We were not aware of the beneficial applications of Black Salt in Biogas Production until we were contacted recently by Ankit Anil Patil, a research scholar from India.

The result is this article which is based upon his paper about the “APPLICATIONS OF BLACK SALT IN BIOGAS PRODUCTION AND EFFECTS ON OTHER IMPURITIES IN BIOGAS”:

Most of our readers are aware that Biogas, a sustainable alternative to fossil fuels, holds immense promise in the world of renewable energy. But, to be really useful biogas production needs to be made more productive and more reliable.

One of the key challenges of biogas production is the presence of impurities, notably hydrogen sulphide.

Enter black salt, an unassuming yet potent agent in improving the quality and safety of biogas.

[boomdevs_toc]

The Role of Black Salt in Enhancing Biogas Quality

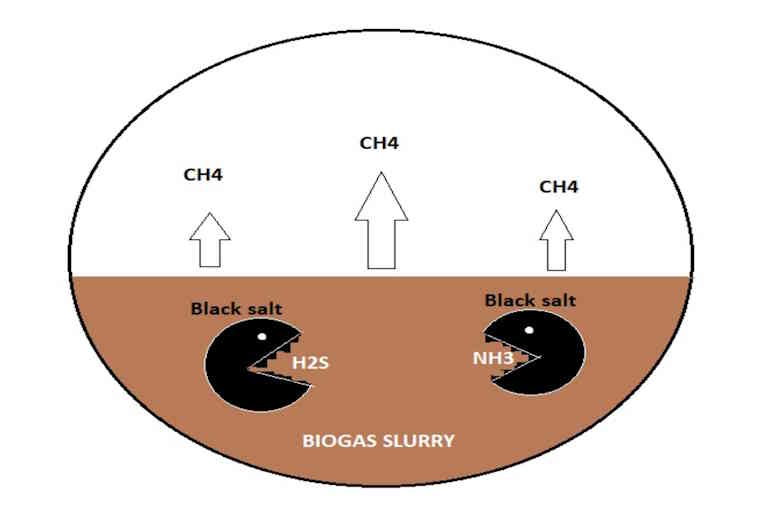

Understanding the various applications and effects of black salt in biogas production is paramount to leveraging its benefits. The research done by Ankit has revealed that Black Salt not only accelerates the anaerobic digestion process but also refines the quality of raw biogas by reducing the concentrations of detrimental impurities.

Chemical Compositions in Black Salt

The efficacy of black salt stems from its varied chemical constituents. Among them:

– Sodium chloride

– Sodium sulfate

– Sodium bisulfate

– Sodium bisulfite

– Sodium sulfide

– Iron (I, II) sulfide

– Hydrogen sulfide

Key Reactions and Impacts

– Iron (I, II) sulfide: This reacts with hydrogen sulfide to form pyrite, thus reducing the concentration of the harmful gas.

Reaction: FeS + H2S→ FeS2 + 2H

– Sodium bisulfate: Mainly used to maintain the pH within the ideal range of 6.5-7.5 for biogas production. Furthermore, its application in the poultry industry to combat ammonia and bacterial levels showcases its versatility.

– Sodium bisulfite: Acting as a reducing agent, it counteracts dissolved oxygen, thereby enhancing biogas quality.

Reaction: 2NaHSO3 + O2→ 2NaHSO4

– Sodium sulfide: Renowned as a desulfurizing and dechlorinating agent.

Benefits of Black Salt to the Anaerobic Digestion Process

The application of black salt is not just limited to improving the gas quality. Its role as a digestive aid has the following implications in biogas production:

– Enhanced Digestion: Incorporating black salt in the feed flow of the digestion slurry refines the raw biogas quality, presenting with reduced hydrogen sulfide and oxygen content.

– Accelerated Process: The digestion process, integral to biogas production, is expedited with the introduction of black salt.

Disadvantages of Using Black Salt in Biogas Production

While black salt has showcased numerous advantages in the realm of biogas production, it's imperative to also acknowledge potential downsides. Understanding these challenges can facilitate better decision-making for producers contemplating its incorporation.

Potential Concerns with Black Salt

1. Cost Implications

The introduction of additives into biogas production inevitably raises financial considerations:

– Initial Investment: Sourcing and introducing black salt as a regular additive can increase operational costs.

– Continuous Monitoring: To avoid overuse and ensure optimal performance, frequent monitoring is essential, leading to additional expenditure.

2. Imbalance in the Digestion Process

The precise amount of black salt required can vary based on several factors:

– Type of Organic Waste: Different waste types might react differently to black salt.

– Variable Temperatures: As temperature impacts the digestion process, the amount and effect of black salt can fluctuate.

Overuse or underuse can potentially disrupt the delicate equilibrium of the anaerobic digestion process, impacting biogas yield.

3. Excessive Sodium Content

Excessive sodium can pose environmental and process-related challenges:

– Environmental Concern: Elevated sodium levels can harm soil structures, reducing their ability to absorb water, leading to surface runoff and potential contamination.

– Digestate Quality: Higher sodium can adversely affect the quality of the digestate (a by-product of anaerobic digestion), which is often used as a soil enhancer.

4. Trace Impurities

Black salt is a naturally mined geological material that contains trace impurities that may be different according to the source and this might introduce unforeseen challenges:

– Chemical Reactions: Unintended reactions might occur due to impurities, potentially creating harmful by-products.

– Interference with Microorganisms: Certain impurities might interfere with the vital microorganisms responsible for anaerobic digestion.

Key Considerations for Producers

For producers contemplating the use of black salt, a few crucial considerations include:

- Thorough Testing: Before full-scale implementation, pilot-scale tests should be conducted to gauge the impact of black salt on specific waste types and conditions.

- Environmental Impact Assessment: Evaluate potential environmental repercussions, especially concerning sodium content.

- Continuous Monitoring: Keep an eye on the digestion process and biogas composition to ensure black salt is exerting the desired effects without introducing new challenges.

Conclusion

Ankit Patil has shown that harnessing the potential of black salt in biogas production can pave the way for cleaner and more efficient renewable energy.

It does this by reducing impurities in the biogas output and bolstering the anaerobic digestion process, black salt emerges as an indispensable asset in the world of sustainable energy.

Black salt is not an expensive commodity in most locations globally and dosing can be done either manually or using commonly available automatic dosing pump equipment.

But, while the applications of black salt in biogas production are undeniably promising, it's crucial to approach its usage judiciously.

Being aware of potential challenges and planning accordingly can help harness the benefits of black salt while mitigating its possible downsides.

Frequently Asked Questions (FAQs): Black Salt in Biogas Production

1. What is the primary role of black salt in biogas production?

Answer:

Black salt serves multiple purposes in biogas production. Its primary roles include:

– Enhancing the anaerobic digestion process.

– Reducing impurities, especially hydrogen sulphide and ammonia, in the raw biogas.

2. How does black salt impact the pH levels in a biogas digester?

Answer:

One of the constituents of black salt, Sodium bisulfate, is used to adjust and maintain the pH within the ideal range of 6.5-7.5 required for biogas production.

3. Can the use of black salt in biogas production be detrimental?

Answer:

Yes, there can be potential challenges. These include:

– Financial implications due to increased operational costs.

– Disruption in the equilibrium of the digestion process if not used judiciously.

– Elevated sodium levels affecting the environment and digestate quality.

– Unintended chemical reactions due to trace impurities in black salt.

4. What is the correlation between black salt and traditional medicinal practices in places like India?

Answer:

In India, black salt, known as ‘kala namak,' is utilized for its medicinal attributes, particularly as a digestive aid. Natural herbal medicines for indigestion problems that contain black salt are popular for addressing digestion issues. This traditional use underscores black salt's potential in improving the digestion process, be it in the human body or in biogas production.

5. Are there any environmental concerns associated with the use of black salt in biogas production?

Answer:

Yes. Elevated sodium levels, stemming from the use of black salt, can be detrimental to soil structures. This can result in reduced water absorption by the soil, leading to increased surface runoff and potential environmental contamination.

6. How can producers mitigate the challenges posed by black salt in biogas production?

Answer:

Producers can adopt several strategies:

- Conduct Pilot Tests: Before large-scale usage, testing black salt on specific waste types and conditions can provide insights.

- Monitor Sodium Levels: To prevent environmental concerns, continuously monitoring sodium levels is crucial.

- Ensure Optimal Usage: Avoid overuse or underuse by frequently checking the biogas composition and adjusting the amount of black salt accordingly.

7. How does black salt affect the rate of biogas production?

Answer:

Black salt aids in accelerating the anaerobic digestion process, potentially leading to a quicker rate of biogas production. Additionally, the improved quality of raw biogas can make the extraction process more efficient.

8. What are the primary constituents of black salt that influence biogas production?

Answer:

Several compounds in black salt influence biogas production. Noteworthy ones include:

– Sodium bisulfate

– Sodium bisulfite

– Sodium sulfide

– Iron (I, II) sulfide

These compounds play a role in reducing impurities, adjusting pH levels, and enhancing the overall digestion process.

9. How much black salt should you add to the digester feed?

How much black salt to add to biogas plants is not well reported. The closest guidance we found was for the addition of table salt.

Adding anything from 2 gm/litre to 12 gm/l to the feed may be optimum (based on table salt NaCl) depending on the feed material. Experimentation using a laboratory bench-scale trial reactor is recommended in order to assess the optimum dosing rate. Source: www.mdpi.com

Conclusion

While black salt offers numerous benefits in biogas production, it's essential to understand its applications, potential challenges, and means of optimizing its usage.

We hope this FAQ section provides clarity on the subject and aids in informed decision-making.