gas appliances with only minor modifications.

With the addition of simple pressure regulators and condensate traps, standard kitchen stoves, water heaters, and space heaters can be adapted to run on biogas. This makes biogas a more cost-effective renewable energy solution.

Reduce Your Energy Costs by 20-60%

Switching to biogas can significantly lower household energy costs, with average savings ranging from 20-60% depending on current energy prices and system efficiency. In areas where natural gas or propane costs are high, the financial savings are even greater.

For a family that spends $150 a month on cooking and heating fuel, biogas could potentially save them more than $1,000 a year, while also providing them with energy security against changes in market prices.

Not only does it reduce the cost of fuel, but many families also report a decrease in garbage collection fees after the installation of biogas systems, as the volume of food waste drops significantly.

In cities where waste disposal is charged by weight or volume, these savings can add hundreds of dollars to your annual total financial benefit.

Shrink Your Carbon Footprint While Making Nutrient-Rich Compost

When you run a biogas system correctly, you're trapping methane that would normally be released into the atmosphere when organic waste decomposes.

Methane is at least 25 times more potent as a greenhouse gas than carbon dioxide, so trapping it is a big win for the environment. A typical home biogas system can prevent the equivalent of 2-4 tons of CO2 emissions every year—like taking a car off the road.

Aside from energy production, biogas systems also produce a nutrient-rich organic fertiliser as a byproduct. This liquid fertiliser contains nitrogen, phosphorus, and potassium that are readily available, along with beneficial microbes that improve the health of the soil.

Garden enthusiasts often report that their yields and plant vigour increase after applying digestate, eliminating the need for commercial fertilizers and creating another way for households to save money.

“Project Planning and Financing | US EPA” from www.epa.gov and used with no modifications.

The 4 Best Biogas Plants for Environmentally-Friendly Homeowners

Choosing the perfect biogas plant for your needs is essential for a successful project. Each model has its own unique benefits in terms of price, upkeep needs, and operational effectiveness.

The climate you live in, the space you have available, and the type of feedstock you plan to use will all play a big role in determining which system will work best for you. For example, understanding biogas generators can help you make an informed decision.

1. Fixed Dome Systems: The Most Long-Lasting Choice

Fixed dome digesters are characterised by a sturdy, stationary concrete or brick chamber that includes a built-in gas collection dome. The price for these systems is usually between $3,000 and $8,000 for home installations, but they can last for more than 20 years with little upkeep.

Their subterranean design offers inherent insulation, which makes them perfect for changing climates and ensures steady gas production even when the temperature varies.

“Fixed-dome Biogas Plants – energypedia” from energypedia.info and used with no modifications.

Fixed dome systems have the primary benefit of being durable and requiring little maintenance. These systems can function for many years with only minor attention due to their robust construction and lack of moving parts.

On the downside, they require expert construction methods to guarantee gas-tight seals, and their fixed volume provides less adaptability for fluctuating waste inputs than other designs.

Few of this type are built outside the tropics.

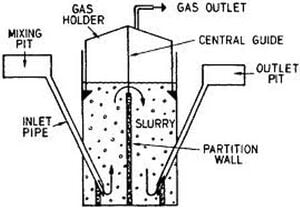

2. Floating Drum Digesters: Simple to Monitor

Floating drum systems employ a movable gas collection chamber that rises and falls depending on the volume of biogas stored. This visible movement allows for easy monitoring of gas production levels—a significant advantage for beginners.

These systems usually cost $2,000-$6,000 for home installations and provide good operational flexibility with moderate lifespans of 8-15 years.

Despite the production rate, the floating mechanism guarantees a steady gas pressure, resulting in a reliable performance for any connected appliances.

Nonetheless, the moving parts necessitate more upkeep than fixed dome systems, with regular cleaning and repainting required to avoid corrosion and gas leakage.

Floating drum systems may need a lot of additional insulation to keep digestion temperatures at their best in colder climates.

“Floating drum biogas digestor” from www.appropedia.org and used with no modifications.

3. Balloon/Tubular Digesters: An Affordable Introduction to Biogas

Balloon digesters are made from strong yet flexible materials like PVC or polyethylene that inflate as biogas is generated. These systems are the least expensive on the market, with full installations ranging from $1,000 to $3,000.

This makes them an excellent choice for those new to biogas who want to try it out without making a substantial financial commitment. Plus, their lightweight design means they can be moved fairly easily if necessary.

While they're cost-effective, balloon systems usually have a shorter lifespan of 3-8 years, depending on the quality of the material and exposure to the environment.

They are more susceptible to physical damage and temperature changes than rigid systems, often needing protection from direct sunlight and physical impacts. For optimal performance, these systems should be installed in climates that are consistent or with additional heating in colder seasons. For more insights on biogas systems, you can explore the future of waste-to-energy solutions.

![]()

“Balloon Digester – Build a Biogas Plant …” from www.build-a-biogas-plant.com and used with no modifications.

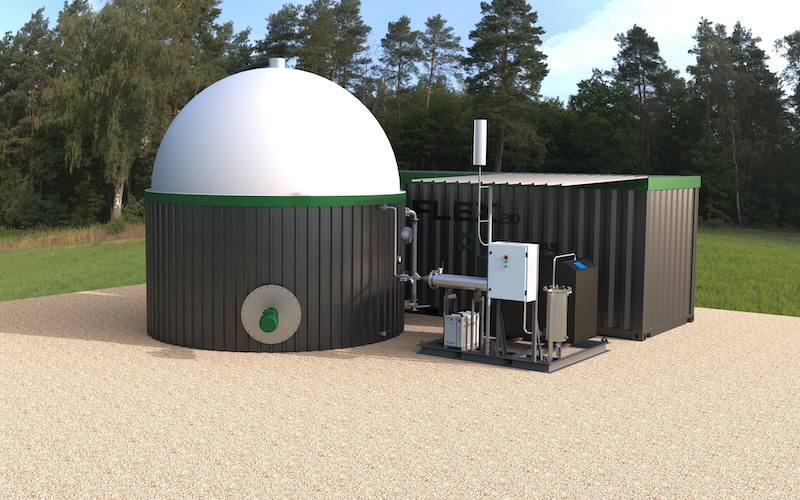

4. Prefabricated Units: Hassle-Free Solutions for Busy Homeowners

Pre-built biogas systems come ready to install with very little site preparation. These units, which you can simply plug in and start using, cost between $3,500 and $10,000 for residential sizes. They also come with advanced features like automated feeding mechanisms, temperature control, and built-in gas filtration systems. For homeowners who don't have much technical expertise or time, these systems are the easiest way to start producing biogas.

Contemporary pre-built units often come with monitoring technology that can connect to smartphone apps, which allows for remote system management and performance tracking. Although they are more expensive, the convenience and reliability of these factory-tested systems make the investment worthwhile for many households. Their modular design also often allows for future expansion as your biogas needs increase.

“Finn Biogas – Small Scale and Modular …” from finnbiogas.com and used with no modifications.

How to Plan Your Biogas Project: 5 Crucial Steps

Implementing a successful biogas project requires careful planning and realistic expectations. Following a structured approach to the design and implementation of the system will help you avoid common mistakes and ensure that your investment provides the maximum return. The planning phase often determines whether a biogas project will succeed or fail, making these preliminary steps as important as the actual construction.

First, Determine How Much Organic Waste You Produce

Before you choose any equipment, you should carry out a thorough waste audit to determine how much feedstock you have available. Keep track of kitchen waste, garden trimmings, and any agricultural residues for at least two weeks to establish reliable averages. As a general rule, each kilogram of food waste can produce about 0.3-0.5 cubic meters of biogas, while fresh animal manure can produce 0.2-0.3 cubic meters per kilogram.

The amount of waste you have is what will dictate the size of the system you need. If you get a system that is too small, it won't be able to handle the volume of your waste. On the other hand, if you get a system that is too large, you will be wasting money and it may not perform as well because it is not being fed enough. For a typical household, if you have 1-2kg of food waste per day, you can support a 1-2 cubic meter digester. This would provide you with 1-3 hours of cooking gas per day. If you have a farm with livestock, you have a lot more potential. A single dairy cow can produce enough manure to generate 1.5-2.5 cubic meters of biogas per day.

Required Equipment for Cooking with Biogas

Switching your kitchen to biogas is a relatively easy process that doesn't require much in the way of equipment changes. Most modern natural gas stoves can be used with biogas, but you'll need to install a pressure regulator (which costs between $50 and $100) and a biogas filter (which costs between $75 and $150) to remove any impurities. Some older stoves might need their gas jets widened to accommodate the slightly different combustion properties of biogas, but this is a simple modification that should cost less than $30 in parts.

If you want the best results, you might want to think about buying a biogas stove that has been specially designed for lower pressure and varying gas quality ($150-300). These stoves have wider burner ports and adjustable air mixtures, which means they can still burn efficiently even if the gas composition changes. If you install a simple condensate trap ($25-50) in the gas line, it will stop moisture from getting to the appliances. This will make sure the appliances work consistently and will also help them to last longer. For more information on biogas systems, you can check out the Biogas Plant Development Handbook.

Heating Solutions for Chilly Regions

In chillier regions, biogas can be used to power water heaters and space heaters with the right modifications. Water heaters usually need more gas than cooking appliances, requiring roughly 0.5 cubic meters of biogas for each hour they're in use. For reliable performance, think about setting up a biogas storage system ($500-1,500) that collects gas during times of low use to meet high heating demands.

Using Biogas to Illuminate Your Home

Biogas lamps offer a renewable source of light that uses only a modest amount of fuel. Regular biogas mantles, which cost between $20 and $40, emit a light that is comparable to kerosene lamps but without the need for fossil fuels or the risk of indoor air pollution. A single cubic meter of biogas can keep a mantle lamp lit for five to six hours, making it one of the most effective applications for small-scale biogas production.

For contemporary uses, biogas-fueled generators ($1,000-3,000) that generate power for standard LED lighting systems are a viable option. Although this method is less efficient than using biogas directly, it fits well with current household electrical systems and provides versatility for powering other equipment. Around 0.7 cubic meters of biogas generates 1 kWh of electricity—sufficient to power ten 10W LED bulbs for 10 hours.

Why Digestate is a Great Fertiliser

When people talk about biogas, they usually focus on the energy it produces. But there's another important aspect to consider: the liquid digestate that's left after the anaerobic digestion process. This is often overlooked in project planning, but it's a valuable resource. The digestate is a nutrient-rich slurry that contains plant nutrients and beneficial microorganisms. It's better for the soil than chemical fertilisers because it improves soil health.

Correctly treated digestate provides three key advantages: it lessens the reliance on synthetic fertilisers, boosts soil structure and water retention, and closes the nutrient cycle by reintroducing organic matter to productive use. For both gardeners and farmers, this byproduct can cover a significant part of the biogas system's expenses through savings on fertiliser and increased crop production. To learn more about how digestate can impact crop production, check out this analysis on biogas yield from maize silage vs. grass silage.

How to Apply Digestate for Optimal Garden Health

For the most effective use, fresh digestate should be diluted with water at a ratio of 1:4 and applied to the soil rather than the leaves of the plants. In vegetable gardens, about 2-3 litres of this diluted mixture should be applied per square meter each month during the growing season. Fruit trees and perennial plants will benefit from a quarterly application of 5-10 litres of the mixture around the drip line. This provides ongoing nutrition without the risk of nutrient burn. For those interested in application methods, consider using a self-propelled slurry spreader to efficiently distribute the mixture.

For large-scale farming needs, you can use specialised spreading equipment to distribute digestate over large areas. Many users report that the best results come from incorporating digestate into irrigation systems through venturi injectors or drip irrigation. This method ensures even distribution and minimises the amount of work required.

How to Store and Age Your Digestate

Once you have fresh digestate, it's best to let it age for two to four weeks before you use it. This allows the remaining organic matter to partially decompose and potentially harmful pathogens to reduce. It's also important to store your digestate in a covered container to prevent nitrogen from being lost through ammonia volatilisation and to protect it from being diluted by rain. For smaller residential systems, a simple 55-gallon plastic drum with a loose lid, which typically costs between $30 and $50, should provide enough storage.

Underground storage tanks are a great option in colder climates because they offer protection from freezing and they reduce the potential for odours. These systems usually cost between $200 and $500 for residential use, but they allow you to access this valuable resource all year round. For bigger operations, dedicated storage tanks are a necessary infrastructure investment that should be accounted for in the initial project budget.

Think about using a strategy that stores digestate seasonally, building up reserves during times of low demand for use during the height of the growing season. This method allows for the most efficient use of nutrients and gives you the flexibility to apply it based on the needs of your crops, rather than the schedule of your digester. For more insights on efficient application methods, explore slurry spreader application services.

Practical Examples of Successful Home Biogas Systems

Studying successful biogas implementations can give us useful insights into practical system design and operation. These practical examples show how different methods can successfully meet specific household needs and environmental conditions while providing reliable returns on investment. For instance, understanding biogas generators can highlight the future potential of waste-to-energy solutions.

Every case study has different priorities – from maximising energy production to minimising maintenance requirements or integrating with existing infrastructure. By studying these different approaches, you can find elements that match your own goals and constraints.

Get Started with a Biogas Project Today

Starting a biogas project doesn't require a large initial investment. You can start by conducting a waste audit to measure your potential feedstock, then research the best system options for your climate and space limitations. You might want to consider reaching out to BiogasPro Solutions, who offer free consultations to help homeowners figure out the best biogas technology for their unique situation and energy needs.

Common Questions

When you're thinking about installing a biogas system, you probably have a lot of questions about how the system works in practice and what kind of results you can expect. The answers below cover the questions that people most often ask when they're thinking about getting a biogas system, based on a lot of experience in the field.

While these broad guidelines apply to most cases, local conditions and specific system designs may lead to variations in performance and operational requirements. The most accurate expectations come from consulting with experienced installers who are familiar with your region. For instance, understanding the future of waste-to-energy systems can provide valuable insights into optimising your setup.

How much organic waste do I need to produce useful amounts of biogas?

On average, one person who prepares their own food (as opposed to consuming supermarket packet meals) generates enough kitchen waste to produce 0.2-0.4 cubic meters of biogas daily, which is enough for 20-40 minutes of cooking. So, a family of four could generate approximately 0.8-1.6 cubic meters daily, enough for 1.5-3 hours of cooking.

If you add yard waste and food scraps from neighbours or local businesses, you could significantly increase your biogas production and potentially meet all your household cooking needs, depending on how much you cook.

Will a biogas system stink?

Biogas systems that are well-designed and maintained should not have a strong odour. The process of anaerobic digestion happens in a closed environment, which traps any smells that would usually be released during regular composting. If there are any smells, it's usually because of maintenance problems like bad sealing or unbalanced feeding practices, which can be easily fixed. The feeding area might have a short, light organic smell like garden compost, but it stays in that area and doesn't spread to other areas.

Is it possible to set up a biogas plant in colder climates?

Biogas plants can function effectively in colder climates if they are designed correctly. Digestion activity slows down below 20°C (68°F) and becomes minimal below 10°C (50°F), but there are a few strategies that can keep the plant productive all year round.

Installing the plant underground can naturally insulate it, while solar thermal collectors, solar panels, or compost heat recovery systems can actively heat the digesters. Insulating the digester with materials like straw bales, foam board, or earth berming can significantly reduce the loss of heat.

If you live in a particularly cold region, you may want to consider a smaller system that is partially housed indoors in utility spaces or greenhouses, or systems that have dedicated heating elements that are powered by some of the biogas that is produced.

While these adaptations can increase your initial investment, they can ensure that your system performs consistently, regardless of how the temperature fluctuates outside.

What if I can't feed my biogas system because I'm away on vacation?

Don't worry if you can't feed your biogas system because you're on vacation. Modern biogas systems are designed to handle interruptions in feeding. If you don't add new inputs for 3-5 days, gas production will slowly decrease.

However, it won't stop completely for 2-3 weeks. If you're going to be away for a while, you can overfeed the system a bit for a few days before you leave.

This will increase biological activity. Also, make sure your gas storage systems are full.

When you get back, don't add a lot of feed all at once. Instead, gradually go back to normal feeding over several days. This will give the microbial population time to reactivate properly.