Is it possible to utilising algae and nanoparticles for a natural form of biogas purification to move anaerobic digestion technology in another step forward in the eco-friendly energy revolution.

In a fascinating development in renewable energy, scientists have found a way to use algae and microscopic particles to transform raw biogas into high-quality biomethane. This innovative approach could, if verified by further studies, make renewable gas production more environmentally friendly and cost-effective.

Let's dive into how this technology would work and why it matters.

What is Biogas and Why Does it Need Cleaning?

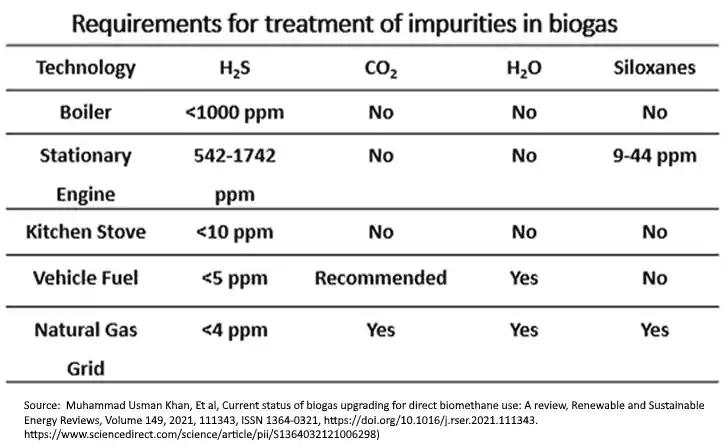

Biogas is created when organic matter breaks down without oxygen – think food waste, agricultural residues, or sewage sludge. While it's renewable, raw biogas isn't pure enough to use directly. It typically contains:

- 45-85% methane (the valuable part we want to keep)

- 25-50% carbon dioxide (which reduces its energy value)

- Small amounts of other contaminants like hydrogen sulfide (which can cause corrosion)

To make biogas useful, we need to remove these impurities – a process called “upgrading.” Traditional methods use chemical processes or physical filtering, but these are expensive and can harm the environment.

The Possible New Green Solution: Photosynthetic Purification

The researchers developed a system that uses nature's own carbon-cleaning technology: photosynthesis. At its heart are two main components:

The Tubular Photobioreactor (TPBR)

Imagine a series of transparent tubes, like a clear snake coiled in the sun. Inside these tubes lives a carefully maintained culture of microscopic algae, primarily a species called Chlorella vulgaris. These tubes are designed to:

- Maximize sunlight exposure for the algae

- Keep temperature and other conditions perfectly controlled

- Prevent contamination from outside organisms

- Allow efficient gas exchange

The Biogas Absorption Column

This is where the cleaning magic happens. Think of it as a tall cylinder where:

- Raw biogas is bubbled up through liquid containing the algae mixture

- The algae naturally consume the carbon dioxide from the biogas

- The cleaned gas emerges from the top, now rich in methane

Adding a High-Tech Twist: Nanoparticles

The researchers added an innovative element: incredibly tiny particles of iron coated in carbon, thousands of times smaller than a human hair. These nanoparticles come in two forms:

- Suspended in liquid

- Dried into a solid

The suspended nanoparticles proved more effective, helping remove 77% of the carbon dioxide compared to 49% with solid particles.

How Does it All Work Together?

- Raw biogas enters the absorption column

- The gas bubbles up through the algae-nanoparticle mixture

- Algae perform photosynthesis, consuming CO2

- The nanoparticles enhance the algae's performance

- Clean biomethane (>90% methane) emerges at the top

- The system also produces valuable algae biomass as a bonus product

Advantages Over Traditional Methods

This biological approach offers several benefits:

- Lower operating costs

- Reduced environmental impact

- Produces useful algae biomass that can be used as fertilizer

- Captures rather than releases CO2

- Can remove multiple impurities simultaneously

Current Challenges

While promising, the system still faces some hurdles:

- Needs careful control of conditions

- Sensitive to high ammonia levels

- Requires optimization of nanoparticle concentrations

- Still scaling up from pilot phase

The Bigger Picture

This technology arrives at a crucial time. Europe's biogas usage has tripled from 77 TWh in 2011 to 223 TWh in 2022, now making up 5.9% of EU natural gas consumption. As we move toward renewable energy sources, innovations like this could help make clean gas production more sustainable and affordable.

Looking Forward

While still in development, this algae-based system represents a promising step toward cleaner, more sustainable energy production. There is an enormous amount of work to be done yet, but the research may show how combining nature's tools (algae) with advanced technology (nanoparticles) can create solutions that are both effective and environmentally friendly.

The researchers need to continue to optimize the system, working to make it ready for pilot studies, and if those work, industrial-scale application. Given the growing importance of renewable gas in our energy mix, this technology could play a significant role in our sustainable energy future.

Let's hope that this example of “green” technology working with nature rather than against it might well be a model for future clean energy solutions.

Sources:

- European Biogas Association. (2023). Statistics on biogas consumption in Europe. [Referenced for biogas production statistics] https://www.europeanbiogas.eu/

- International Energy Agency. (2024). Global biogas and biomethane production data. [Referenced for global production trends] https://www.iea.org/

- Khan, M.U., et al. (2021). “Current status of biogas upgrading for direct biomethane use: A review.” Renewable and Sustainable Energy Reviews. https://doi.org/10.1016/j.rser.2021.110588

- Hoyos, E.G., et al. (2024). “Improving photosynthetic biogas purification via process aeration and nanoparticle supplementation.” Bioresource Technology. https://doi.org/10.1016/j.biortech.2024.131987

- Ángeles, R., et al. (2021). “Influence of biogas supply regime on photosynthetic biogas upgrading performance in an enclosed algal-bacterial photobioreactor.” Algal Research. https://doi.org/10.1016/j.algal.2021.102355

- Muñoz, R., et al. (2015). [Referenced for biogas upgrading specifications and standards] https://doi.org/10.1016/j.watres.2015.02.051

- Cantera, S., et al. (2021). “Impact of the algal-bacterial community structure, physio-types and biological and environmental interactions on the performance of a high rate algal pond treating biogas and wastewater.” Fuel. https://doi.org/10.1016/j.fuel.2021.120578

- Marín, D., et al. (2022). [Referenced for pilot and semi-industrial scale studies] https://doi.org/10.1016/j.fuel.2022.124241

- Vargas-Estrada, L., et al. (2023). [Referenced for nanoparticle performance data] https://doi.org/10.1016/j.biortech.2023.129324