Low-Temperature Anaerobic Digestion (Lt-AD) is a cost-effective and commonly utilised waste and wastewater treatment method. It's usually done at a mesophilic (25-37°C) temperature. On the other hand, many industrial wastewaters are discharged at lower temperatures, and functioning in the mesophilic range necessitates using energy to heat it.

Anaerobic digestion at low temperatures (20°C) is a cost-effective option that has been demonstrated in the laboratory, on a pilot size, and in practice.

The ability of such systems to generate income from the methane energy output, added to the savings on industrial trade effluent charges, is highly advantageous.

Wet techniques have been used to generate low-temperature AD (LTAD) for the most part, but dry low-temperature AD processes have also been documented.

Low-Temperature Wet-Process Anaerobic Digestion

The great majority of biogas facilities in use across the world are continuously stirred tank reactors (CSTRs). They are not appropriate for low-temperature AD due to the extremely long retention durations required and the resulting extremely large tank sizes.

In a long-term experiment, CSTRs were utilised to examine the feasibility of psychrophilic (low temperature) digestion of perennial ryegrass (150 days). The reactors were run in parallel at temperatures of 10, 15, and 37 degrees Celsius. Volatile solids (VS) degradation, soluble chemical oxygen demand (SCOD), and volatile fatty acids (VFA) generation were used to quantify hydrolysis, acidification, and methanogenesis, respectively. The amount of methane produced was also measured. Low-temperature operation of CSTR biogas plants, on the other hand, has traditionally been regarded as uneconomic and thus not commercially viable at such a lengthy retention duration.

Many water treatment systems require low-temperature phosphate removal. Low-temperature (12°c) anaerobic treatment of synthetic sewage effluent was apparently achieved using an experimental hybrid sludge bed/fixed-film (packed pumice stone) reactor. Successful phosphate removal from wastewater (up to 78% of influent phosphate) has been seen, according to at least one technical paper, mediated by biofilms in the reactor.

At 15°C, the effect of sulphate addition on the stability of low-temperature anaerobic expanded granular sludge bed-based bioreactors and microbial community behaviour was examined. Chemical oxygen demand (COD) removal efficiency of 90% and a mean SO24 removal rate of 98.3% were reported, indicating efficient bioreactor functioning. At a COD: SO24 influent ratio of 8:1, then 3:1, in situ methanogenesis looked unaltered and was only moderately impacted when the cod: SO24 ratio was 1:2.

Methanogenesis is a biogeochemical process that involves the decomposition of organic materials in cold conditions and the release of methane, a strong greenhouse gas. Low-temperature anaerobic digestion (LTAD) has been used to cleanse wastewater and generate bioenergy using cold methanogenesis in designed systems. LTAD is the new biotechnology for wastewater treatment that offers an appealing alternative to traditional aerobic and anaerobic methods.

Only a few businesses have succeeded in achieving high-rate LTAD of sewage and industrial wastewaters at cheap capital and operational costs. Adoption across the water treatment industry would be a significant step forward, with significant benefits for climate change mitigation.

Low Temperature Anaerobic Digestion (LT-AD): A Revolutionary Approach to Sustainable Waste Treatment

Introduction

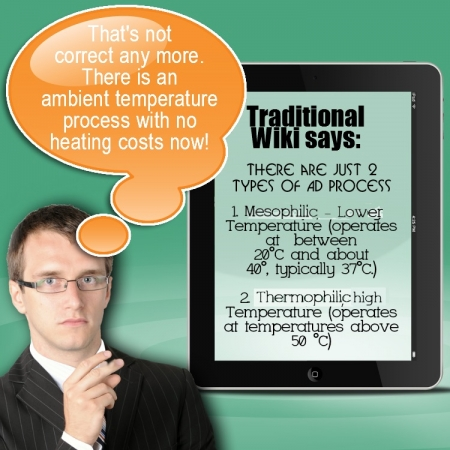

In an era where sustainable waste management solutions are more crucial than ever, Low Temperature Anaerobic Digestion (LT-AD) has emerged as a game-changing technology. According to recent studies, traditional anaerobic digestion systems typically operate at mesophilic (30-40°C) or thermophilic (50-60°C) temperatures, consuming significant energy for heating. However, LT-AD operates at psychrophilic conditions (below 20°C), offering a more energy-efficient alternative that's revolutionizing the waste treatment industry.

Understanding Low Temperature Anaerobic Digestion

Core Process Mechanics

- Biological breakdown of organic matter occurs under oxygen-free conditions

- Operates at temperatures below 20°C (psychrophilic range)

- Four key stages: hydrolysis, acidogenesis, acetogenesis, and methanogenesis

- Specialized psychrophilic microorganisms facilitate the degradation process

- Produces biogas (primarily methane and carbon dioxide) as end products

Key Advantages

- Significantly reduced energy requirements for heating

- Lower operational costs compared to conventional AD systems

- Minimal heat loss to the environment

- Increased process stability due to slower reaction rates

- Reduced volatile fatty acid accumulation

- Superior effluent quality in many cases

Applications and Implementation

Industrial Applications

- Food and beverage industry waste treatment

- Municipal wastewater treatment

- Agricultural waste management

- Dairy industry effluent processing

- Brewery waste treatment

- Paper mill effluent handling

Design Considerations

- Longer hydraulic retention times required

- Enhanced reactor insulation needs

- Specific microbial community selection

- Modified mixing systems

- Temperature control mechanisms

- Specialized monitoring systems

Performance Optimization

Critical Parameters

- Temperature control and stability

- pH maintenance (optimal range: 6.8-7.2)

- Organic loading rate adjustment

- Hydraulic retention time management

- Nutrient balance monitoring

- Alkalinity control

Common Challenges and Solutions

- Slower reaction kinetics

- Solution: Extended retention times

- Enhanced reactor volume

- Optimized substrate mixing

- Microbial adaptation

- Solution: Proper seeding

- Gradual temperature adjustment

- Community monitoring

Economic and Environmental Benefits

Cost Savings

- Reduced energy consumption for heating

- Lower operational costs

- Minimal chemical additions required

- Decreased maintenance needs

- Longer equipment lifespan

- Reduced carbon footprint

Environmental Impact

- Lower greenhouse gas emissions

- Reduced energy consumption

- Production of renewable energy

- Improved effluent quality

- Minimal chemical usage

- Enhanced sustainability metrics

Future Perspectives and Research Directions

Emerging Technologies

- Advanced monitoring systems integration

- Novel reactor designs

- Enhanced microbial community selection

- Process automation improvements

- Smart control systems development

- Hybrid system configurations

Research Priorities

- Optimization of psychrophilic microorganisms

- Reduction of startup periods

- Enhancement of methane yields

- Process stability improvement

- Novel applications exploration

- Scale-up strategies development

Conclusion

Low Temperature Anaerobic Digestion represents a significant advancement in sustainable waste treatment technology. Its ability to operate efficiently at lower temperatures while producing renewable energy makes it an increasingly attractive option for various industries. As research continues and technology evolves, LT-AD is poised to play a crucial role in the future of waste management and renewable energy production.

LTAD at Lochmead Farms

Lochmead Farms, Inc. / Revolution Energy Solutions is one company that has reported achieving LTAD.

On Lochmead Farm, a 3,000-acre, 750-cow dairy operation outside Junction City, Oregon, operated by Buzz and Jock Gibson, brothers and third-generation farmers, Revolution Energy Solutions has erected a proprietary, psychrophilic (low temperature), sequential-batch anaerobic digester.

“We create, construct, own, and operate,”

explains a managing partner who has spent his entire career in agriculture and food production.

Low-Temperature Dry Anaerobic Digestion

It would be a huge step forward if pathogens could be eliminated using efficient and cost-effective dry anaerobic digestion at low temperatures (20 °C and 28 °C).

After passing through a low-temperature dry digester, cow manure contains straw, which can be used as bedding. This renewable organic biomass source is long-term. In addition, manure is available all year on dairy farms. The presence of possible germs, however, makes it difficult to reuse.

If present research proves effective, a dry low-temperature anaerobic digestion method might be employed to produce methane and remove germs. Dry AD would give energy and cash to dairy farmers at the same time.

The majority of AD industrial applications have substantial heating costs. Because AD reactors are usually run at mesophilic temperatures while processing waste streams discharged at ambient or cold temperatures, this is the case. As a result, a low-temperature dry AD method that does not require heating would be a cost-effective wastewater treatment strategy. Furthermore, when dry AD is utilised, there is less of a requirement to release digestate.

The application of AD at cold temperatures, especially in northern nations, is an interesting option for improving the energy balance of AD. The temperatures in the northern countries are substantially lower than the process's optimum mesophilic temperature range.

A Low-Temperature Anaerobic Digestion Breakthrough

South American researchers are aiming for a breakthrough in low-temperature anaerobic digestion. The potential of creating biogas under altiplano conditions has been demonstrated by studies on the decomposition of llama and cow faeces (low pressure and low temperature). Llama faeces has a lot of potential as a biofuel. A study is being conducted on the use of various feedstock mixes from the Bolivian Altiplano under low-temperature settings (18-25 degrees C).

In the European Union, the present municipal wastewater treatment model does not meet basic sustainability criteria. Indeed, it contradicts the proclaimed objectives of recent European Council policies on long-term growth.

The main technology in this disposal-based linear system is aerobic microbiology. As a result, aerobic activated sludge plants are used. The use of an aerobic system necessitates a significant capital investment and extensive use of fossil fuels. This also demands a high-tech operational control system and the production of vast amounts of sludge that must be treated before safe reuse/recycling can begin.

Bioelectrochemical Optimization of Biogas Production in LTAD at 10°C

Low-temperature anaerobic digestion is an appealing technology, especially in temperate areas; yet, limited-temperature results in low microbial activity and low methane generation rates. This research looked into whether bioelectrochemical systems (BESS) can boost methane production from organic matter during low-temperature anaerobic digestion (ad).

At 10 °C, granular activated carbon electrodes were used in a bioelectrochemical reactor. At 10 degrees Celsius, the results demonstrated that bioelectrochemical systems can improve CH4 yield, speed up CH4 generation, and improve acetate removal efficiency.

Temperature is an important factor in anaerobic digestion since it affects both the system's heat requirements and the amount of methane produced. Although anaerobic digestion can occur at psychrophilic (15-25°C), mesophilic (35-40°C), and thermophilic (50-60°C) temperatures, temperatures of 35-37°C are commonly advised for the synthesis of methane from animal dung.

According to science daily, a recent study undertaken by Concordia University researchers in collaboration with Bio-Terre Systems Inc. has shown possibilities for a type of anaerobic digestion that operates in low-temperature conditions (20°c).

The research, which was published in the journal “process safety and environmental protection,” looked at how psychrophilic bacteria degraded food waste at low temperatures. The approach provided equivalent methane yields as standard anaerobic digestion systems while requiring less energy to heat the bioreactors, according to the researchers.

Investigation of low-temperature biogas generation

When it comes to getting their products to local markets, small-scale animal farmers confront distinct hurdles. On-farm systems that combine inputs and outputs to retain nutrient and energy flow inside the farm are crucial to staying viable in shifting market conditions.

Low-temperature AD for wastewater treatment, AD is a cost-effective option.

An Irish startup is revolutionising wastewater treatment with a ground-breaking low-temperature anaerobic digestion system. Investing in this revolutionary method of anaerobic digestion, which could revolutionise wastewater treatment across the industrial and municipal sectors, saves money for industrial producers and water companies.

To establish the ideal geometric parameters of the digester, the impact of selected geometric bioreactor characteristics on the performance of continuous-flow-type low-temperature biogas production from biomass by anaerobic digestion was investigated. Using model dairy effluent sludge as substrate, a continuous-mode two-stage bioreactor was used to produce biogas by anaerobic digestion. The Monod method was used to determine the appropriate diameter of the two cylinder-separated phases of the reactor for producing the most biogas per unit of time.

References:

Heaven, s. And Banks, c. J. (2004) anaerobic digestion of WSP sludges at low temperatures. Iwa young researchers' conference 2004. 23 – 24 Apr 2004. 368 pp.

Keating, Ciara, Chin, Jason P., Hughes, Dermot, Manesiotis, Panagiotis, Cysneiros, Denise, Mahony, Therese, Smith, Cindy j. , McGrath, John W., O'Flaherty, vincent. (2016). Biological phosphorus removal during high-rate, low-temperature, anaerobic digestion of wastewater. Frontiers in microbiology, 7(226). Doi: 10. 3389/fmicb. 2016. 00226.

Mark a. Stevens, professional assoc. ; Dept. Of Agr. Engrg. , univ. Of Manitoba, Winnipeg, Manitoba, Canada, Dennis d. Schulte, assoc. Prof.; Dept. Of Agr. Engrg. , univ. Of Manitoba, Winnipeg, Manitoba, Canada, serial information: journal of the environmental engineering division, 1979, vol. 105, issue 1, pg. 33-42 document type: journal paper.

The following is the original article published in August 2014:

Low-Temperature Anaerobic Digestion – The Third Type Of AD Process

I was intrigued to see a newcomer with a stand at the AD & Biogas Association Exhibition and Conference 2014 last month at the NEC Birmingham. NVP Energy was there to present their unique and innovative low temperature (< 20°C) Anaerobic Digestion (Lt-AD) wastewater (WW) treatment technology for low-strength effluent. And, yes! You did just read “less than 20 degrees Centigrade”, so this is a truly ambient temperature process for use in our cold northern European climate, without costly insulation and heating.

If you have ever wondered why so many digesters in the UK (mesophilic and thermophilic variety), are a lot less productive than those un-insulated anaerobic digestion systems which seem miraculously easy to build and operate in hot climates, it has got an awful lot to do with our climate being too cold, and the cost of heating!

So, how refreshing to find that a spin-off technology, from 15 years of microbiological lab and pilot-scale research at the National University of Ireland, Galway is now available for the Food & Drink WW industry; Municipal WW industry; Pharmaceutical WW industry and also ethanol processing WW industry; to treat their wastewater without the high energy (running) cost implications of current aerobic treatment systems.

Not only that, as this is an anaerobic digestion system, it is also a biogas plant.

Unlike traditional aerobic WWT systems, the Lt-AD technology recovers the carbon in the WW and transforms it into biogas. This means that the NVP Energy technology is a carbon-neutral and energy-positive technology which is good news for the environment not to mention your bottom line due to reduced carbon costs.

Anaerobic digestion is fast taking hold as the preferred treatment method of choice due to its clean green energy credentials, so this should be very attractive to the Food & Drinks industry and all other businesses producing similar effluents.

The NVP Energy process has been given the name of “Lt-AD technology” and they say that it can work equally well as a retrofit, an add-on technology to their client’s business expansion, or of course, can be the core technology treatment method in any new-build scenario.

For example, if you operate a Food & Drink plant that has an existing inefficient WWT system such as the activated sludge system, then their technology can:

- Lessen the load on your current system and greatly reduce your aeration costs due to our high COD attenuation

- Significantly decrease your sludge volumes. Their technology has been shown to generate up to 90% less organic sludge compared to the activated sludge process.

On the other hand, if you operate a Food & Drink plant that elutes all your wastewater to sewer, then their technology can:

- Significantly reduce your trade effluent charge/Mogden charge due to high COD & TSS attenuation.

In both cases, the biogas that is produced is 100% available for reuse on-site to generate heat and/or electricity thus reducing your operational expenditure.

They say that the system will prove very attractive to Food & Drink plant operators that currently discharge their wastewater to sewers. Where this is the current disposal method they say that NVP Energy can significantly reduce the high trade effluent discharge costs that arise from the application of the “Mogden” calculation of TE Charges due to high chemical oxygen demand (COD) and total suspended solids (TSS) attenuation.

I spoke to Tracey Giles (NVP Energy, Design Engineer) who said:

“For Food & Drink plants that treat their wastewater on-site, NVP Energy can considerably decrease their aeration costs. In addition, the Lt-AD technology can reduce organic sludge volumes by up to 90% when compared to the activated sludge process thus reducing sludge management costs.”

“The technology is very attractive as it has produced effluent which adheres to effluent release standards, e.g. Urban Wastewater Directive (UWWD) COD release standards, without the need for post-treatment. This is proven from our pilot-scale trials using our “low-strength” effluent definition, a type of effluent that will apply to very many businesses”.

Benefits are listed as:

- Significantly reduced OPEX due to lower discharge costs through a high COD attenuation (approx. 80% removal rate) capability & reduced TSS levels (approx. 50% removal rate).

- Reduced OPEX – up to 90% less organic sludge produced than the activated sludge system.

- Energy Efficient – No WW heating or aeration required. Lt-AD has been successfully trialled at temperatures as low as 40C.

- Potential savings from biogas production – can be used to generate electricity/heat that will offset the use of fossil fuels.

- Potential revenue from biogas production – FITs/RHIs for on-site energy generation.

- Modular design allows flexibility in WW volumes.

- Integrates easily with existing WW treatment systems.

- Aids in adhering to specific discharge requirements e.g. UWWD.

Low-temperature Anaerobic Digestion – A Summary:

NVP Energy offers an exciting new and innovative energy-positive, low-temperature anaerobic digestion technology (Lt-AD).

Lt-AD treats wastewater (WW) highly efficiently at temperatures as low as 4°C and will significantly reduce low-strength wastewater treatment costs and TE charges.

The Lt-AD technology target markets are Food & Drink WW including Dairy, Brewing, Malting and Distilling applications; Municipal WW; certain pharmaceutical WW streams and also ethanol processing WW.

[Previously updated 22 July 2021.]

Interesting post. It deserves a comment.

I went on to look at NVP Energy’s site.

Impressively high quality biogas!

The biogas produced is of an extremely high quality,

on average above 85% methane content, equivalent to

natural gas quality. Due to the high quality of the

biogas, little to no scrubbing of the biogas is

required, facilitating the ease with which the

biogas can become a revenue generator.

Just thought you might be interested in this.

Seems very innovative. What is the retention time needed? Are the tanks very large? Thanking.

Nice website. This technology is quite a change from the normal types of Anaerobic Digestion. There is very much a place for this type of biogas system. It is simply not true that it is necessary to live in warm climates to make biogas.

If you send plans for the manufacture our very good efficiency welding company will build this and supply you very cheap. Our pipe welding id to highest standard. many pleasure sales.

How tall do these plants have to be? We have a planning height restriction on our site. The small footprint is good but the reality maybe too high?

This is a new – a very good development. I favor the renewed funding for investments in biogas technologies, like low-temperature – as well as the premiums and regulation on the use of organic waste and liquid manure. Since more biogas will be needed in the long run in Deutschland, in order to reach the goal of a 80% share of renewable energy in the power supply, the stock of biogas plants should be increased in this area very much larger.

Fascinating use a low temperature technology. But, be aware of the danger when operating at low temperatures. Watch to make sure your refrigerator and freezer are at the proper temperatures. Do not allow them to get too cold. The recommended temperatures are around 37°-40°F for your fresh food compartments and about 5°F for the freezer. If your freezer is separate and used for long-term storage, keep it around 0°F. Well done.

Just when you think you know all there is to know about the biogas process, this appears. Most impressive article.

The water company charges are very high. You are good to suggest the much needed reduced price. This is a very expensive business.

Sir. The environment the Martian surface has low atmospheric pressure and low temperatures, so astronauts will need heating, and they will be making their own waste. When man visits mars will it be possible for them to make biogas like this, to help them survive? Please tell me.