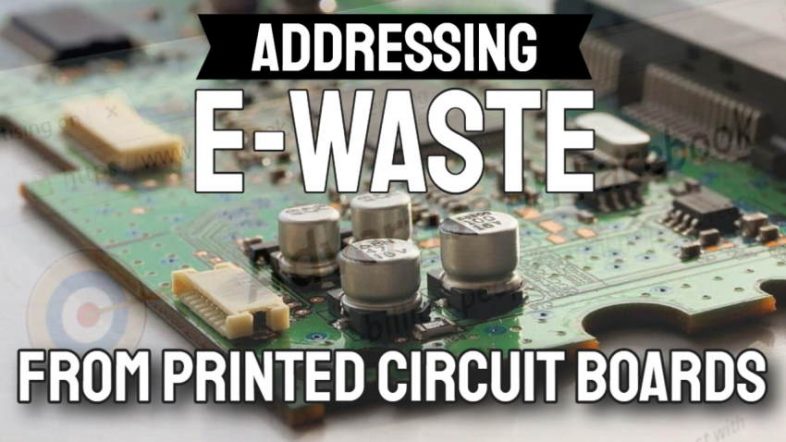

In addressing sustainable waste in the past, we’ve written specifically about the needs of industrialized nations. Another vital need of developed nations is for them to address the sustainability issues created by E-Waste from printed circuit boards specifically.

We've touched on the “treating and sanitizing of wastes” in this blog before. so, in this article, we pick up on that topic again in one area in which treating waste is a particularly important process.

This is in the electronics sector, and specifically the smartphone market which results in large quantities of E-Waste from the printed circuit board inside every one of them.

E-Waste From Printed Circuit Boards

The actual casings of modern smartphones are not particularly harmful; they last long enough with most users that the cycle of disposing of them and obtaining new ones is not dramatically damaging. On the whole, however, the environmental impact of smartphones is severe. This is largely because of the materials inside of them — which require significant emissions to mine and produce, and which are particularly difficult to dispose of.

A portion of that problem relates to metals and other substances that are used in small amounts in the building of smartphones.

However, in this piece, we’re focusing primarily on printed circuit boards. These small electrical processing units, also called “PCBs,” are present and wholly necessary in all modern smartphones. And historically speaking, they can be problematic from a recycling standpoint. They don’t degrade naturally, and they often end up tossed into landfills after use, allowing potentially harmful materials back into the environment.

Fortunately, there are numerous aspects of modern PCB design that are helping to minimize the impact of these components on the environment.

Biodegradable Materials

Right now it’s unclear how widely biodegradable PCB alternatives are being used. However, there has been some word of such products being designed in recent years. A range of natural and plant-based materials including even fibres pulled from the stems of bananas have been used to make them, and the production methods have supposedly been eco-friendly as well.

Again, it’s hard to tell where these PCBs are being applied, and widespread usage may not be a reality for some time. But it could be that PCB material will move in a more sustainable direction in the future.

3D-Printed PCBs

3D printing is viewed by many as a sustainable production method purely because it wastes less material than other options. And recently we’ve begun to see 3D printing used for PCB design. This process requires highly capable design software, but in the end, it can result in PCBs that are made only with the exact amount of material they require to operate. By contrast, an ordinary PCB may result in little bits and pieces of waste that are no longer useful, and which thus become unnecessary waste. In this sense, while 3D printing doesn’t solve the ultimate recycling issue, it does make for more responsible production, potentially on a significant scale.

More Durable Designs

One piece on the e-waste associated with PCBs eyed some recommendations for waste management and pointed out that designing for durability can also be a solution. We mentioned above that certain parts of smartphones are not particularly harmful simply because the devices last a long time. In theory, PCBs could also be made less harmful if they become more durable, and thus need to be replaced less frequently. In part for this reason we’ve begun to see PCBs manufactured using a broader range of materials, as well as dense, multi-layered stacks of material that are somewhat more robust in their construction.

One piece on the e-waste associated with PCBs eyed some recommendations for waste management and pointed out that designing for durability can also be a solution. We mentioned above that certain parts of smartphones are not particularly harmful simply because the devices last a long time. In theory, PCBs could also be made less harmful if they become more durable, and thus need to be replaced less frequently. In part for this reason we’ve begun to see PCBs manufactured using a broader range of materials, as well as dense, multi-layered stacks of material that are somewhat more robust in their construction.

E-waste from PCBs may not be a problem that can be entirely solved, at least in the near future. But there are positive steps being made, as PCB designers and suppliers apply new methods and materials to their processes.

PCBs Made from Biodegradable Materials – Organic Printed Circuit Boards – An Update

(Updated May 2023 with new research information since our original posting in 2020.)

When first we wrote on this subject (eWaste From Printed Circuit Boards) the connection between PCBs and organic waste with biogas production, appeared to be remote. That was until we became aware that scientists were developing sustainable PCBs using biodegradable materials and organic material waste might be a source for the material.

The intervening 3 years have seen a surge in interest in sustainable materials and eco-friendly technologies.

As a result, researchers have continued exploring new ways to create electronic devices that are both functional and environmentally responsible. One promising area of research still being investigated, is the use of organic waste to create eWaste From Printed Circuit Boards which can be recycled into new printed circuit boards.

PCBs Made from Food Waste, Paper Waste, and Agricultural Waste are Possible

Are you interested in the latest innovations in eco-friendly technologies? If so, you'll want to hear about the exciting developments in eWaste from Printed Circuit Boards made from organic waste.

Researchers have been exploring new ways to create electronic devices that are both functional and sustainable, and recent studies have shown that organic waste materials can be used to create high-quality printed circuit boards.

Not only does this provide a sustainable alternative to traditional materials, but it also offers potential benefits in terms of performance and cost-effectiveness. Keep reading to learn more about this cutting-edge area of research and its potential impact on the electronics industry.

Not only does this provide a sustainable alternative to traditional materials, but it also offers potential benefits in terms of performance and cost-effectiveness. Keep reading to learn more about this cutting-edge area of research and its potential impact on the electronics industry.

Recent developments in the “E-Waste From Printed Circuit Boards” field have shown that it is possible to create printed circuit boards using a variety of organic waste materials, including food waste, paper waste, and agricultural waste. These materials are tipped to be possible raw materials for PCB use if processed to extract cellulose, lignin, or other useful components that can be used to create high-quality printed circuit boards.

One major benefit of using organic waste in this way is that it provides a sustainable alternative to traditional materials like fibreglass and copper, which can be harmful to the environment. Additionally, organic waste materials are often readily available and inexpensive, making them an attractive option for manufacturers.

Recent studies have shown that printed circuit boards made from organic waste can be just as effective and durable as those made from traditional materials. In fact, some researchers have suggested that these eco-friendly materials could actually outperform traditional materials in certain applications.

While there are still some challenges to overcome in terms of scalability and commercial viability, the progress made in this area is encouraging. As more and more companies look to adopt sustainable practices, the use of organic waste in printed circuit board manufacturing could become a more widespread and accepted practice in the electronics industry.

At “end of life” the organic content of these new sustainable organic PCBs might end up in an anaerobic digester to give back their embedded energy. It is not a truly “circular economy” solution but this is getting close.

[This post was originally published in April 2020.]