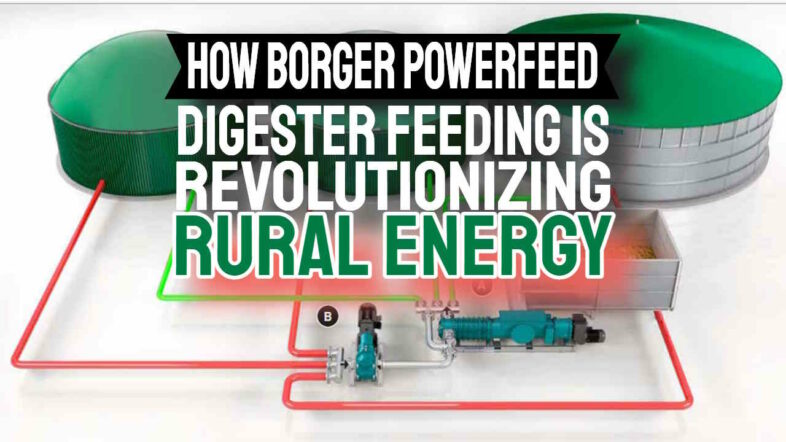

In this article, we explain how the Borger Powerfeed Biogas Feeding System powers the biogas digesters which are revolutionizing rural energy production. This is followed here by a Press Release which provides a case study of it powering up a farm in Sychtyn, North Wales.

Introducing the Borger Powerfeed

The Borger Powerfeed is a biogas plant feeding system that is designed to make the process of anaerobic digestion more efficient and reduce demands on operator time on busy farms. The system is used in biogas plants to feed organic waste, such as food waste and manure, into the digester where it is broken down by microorganisms to produce biogas.

The Powerfeed system features a compact design that allows for a high volume of organic waste to be processed and dosed into the digester tanks automatically at regular intervals.

This in turn may lead to increased biogas production because the microorganisms grow most efficiently when continually being fed on an hourly basis.

Additionally, the system is equipped with a number of features that make it low maintenance, including:

- a self-cleaning rotor and

- a wear-resistant material is used that reduces the need for frequent repairs and replacements.

The system is also designed to be user-friendly, with an intuitive control panel that makes it easy to operate and monitor the feeding process. This allows for greater control over the biogas production process and helps to ensure that the plant is operating at peak efficiency.

Overall, the Borger Powerfeed is a cutting-edge feeding system that offers many benefits to biogas plant operators, including:

- increased efficiency,

- low maintenance, and

- user-friendly automatic operation.

Whether you are a small-scale operator or a large-scale producer, the Powerfeed system can help you to take your biogas production to the next level.

Press Release (April 2023):

Raw Power at rural biogas plant with low-maintenance Borger Powerfeed feeding system

When Edward Vaughan decided to diversify into renewable energy at his fifth-generation family farm in Sychtyn, North Wales, he could have been tempted perhaps to have built as big an anaerobic digestion plant as possible, but his attention to the economies of scale has paid off.

The biogas plant, from which an impressive 80% of clean, renewable energy is exported, has slotted right into the existing land at JB & E Vaughan, rather than the farm having to change to accommodate the new technology.

“Seven years ago, it was all completely new”, said Edward, “but you learn by your mistakes and have to quickly get to grips with the learning curve. The price of energy wasn’t the main driver then. We’d just reached a point where it made sense to diversify, control our costs and not have all our eggs in one basket. A decade ago, we’d invested in a 250kW wind turbine, and moving forward with a biogas plant that could require plenty of extra work, we wanted simplicity, but with maximum output”.

Producing grass silage and spring barley on the 850-acre farm, Edward also has his 300-strong beef herd to look after, plus 1200 sheep. So, part of that wish for simplicity and importantly, easy maintenance, came in the form of investing in an automated Powerfeed unit from Borger, to convey the organic feedstock of crops, manure and chicken litter.

“We did our homework properly”, added Edward, “visiting farms to see the Borger unit in operation and find out why it had been so strongly recommended. Feedstock for biogas is always going to cause wear and tear on equipment, so we also wanted a UK company that wouldn’t keep us waiting for spare parts when we needed them”.

The Powerfeed set-up, which includes a Borger rotary lobe pump, can integrate into an existing biogas system at an appropriate point in the pressure pipe system to convey the feedstock into the flow pipeline. It is a closed system, so it prevents odours from escaping and prevents gas leaks. Only light agitation in the tank is required, so power consumption is kept to a minimum.

“Price-wise, it was competitive”, said Edward, “and we also wanted to work together with a company where we could fine-tune equipment to suit our needs. After seeing how the process worked for our feedstock, we worked with Borger to slightly modify the Powerfeed, so that it could operate in reverse as well as forwards. When needed, this helps keep everything moving better and prevents any blocking. To this day, we can still pick up the phone to Borger and they’ll help with advice”.

Edward built a filling hopper to supply the organic matter to the Powerfeed, which is designed with an auger shaft that also breaks down the feedstock and compresses it towards the press channel. This leads to the flushing unit, which is connected to the flow pipeline. The clumps that form in the press channel have the effect of a self-renewing seal. The substrates obtain a larger surface area, removing trapped air.

Every two and a half to three hours, 2.5 tonnes of organic matter at JB & E Vaughan is fed through by the automated system into the biogas plant digester, which comprises primary and secondary tanks (both 1200m3). The farm also benefits from two boilers, which bring the total power output up to 450kW. Once again, that important planning and economies of scale came into play as the existing infrastructure for the wind turbine helped minimise gas-to-grid connection costs for the exported energy.

“The plant produces plenty of power”, continued Edward, “but with the Borger Powerfeed as part of the set-up, we also benefit from the very good quality digestate that we get from the end of the process. We add farmyard manure to our feedstock, which might not produce that much gas but is very good for the biology. Our soil is so much healthier. You can see loads more activity. It’s full or worms! We no longer have to buy fertiliser, which as all farmers know, has had a huge increase in price.

This has become a big part of us keeping our costs under control. Also, the low pH of the fertiliser at around four to five meant that what we were adding was really too acidic, whereas the biogas digestate at a pH of around 7.8 acts more like an alkaline”.

He continued:

“Overall, everything pretty much runs of its own accord, which is what I hoped for at the very beginning; and I can monitor the whole plant remotely. There are very few moving parts in the Borger Powerfeed, so there isn’t excessive wear, but running a biogas plant properly is a 24/7 job, so we have a complete set of spares available to prevent any downtime.“

To learn more go to the Borger Brochures page here and download the Borger Powerfeed pdf File.

Borger UK 01902 798 977

www.boerger.com

uk@boerger.com

— ends —

This has become a big part of us keeping our costs under control. Also, the low pH of the fertiliser at around four to five meant that what we were adding was really too acidic, whereas the biogas digestate at a pH of around 7.8 acts more like an alkaline”.

This has become a big part of us keeping our costs under control. Also, the low pH of the fertiliser at around four to five meant that what we were adding was really too acidic, whereas the biogas digestate at a pH of around 7.8 acts more like an alkaline”.