How upgrading biogas to biomethane works, in other words, making the transition from biogas, which is at first raw, to biomethane (purified, biologically produced, methane), that is essential for the most valuable sustainable use of the energy.

The raw biogas that bubbles up out of the liquid in the digester tank contains unwanted impurities such as water and carbon dioxide, a trace of hydrogen sulphide, and more.

So to produce a product containing only methane (just like natural gas) is a technological feat.

However, today it is being accomplished in increasing quantities, and the resulting gas is known as biomethane which is greater than 99% methane. Since 2017 the majority of new UK commercial biogas plant projects have been built with upgrading technology for biomethane production from day 1.

Did you know that biogas upgrading is vital for transforming organic waste into renewable energy? By refining raw biogas into biomethane, we not only enhance its usability but also contribute significantly to environmental sustainability and energy independence.

What You Will Learn About Biogas Upgrading to Biomethane

- Understanding biogas upgrading is essential for enhancing the quality and usability of biogas as a renewable energy source.

- The transition from biogas to biomethane plays a crucial role in reducing greenhouse gas emissions and providing cleaner alternatives to fossil fuels.

- Various technologies, such as membrane separation and pressure swing adsorption (PSA), are used to effectively upgrade biogas, each with its distinct advantages.

- Anaerobic digestion is the fundamental process for producing biogas, enabling the conversion of organic waste into a valuable energy resource.

- Upgrading biogas supports energy security, reduces reliance on fossil fuels, and offers economic opportunities through job creation in the renewable energy sector.

Understanding Biogas Upgrading Systems in Renewable Energy

Biogas upgrading is a crucial process in the realm of renewable energy. It involves the refinement of raw biogas, which is produced from organic waste, into a higher-quality product known as biomethane. This transformation not only enhances the usability of biogas but also contributes significantly to sustainable energy generation.

In essence, biogas upgrading helps in separating impurities from the raw biogas, resulting in a cleaner fuel that can be utilized in various applications. By improving its quality, biogas can effectively replace traditional fossil fuels, making it a vital component in the transition towards renewable energy sources.

Overview of Biogas Upgrading

At its core, biogas upgrading is about elevating the quality of biogas. This typically involves removing carbon dioxide, hydrogen sulphide, and other contaminants to produce biomethane. The role of biogas upgrading is paramount; it allows biogas to meet the standards required for use in transportation, heating, and electricity generation.

Here are some key points about biogas upgrading:

- Enhances the energy content of biogas.

- Makes biogas suitable for injection into natural gas grids.

- Enables the production of renewable natural gas (RNG).

Overall, the upgrading of biogas plays a significant role in maximizing its potential as a clean energy source. By investing in upgrading technologies, we can take full advantage of the energy produced from organic waste.

Transition from Biogas to Biomethane

The transition from biogas to biomethane is an essential step in the journey toward renewable energy solutions. Biomethane is essentially purified biogas that contains a high percentage of methane, making it a clean alternative to fossil fuels. This process not only boosts the energy output but also reduces harmful emissions.

By converting biogas into biomethane, we can create renewable natural gas (RNG) that can be used in various applications:

- Power generation in combined heat and power (CHP) systems.

- Fuel for vehicles in the transportation sector.

- Natural gas for residential heating and cooking via the existing “natural gas” grid. (A process known as gas to grid injection (GGI).)

As we shift towards cleaner energy practices, the importance of biogas upgrading cannot be overstated. It paves the way for sustainable energy solutions that benefit both the environment and the economy.

Defining Biogas Upgrading and Its Importance

Biogas upgrading is not just a technical process; it represents a vital advancement in energy production. The definition of biogas upgrading revolves around the separation of methane from other gases present in biogas. The goal is to produce biomethane, which is valuable for various renewable energy applications.

Understanding what constitutes biogas upgrading is crucial for appreciating its significance in renewable energy. Through efficient upgrading processes, we can transform waste into a resource, making a meaningful impact on energy strategies around the world.

What Constitutes Biogas Upgrading?

Biogas upgrading involves several key processes aimed at enhancing the quality of biogas. The main focus is on separating methane from carbon dioxide and other unwanted gases. Here’s a quick rundown of the typical steps involved:

- Purification of raw biogas.

- Separation of methane for higher energy content.

- Production of biomethane suitable for various uses.

This transformation is central to the creation of renewable natural gas (RNG). By understanding these processes, we can better appreciate the value of biogas upgrading in the broader context of renewable energy.

At the same time there is potential to use the byproducts that can be sold after further purification. An example is the use of the carbon dioxide, often described as CCU (carbon capture and utilisation.

Why Upgrading Biogas Matters

Upgrading biogas is significant for several reasons. First, it provides a cleaner source of energy, which is crucial for reducing greenhouse gas emissions. Second, upgraded biogas can be used in many applications, enhancing energy security and sustainability.

The benefits of upgrading biogas extend beyond environmental impacts:

- Supports energy generation and reduces reliance on fossil fuels.

- Facilitates the use of biogas in transportation.

- Offers economic opportunities through job creation in the renewable energy sector.

Overall, the importance of upgrading biogas cannot be overlooked. It represents a step forward in our efforts to harness renewable energy effectively.

The Role of Anaerobic Digestion in Biogas Production

Anaerobic digestion is the foundational process that leads to biogas production. In simple terms, it’s the breakdown of organic materials by microorganisms in the absence of oxygen. This process is vital for creating the raw biogas that will eventually undergo upgrading.

Anaerobic digestion is essential for several reasons:

- It reduces waste by breaking down organic materials.

- It produces biogas as a renewable energy source.

- It contributes to nutrient-rich digestate, which can be used as fertilizer.

In conclusion, understanding anaerobic digestion helps us appreciate its critical role in the entire biogas upgrading process. By effectively managing organic waste, we can turn it into a valuable resource for renewable energy production.

Gas Purification Techniques and Their Applications

Gas purification techniques are essential in enhancing the quality of biogas before upgrading. These methods, such as chemical scrubbing and absorption, help to remove unwanted compounds like hydrogen sulfide and moisture. This step is crucial as it ensures that the upgrading process is efficient and that the resulting biomethane meets regulatory standards.

Common gas purification methods, prior to separation, include:

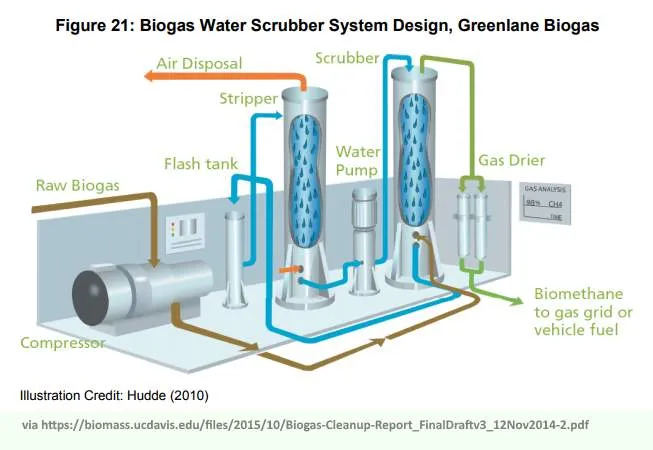

- Water Wash Technology: Cleans biogas using water to remove contaminants.

- Chemical Scrubbing: Removes impurities using chemical solvents.

- Drying Agents: Absorb moisture to improve gas quality.

- Filtration Systems: Physically filter out particulates and contaminants.

Water Wash Technology

Water wash technology offers a straightforward method for upgrading biogas but the degree of purification is limited and does not produce true biomethane. It is often used for cooking gas purposes in simple small biogas plants.

This process involves passing biogas through water, which absorbs impurities while allowing methane to pass through. The simplicity of this system makes it an attractive option, especially in smaller biogas facilities.

Some considerations for water wash technology include:

- Cost-Effectiveness: Generally lower capital costs than other technologies.

- Low Environmental Impact: Uses water as a natural absorbent.

- Lower Efficiency: Might not achieve the highest purity levels compared to advanced methods. But this may be adequate for lower tech uses.

It is after the above pre-separation stages when one or more of the 4. pre separation stages above are completed that the biogas flow move to one the upgrading technologies below:

Key Gas Grid Injection Quality Upgrading Technologies Overview

There are several technologies available for upgrading biogas, each with its unique advantages and challenges. These technologies are designed to separate methane from other gases, ensuring that the end product meets the required standards for use as renewable natural gas (RNG). Understanding these methods helps in selecting the most suitable technology for specific biogas sources.

Some key technologies include:

- Membrane Separation: Uses selective membranes to separate methane from carbon dioxide.

- Pressure Swing Adsorption (PSA): Employs varying pressure to separate gases based on their adsorption characteristics.

- Amine Scrubbing: Utilizes chemical solvents to absorb carbon dioxide and other impurities.

Membrane Separation Technology

Membrane separation technology is a popular method due to its efficiency in producing high-purity biomethane. This technique involves passing biogas through membranes that selectively allow methane to pass while blocking other gases. As a result, this method not only improves methane purity but also minimizes energy consumption compared to other methods.

The benefits of membrane separation include:

- High Purity: Achieves purity levels that often exceed 95% methane concentration.

- Low Energy Consumption: Operates efficiently with lower energy requirements.

- Compact Design: Requires less space compared to traditional systems.

1. Pressure Swing Adsorption (PSA)

Pressure Swing Adsorption (PSA) is another effective upgrading technology that separates gases based on their physical properties. In this method, biogas is passed through an adsorbent material at high pressure, allowing certain gases to stick while others pass through. When the pressure is released, the adsorbed gases are removed, resulting in a concentrated stream of methane.

Advantages of PSA include:

- Effective Separation: Capable of achieving high methane recovery rates.

- Flexibility: Can be adjusted for various biogas compositions.

- Proven Technology: Widely used in many biogas upgrading facilities.

2. Amine Scrubbing Method

The amine scrubbing method is a well-established technique in biogas upgrading. It employs a solution of amines that chemically react with carbon dioxide and hydrogen sulfide, thereby removing these impurities from the biogas. While effective, this method requires careful management of the chemical solution and can involve additional operational costs.

Key benefits and limitations include:

- Effective Removal: Highly effective for removing acidic gases.

- Operational Complexity: Requires ongoing maintenance of the chemical solution.

- Environmental Concerns: Disposal of waste chemicals must be managed responsibly.

Comparative Analysis of Upgrading Technologies

Choosing the right biogas upgrading technology depends on various factors including costs, efficiency, and biogas composition. The table below summarizes the effectiveness and applications of each technology, helping stakeholders make informed decisions.

| Technology | Effectiveness | Cost | Application |

|---|---|---|---|

| Membrane Separation | High purity (>95%) | Moderate | Small to medium scale |

| PSA | High recovery | Moderate to high | Medium to large scale |

| Amine Scrubbing | Very effective | High | Large scale |

| Water Wash | Moderate purity | Low | Small scale |

The Journey of Biogas to Biomethane

A Case Study Production of Biogas

Biogas is produced through the process of anaerobic digestion, which occurs in environments such as landfill sites, wastewater treatment plants, and dedicated anaerobic digestion facilities. This process involves the breakdown of organic matter in the absence of oxygen, resulting in the production of biogas—a mixture of methane, carbon dioxide, and other trace gases.

Initial Treatment: Cooling and Dehumidification

As the biogas enters the upgrading facility, it undergoes an initial treatment where it is cooled and dehumidified. This step is crucial for removing excess moisture and preparing the gas for further purification. The heat extracted during this stage can be repurposed, showcasing the efficiency and sustainability of the process.

Purification through Active Carbon Filters

Following the initial treatment, the biogas is transported to active carbon filters. Here, contaminants such as hydrogen sulphide and other impurities are removed, ensuring that the gas meets the required purity standards for further processing.

Compression and Membrane Technology

Once purified, the biogas is compressed to the necessary pressure for the membrane system. This system consists of three stages, each designed to separate methane from carbon dioxide with increasing levels of purity.

Stage 1: Separation of Methane and Carbon Dioxide

In the first stage, the compressed gas passes through a membrane with a higher selectivity for carbon dioxide. This effectively separates the biogas into a methane-rich gas and a carbon dioxide-rich stream.

Stage 2: Achieving High Methane Purity

The methane-rich gas from the first stage is then transported to the second stage for further purification. This stage focuses on achieving the desired high methane purity necessary for biomethane.

Stage 3: Maximizing Methane Recovery

The process continues in the third stage, where the aim is to recover as much methane as possible from the carbon dioxide-rich gas. The very pure carbon dioxide produced can then be liquefied for other uses.

Recycling and Methane Recovery

The permeate from the second stage and the residual gas from the third stage are recycled within the system. This recycling process ensures a recovery rate of methane above 99%, showcasing the efficiency of membrane technology in biogas upgrading.

Final Touches: Odorization and Injection

Before the biomethane is ready for use, a trace amount of odorant, typically tetrahydrothiophene (THT), is added. This gives the gas its distinctive natural gas fragrance, which aids in leak detection and ensures safety. The biomethane is now ready to be injected into the natural gas grid or used to produce Compressed Natural Gas (CNG) for various applications, including:

- cooking,

- heating, and powering methane gas-driven vehicles.

Process Steps: “How Biogas Upgrading to Biomethane Works” using Membrane Separation Technology

- Biogas Production: Biogas is produced through anaerobic digestion at facilities like landfill sites, wastewater treatment plants, and anaerobic digestion plants, utilizing organic matter breakdown in the absence of oxygen.

- Initial Treatment: The first step in upgrading biogas involves cooling and dehumidifying the gas to prepare it for purification, with the extracted heat being repurposed for other uses.

- Purification Process: Active carbon filters are used to remove contaminants such as hydrogen sulphide and other impurities, ensuring the biogas is clean and suitable for further processing.

- Compression and Membrane Technology: The purified biogas is compressed and passed through a three-stage membrane system designed to separate methane from carbon dioxide, achieving high levels of methane purity.

- Efficiency of Membrane Technology: Membrane technology allows for a highly efficient separation process, with a methane recovery rate above 99%, showcasing its effectiveness in biogas upgrading.

- Recycling and Recovery: The process includes recycling the permeate from the second stage and the residual gas from the third stage to maximize methane recovery and efficiency.

- Final Processing: Before being injected into the natural gas grid or used to produce CNG, the biomethane is odorized with a trace amount of THT for safety and leak detection purposes.

- Sustainability and Environmental Impact: Upgrading biogas to biomethane using membrane technology offers a sustainable and efficient alternative to fossil fuels, contributing to the reduction of greenhouse gas emissions and supporting the global energy transition.

Conclusion to How Upgrading Biogas to Biomethane Works

The upgrading of biogas to biomethane using membrane technology represents a significant advancement in renewable energy production. This process not only contributes to the reduction of greenhouse gas emissions but also provides a sustainable alternative to fossil fuels. With its high efficiency, sustainability, and wide range of applications, biomethane production is poised to play a pivotal role in the global energy transition.

Frequently Asked Questions (FAQs)

Frequently Asked Questions (FAQs)

- What is biogas upgrading?

Biogas upgrading is the process of refining raw biogas to enhance its quality, typically by removing impurities and increasing the concentration of methane to produce biomethane. - Why is upgrading biogas important?

Upgrading biogas is crucial for reducing greenhouse gas emissions, enhancing energy security, and enabling the use of biogas in various applications such as transportation and heating. - What technologies are used for biogas upgrading?

Common technologies include membrane separation, pressure swing adsorption (PSA), amine scrubbing, and water wash technology, each with its unique advantages. - How does anaerobic digestion relate to biogas production?

Anaerobic digestion is the process that breaks down organic materials in the absence of oxygen, resulting in the production of raw biogas that can then be upgraded. - What are the benefits of using upgraded biogas?

Upgraded biogas, or biomethane, can be utilized as a clean energy source, reducing reliance on fossil fuels, and contributing to job creation in the renewable energy sector.

How is biomethane produced from biogas?

Biomethane is produced from biogas through a process called upgrading, which involves cooling and dehumidifying the biogas, purifying it through active carbon filters to remove contaminants, compressing it, and then separating methane from carbon dioxide using a three-stage membrane system. Finally, an odorant is added for safety before it is ready for use.

Why is the membrane technology important for biogas upgrading?

Membrane technology is crucial for biogas upgrading because it allows for the efficient separation of methane from carbon dioxide and other impurities, achieving a high purity of biomethane. This technology ensures a recovery rate of methane above 99%, making the process highly efficient and sustainable.

What are the applications of biomethane?

Biomethane can be injected into the natural gas grid, used to produce compressed natural gas (CNG) for vehicles, and applied in domestic settings for cooking and heating. It serves as a renewable and sustainable alternative to fossil fuels.

How does the initial treatment of biogas work?

The initial treatment involves cooling and dehumidifying the biogas to remove excess moisture. This step prepares the gas for further purification and allows the extracted heat to be reused for other purposes.

What contaminants are removed during the pre separation stage?

During the purification stage, contaminants such as hydrogen sulphide and other impurities are removed using active carbon filters. This ensures that the biogas meets the required purity standards for upgrading to biomethane.

How does the three-stage membrane system work?

The three-stage membrane system works by separating methane from carbon dioxide and other gases at increasing levels of purity. The first stage separates the biogas into methane-rich and carbon dioxide-rich streams. The second stage further purifies the methane, and the third stage maximizes methane recovery from the carbon dioxide-rich gas.

What is the purpose of adding an odorant to biomethane?

An odorant, typically tetrahydrothiophene (THT), is added to biomethane to give it a distinctive natural gas fragrance. This aids in leak detection and ensures safety when the gas is used in domestic and industrial applications.

Can biomethane be used in vehicles?

Yes, biomethane can be used to produce compressed natural gas (CNG), which is a clean and sustainable fuel option for methane gas-driven vehicles. This reduces the reliance on fossil fuels and contributes to lower greenhouse gas emissions.

What are the environmental benefits of upgrading biogas to biomethane?

Upgrading biogas to biomethane reduces greenhouse gas emissions by repurposing organic waste into renewable energy. It provides a sustainable alternative to fossil fuels, contributes to energy security, and supports waste management and circular economy initiatives.