The Costs of Anaerobic Digestion are of course what everyone thinking of embarking upon a biogas project wants to know. At the same time very few AD Plant owners and contractors give out their costs to a general audience. Finding costs and income data is rare.

That's understandable due to the commercially sensitive nature of such information.

So, to assist our readers we have done the research for you, with 5 resources provided below which help assess AD Plant Costs.

Visit the main AD Community website AD costing page here, or stay here, scroll down and read!

We have found the following downloadable resources which provide information on farm waste anaerobic digestion costs:

1. Downloadable pdf (Chapter for a Conference Paper) Titled “Costs of Anaerobic Digestion”

Excerpt from the pdf:

The cost of a complete dairy waste management system may exceed $1,200 per cow.

Anaerobic digestion system [capital] costs, however, are confined to the cost of the anaerobic process, solids handling, and energy production.

A review of the anaerobic digestion system costs at U.S. dairies compiled by Lusk has established that the typical anaerobic system constructed in the U.S. had an average cost of $470 per cow.

- The proposed thermophilic digestion project at Three Mile Farm (21,000 cows) in Oregon projected a cost of $710 per cow.

- The proposed contact process at Myrtle Point (4,500 cows) Oregon has a proposed cost of $678 per cow for digestion, solids handling, and power generation.

- The recently constructed Cal Polly flush system anaerobic lagoon had a cost of $800 per cow.

- Anaerobic systems for digestion, solids processing, and generation are expected to cost $500 to $800 per cow.

Per-cow capital cost estimates can be deceptive since some processes treat the entire waste stream while others treat only a portion of the waste stream.

For example, the plug flow systems documented by Lusk treat only the concentrated portion of the manure while excluding the milking parlour waste (15% of dairy manure).

For example, the plug flow systems documented by Lusk treat only the concentrated portion of the manure while excluding the milking parlour waste (15% of dairy manure).

As pointed out earlier, the use of any particular system will have an effect on the other. For example:

- If a flush system is used the anaerobic digester must be larger.

- If pre-screening and sedimentation are used, the amount of energy produced will be lower.

- If there is post-processing, that will also raise the cost of ultimate solids disposal.

In many cases, solids must be exported from the site and transport costs need to be added.

Note: Methane digester cost is given based on 2009 figures or earlier.

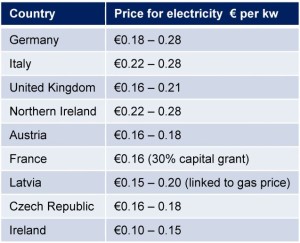

2. Tariffs Payable to Electricity Power Generators Feeding Power into Local Electricity Grids

Having provided some information on on-farm biogas plant costs we are aware that the next question is:

“So what would the farm business be paying for that electricity if they were not generating it themselves”.

So, we found the McDowell Purcell article linked below, which discusses the EU electricity payments which the biogas plant operator can receive for their power fed out into the local electricity distribution grid.

The full article also includes a table of electricity charges within EU nation-states. For your information we have included that table below, however, you should also visit the original web page which is at:

McDowell Purcell Solicitors – Website Provides Anaerobic Digestion Electricity Costs Comparison

The author, from Mc Dowell Purcell Solicitors, makes the point that with the notably lower electricity tariffs available in Ireland AD developers are forced to rely on income derived from gate fees in which the waste producer pays the AD plant to take the waste.

The requirement for a reasonably high gate fee, before anaerobic digestion plants become financially viable, is a substantial barrier to the emergence of Anaerobic Digestion Plant projects.

The gate fee is much more important for Irish plant operators due to their low electricity charges. via www.mcdowellpurcell.ie.

Costs of Anaerobic Digestion

3. WRAP Data on Anaerobic Digestion Gate Fees in the UK

So, what might those gate fees which an Anaerobic Digestion Plant operator can charge to accept suitable organic waste at the site gate, amount to, we asked ourselves? Well, there is information available, and which seems to be annually updated, at the UK Government Funded WRAP website which suggests a median gate fee price in the UK for an anaerobic digestion plant, at £41/tonne in 2012.

So, what might those gate fees which an Anaerobic Digestion Plant operator can charge to accept suitable organic waste at the site gate, amount to, we asked ourselves? Well, there is information available, and which seems to be annually updated, at the UK Government Funded WRAP website which suggests a median gate fee price in the UK for an anaerobic digestion plant, at £41/tonne in 2012.

“WRAP’s fifth annual Gate Fees report presents a summary of gate fees charged for a range of alternative waste treatment, recovery and disposal options, together with an analysis of the factors likely to influence future gate fees and comparison with last year’s report.”

You can check out the WRAP report and their table of gate fees here: wrap.org.uk Gate Fees Reports

4. US EPA Report on Benefits, Costs and Operating Experience at Seven New Agricutural Anaerobic Digesters

Abstract: Farmer motivation for building and operating anaerobic digesters has expanded from solely energy benefits to include manure treatment cost savings, nutrient conversion, odour and pathogen control, and byproduct recovery.

Abstract: Farmer motivation for building and operating anaerobic digesters has expanded from solely energy benefits to include manure treatment cost savings, nutrient conversion, odour and pathogen control, and byproduct recovery.

AgSTAR has provided technical assistance to seven farms to assist them through the development, installation, start-up and operating phases of their anaerobic digestion projects.

Three dairy plug flow digesters (NY, CT, OR), three covered pig manure lagoons (NC, VA, IA), and one heated mixed pig manure digester (IL) have been placed in operation since January 1997 with AgSTAR technical assistance.

The farms and their digester systems are described.

The cost of the digester systems are summarised. Biogas recovery and use in boilers or engine generators are discussed for each farm.

Startup and operational lessons learned are presented. References and calculations are included. via www.epa.gov

5. NNFCC Anaerobic digestion cost calculator

Farmers can calculate the viability of future anaerobic digestion projects by using the latest edition of the AD cost calculator from the National Non-Food Crops Centre.

Start-up costs for AD plants can vary greatly – a farm-based digester using waste from 250 cows and 150ha of maize, with a capacity of around 275kWe can cost upwards of £1.2m, while a typical 2MW digester using 40, 000t of food waste could cost three to five times as much to establish.

The calculator can be downloaded from nnfcc.co.uk Publications – The latest edition at the time of writing was dated 2016.

Community Anaerobic Digestion Plant

Considering that a centralized on-farm community Anaerobic Digestion Plant might operate at a throughput annually of 30,000tpa, that means that the gate fee income alone might easily amount to £125,000 annually and that is just one income stream and does not include the revenue from the power production (Pricing date: 2013). For more on Gate Fees for Food Waste click here!

Updated information July 2023:

Table showing the costs of anaerobic digestion in the United States:

| Type of Cost | Description | Cost Range |

|---|---|---|

| Capital Cost | Cost per cow for anaerobic systems for digestion, solids processing, and generation | $500 to $800 per cow(Ref: 1) |

| Electricity Income | Minimum selling electricity price of 6.40 ¢/kWh | $0.064 per kWh(3) |

| Gate Fee Income | “Gate fees” for certain agricultural feedstocks may be as high as USD 100/tonne in some regions | Up to $100 per tonne(2) |

Note that the costs presented here are for commercial scale projects (not anaerobic digester for home type installations), not exhaustive and may vary depending on the specific context and location.

Reference Sources for the table above:

1. Sustainable supply potential and costs – Outlook for biogas and biomethane: Prospects for organic growth – Analysis – IEA. Average costs of biogas production technologies per unit of energy … whereas in other cases “gate fees” for certain agricultural feedstocks may be as high …

2. [PDF] Life Cycle Cost Analysis of the Operations of Anaerobic Digesters in Iowa.

This study seeks to evaluate the economic implication of a biogas digester built from composite material to ascertain its cost-effectiveness. Researchgate

4. Project expenses and fund sources for the anaerobic digester and…

Economic feasibility of converting cow manure to electricity: A case study … price (MSP) ranged from $77 ton⁻¹ for the base product (pellets)… Download Table – ResearchGate.

5. Note on Financial Analysis of Biomethane Production

The full cost of producing biomethane at a dairy includes an anaerobic digester that generates and collects the biogas as well as the upgrading facility.

FAQs on Costs of Anaerobic Digestion

1. What is the average capital cost per cow for an anaerobic digestion system?

The capital cost per cow can vary significantly based on the size and complexity of the anaerobic digestion system. This can range from a few hundred to several thousand dollars per cow, depending on factors like local labour costs, materials, the technology used, and more. It's crucial to get a detailed quote based on your specific needs and circumstances.

2. How much electricity can an anaerobic digestion system produce?

The amount of electricity generated by an anaerobic digestion system depends on the quantity and type of organic waste, the efficiency of the digester, and the efficiency of the generator. On average, a cow can produce enough manure to generate between 2 to 3 kWh of electricity per day.

3. What is a gate fee in the context of anaerobic digestion?

A gate fee is the charge levied on waste producers for the treatment and disposal of waste. In the context of anaerobic digestion, a gate fee can be a significant source of income, particularly if the digester accepts waste from external sources like food businesses or municipalities.

4. How does electricity income contribute to the overall profitability of an anaerobic digestion system?

Electricity produced by an anaerobic digestion system can be sold back to the grid, providing a steady income stream. This income can offset operational costs and contribute to the overall profitability of the system.

5. How can I calculate the ROI of an anaerobic digestion system?

To calculate the ROI of an anaerobic digestion system, you'll need to consider the capital cost, operating costs, potential income from gate fees, and potential income from selling electricity. This calculation can be complex and might require expert advice to ensure all relevant factors are included.

6. Are anaerobic digesters profitable?

The profitability of an anaerobic digester can vary depending on a range of factors. These include the initial capital costs, ongoing operating costs, income from gate fees, and income from selling the generated electricity or biogas. Additionally, the type and volume of waste input can impact profitability. It's also important to factor in potential savings in waste management costs. Although setting up an anaerobic digestion system requires an upfront investment, many find it to be profitable in the long run due to the income and cost savings it can provide.

[Previosusly updated 22 May 2020. Last updated 15 July 2023.]

I think it is a great solution to our energy needs. Not as great as wind or solar power but biomass is the way forward for farmers etc.