In this article, we discuss the use of slurry pumps in slaughterhouse waste pumping applications and include an Abattoir Waste Case Study to illustrate the successful use of ascrew centrifugal pump to feed the digester tank at an anaerobic digestion plant.

Key Takeaways

- Specialized slurry pumps are essential for slaughterhouse waste management as they can handle solids, bone fragments, and high-fat content unlike standard centrifugal pumps.

- Screw centrifugal pumps and chopper pumps are particularly effective for abattoir applications, with the VerderHUS screw channel pump proving successful in case studies.

- Key features to look for include solid handling capability of at least 30-50mm, corrosion-resistant materials like duplex stainless steel, and self-priming functionality.

- Proper pump selection can reduce downtime by up to 70% and maintenance costs by 40% compared to using inappropriate pumps for slaughterhouse waste.

- Implementing the right slurry pump system helps slaughterhouses meet strict environmental regulations while potentially generating value through biogas production.

Finding the right equipment for handling slaughterhouse waste can make or break your operation's efficiency. Slaughterhouse waste presents one of the most challenging pumping scenarios in any industry due to its variable consistency, corrosive properties, and solid content. The wrong pump choice leads to constant blockages, excessive maintenance, and potential regulatory violations.

Eddy Pump Corporation, a leader in extreme solids handling pumps, has developed specialized solutions that address the unique challenges of slaughterhouse waste management. Their high-solids handling technology allows for efficient processing of waste streams containing bone fragments, tissue, fat, and other solids that would clog conventional pumps within hours of operation.

Article-at-a-Glance

This comprehensive guide will walk you through everything you need to know about selecting and implementing the right slurry pumps for slaughterhouse applications. We'll explore the various pump technologies available, key features to consider, common challenges to overcome, and best practices for installation and maintenance. By the end, you'll have a clear understanding of how to optimize your waste handling system for maximum efficiency and compliance.

Why Specialized Slurry Pumps Are Critical for Slaughterhouse Waste

Standard pumping solutions simply cannot handle the unique demands of slaughterhouse waste. Conventional centrifugal pumps quickly fail when confronted with the mixture of solids, fats, and fluids that characterize abattoir waste streams. The viscosity of the slurry varies constantly, and the presence of bone fragments, hair, and tissue creates frequent blockages in ordinary pumps.

Slaughterhouse waste is also highly corrosive due to its acidic nature and high salt content. This corrosivity rapidly degrades standard pump components, leading to premature failure and costly replacements. Additionally, the waste often contains stringy materials that wrap around impellers and shaft seals, causing mechanical failures and seal leakage.

Environmental regulations regarding the disposal and treatment of slaughterhouse waste have become increasingly stringent worldwide. Non-compliant waste handling can result in heavy fines, operational shutdowns, and reputational damage. Specialized slurry pumps designed for abattoir applications ensure proper waste conveyance to treatment facilities, supporting regulatory compliance while maintaining operational efficiency.

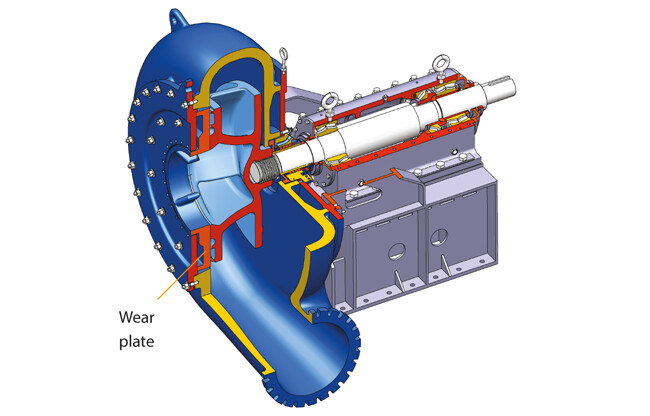

“Slurry pump | KSB” from www.ksb.com and used with no modifications.

Types of Slurry Pumps That Handle Abattoir Waste Effectively

Several pump technologies have proven effective in the challenging environment of slaughterhouse waste handling. Each design offers specific advantages depending on the particular characteristics of your waste stream and processing requirements. Understanding these differences is crucial for selecting the optimal solution for your facility.

Screw Centrifugal Pumps

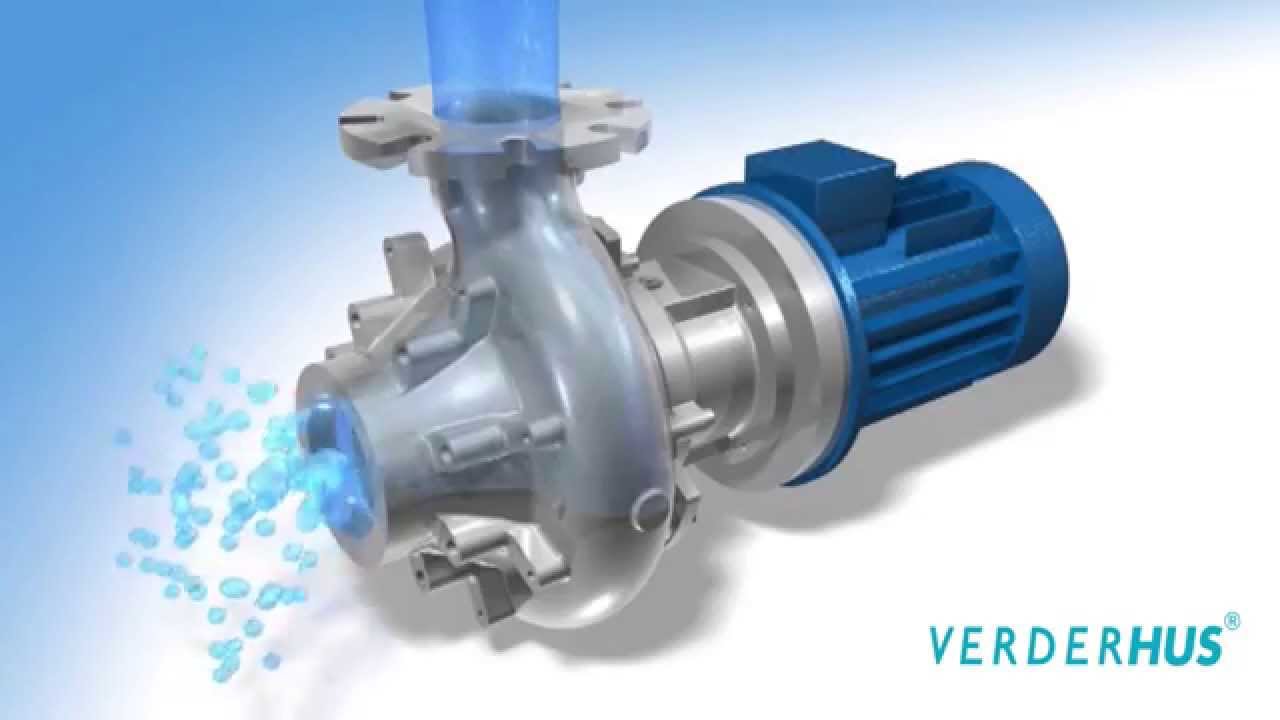

Screw centrifugal pumps, like the VerderHUS mentioned in case studies, represent one of the most effective solutions for slaughterhouse waste. These pumps combine the benefits of positive displacement and centrifugal designs, creating a hybrid that excels at handling high-viscosity slurries with significant solid content. The helical screw inlet effectively handles solids up to 60mm in size while maintaining efficient flow characteristics.

The primary advantage of screw centrifugal pumps is their resistance to clogging even when handling waste containing bone fragments, connective tissue, and other solid materials. Their design allows them to maintain performance even when slurry consistency changes throughout the day. Many facilities have reported run times of 6-12 months without maintenance interruptions after switching to screw centrifugal technology.

The VerderHUS screw centrifugal pump was tested successfully and offered the perfect solution.

The VerderHUS screw centrifugal pump was tested successfully and offered the perfect solution.

Progressive Cavity Pumps

Progressive cavity pumps utilize a rotor turning inside a rubber stator to create a series of sealed cavities that move the slurry from intake to discharge. This design creates consistent, pulse-free flow regardless of pressure conditions, making it suitable for certain slaughterhouse applications. The gentle pumping action prevents damage to sensitive equipment downstream and minimizes emulsification of fats in the waste stream. For more information on waste management techniques, you can explore evaporation techniques for digestate sludge.

While effective for some applications, progressive cavity pumps do have limitations when handling abattoir waste. The rubber stators can deteriorate quickly when exposed to certain chemicals or if run dry, and hard solids like bone fragments can damage the rotor-stator interface. Additionally, these pumps often require pre-processing of waste to remove larger solids, adding complexity to the system.

When properly applied and maintained, progressive cavity pumps can provide reliable service for moderately challenging waste streams. They excel particularly in applications where the waste has already undergone primary screening to remove larger solids. For those interested in maximizing waste processing efficiency, understanding the best practices for biogas yield analysis can be beneficial.

Submersible Chopper Pumps

Submersible chopper pumps incorporate cutting mechanisms that slice solids into smaller pieces before they enter the pumping chamber. This capability makes them especially valuable for raw slaughterhouse waste handling where large solids are present. The cutting action reduces particle size, preventing blockages while allowing the pump to handle a wider range of waste consistencies. For more insights on waste management, explore our guide on anaerobic digestion process steps.

These pumps can be installed directly in collection pits or tanks, eliminating the need for separate lift stations and reducing overall system footprint. Their submerged operation provides natural cooling and prevents issues related to air entrainment or priming. Modern designs incorporate sealed motor chambers and moisture detection systems to prevent electrical failures in the harsh environment.

Air-Operated Diaphragm Pumps

Air-operated diaphragm pumps offer significant advantages for specific slaughterhouse applications, particularly where variable flow rates and the ability to handle highly viscous materials are required. These pumps operate through the alternating inflation of diaphragms, creating a positive displacement effect without rotating components that can be damaged by solids. Their self-priming capability allows them to run dry without damage, a significant benefit in slaughterhouse environments where inlet conditions can vary.

The ability to handle solids up to 25mm in diameter makes diaphragm pumps suitable for certain waste streams, though they typically cannot match the solids-handling capability of chopper or screw centrifugal designs. Their relatively low efficiency compared to other pump technologies results in higher operational costs over time, but this drawback is often offset by their exceptional reliability and minimal maintenance requirements in challenging environments.

Key Features to Look for in Slaughterhouse Waste Pumps

Selecting the right pump for slaughterhouse waste requires careful consideration of several critical features that directly impact performance and reliability. These considerations go beyond basic flow rates and pressure requirements to address the unique challenges presented by abattoir waste streams.

Solids Handling Capability

The most fundamental requirement for any slaughterhouse waste pump is the ability to process solids without clogging. Look for pumps with documented capability to handle solids of at least 30-50mm in diameter, depending on your specific waste stream characteristics. The pump's internal passages should be designed to prevent hang-up points where fibrous materials could accumulate and cause blockages.

Advanced designs like the non-clog impellers found in modern slurry pumps significantly reduce the risk of solids jamming between vanes. Some manufacturers now offer specialized impeller designs with recessed vanes or semi-open configurations that maintain efficiency while maximizing solids passage. Testing has shown that proper impeller selection alone can reduce clogging incidents by up to 80% in slaughterhouse applications.

Corrosion-Resistant Materials

The highly corrosive nature of slaughterhouse waste necessitates construction materials that can withstand continuous exposure to acids, salts, and biological compounds. Duplex stainless steel (such as 2205 grade) offers an excellent balance of corrosion resistance and mechanical strength for most applications. For particularly aggressive waste streams, super duplex stainless steel or specialized alloys like Hastelloy may be necessary despite their higher cost.

All wetted parts, including impellers, casings, shafts, and wear rings, should be constructed from appropriate corrosion-resistant materials. Rubber components must be compatible with the specific chemicals present in your waste stream, as certain compounds can cause rapid deterioration of standard elastomers. Hard-facing treatments or coatings on wear surfaces can further extend component life in abrasive conditions. For more information on optimizing waste management processes, you might consider exploring biogas yield analysis best practices.

Self-Priming Functionality

Self-priming capability eliminates the need for foot valves or external priming systems, simplifying installation and reducing potential failure points. This feature is particularly valuable in slaughterhouse environments where waste levels may fluctuate, potentially causing standard centrifugal pumps to lose prime and require manual intervention. Look for pumps that can re-prime themselves after running dry without operator assistance.

The best self-priming designs can lift waste from depths of 8 meters or more, providing flexibility in system layout and pump placement. This capability reduces construction costs by allowing pumps to be installed at convenient locations rather than requiring deep pits or sumps. Some manufacturers now offer enhanced self-priming designs that can handle air entrainment of up to 50% without losing prime, a significant advantage when dealing with foamy waste streams.

Ease of Maintenance Access

Even the best-designed pumps require periodic maintenance, so accessibility for service is a critical consideration. Back-pullout designs allow impeller and wear component inspection without disturbing piping connections, reducing downtime and labor costs. Quick-release covers and inspection ports facilitate routine checks without complete disassembly. For more information on suitable slurry pumps, visit our product page.

The total cost of ownership is heavily influenced by maintenance requirements, with labor often exceeding parts costs over the life of the equipment. Advanced designs now incorporate features like external adjustment of clearances, cartridge-style mechanical seals that can be replaced without precision alignment, and monitoring ports that allow inspection of critical components without disassembly. These features can reduce maintenance time by up to 60% compared to conventional pump designs.

Energy Efficiency Considerations

While handling capability is the primary concern for slaughterhouse waste pumps, energy efficiency should not be overlooked. Modern high-efficiency motors and optimized hydraulic designs can significantly reduce power consumption without compromising performance. Variable frequency drives (VFDs) allow pumps to operate at the minimum required speed for current conditions, further reducing energy usage during periods of lower flow.

Life cycle cost analysis often reveals that higher initial investment in more efficient equipment yields substantial savings over the operational life of the system. Premium efficiency motors typically consume 3-8% less energy than standard models, providing payback periods of 1-3 years in continuous operation. Some manufacturers now offer hydraulic efficiency enhancements that can improve overall pump efficiency by 5-15% compared to conventional designs while maintaining solids handling capability.

Common Challenges When Pumping Slaughterhouse Waste

Understanding the specific challenges associated with slaughterhouse waste pumping is essential for designing effective systems. Each of these challenges requires specific design considerations and operational strategies to maintain reliable performance.

Dealing with Bone Fragments and Solid Materials

Bone fragments represent one of the most problematic components in slaughterhouse waste streams, with their irregular shapes and hardness causing damage to conventional pumps. These fragments can become wedged between impeller vanes and wear plates, causing immediate blockages or gradual wear that reduces efficiency. Advanced pumps designed specifically for slaughterhouse applications incorporate features like hardened cutting edges, increased clearances, and non-clog impeller designs to manage these materials effectively.

Pre-screening systems can remove larger bone fragments before they reach the pumps, though this adds complexity and maintenance requirements to the overall system. The most effective approach typically combines appropriate pre-processing with pumps specifically designed to handle the remaining solids. Testing has shown that specialized slurry pumps can process waste containing bone fragments up to 30mm without clogging, eliminating the need for fine screening in many applications.

Managing High Fat Content

The high fat content typical of slaughterhouse waste creates multiple challenges for pumping systems. Fats can accumulate on internal surfaces, gradually restricting flow passages and reducing efficiency. At lower temperatures, fats can solidify, causing severe blockages that require disassembly and manual cleaning to resolve. Additionally, fats can degrade certain elastomers and sealing materials, leading to premature failure of critical components.

Preventing Blockages and Clogs

Blockages remain the most common cause of downtime in slaughterhouse waste pumping systems, requiring comprehensive prevention strategies. Beyond appropriate pump selection, system design plays a crucial role in minimizing clogging risk. Piping should maintain minimum velocities of 1.5-2.0 meters per second to prevent solids from settling, while avoiding sharp bends where materials can accumulate.

Regular flushing cycles using clean water can prevent buildup of materials on internal surfaces, particularly in areas with lower flow velocities. Some advanced systems incorporate automatic reversing capability, briefly running the pump backward when increased power draw indicates the beginning of a blockage. This feature can dislodge materials before they cause complete stoppage, significantly reducing maintenance interventions.

Handling Variable Waste Composition

The composition of slaughterhouse waste can vary dramatically throughout the day and between processing runs, presenting a significant challenge for pumping systems. A pump that performs perfectly with one waste stream may struggle when the solid content, viscosity, or chemical composition changes. The most successful installations incorporate flexibility to handle these variations, often through variable speed drives that adjust pump performance to current conditions.

Real-World Success: Abattoir Waste Pumping Case Study

A comprehensive understanding of slaughterhouse pump applications is best illustrated through real-world implementation. The following case study demonstrates how proper pump selection solved persistent problems at a major European abattoir that was experiencing frequent failures with conventional pumping equipment when handling waste to feed their biogas digester.

Problem Identification

The facility processed approximately 1,000 cattle daily, generating significant volumes of waste containing bone fragments, tissue, blood, and wash water. Their existing centrifugal pumps required intervention every 2-3 days due to clogging, with each incident resulting in 4-6 hours of downtime for cleaning and repair. Annual maintenance costs exceeded €45,000, not including production losses from system downtime. Additionally, the inconsistent waste delivery to their anaerobic digester was reducing biogas production efficiency by approximately 30% compared to design capacity.

Pump Selection Process

After analyzing the specific characteristics of the waste stream, including solids content, viscosity ranges, and flow requirements, the facility replaced their conventional centrifugal pumps with VerderHUS screw centrifugal pumps. These units were selected for their ability to handle solids up to 60mm in size while maintaining efficiency across varying viscosities. The implementation included VFD controls to adjust performance based on waste characteristics and flow requirements throughout the processing cycle.

Implementation Results

After six months of operation with the new pumping system, the facility reported a reduction in pump-related downtime of over 90%. The screw centrifugal pumps operated continuously for up to three months between scheduled maintenance intervals, compared to the 2-3 day runtime of the previous system. Maintenance costs decreased by approximately 75%, while biogas production increased by 28% due to more consistent feeding of the digester. The total return on investment period for the new pumping system was just 11 months, primarily due to reduced maintenance costs and increased energy production.

This real-world example clearly demonstrates the transformative impact that proper pump selection can have on overall facility operations. The initial investment in specialized equipment was quickly offset by operational improvements and reduced maintenance requirements. Staff also reported significant quality-of-life improvements due to the dramatic reduction in emergency maintenance calls and after-hours interventions. For more insights into optimizing facility operations, explore evaporation techniques for digestate sludge.

Troubleshooting Common Issues

Even with diligent maintenance, occasional issues will arise that require troubleshooting and correction. Develop a systematic approach to problem identification and resolution, starting with the simplest and most common causes. When pumps fail to deliver expected flow or pressure, first check for inlet restrictions, closed valves, or air entrainment that could affect performance. For electrically driven pumps, verify proper voltage and current draw before assuming mechanical issues are responsible.

Environmental and Regulatory Benefits of Proper Waste Handling

Beyond operational improvements, proper slaughterhouse waste pumping systems contribute significantly to environmental compliance and sustainability goals. Modern regulations require careful management of abattoir waste to prevent contamination of water sources and minimize odor and emission issues. Effective pumping systems ensure reliable transfer of waste to treatment facilities, supporting compliance with increasingly stringent environmental standards while potentially generating value through biogas production or other recovery processes.

Selecting the Right Slurry Pump: Your Decision Guide

Choosing the optimal slurry pump for a specific slaughterhouse application requires careful evaluation of multiple factors. The decision should balance initial cost against long-term performance, reliability, and maintenance requirements. Involve both operations and maintenance personnel in the selection process to ensure all perspectives are considered. For a deeper understanding of the anaerobic digestion process steps, which can influence pump selection, explore this comprehensive guide.

- Thoroughly analyze waste characteristics including solids content, particle size, and viscosity range

- Calculate required flow rates based on peak production conditions plus safety margin

- Consider total system requirements including suction conditions, discharge pressure, and control needs

- Evaluate life cycle costs rather than focusing exclusively on initial purchase price

- Request references from manufacturers for similar applications

- Consider standardization with existing equipment to simplify maintenance and spare parts inventory

The most successful selections typically result from detailed application reviews with pump manufacturers or specialists who understand both the equipment capabilities and slaughterhouse-specific challenges. Many suppliers offer testing services that can evaluate your actual waste material before final selection, providing valuable verification of performance predictions.

When comparing options, consider not only the pump itself but the total package including base, coupling, drive system, and controls. The most appropriate technology may vary depending on your specific waste characteristics and processing requirements. In some cases, a combination of different pump types may provide the best overall solution, with each technology handling the portions of the waste stream for which it is best suited.

Waste Volume Assessment

Accurate assessment of waste volumes forms the foundation of proper pump sizing. Slaughterhouse waste generation typically correlates with production throughput, but variations can occur based on processing methods, cleaning practices, and seasonal factors. Collect data over multiple production cycles to establish both average and peak flow requirements. Include all waste streams that will pass through the pumping system, including process waste, cleanup water, and any materials from auxiliary operations.

Solids Content Analysis

The proportion and characteristics of solids in the waste stream heavily influence pump selection. Conduct sampling and analysis to determine both the percentage of solids by volume and the size distribution of solid particles. For slaughterhouse applications, also evaluate the nature of the solids, distinguishing between hard materials like bone fragments and softer tissue that may behave differently during pumping.

Laboratory analysis should include settling tests to determine how quickly solids separate from liquids when flow stops, as this affects restart requirements and potential for blockages. Viscosity measurements across the expected temperature range provide crucial information for sizing motors and selecting appropriate pump types. Some equipment suppliers offer specialized testing services that can evaluate your specific waste material under various operating conditions.

Budget Considerations

While initial purchase cost is an important factor, focusing exclusively on acquisition price often results in higher total costs over the equipment lifetime. A more expensive pump with superior solids handling capability and wear resistance may provide significantly lower total cost of ownership through reduced maintenance requirements and longer service life. Compare options based on anticipated life cycle costs, including initial purchase, installation, energy consumption, maintenance requirements, and expected service life. For example, exploring submersible slurry pumps can be a cost-effective choice for specific applications.

Long-term Operational Cost Calculations

Comprehensive analysis of long-term costs provides the most accurate basis for equipment selection. Energy consumption typically represents 30-50% of lifetime costs for continuously operated pumps, making efficiency an important consideration despite the challenging nature of slaughterhouse waste. Maintenance costs, including both routine service and major overhauls, can vary dramatically between pump types and should be carefully evaluated based on manufacturer data and user experiences in similar applications.

Downtime costs associated with pump failures or maintenance requirements can exceed all other expenses in high-throughput operations where production interruptions have significant financial impact. Consider both scheduled maintenance requirements and the likelihood of unscheduled failures when evaluating total cost of ownership. The most appropriate selection balances reliability, maintenance needs, efficiency, and initial cost to provide the lowest overall cost per unit of waste processed.

Future-Proof Your Waste Management System

Investing in slaughterhouse waste pumping infrastructure requires consideration of future needs and regulatory trends. Design systems with capacity for anticipated production increases and flexibility to adapt to changing waste characteristics or treatment requirements. Consider modular approaches that allow for expansion or modification without replacing the entire system. Emerging technologies like advanced monitoring systems and predictive maintenance capabilities can extend equipment life while reducing operational costs, providing value that justifies potential premium costs during initial installation.

Frequently Asked Questions

The following questions address common concerns regarding slaughterhouse waste pumping systems, providing practical guidance for selection, operation, and maintenance of these specialized systems.

How often should I replace wear parts in a slaughterhouse slurry pump?

Wear part replacement intervals vary significantly based on specific application conditions and pump design. The following table provides general guidelines, but actual intervals should be determined based on performance monitoring and inspection.

| Component | Typical Replacement Interval | Signs of Wear Requiring Replacement |

|---|---|---|

| Impellers | 6-18 months | Reduced flow/pressure, increased power consumption |

| Wear Plates | 6-12 months | Excessive clearance, visible grooving or pitting |

| Mechanical Seals | 12-24 months | Visible leakage, contamination of seal fluid |

| Shaft Sleeves | 12-24 months | Visible scoring or grooving, seal failures |

Implementing a condition-based replacement strategy rather than fixed intervals often provides the best balance of reliability and cost effectiveness. Modern monitoring techniques, including vibration analysis and performance trending, can identify optimal replacement timing before failures occur but without premature replacement of serviceable components. For more information on maximizing output and efficiency, you might consider exploring best practices for maximizing output.

Some manufacturers now offer hardened components or special coatings that can extend service life by 2-3 times compared to standard materials, providing significant value despite higher initial costs. These enhanced components are particularly beneficial in highly abrasive applications where standard parts would require frequent replacement.

Always use manufacturer-approved replacement parts to ensure proper fit and material compatibility. Attempting to save money with non-OEM parts often results in reduced performance, shortened service life, and potentially catastrophic failures that far outweigh the initial cost savings. For more insights on maintaining equipment efficiency, consider exploring evaporation techniques for digestate sludge.

Can standard centrifugal pumps handle slaughterhouse waste?

Standard centrifugal pumps are generally unsuitable for raw slaughterhouse waste due to severe limitations in solids handling capability. Conventional designs quickly clog when confronted with the bone fragments, tissue, and fibrous materials typically present in abattoir waste streams. Their open impeller designs and narrow passages create numerous points where solids can become trapped, leading to blockages that require disassembly and manual cleaning to resolve.

When standard centrifugal pumps are employed in slaughterhouse applications, they typically require extensive pre-processing of the waste to remove solids, often involving screens, macerators, and settling tanks. This additional equipment increases system complexity, maintenance requirements, and capital costs while creating additional potential failure points. Even with pre-processing, standard pumps often experience accelerated wear and frequent seal failures due to the abrasive and corrosive nature of the waste.

Modified centrifugal designs specifically engineered for slurry applications provide significantly better performance by incorporating features like recessed impellers, increased internal clearances, and hardened components. These specialized designs can handle moderate solids content while maintaining reasonable efficiency, though they still cannot match the capabilities of purpose-built slaughterhouse waste pumps for challenging applications.

In limited cases where the waste stream has very low solids content and has undergone significant pre-treatment, standard centrifugal pumps may provide adequate performance. This might include applications handling only the liquid fraction after effective solid separation or final effluent streams from treatment processes. Even in these applications, material selection remains critical to ensure corrosion resistance and reasonable service life.

- Standard centrifugal pumps typically limit solids to 5-10mm maximum size

- Specialized slaughterhouse waste pumps can handle solids from 30-60mm

- Maintenance frequency with standard pumps can be 5-10 times higher

- Energy consumption may increase 15-25% as standard pumps wear

- System reliability with specialized pumps typically exceeds 95% vs. 60-70% for standard designs in the same application

What safety features should I look for in slaughterhouse waste pumps?

Safety considerations for slaughterhouse waste pumping systems should address both operator protection and prevention of environmental incidents. Look for designs that minimize exposure to waste during maintenance by incorporating features like back-pullout casings that allow access to wear components without disconnecting piping. Seal monitoring systems provide early warning of potential leakage before failure occurs, while temperature and vibration monitoring help prevent catastrophic failures that could create safety hazards. For submersible applications, moisture detection systems in motor housings prevent electrical hazards by shutting down equipment before water intrusion can create dangerous conditions.

How do I calculate the correct pump size for my abattoir waste volume?

Proper sizing begins with accurate flow requirements based on waste generation rates during peak production periods plus an appropriate safety margin (typically 10-15%). For variable waste generation, consider whether storage capacity exists to allow for averaged pumping rates or if the system must handle peak instantaneous flows. Beyond flow rate, head requirements must account for both static lift and friction losses in the piping system, with additional allowance for the increased friction created by the solids content of the slurry. Most pump manufacturers provide tools or software to assist with these calculations, incorporating factors for specific gravity and viscosity effects on performance. Always verify that the selected pump will operate near its best efficiency point under normal conditions, avoiding both oversizing that leads to excessive energy consumption and undersizing that creates reliability issues.

Are there specific regulations for pumping slaughterhouse waste to biogas digesters?

Regulatory requirements for waste handling systems feeding biogas digesters vary by location but typically address several common concerns. Material containment standards prevent leakage or spillage during transfer operations, while monitoring requirements may include flow measurement and sampling capabilities to verify proper operation. Some jurisdictions require specific pre-treatment steps before waste can enter digestion systems, potentially including screening, pH adjustment, or temperature control. The pumping system must support these requirements while maintaining reliability to prevent environmental incidents.

European regulations under the Animal By-Products Regulation (EC) No 1069/2009 establish specific requirements for handling Category 2 and 3 materials, including most slaughterhouse waste intended for biogas production. These regulations mandate containment standards, traceability requirements, and specific treatment parameters including minimum temperatures and residence times. In the United States, regulations vary by state but typically fall under state environmental protection agencies with oversight from federal EPA biogas regulations.

Beyond regulatory compliance, many biogas system operators establish their own technical requirements for incoming waste to optimize digester performance. These may include maximum particle size limitations, consistent delivery schedules, and specific nutrient balance parameters. The pumping system must reliably deliver waste meeting these specifications to maintain optimal biogas production and prevent digester upsets that could require costly intervention. For more information on the process, you can explore what a biogas reactor is and how it functions within the system.

When designing systems for biogas applications, consider incorporating inline monitoring capabilities for key parameters like pH, temperature, and solids content. These monitoring systems can provide early warning of potential issues before they affect digester performance, allowing for adjustments to waste handling practices as needed. Some advanced systems now incorporate automated adjustment capabilities that can blend waste streams or add amendments to maintain optimal digester feeding characteristics.

Consult with both regulatory authorities and biogas system suppliers during the design phase to ensure that all requirements are properly addressed. Documentation of system capabilities and operating procedures may be required as part of the permitting process, particularly for new installations or significant modifications to existing systems.

Eddy Pump Corporation offers specialized consultation services for slaughterhouse waste pumping applications, helping facilities optimize their waste handling while ensuring regulatory compliance and maximizing potential value recovery through biogas production.

[This post is an updated version of an article initially posted in July 2017. Updated on 14 December 2021, and rewritten 12 October 2025.]

hi i like to install a 3 mw bio gas plant in Jakata next to abbatoir. what pumps to use?

I want organic pumps

For bio gas plant

Norat

We are UK based. If you seek equipment for delivery in the UK or EU nation, please provide full details by completing the form on our “Contact Us ‘ page, and we will reply.