Biochar benefits derive from it being a stable, carbon-rich material produced by heating organic biomass (such as wood waste or crop residues) in a low-oxygen environment, a process known as pyrolysis. Biochar acts as a “permanent” soil improver because it does not decompose like traditional compost.

Managing food waste often feels like putting out fires with a bucket full of holes. You want to cut greenhouse gas emissions and squeeze every joule of energy from your organic material, but problems like acid build-up and unstable biogas output keep throwing a spanner in the works.

If you are tired of seeing your anaerobic digestion (AD) tanks struggle with erratic pH levels or “volatile fatty acids (VFAs) creeping past the safe 300 mg/L zone”, you are not alone.

A breakthrough study from the Chinese Academy of Sciences (Sugiarto et al., December 2025) has shown that using biochar in AD systems does more than just patch leaks. It boosted “hydrogen production by up to 88%” and kept methane output steady at 1,900 millilitres per day, even when the tanks were pushed to their limit. 1

This guide will walk you through how biochar can turn your waste streams into reliable energy generators, help you hit PAS 110 digestate standards (UK), and maximize your returns under the UK's Green Gas Support Scheme.

So, grab a coffee and let's break down exactly how this simple carbon addition can change your daily operations.

Key Takeaways

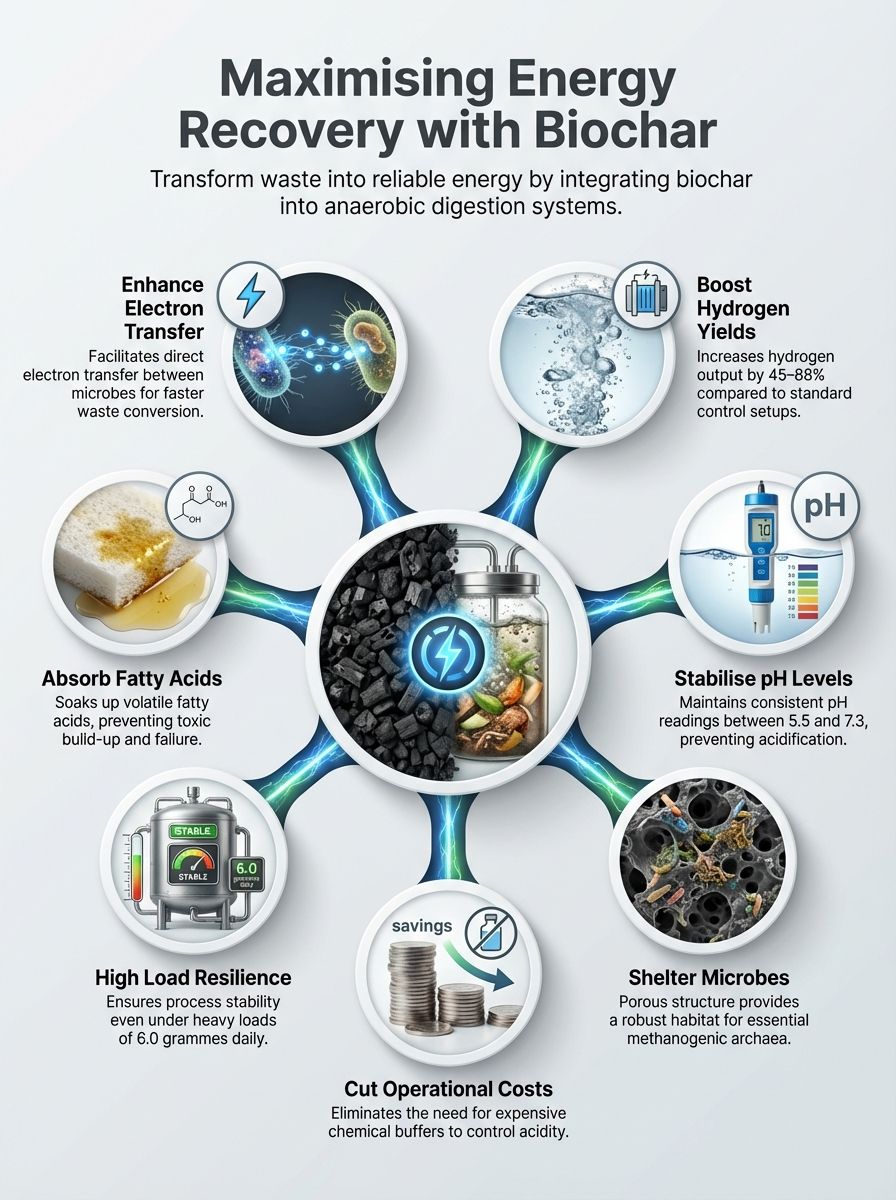

- Massive Hydrogen Boost: Adding biochar to two-phase anaerobic digesters increased hydrogen yields by 45–88% in the Sugiarto et al. (Dec 2025) trials.

- Financial Impact: With the Green Gas Support Scheme (GGSS) paying roughly 6.86p per kWh for Tier 1 biomethane (Oct 2025 rates), stabilising your output directly protects your revenue.

- Better Stability: Biochar kept reactor pH stable between 5.5 and 7.3 and prevented propionic acid build-up, even at high loading rates of 6.0 g VS/L/day.

- Microbial Support: It acts as a conductive home for Methanosarcinaceae archaea, enabling “Direct Interspecies Electron Transfer” (DIET) for faster gas production.

- Operational Savings: Using biochar reduces the need for costly chemical buffers like caustic soda, which currently costs around £270–£310 per tonne in the UK.

Why Biochar Is Important in Anaerobic Digestion

Biochar steps into the digester like a seasoned shift manager, organising the chaos and helping everyone work more efficiently. By providing a physical structure for bacteria to cling to, it transforms a volatile soup into a stable, high-performing ecosystem.

What challenges affect conventional one-phase digesters?

One-phase digesters often struggle to keep **microbial life stable**, much like trying to juggle too many balls at once. The biggest headache for most operators is the delicate balance between acid-forming bacteria and methane-forming archaea.

When you push feed rates too high, acidogens work faster than methanogens can consume the acids. This causes **volatile fatty acids (VFAs)** to accumulate. In a healthy digester, VFA levels sit comfortably between 50 and 300 mg/L. However, if that number spikes towards **2,000 mg/L**, you are in dangerous territory. 1

> “Too much acid can turn your digester into a ticking time bomb, killing the very microbes you rely on for revenue.”

Operators often try to fix this with chemical buffers like caustic soda. While effective in the short term, this is a costly plaster. Caustic soda prices have hovered around **£270 to £310 per tonne** in the UK throughout 2025. Constant dosing not only drains your budget but can also lead to sodium toxicity, which limits your ability to spread the final digestate on agricultural land under **PAS 110 regulations**. 2

What are the limitations of Two-Phase Anaerobic Digestion (TPAD) systems?

TPAD systems are designed to separate the acid-making and methane-making stages, but they aren't bulletproof. They often struggle with **acid accumulation** transferring from the first tank to the second, which disrupts the sensitive methanogens.

These setups are particularly sensitive to high organic loading rates (OLR). When a surge of food waste enters the system, **propionic acid**—a stubborn VFA that is notoriously hard to break down—can build up quickly. 3

Managing two phases also doubles your complexity. You need separate temperature controls and monitoring equipment for each tank. 4 While TPAD is generally more efficient than single-phase, the operational costs (OpEx) are higher. This is where biochar becomes a game-changer; it offers a passive stability mechanism that doesn't require pumps, sensors, or daily manual intervention.

Research on Biochar Integration

Recent studies are reshaping how we think about digester additives. Scientists are using advanced tools like gas chromatography and microbial DNA analysis to prove that biochar isn't just an additive—it's a catalyst.

How does biochar improve TPAD performance?

Biochar acts as both a sponge and a shelter. In the landmark study by **Sugiarto et al. (Chinese Academy of Sciences, December 2025)**, researchers tested TPAD reactors treating food waste over a 100-day period. They pushed these systems hard, testing seven stages of organic loading from a gentle 0.5 up to a heavy-duty **6.0 g VS per litre per day**.

The results were stark. While control reactors failed at high loads due to acidification, the biochar-amended reactors kept humming along. 5

Why? The porous surface of the biochar (often exceeding **300 m²/g**) absorbed the shock of sudden acid spikes. It also retained critical nutrients like **calcium and magnesium**, preventing them from washing out. This creates a “buffering reservoir” inside the tank that chemical dosing simply cannot replicate.

What is the impact of biochar on hydrogen and methane yields?

The numbers from the Sugiarto study are incredibly promising for any plant manager looking at their efficiency metrics.

* **Hydrogen Production:** Yields shot up by **45 to 88 percent** compared to control groups, even at the highest loading rates. 6

* **Methane Stability:** Methane output held steady at approximately **1,900 millilitres per day**.

For UK operators, this stability is directly linked to revenue. Under the **Green Gas Support Scheme (GGSS)**, the Tier 1 tariff for biomethane injection is currently around **6.86 pence per kWh** (as of October 2025).

A digester that crashes or fluctuates loses days of production. If biochar prevents just one “souring” event per year, the saved revenue from that downtime alone often pays for the biochar multiple times over. 7

Benefits of Biochar in Anaerobic Digestion

When you add biochar, you aren't just adding carbon; you are building a city for your microbes. It gives them a sturdy home, protecting them from washout and toxic shifts in their environment.

How does biochar enhance gas yield and microbial resilience?

Biochar boosts **gas output** by enabling a process called **Direct Interspecies Electron Transfer (DIET)**.

Normally, bacteria have to produce hydrogen, which methanogens then consume to make methane. It's a slow, chemical handover. Biochar is electrically conductive. It allows microbes like *Geobacter* to transfer electrons directly to *Methanosarcinaceae* archaea through the biochar surface, skipping the hydrogen step entirely.

This speeds up digestion significantly. In biochar-treated reactors, pH readings remained rock solid between **5.5 and 7.3**, while control setups fluctuated wildly. 8

| Feature | Chemical Buffers (e.g., Caustic Soda) | Biochar Addition |

|---|---|---|

| Mechanism | Reacts chemically to neutralise acid | Adsorbs acids; provides habitat |

| Longevity | Consumed immediately (Single-use) | Persists in the tank (Continuous) |

| Cost Impact | High recurring cost (£270+/tonne) | One-time or periodic dosing |

| Side Effects | Sodium buildup (toxicity risk) | Enhances digestate value (Soil health) |

How does biochar stabilise pH and reduce volatile fatty acids?

Think of biochar as a safety net. Its porous structure soaks up excess protons and acids, preventing the pH crashes that kill methanogens.

In trials, even when “volatile fatty acids (VFAs)” like propionic acid began to rise due to heavy loading, the biochar reactors maintained a pH of 5.5 or higher, whereas control reactors slid to a lethal 4.5. 1

For an operator, this means you can run your plant at a higher loading rate—processing more waste and generating more gas—without the constant fear of the system tipping over. It effectively increases your plant's capacity without needing to build new tanks.

How does biochar strengthen syntrophic relationships?

Microbes in a digester are like a relay team. If one runner drops the baton, the race is over. Biochar strengthens the “handshake” between these organisms.

By clustering bacteria and archaea together on its surface, biochar minimises the distance chemicals need to travel. This tight community structure is far more resilient to shocks.

Insider Tip: Not all biochar is created equal. For anaerobic digestion, aim for a particle size between 2mm and 10mm. Dust is too fine and can clog pumps, while large chunks reduce the surface area available for microbes.

Practical Applications of Biochar in Anaerobic Digestion

Biochar is moving from the lab to the real world. Major UK utilities and waste firms are already exploring its potential to close the loop on waste treatment.

Where is biochar used in waste and biogas treatment systems?

We are seeing biochar adoption in municipal waste sites and agricultural biogas plants across the UK. For example, Severn Trent and United Utilities have been running trials exploring how carbon-rich additives and advanced recovery techniques can optimise their sludge treatment centres. 1

The real beauty lies in the digestate. In the UK, digestate must meet PAS 110 standards to be sold as quality biofertiliser. Biochar helps here too. By locking up heavy metals and reducing potential toxins, it helps ensure your final product passes the test.

Suppliers like Carbon Gold and Onnu Biochar are now providing specific grades of biochar aimed at industrial and agricultural use, making it easier for plant managers to source consistent material.

This supports the circular economy model. You take waste, generate energy, and produce a biochar-enriched fertiliser that farmers actually want because it improves soil water retention and nutrient holding capacity.

How does biochar reduce chemical buffer use and improve reliability?

Using biochar can make chemical buffers almost redundant in stable systems.

Once researchers introduced biochar into TPAD systems, they found they could operate at organic loading rates up to 6.0 g VS per litre each day without adding a single drop of external buffer. 9

This is a massive win for OpEx. If you are currently spending thousands a month on buffering agents to correct pH swings, switching to a biochar dosing strategy could slash those costs. Plus, you reduce the health and safety risks associated with handling corrosive chemicals on-site.

Conclusion

Turning waste into energy isn't just smart; it's essential for the UK's net-zero targets. The data is clear: adding biochar to your anaerobic digestion process is one of the most effective upgrades you can make in 2025.

By boosting hydrogen yields by up to 88% and stabilizing methane output, biochar directly protects your GGSS revenue and reduces operational headaches. It allows you to push your plant harder, process more waste, and spend less on emergency chemical fixes.

So, if you are looking to optimise your AD plant, start small. You may want to trial a biochar dose in one of your tanks and watch the VFA levels stabilize. It might just be the best investment you make this year.

Biochar Benefits – FAQs

1. What is biochar, and how does it help with energy recovery in the anaerobic digestion process?

Biochar is a carbon-rich material produced by pyrolysing organic matter, and research from the University of Edinburgh indicates it can increase biogas production by up to 10%. By adding it to your digester, you stabilise the process and reduce ammonia inhibition, which allows you to recover significantly more energy from the same volume of waste.

2. How does biochar improve soil fertility after anaerobic digestion?

Recent 2024 field trials by SRUC and UKCEH found that applying biochar-enhanced slurry increased grassland yields by 16% compared to using slurry alone. It works by preventing nutrient leaching, ensuring that nitrogen and key minerals remain available for crop uptake rather than washing away into local watercourses.

3. Can using biochar reduce greenhouse gases or help combat climate change?

Yes, burying biochar effectively locks carbon into the soil for centuries, serving as a critical tool for meeting the UK government’s Net Zero 2050 targets.

4. Does biochar work well in all types of soil?

It fits both, but it is particularly powerful for sandy soils where it can increase water-holding capacity by up to 22%, helping crops survive dry spells. For heavy clay soils, the porous structure improves aeration and drainage, making it a versatile amendment for varied British farmland.

5. Are there any links between ancient Amazonian dark earth (terra preta) and modern uses of biochar?

Absolutely, as the fertile “Terra Preta” soils of the Amazon were created centuries ago by mixing charcoal with organic waste. Modern science simply replicates this indigenous wisdom, allowing us to turn today’s organic waste into a valuable resource for long-term soil health.

6. Will using biochar affect my fertiliser needs or crop productivity over time?

You will likely reduce your reliance on expensive mineral fertilisers, as biochar acts like a battery that stores and slow-releases nutrients to plant roots. Because the soil retains nitrogen more effectively, you get stronger crop productivity without needing to apply fresh inputs as frequently.

References

- ^ https://pmc.ncbi.nlm.nih.gov/articles/PMC9077033/

- ^ https://www.sciencedirect.com/science/article/abs/pii/S1364032118308505

- ^ https://pmc.ncbi.nlm.nih.gov/articles/PMC10506435/

- ^ https://www.sciencedirect.com/science/article/abs/pii/S1364032120300435

- ^ https://www.sciencedirect.com/science/article/abs/pii/S2213343722017432

- ^ https://www.researchgate.net/publication/347071116_Effect_of_biochar_in_enhancing_hydrogen_production_by_mesophilic_anaerobic_digestion_of_food_wastes_The_role_of_minerals

- ^ https://www.sciencedirect.com/science/article/pii/S0301479723022466

- ^ https://www.sciencedirect.com/science/article/pii/S2405844023083081

- ^ https://www.researchgate.net/publication/353983593_A_review_of_biochar_in_anaerobic_digestion_to_improve_biogas_production_Performances_mechanisms_and_economic_assessments (2025-08-10)