Key Takeaways

- Liquefying biogas enhances its energy density by up to 600 times, making it more efficient to store and transport.

- Biogas must be purified by removing impurities like carbon dioxide and hydrogen sulfide before it can be liquefied.

- Methods like cryogenic cooling and membrane filtration are used to liquefy biogas.

- Liquefied biogas can be used as a transportation fuel, for heating, and in electricity generation.

- Advanced technologies and supportive policies are paving the way for more widespread use of liquefied biogas.

The Importance of Liquefying Biogas

In the quest for renewable energy solutions, liquefying biogas stands out as a crucial advancement. This process not only enhances the energy potential of biogas but also addresses several logistical challenges associated with its use. Most importantly, liquefying biogas transforms it into a more versatile and manageable form, opening up a plethora of applications.

Boosting Energy Density

Biogas, in its natural state, consists mainly of methane and carbon dioxide. By liquefying biogas, we significantly increase its energy density. This means that the same volume of liquid biogas holds much more energy than its gaseous counterpart. This increase, up to 600 times more energy per unit volume, makes it a powerful and efficient energy source.

Imagine trying to store a balloon filled with air versus a bottle filled with water; the latter holds more substance in the same space. Similarly, liquefied biogas takes up less space while packing more energy, making it ideal for storage and transportation.

Facilitating Easy Transportation

Transporting gas can be tricky due to its low density and high volume. Liquefying biogas resolves this by reducing its volume, making it much easier to transport over long distances. This is especially beneficial for areas that lack an extensive pipeline infrastructure.

For example, liquefied biogas can be transported in specialized tankers or containers, reaching remote areas where laying pipelines would be impractical or too costly. Therefore, liquefying biogas not only optimizes transport but also extends its reach to a broader range of users.

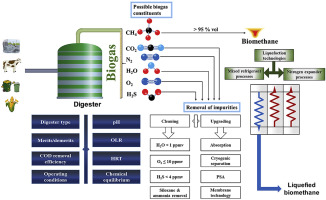

![]()

“biomethane liquefaction …” from www.sciencedirect.com and used with no modifications.

Enhancing Storage Capabilities

One of the significant challenges with biogas is its storage. In its gaseous form, it requires large storage facilities, which can be expensive and space-consuming. Liquefying biogas, however, allows it to be stored in cryogenic tanks for long periods without significant energy loss.

This means that energy producers can store surplus biogas during times of low demand and release it when the demand spikes, ensuring a stable and reliable energy supply. It's a practical solution that enhances the flexibility and resilience of energy systems.

“Biogas to liquefied biomethane …” from www.sciencedirect.com and used with no modifications.

Reducing Environmental Impact

Liquefying biogas also has environmental benefits. By capturing and utilizing methane—a potent greenhouse gas—biogas liquefaction helps mitigate climate change impacts. Instead of releasing methane into the atmosphere, which contributes to global warming, we can convert it into a valuable energy source.

Moreover, the process supports sustainable waste management by utilizing organic waste to produce biogas, which is then liquefied. This not only reduces landfill waste but also promotes a circular economy where waste is turned into a resource.

Challenges in Biogas and Liquid Methane Handling

Despite its advantages, handling biogas and its liquefied form presents certain challenges. Understanding these hurdles is essential for anyone looking to delve into the world of biogas liquefaction.

- Variable Composition of Biogas

- Contaminant Management

- Storage and Infrastructure

“How to Convert Biogas into Liquid …” from blog.anaerobic-digestion.com and used with no modifications.

Variable Composition of Biogas

Biogas is produced through the anaerobic digestion of organic materials, which means its composition can vary depending on the source material. This variability poses a challenge in standardizing the liquefaction process. For instance, biogas from agricultural waste might have a different methane concentration compared to that from municipal waste.

To address this, precise monitoring and adjustment of the biogas composition are required before liquefaction. This ensures that the final product meets quality standards and is safe for use.

Cryogenic Cooling Systems

Cryogenic cooling is one of the most effective methods for liquefying biogas. This process involves cooling the biogas to extremely low temperatures, typically below -160 degrees Celsius, where it transitions from a gaseous to a liquid state. The technology behind cryogenic cooling is sophisticated, relying on advanced refrigeration systems to achieve these frigid temperatures.

One key advantage of cryogenic systems is their ability to handle large volumes of biogas efficiently. They are particularly well-suited for industrial applications where large-scale biogas liquefaction is required. However, the initial investment and operational costs can be significant, necessitating careful planning and consideration of cost-benefit ratios.

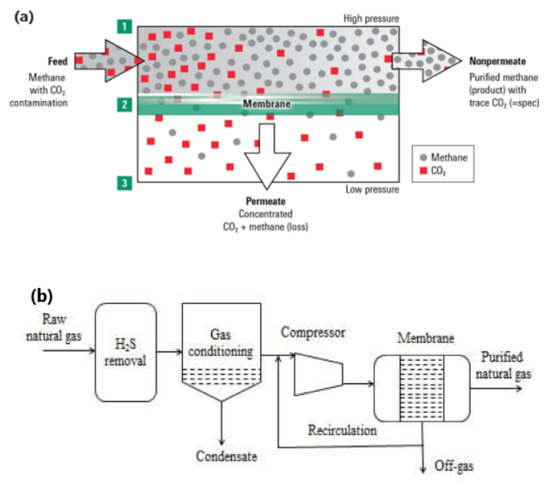

Membrane Filtration Processes

Membrane filtration is another innovative technique used in the liquefaction of biogas. This process involves passing biogas through semi-permeable membranes that separate methane from other gases, like carbon dioxide and hydrogen sulfide. Once purified, the methane is then cooled and liquefied.

Membrane filtration is favored for its simplicity and efficiency, particularly in smaller-scale operations. It's a modular solution, meaning it can be easily scaled up or down depending on the volume of biogas being processed. Moreover, this method offers a high degree of purity in the end product, making it a reliable choice for various applications.

“Membrane Technology …” from www.mdpi.com and used with no modifications.

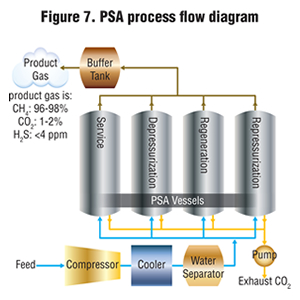

Pressure Swing Adsorption (PSA)

Pressure Swing Adsorption is a widely used technology in the purification and liquefaction of biogas. This method involves using adsorbent materials to capture impurities under high pressure. Once these impurities are removed, the pressure is reduced, and the purified methane is collected and subsequently liquefied. For more insights into the process, explore biogas liquefaction techniques.

PSA systems are renowned for their robustness and effectiveness in removing a wide range of contaminants. They are often employed in conjunction with other technologies, such as cryogenic cooling, to enhance the overall efficiency of the liquefaction process. This combination ensures that the resulting liquid biogas is of high quality and suitable for various end uses.

“Basics Of Biogas Upgrading | BioCycle” from www.biocycle.net and used with no modifications.

Optimizing the Liquefaction Process

To maximize the benefits of biogas liquefaction, it's crucial to optimize the process. This involves leveraging advanced technologies and techniques to enhance efficiency, reduce costs, and improve the quality of the final product.

Optimization requires a thorough understanding of the biogas composition, the specific needs of the end-users, and the capabilities of the liquefaction technologies in use. By addressing these factors, we can ensure that the process is as efficient and effective as possible.

Utilizing Advanced Cooling Systems

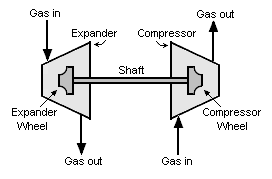

Advanced cooling systems play a pivotal role in optimizing the liquefaction process. These systems are designed to achieve the low temperatures required for biogas liquefaction with minimal energy consumption. Technologies such as turbo-expanders and advanced heat exchangers are commonly used to improve cooling efficiency. For more insights on enhancing biogas systems, explore our biogas plant mixing guide.

“Turboexpander – Wikipedia” from en.wikipedia.org and used with no modifications.

Improving Energy Efficiency

Improving energy efficiency is a critical aspect of optimizing biogas liquefaction. By minimizing energy usage during the cooling and purification stages, we can reduce operational costs and enhance the overall sustainability of the process. This can be achieved through the use of energy recovery systems, which capture and reuse waste heat generated during the liquefaction process.

Incorporating Renewable Energy Sources

Incorporating renewable energy sources, such as solar or wind power, into the liquefaction process can further enhance its sustainability. By powering the liquefaction systems with renewable energy, we can reduce the carbon footprint of the entire operation, aligning it with broader environmental goals and policies.

Applications of Liquefied Biogas and Liquid Methane

Liquefied biogas and liquid methane have a wide range of applications, making them valuable resources in the renewable energy landscape. These applications span various sectors, from transportation to residential and industrial uses.

Transportation Fuel Benefits

“bio methane offering …” from envirotecmagazine.com and used with no modifications.

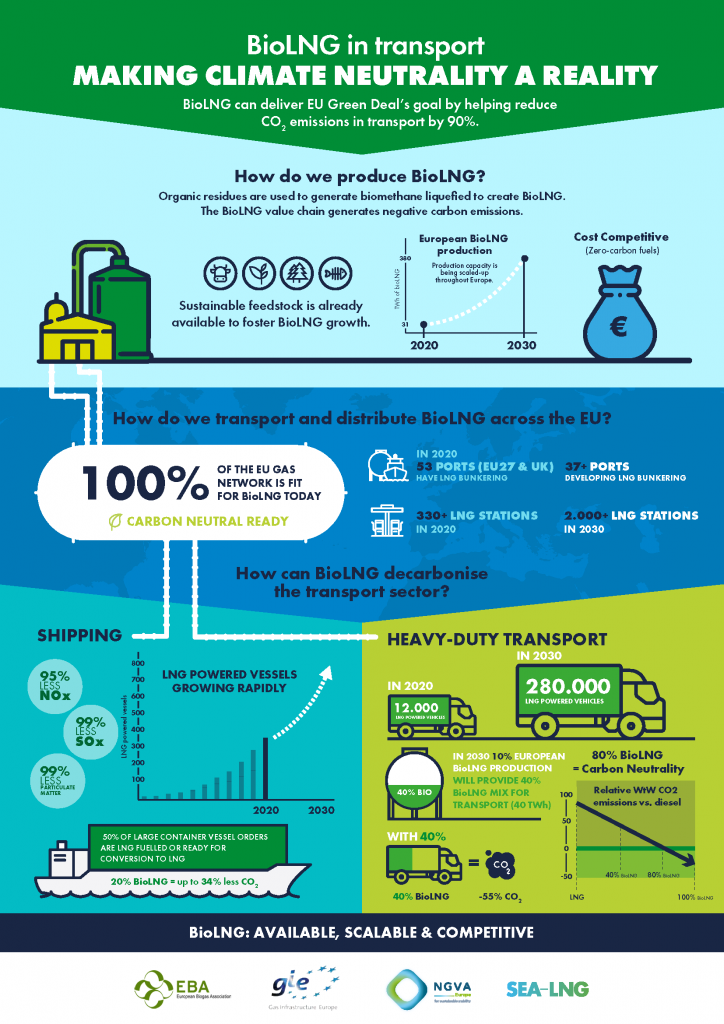

One of the most promising applications of liquefied biogas is as a transportation fuel. Due to its high energy density, it is particularly suitable for heavy-duty vehicles, such as trucks and buses, which require substantial amounts of fuel. Using liquefied biogas as a fuel reduces greenhouse gas emissions, contributing to cleaner air and a healthier environment.

Industrial and Residential Heating

Liquefied biogas can also be used for heating purposes in both industrial and residential settings. Its high energy content makes it an efficient and cost-effective option for heating systems. In industrial applications, it can be used to power boilers and other heat-generating equipment, while in residential areas, it can provide a reliable source of heat during colder months.

Besides that, the use of liquefied biogas for heating reduces reliance on fossil fuels, supporting the transition to a more sustainable energy system.

Electricity Generation

Another significant application of liquefied biogas is in electricity generation. By converting biogas into electricity, we can provide a consistent and renewable power source for homes and businesses. This is particularly beneficial in remote areas where access to the conventional power grid is limited.

By integrating liquefied biogas into electricity generation systems, we not only enhance energy security but also contribute to a more sustainable and resilient energy infrastructure.

Successful Case Studies

Numerous successful case studies worldwide demonstrate the potential of liquefied biogas. For example, in Sweden, biogas liquefaction projects have been instrumental in reducing the country's reliance on fossil fuels for transportation. These projects showcase the economic and environmental benefits of adopting liquefied biogas as a primary energy source.

Innovative Biogas Projects Worldwide

Innovative biogas projects are paving the way for a cleaner, more sustainable future. For instance, in Germany, a biogas plant in the city of Schwandorf is using local agricultural waste to produce liquefied biogas, which is then used to fuel public buses. This initiative not only reduces emissions but also supports local farmers by providing them with a market for their waste products.

Similarly, in India, a project in Pune is transforming food waste from local markets into biogas. This biogas is then liquefied and used to power local businesses and homes, providing a reliable and eco-friendly energy source. These projects highlight the versatility and potential of liquefied biogas in addressing both energy and waste management challenges.

Community Impact and Economic Benefits

Liquefied biogas projects have significant community and economic benefits. By creating a local source of renewable energy, these projects reduce dependency on imported fossil fuels, keeping energy costs stable and predictable. They also generate jobs in the construction, operation, and maintenance of biogas facilities.

In addition, communities benefit from improved waste management practices, as organic waste is diverted from landfills to biogas plants. This not only reduces methane emissions from decomposing waste but also extends the life of existing landfill sites. Moreover, the use of local waste materials helps foster a circular economy, where resources are continuously reused and recycled. For more insights, read about the UK's progress towards biodegradable waste diversion.

“BioLNG makes carbon neutrality …” from sea-lng.org and used with no modifications.

Future Directions in Biogas Liquefaction

The future of biogas liquefaction looks promising, with advancements in technology and growing support from governments worldwide. As more countries recognize the importance of reducing carbon emissions and transitioning to renewable energy, biogas liquefaction will likely play a crucial role in this transformation.

Investment in research and development is essential to further enhance the efficiency and cost-effectiveness of biogas liquefaction technologies. By focusing on innovation, we can unlock the full potential of biogas as a renewable energy source and drive the transition to a more sustainable energy future.

Technological Advancements

Technological advancements in biogas liquefaction are crucial for improving efficiency and reducing costs. New techniques in cryogenic cooling and membrane filtration are making it easier to liquefy biogas at a lower cost. Moreover, the integration of artificial intelligence and machine learning in process optimization is expected to further enhance the efficiency of biogas liquefaction plants.

Regulatory and Policy Support

Government policies and regulations play a significant role in promoting biogas liquefaction. Incentives such as tax breaks, subsidies, and grants can encourage investment in biogas infrastructure and technology. Additionally, setting renewable energy targets and mandates can drive the adoption of biogas as a mainstream energy source.

Expanding Market Opportunities

The market for liquefied biogas is expanding as more industries recognize its benefits. Sectors such as transportation, agriculture, and manufacturing are increasingly adopting liquefied biogas to reduce their carbon footprint and meet sustainability goals. As demand grows, there will be more opportunities for innovation and investment in biogas technologies.

Frequently Asked Questions

Many people have questions about biogas liquefaction and its applications. Here, we address some of the most common inquiries to help you better understand this renewable energy source.

What Is the Process of Liquefying Biogas?

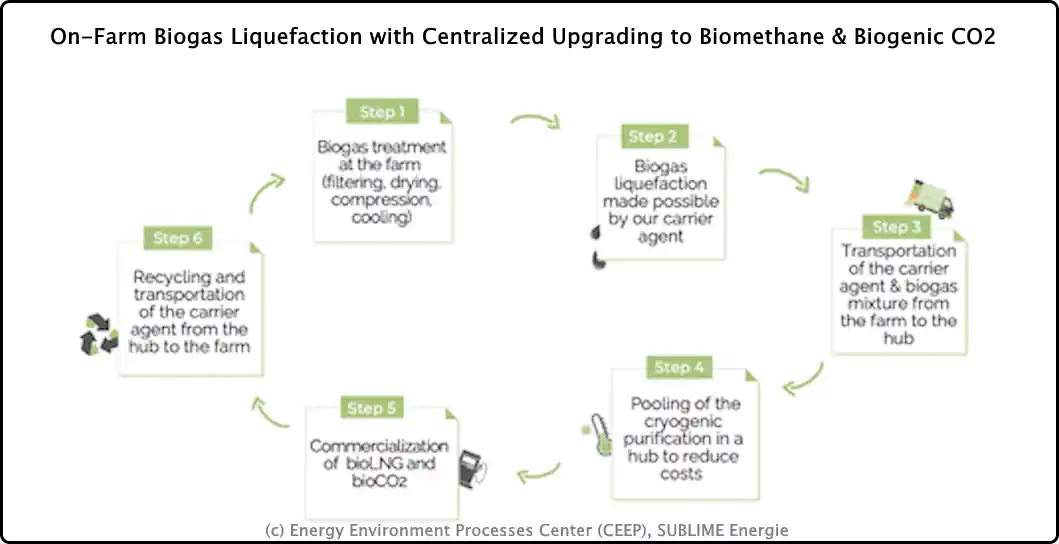

The process of liquefying biogas involves several key steps. First, biogas is purified to remove impurities such as carbon dioxide, hydrogen sulfide, and water vapor. This is typically done using techniques like membrane filtration or pressure swing adsorption.

The purified biogas, primarily methane, is then cooled to cryogenic temperatures, around -160 degrees Celsius, where it transitions into a liquid state. This liquid form, known as bio-LNG, is easier to store and transport, making it a versatile energy source.

Once liquefied, bio-LNG can be used in various applications, from transportation to electricity generation, providing a clean and efficient energy solution.

How Does Liquefied Biogas Compare to Other Fuels?

Liquefied biogas, or bio-LNG, offers several advantages over traditional fossil fuels. It has a higher energy density, meaning it can store more energy in a smaller volume. This makes it particularly useful for applications where space and weight are concerns, such as in transportation. For more insights into the differences and benefits, check out this comparison of biogas vs biomass energy.

Moreover, bio-LNG is a renewable energy source, reducing greenhouse gas emissions compared to fossil fuels. It is also produced from waste materials, supporting sustainable waste management practices and contributing to a circular economy.

What Are the Environmental Benefits of Biogas Liquefaction?

Biogas liquefaction offers numerous environmental benefits. By capturing methane emissions from organic waste, it helps mitigate climate change impacts. Methane is a potent greenhouse gas, and its capture and conversion into energy prevent it from entering the atmosphere.

Additionally, liquefied biogas reduces reliance on fossil fuels, decreasing carbon emissions and air pollution. It also promotes sustainable waste management by diverting organic waste from landfills and converting it into a valuable energy source. For more information, you can read about the UK's progress towards biodegradable waste diversion.

- Reduces greenhouse gas emissions

- Supports sustainable waste management

- Promotes a circular economy

These environmental benefits make biogas liquefaction an essential component of a sustainable energy future.

Are There Specific Industries That Benefit Most from Liquefied Biogas?

Several industries stand to benefit significantly from the adoption of liquefied biogas. The transportation sector, in particular, can leverage bio-LNG as a clean alternative to diesel and gasoline. Heavy-duty vehicles, such as trucks and buses, can achieve significant emissions reductions by switching to bio-LNG.

In addition, industries with high energy demands, such as manufacturing and agriculture, can use liquefied biogas to power their operations sustainably. Residential and commercial heating systems can also benefit from the clean energy provided by bio-LNG.

- Transportation (trucks, buses)

- Manufacturing and industrial operations

- Agriculture (farm equipment)

By adopting liquefied biogas, these industries can reduce their environmental impact and support the transition to a more sustainable energy system.

What Are the Challenges in Scaling Biogas Liquefaction Technologies?

Scaling biogas liquefaction technologies presents several challenges. One of the primary obstacles is the high initial investment required for setting up biogas plants and liquefaction facilities. These costs can be a barrier for small-scale producers and communities looking to adopt the technology.

Additionally, the variability in biogas composition can complicate the standardization of the liquefaction process. Ensuring consistent quality and performance across different feedstocks requires careful monitoring and adjustment. For more insights into optimizing biogas systems, you can explore this guide on biogas plant mixing.