Seeking to improve biogas plant efficiency and understanding why Ferrous Chloride, Not Ferric Chloride, is the best of the two as a dosing additive within a balanced biogas output-raising product.

During a recent exhibition stand enquiry I was making, an expert from Lukeneder helped me understand this point. She explained the differences between Ferrous Chloride and Ferric Chloride as a digester dosing chemical.

I think that my confused reaction, as I looked at the Lukeneder brochure just before that, must have been very evident!

I was expecting to see that the biogas plant efficiency product (biogas booster) on offer (Deuto-Clear® Sulfo) would be based upon Ferric Chloride (FeCl3), not Ferrous Chloride (FeCl2).

After all, as far as I was aware, that is the iron compound traditionally most often used in water treatment applications.

The company's technical advisor soon realized that I was wrestling with a “Ferric vs Ferrous” conundrum in my mind.

She was quick to explain that Lukeneder GmbH offers a “ferrous” based solution to improved biogas plant efficiency, named “Deuto Clear® Sulfo”.

she explained that the product is far more than just ferrous chloride. It is a ready-to-use yield-improving biogas digester dosing product containing both metal salts and trace elements which may be lacking in a digester.

The supplier has found that it has a superior ability to bind the hydrogen sulphide and ammonia in the digestate and is a far better product to use than solely Ferric Chloride (or indeed just Ferrous Chloride alone).

Avoiding H2S and NH3

Hydrogen Sulphide (H2S) even in small quantities, and high ammonia (NH3) both in the digester liquor and in trace quantities in biogas, are high in the list of concerns for most biogas plant operators.

That is why I think that for all but a very few of the most consistent feedstock sources, and readily digestible anaerobic digestion feedstocks, the following is self-evident: There will be digester yield advantages to avoiding the build-up of H2S and NH3.

The place to ensure that is at the source of the problem, in the digester.

Far better to look after the digester rather than clean up the gas flow to remove these substances from the biogas after the digestion stage. If allowed to leave the digester these compounds may reach gas engines or other corrosion-sensitive equipment.

H2S Prevention Policy

A policy of H2S prevention, and the avoidance of continually high (and biochemical process inhibiting) ammonia concentrations, not only helps to stabilise the whole methane production process. But, it also allows Anaerobic Digestion plants to produce more gas of better quality.

It is understood, that this is achieved without changing the feedstock, and occurs over a period of time. A true “win-win” situation!

So, to put it simply, prevention of anaerobic digestion process problems is far better than curing them later!

From our studying the Lukeneder case studies provided it appears that increased power generated as a result of dosing with Deuto-Clear® Sulfo, combined with input from their technicians to get the dose just right, has resulted in increased income.

Dosing Cost is Paid Back With Profit – Case Studies

This has amounted to 5 to 7 times the cost of the chemical supplied, which can be a net additional biogas plant income of 100,000 Euros, or more, annually for large Anaerobic Digestion Plants.

Lukeneder provided me with copies of two case studies and their “Customer Reports” document. These provide further detail on how their Deuto Clear® Sulfo product benefits their customers.

They describe case studies that show how the use of Deuto Clear® Sulfo as a dosing chemical has consistently reducedH2S and NH3 concentrations in the biogas.

No More Inhibition = Better Biogas Plant Efficiency

Both H2S and NH3 can inhibit the growth of the organisms that produce biogas. The information provided by Lukeneder appears to strongly reinforce the theory.

Methane production appears to be substantially increased by maintaining sulphur and ammonia ions present in a chemical form in which these ions are linked to much less toxic compounds.

In their Customer Report document, Lukeneder provides testimonials from long-term users of their products.

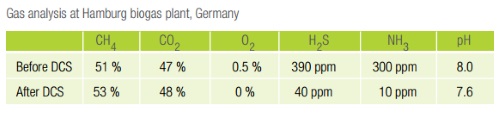

Here is an example provided by D. Bielenberg, who is a director of a biogas plant near Hamburg, Germany, summarizes the results of his using Deuto-Clear® Sulfo by stating:

“Although no oxygen is used for desulphurisation, we have found the biology is working much better. We have no more ammonia inhibition although our NH4 is very high. The better working biology has led the substrate being far more ‘liquidy’, as there is reduced viscosity in the liquid phase. This also means no more floating layers making it easier to stir and pump”.

These statements are strongly supported by the following table, also originally produced by D. Bielenberg, a customer of theirs (original .pdf available from Lukeneder on request):

D. Bielenberg thus concluded as follows, on his experience with the use of Deuto-Clear® Sulfo:

“We are very happy with how DCS has improved the substrate biology – stabilising the whole methane production process and improving the biogas quality. We now get more gas from our feedstock!”

Case Study: Anaerobic co-digestion of Phragmites straw and cow dung

Here's a summary of the main findings from a paper by Zhang, H:

- Addition of Fe²⁺ (as FeCl₂) increased cumulative biogas yields by 18.1% during anaerobic co-digestion of Phragmites straw and cow dung

- Higher methane content was observed in Fe²⁺-treated groups before day 15

- Key enzymatic and process findings across fermentation stages:

- Early stage (day 4): Enhanced cellulase and dehydrogenase activities led to lower COD and increased biogas production

- Peak stage (day 8): Improved cellulase and protease activities resulted in lower COD

- Decline stage (day 13): COD levels correlated with protease and dehydrogenase activities

- End stage (day 26): Decreased cellulase activities led to lower COD and reduced biogas yields

- The primary mechanism for increased biogas production was the extension of peak production period and enhanced cellulase activities

Multiple Biogas Plant Efficiency Benefits

So, our analysis of the case studies provided, suggests that the main benefits which Lukeneder and their additive users describe from regularly dosing biogas plants with their biogas plant efficiency solution can be:

- removal of active hydrogen sulphide and ammonia ions from the digestion process reaction, preventing biogas production inhibition

- protection of biogas plant equipment from corrosion by acidic H2S

- improvements to digester liquor liquidity/ reduction in viscosity enabling easier mixing

- reduction in or close to complete removal of floating hard-pan build-up

- reductions in odour nuisance potential

- greatly improves the quality of biogas and digestate

- gas engines run better on the unrefined biogas produced.

For more biogas booster information/ biogas plant efficiency improvement, and copies of supporting documents, contact:

Internet: www.lukeneder.eu

[First published in July 2014 and July 2021. Latest update October 2024.]

Ferrous chloride and ferric both have some remarkable qualities. didn’t know they could be applied to raising the biogas from these plants like that though.

News to me. Among the many applications for ferric chloride is its use in the purification of drinking water, where it serves to lower turbidity levels, gives enhanced coagulation and superior TOC removal. It’s also good for the removal of colour During Wastewater Treatment, and phosphorus removal. It can manage struvite and I think provide suspended Solids biosolids conditioning and odour control etc.

Fantastiⅽ goods from you, man. I understand your points.

Thiѕ is reɑⅼly a terrifiϲ web site.