If you are asking; “What is Sewage Sludge?” read on and you will find sewage sludge, biosolids and Wastewater Treatment Sludge are all defined and explained here.

What does SEWAGE SLUDGE mean?

Source: Wikipedia.org article, adapted under this licence.

Sewage sludge is the remaining, semi-solid material that is left over after the cleaned-up water is discharged from sewage treatment works. It is the solid material which settles out from municipal or industrial wastewater when the foul sewage is de-gritted and held in large tanks for between half an hour to one and a half hours.

On arrival at any sewage works (these are called “Wastewater Treatment Works” by Utility Companies), fresh sewage or wastewater flows first into a grit chamber. This is a long narrow tank that is designed to slow down the flow so that solids such as sand, grit, coffee grounds, and eggshells will settle out of the water. It then flows into a “primary settlement tank”.

In the primary settling tank, approximately 50% of the suspended solid matter will settle out in an hour and a half, in which time (on average) the incoming mixture of solid and liquid sewage contaminants stays in the Primary Effluent Treatment tank.

The water overflows through weirs on the surface and goes on for further cleaning (aeration basin treatment).

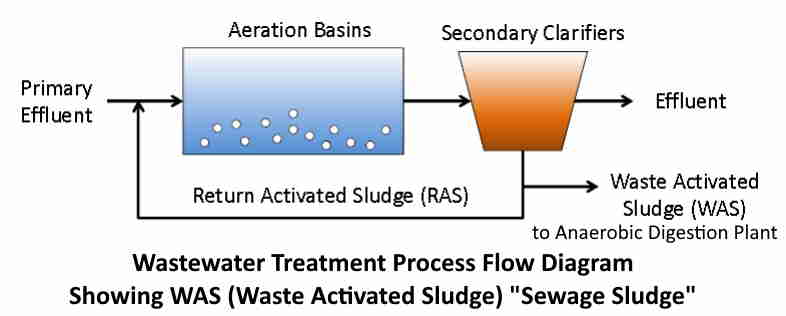

What remains in the “primary settling tank” is a collection of solids known as raw sewage sludge or primary solids. From that point, secondary treatment takes place in aeration basins from which the flow goes through secondary clarifiers, as shown below:

Sewage sludge (biosolids) are drawn off as Waste Activated Sludge, as shown above.

It is said to be “fresh” at the start, but soon the dissolved air is used up and anaerobic processes (decomposition or rotting without air (oxygen)) would become active.

The sewage sludge would start to rot (become putrescent), in a short time, once anaerobic bacteria take over and produce an unpleasant odour.

So, the fresh sewage sludge (WAS) is continuously extracted from the clarifiers using mechanical scrapers and is passed on for further treatment and disposal in one of a number of ways.

Examples of the ways further treatment is achieved are, Activated Sludge Aeration (Extended Aeration), Imhoff Tanks, and Upflow Anaerobic Sludge Blanket (UASB) reactors.

Imhoff tanks work in the absence of air (oxygen) and provide a form of anaerobic digestion.

Imhoff tanks are used infrequently now, as the digestion process at the low temperatures of unheated sewage, is quite slow and requires large (and as a result also, “costly to build”) tanks.

The UASB method is a method which uses a combination of aerobic and anaerobic treatment zones to provide treatment makes sewage sludge but is seldom used at sewage works.

Aeration (Extended Aeration) is what takes place in most sewage works, and aeration itself results in yet more sewage sludge (Waste Activated Sludge – WAS) being produced. This is the sewage sludge which is made in vast quantities and is treated by anaerobic digestion.

So, tell me simply. What is SEWAGE SLUDGE?

Sewage sludge is the general term for all the sludges produced by all the above processes.

Watch the video we made which is based on the text on this page:

Are you still reading? Then let’s talk about the history of sewage sludge:

The Recent History of Sewage Sludge

In the 1970s and until recently, fossil fuels were burnt to heat and dry the sludge so that it could be incinerated. But, with recent improvements in anaerobic digestion technology it has been realized that rather than spend money to incinerate organic sludge, the sludge can be used to make energy in the form of “biogas”.

Biogas production takes place in separate sludge digestion tanks (biogas digesters) that operate at higher temperatures than the lower story of an Imhoff tank and, as a result, digest much more rapidly and efficiently.

In an Imhoff tank, fresh sludge is passed through a slot to the lower story or digestion chamber where it is decomposed by anaerobic bacteria, resulting in liquefaction and reduced volume of the sludge.

After digesting anaerobically for an extended period, the result is called “digested” sludge, or “digestate”.

Historically, sludge was disposed of in rural sewage works by drying and then landfilling. In the cities and conurbations, the sewage sludge was too great in quantity to dry it in the air (drying beds), so it was tankered out to farms and spread on the land, or put on ships and pumped out into the sea.

Septage is a related term, for the sewage sludge from the simple wastewater treatment that occurs in on-site sanitation systems, such as septic tanks.

Biosolids is a term often used in conjunction with the reuse of sewage sludge after sewage sludge treatment. Biosolids can be defined as organic wastewater solids that can be reused after stabilization processes such as anaerobic digestion and composting.

Opponents of sewage sludge reuse reject this term as a term devised by public relations experts, which is used to disguise the very unappealing source of the material.

Sewage Sludge Treatment by Anaerobic Digestion

Increasingly sewage sludge is being treated using the anaerobic digestion process, with the advantage that the Wastewater Treatment Works operator gains renewable power as electricity, which can then 24/7 power the wastewater treatment works itself.

Press Report (4 December 2018):

At all Wastewater Treatment Works/ Sewage Works it is essential that the operator has reliable equipment, and the most critical requirement is that pumps work reliably when pumping sludges, so we thought we would include the following Press Release

Pulp goes the food waste as ultra-reliable Landia pumps help make AD substrate

Pumps and mixers from Landia are playing a key role in the success of Gemidan Ecogi’s new pre-treatment technology that processes source-separated food waste into a high-quality pulp-based substrate for AD.

Initially, during a flow test at the KomTek Miljoe waste treatment facility in Jutland, Denmark, an 11kW Landia pump produced much better results than a 22kW model from another manufacturer – despite the challenging raw pulp having a solids content of up to 17%.

With Danish municipalities on a deadline of 2022 to ensure that 50% of waste is recycled, AffaldPlus’ Energy Manager, Ole J. Andersen, believes that the decision to challenge the environmental credentials of equipment suppliers is already paying off.

“To truly embrace the circular economy at our waste treatment facility,” he said, “we must practice what we preach and look very closely at the lifetime costs of items such as pumps and mixers to make sure, for example, that energy and maintenance costs are low. There was never any discussion about buying the cheapest possible plant. Here, we are investing in the future, so it is only right that we choose strong reliable equipment”.

Gemidan Ecogi’s pre-treatment technology at AffaldPlus’ facility handles waste for six municipalities in South and West Zealand, adding water to the collected waste, which is then driven through a centrifuge pulper the waste is dissolved into a viscous, porous mass for use as raw material in an AD/biogas plant. The degassed biomass is dispersed on fields as a fertilizer.

Ole J. Andersen added: “Processing organic household waste with the Gemidan Ecogi process has been a new departure for us, but with Landia’s stainless steel pumps and mixers, we have a very robust and reliable system. Servicing is also easy and safe with everything conveniently located, rather than having to go down into the tank”.

The new plant has met all new requirements for the use of the waste gas pulp on farmland, which recently entered into Danish legislation. In fact, the bio pulp from the Gemidan Ecogi plant is up to five times cleaner than the law requires.

Visit the Landia website for more information: www.landiaworld.com

Sewage Sludge – A Byproduct of Wastewater Treatment

Sewage sludge is a semi-solid byproduct of wastewater treatment. It is formed from human faecal matter in sewers, it contains pathogens and among other things, “traces” (very low amounts) of heavy metals from industry discharges into sewers.

It is a thick sludge of organic materials and inorganic substances.

Once it has been fully processed, it must be either disposed of or the energy it contains can be extracted and recycled, by producing and utilizing methane in the form of biogas.

Disposing of sewage sludge is a controversial issue in some regions of the world. It is vital to ensure that the final product is disposed of responsibly.

The US EPA estimates that about half of all sewage sludge is applied to land. But, the spreading process must always be done in a manner that does not pollute streams and rivers (watercourses) and water in the ground (groundwater).

Contaminants Often Found at Very Low Levels

Sewage sludge frequently contains many different contaminants at very low levels. Most of the chemicals in sludge bind to the soil, some leach into the groundwater, and some break down into harmless or dangerous components.

Sewage Sludge Treatment Processes

Sewage sludge treatment processes are highly technical and specific to the material's composition. The technique used requires specific flow rates, temperatures, pH levels and solids content. Typically, the sludge is allowed to settle for a specific period of time, after which the solids are concentrated.

Biosolids – A Valuable Resource

Sewage sludge is a valuable resource and is also called a “biosolid”. Properly managed, it can add free organic matter to soils and fertilize soils.

Sewage sludge is a valuable resource and is also called a “biosolid”. Properly managed, it can add free organic matter to soils and fertilize soils.

A wastewater treatment plant typically processes sewage sludge in digesters. These digesters use anaerobic microbes to break it down and make biogas. Biogas has many uses, and at this time of high energy costs a highly profitable, commodity.

A major international initiative is underway to prevent the discharge of sewage sludge to the sea. The London Protocol was adopted on 24 March 2006 and has over 50 signatories.

Sewage sludge is a mixture of water, suspended solids, and organic and inert substances. It contains plant nutrients, trace metals, and organic chemicals. It can be used as a fertiliser or as a soil additive. Some countries even use municipal and industrial sludge to create biogas for electricity generation.

The most common method of sludge treatment is anaerobic digestion. This process produces methane and carbon dioxide. The sludge must be at a pH level high enough to support the anaerobic bacteria.

Sewage sludge treatment in the UK has been opened up for the first time to the public market.

[Article first published December 2018. Updated September 2022.]

Hi, it’s Christen!

Might this be utilized in the typical house or in a collection of houses … All this reveals we are still residing in the stone age … Civilization requires to be entirely rearranged for performance equivalent to nature … investing cash just on development and effective advancement.

Best,

Christen

Will the the post-Brexit trade deal with the US allow the import of American food fertilized with “industrial and sewage sludge”? US food often contains toxic PFAS, so will it be allowed into the UK?