Are you operating one or more anaerobic digestion plants? If so, fail the indicators (KPIs) in our list of the top 5 KPIs for anaerobic digestion plants and you will most likely lose money.

Anaerobic digestion (AD) plants have been increasingly recognized as an effective solution to not only generate renewable energy but also to reduce greenhouse gas (GHG) emissions. By converting domestic waste or energy crops into biomethane gas and power-to-grid, AD plants contribute to creating a circular economy. However, to guarantee that an AD plant operates at its peak efficiency and is both safe and profitable, it is imperative to continuously monitor and optimize various key performance indicators (KPIs).

This approach is essential to help an AD plant reach its full potential. In this article, we will detail the critical operational, health, and safety KPIs that are crucial for the successful operation of an AD plant.

[boomdevs_toc]

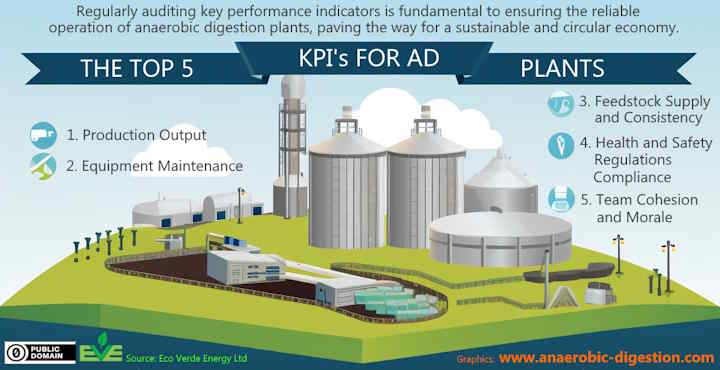

A List of the Top 5 KPIs for Anaerobic Digestion Plants

1. AD Plant Production Output

The production output, which is the amount of combined heat and power (CHP) generated from energy crops and plant waste per hour, is a primary KPI for an AD plant. This output is usually measured in MWh for electricity and cubic meters of biomethane for gas. Ensuring consistent and optimum output levels is vital for meeting revenue-generating activities and fulfilling CHP agreements. Therefore, it is crucial to implement a management system that monitors the quality, control, and timely delivery of feedstocks along with biogas production and yield.

2. Equipment Maintenance

The successful operation of an AD plant heavily relies on its equipment. Any malfunction can potentially be dangerous and lead to costly downtime. Regular maintenance checks are essential to identify and address any issues before they escalate into significant problems. Implementing a planned maintenance schedule and setting specific KPIs around it will ensure that the equipment is safe, and reliable, and supports efficiencies across the plant and the wider business.

3. Feedstock Supply and Consistency

A regular and reliable supply of feedstock, preferably sourced from local homes, farms, and businesses, is essential for maintaining a true circular economy and ensuring consistency of outputs. Fluctuations in supply can lead to reduced output and production losses. Therefore, setting KPIs around the sourcing and quality of feedstock is crucial to ensure that feedstock supplies remain consistent and reliable.

4. Health, Safety, and Environmental Risks

Compliance with legal requirements is fundamental for developing a successful risk management framework. Eco Verde Energy (EVE) regularly reviews its operations through its Health, Safety, Environment, and Quality (HSEQ) team to ensure that the legal register is updated and reflects the actions taken to ensure operations align with legislative requirements. These actions are tracked through a site operations team to guarantee the delivery of the requirement.

The HSE performance of their AD plant clients is also internally benchmarked by EVE using predefined audit and inspection standards. This not only provides the client with a quick reference to HSE performance but also allows them to compare their performance with other AD sites.

5. Team Cohesion and Morale

People are the driving force behind any business, and an AD plant is no different. Achieving a shared objective will be made easier by creating a positive work atmosphere that encourages:

- a sense of clarity,

- stability, and

- purpose.

Shared objectives, a unified sense of purpose, and a skilled team form a solid foundation for addressing broader operational factors and achieving other business KPIs. Providing training, identifying opportunities for progression, and upskilling can instill a sense of pride and security in employees, thereby improving morale and productivity.

Eco Verde Energy (EVE) has a proven track record of successfully managing and onboarding AD plants by employing a standardized audit approach.

Conclusion to Top 5 KPIs for Anaerobic Digestion Plants

To accurately assess the performance of an AD plant, operators must consider a holistic approach that encompasses various KPIs, including operational maintenance, compliance with health and safety regulations, and building a supportive team environment.

Following these procedures has enabled the EVE team to set internal benchmarks and achieve a target of 90% for operational performance and health and safety compliance. By focusing on these essential KPIs, operators can ensure that their AD plants operate efficiently, safely, and profitably, ultimately contributing to a sustainable and circular economy.

Based Upon the article: “Key performance indicators for operating anaerobic digestion plants” by Eco Verde Energy Limited.

Frequently Asked Questions (FAQs)

What are the Key Performance Indicators (KPIs) for an AD plant?

KPIs for an AD plant include:

- AD Plant Production Output: The amount of combined heat and power (CHP) generated from energy crops and plant waste per hour.

- Equipment Maintenance: Regular maintenance checks to ensure the equipment is safe and reliable, and supports efficiencies across the plant.

- Feedstock Supply and Consistency: Regular and reliable supply of feedstock sourced from local homes, farms, and businesses.

- Health, Safety, and Environmental Risks: Compliance with legal requirements and developing a successful risk management framework.

- Team Cohesion and Morale: Fostering a positive working environment by inspiring a clear sense of direction, stability, and purpose.

Why is it important to monitor and optimize KPIs in an AD plant?

Monitoring and optimizing KPIs are crucial for ensuring the AD plant operates efficiently, safely, and profitably. It helps in:

- Meeting revenue-generating activities and fulfilling CHP agreements.

- Preventing dangerous malfunctions and costly downtimes.

- Well-run AD plants contribute toward society developing a truly circular economy.

- Ensuring compliance with legal requirements and reducing environmental risks.

- Building a supportive team environment and improving employee morale and productivity.

- Reduces risk of financial underperformance.

How does Eco Verde Energy (EVE) ensure the successful operation of an AD plant?

EVE employs a standardized audit approach to manage and onboard AD plants. This approach includes:

- Regular reviews by the HSEQ team to ensure compliance with legislative requirements.

- Using standardized audit and inspection criteria to benchmark the HSE performance of AD plant clients.

- Concentrating on a proactive risk management strategy that includes frequent site inspections, proactive hazard and near-miss reporting, training and awareness initiatives, and open forums with site teams.

What are the benefits of operating an AD plant?

Operating an AD plant has several benefits:

- Generates renewable energy and reduces greenhouse gas emissions.

- Contributes to creating a circular economy by converting domestic waste or energy crops into biomethane gas and power-to-grid.

- Minimizes costs of waste recycling and disposal.

- Creates a positive move toward making any company more sustainable in their operations.

Well, you see, it’s all about tending to the machinery, mate. Without proper maintenance, you’re asking for trouble. EVE’s got the right idea with their planned maintenance – keeps things running smooth and trouble-free.