Anaerobic digestion plants employ a natural biological process to turn organic matter, such as food waste and manure, into biogas and digestate. The biogas, primarily methane and carbon dioxide, can be used to generate electricity, heat, or even fuel vehicles. The digestate, a nutrient-rich substance, can be used as a fertilizer for agriculture.

Key Takeaways – About Anaerobic Digestion Plants

- Anaerobic digestion (AD) plants convert organic waste into biogas and nutrient-rich digestate while dramatically reducing greenhouse gas emissions.

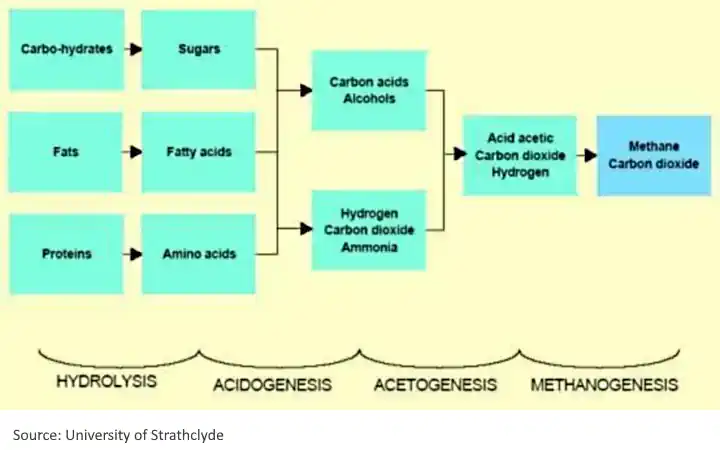

- The process involves four biological stages: hydrolysis, acidogenesis, acetogenesis, and methanogenesis, occurring in oxygen-free environments.

- Anaerobic digestion plants can generate significant revenue through energy sales, tipping fees, and government incentives while diverting waste from landfills.

- The digestate byproduct serves as an excellent organic fertiliser, closing the nutrient loop and reducing dependency on synthetic alternatives.

- Temperature control, feedstock selection, and retention time are crucial factors affecting the efficiency and output of anaerobic digestion systems.

Imagine turning yesterday's food waste into tomorrow's electricity and fertiliser. That's exactly what anaerobic digestion plants accomplish, creating a perfect closed-loop system that exemplifies sustainable resource management in action.

The global push toward renewable energy solutions has spotlighted anaerobic digestion (AD) as a powerful technology with multiple benefits. Not only does it tackle waste management challenges, but it also generates clean energy and valuable byproducts. Veolia's environmental solutions have been at the forefront of implementing these systems worldwide, helping communities and businesses harness the power of organic waste transformation.

From small farm-based operations to massive municipal facilities, anaerobic digestion represents one of our most versatile renewable energy technologies. The beauty lies in its ability to address multiple environmental challenges simultaneously, creating a truly circular approach to resource management. Let's dive into how these remarkable systems work and why they're becoming increasingly essential in our renewable energy landscape.

Turning Waste into Gold: How Anaerobic Digestion Plants Work

Anaerobic digestion occurs naturally wherever organic matter decomposes without oxygen present—from swamps to landfills to animal digestive systems. What makes AD plants remarkable is how they harness and optimise this natural process in controlled environments.

These sophisticated facilities accelerate decomposition while capturing the valuable outputs that would otherwise be lost to the atmosphere. For instance, Landia's GasMix system exemplifies innovative technology used in these plants to enhance efficiency and output.

At its core, anaerobic digestion is a biological process where microorganisms break down organic material in the absence of oxygen. This controlled decomposition happens inside sealed tanks called digesters, where specific temperature and mixing conditions are maintained to optimize the growth of beneficial bacteria. The result? Biogas is rich in methane and a nutrient-dense liquid called digestate.

The versatility of these systems is particularly impressive. AD plants can process virtually any organic material—from food waste and crop residues to manure and sewage sludge. This flexibility makes them applicable across agricultural, municipal, and industrial sectors, providing tailored solutions for diverse waste streams.

The Complete Anaerobic Digestion Process Explained

Understanding the biological stages of anaerobic digestion helps appreciate the complexity and elegance of these systems. The process unfolds in four distinct yet interconnected phases, each driven by different groups of microorganisms working in harmony. For a deeper dive into the basic processes involved, explore this comprehensive guide.

First comes hydrolysis, where complex organic compounds like carbohydrates, proteins, and fats are broken down into simpler molecules. Next, during acidogenesis, these simple compounds convert into volatile fatty acids, alcohols, hydrogen, and carbon dioxide. The third stage, acetogenesis, transforms these intermediate products into acetic acid, hydrogen, and carbon dioxide. Finally, methanogenesis occurs when specialised archaea convert these products into biogas, primarily composed of methane (50-75%) and carbon dioxide (25-50%).

This biological cascade happens continuously within the digester tank, with each stage dependent on the previous one. Modern AD plants carefully monitor and optimise conditions to ensure these microbiological communities thrive and produce maximum biogas yields.

- Hydrolysis: Breaking down complex compounds into simple sugars, amino acids, and fatty acids

- Acidogenesis: Converting simple molecules into volatile fatty acids, alcohols, and gases

- Acetogenesis: Transforming acids and alcohols into acetic acid, hydrogen, and carbon dioxide

- Methanogenesis: Producing biogas from acetic acid, hydrogen, and carbon dioxide

Feedstock Preparation: Getting Waste Ready for Digestion

Before organic material enters the digester, proper preparation is essential for optimal performance. The quality and consistency of feedstock directly impact biogas production and system stability. Most facilities incorporate pre-treatment steps to remove contaminants and enhance digestibility, ensuring the microbial communities can efficiently break down the material. Discover how efficient biogas waste management can optimise these processes.

For food waste and municipal solid waste, this typically involves removing non-organic materials like plastics and metals, followed by size reduction through grinding or shredding. Agricultural feedstocks might require chopping or blending to increase surface area. Some advanced facilities also implement thermal or enzymatic pre-treatments to break down resistant materials like lignocellulosic biomass, significantly boosting biogas yields.

The moisture content of incoming material also matters greatly. While some digesters handle high-solids waste (dry digestion), others operate better with liquid slurries (wet digestion). Many facilities blend multiple feedstocks to achieve the ideal consistency and nutrient balance, creating a “recipe” that maximises biogas production while maintaining system stability.

A large anaerobic digestion plant sewage sludge hydrolysis feedstock pretreatment facility at a commercial UK AD Plant processes.

A large anaerobic digestion plant sewage sludge hydrolysis feedstock pretreatment facility at a commercial UK AD Plant processes.

Primary Digestion: Where the Magic Happens

Inside the digester tank is where the true transformation occurs. These tanks range from simple covered lagoons to sophisticated temperature-controlled vessels, depending on the scale and sophistication of the operation. Regardless of design, all digesters create the oxygen-free environment essential for anaerobic microorganisms to thrive and break down organic matter.

Modern digesters incorporate mixing systems to ensure uniform digestion, prevent settling, and maintain contact between microorganisms and feedstock. This mixing might be accomplished through mechanical agitators, gas recirculation, or hydraulic mixing.

Temperature control is equally critical, with most commercial systems operating in either mesophilic (95-105°F/35-40°C) or thermophilic (125-135°F/50-57°C) conditions to optimise microbial activity.

The digestion process typically takes 15-30 days, depending on temperature, feedstock characteristics, and system design. During this retention period, organic material gradually converts to biogas, which collects in the headspace of the digester or in separate gas storage systems. Meanwhile, the material becomes increasingly stabilised as volatile compounds transform into methane and carbon dioxide.

Biogas Collection and Processing

The crown jewel of anaerobic digestion is biogas—a versatile renewable fuel that can generate electricity, heat, or be upgraded to natural gas quality. Raw biogas contains 50-75% methane, 25-50% carbon dioxide, and trace amounts of other gases like hydrogen sulfide and ammonia. Before utilisation, this gas typically undergoes cleaning to remove contaminants that could damage equipment or reduce energy content.

Most commonly, biogas fuels combined heat and power (CHP) engines that generate electricity while capturing heat for maintaining digester temperature or other on-site uses. This cogeneration approach achieves impressive efficiency rates of 80-90%. Alternatively, biogas can be upgraded to biomethane by removing carbon dioxide and other impurities, creating a renewable natural gas virtually identical to fossil natural gas and suitable for pipeline injection or vehicle fuel.

The energy potential from biogas is substantial. A medium-sized facility processing 100 tons of food waste daily can generate roughly 2-3 megawatts of electricity—enough to power approximately 2,000 homes while also providing valuable thermal energy.

Digestate Management and Usage

Beyond biogas, anaerobic digestion produces digestate—the processed organic material remaining after digestion. Far from being a waste product, digestate represents a valuable resource containing nearly all the nutrients from the original feedstock in forms more readily available to plants. This makes it an excellent organic fertiliser that can displace synthetic alternatives in agricultural applications.

Digestate typically undergoes separation into liquid and solid fractions for different applications. The nutrient-rich liquid portion works well as a direct fertiliser that can be applied through irrigation systems, while the fibre-rich solid fraction can be composted, used as animal bedding, or applied as a soil amendment that improves structure and water retention. Some advanced facilities further process digestate to create specialised fertiliser products or extract valuable compounds.

By returning digestate to farmland, AD systems close the nutrient loop, reducing dependence on energy-intensive synthetic fertilisers while improving soil health. This aspect of anaerobic digestion exemplifies circular economy principles, where outputs become valuable inputs for other processes.

5 Major Environmental Benefits of Anaerobic Digestion

The environmental advantages of anaerobic digestion extend far beyond renewable energy production. These systems address multiple environmental challenges simultaneously, creating cascading benefits for climate, air quality, water systems, and soil health.

1. Dramatic Reduction in Greenhouse Gas Emissions

When organic waste decomposes in landfills, it generates methane—a greenhouse gas 25-28 times more potent than carbon dioxide over a 100-year period. Anaerobic digestion captures this methane before it escapes to the atmosphere, then converts it to carbon dioxide through combustion. This conversion, plus the displacement of fossil fuels with renewable biogas, creates a double climate benefit.

Studies show that well-managed AD systems can reduce greenhouse gas emissions by 60-80% compared to conventional waste management and energy generation methods. For example, processing one ton of food waste through anaerobic digestion instead of landfilling can prevent approximately 0.5-1 ton of CO2 equivalent emissions, depending on system efficiency and how the biogas is utilised.

These climate benefits have made anaerobic digestion a key technology in many national and regional climate action plans, with some jurisdictions specifically mandating organic waste diversion to AD facilities as part of their emissions reduction strategies.

2. Diversion of Organic Waste from Landfills

Organic materials constitute roughly 30-40% of municipal solid waste in developed countries and even higher percentages in many developing regions. Diverting this material from landfills through anaerobic digestion extends landfill lifespans, reduces leachate production, and minimises associated environmental impacts, including groundwater contamination risks.

The waste reduction benefit is particularly significant for high-moisture wastes like food scraps and agricultural residues, which often perform poorly in other waste management systems. A single medium-sized AD facility can divert thousands of tons of organic waste annually, dramatically reducing the environmental footprint of local waste management operations.

“Each ton of food waste processed through anaerobic digestion instead of landfilling saves approximately 1-1.5 cubic yards of landfill space while generating enough electricity to power an average household for 1-2 months.” – Environmental Protection Agency

3. Production of Renewable Energy

The biogas generated through anaerobic digestion represents a flexible, on-demand renewable energy source that complements intermittent renewables like solar and wind. Unlike these weather-dependent sources, biogas production remains constant regardless of external conditions, providing valuable baseload power or peaking capability as needed.

This renewable energy displaces fossil fuels in various applications, from electricity generation to heating to transportation fuels. The energy is particularly valuable because it derives from waste materials rather than dedicated energy crops, avoiding land-use conflicts between food and fuel production. When upgrading biogas to biomethane, the product becomes fully interchangeable with natural gas, leveraging existing gas infrastructure for distribution and use.

Many AD facilities generate significant excess energy beyond what's needed for process operations. A typical food waste digester can export 75-80% of its energy production, creating a valuable revenue stream while contributing clean energy to surrounding communities.

4. Creation of Nutrient-Rich Fertiliser

The digestate byproduct from anaerobic digestion contains nitrogen, phosphorus, potassium, and various micronutrients in forms more readily available to plants than those in the original feedstock. This natural fertiliser reduces the need for synthetic alternatives, which typically require significant energy inputs for production and can contribute to water pollution through runoff.

Using digestate as fertiliser completes a true circular economy model, returning nutrients to the soil to grow more food or biomass. Research indicates that digestate application can improve soil structure, increase organic matter content, enhance water retention, and support beneficial soil microbial communities. These soil health benefits extend beyond simple nutrient replacement, creating more resilient agricultural systems. For more insights on efficient biogas waste management, read about the Methane Digester UK story.

For farmers operating on-farm digesters, this nutrient recycling creates significant cost savings through reduced fertiliser purchases while improving manure management. Some commercial AD facilities have developed specialised digestate products for different agricultural applications, creating additional value streams beyond biogas production.

5. Decreased Water Pollution

When organic waste is managed improperly, it can lead to significant water pollution through runoff and leaching. Anaerobic digestion systems effectively contain and process these materials, preventing nutrients, pathogens, and organic compounds from entering waterways where they could cause eutrophication, harmful algal blooms, and disruption of aquatic ecosystems.

The digestion process itself reduces pathogen levels through a combination of competitive exclusion, antimicrobial compounds produced by certain bacteria, and in thermophilic systems, through high temperature exposure. Studies show pathogen reductions of 99% or greater for many common microorganisms, significantly reducing potential health risks associated with agricultural runoff or wastewater discharge.

Additionally, the controlled application of digestate as fertiliser allows for precise nutrient management compared to raw manure or other organic wastes. This precision helps farmers apply only what crops need, reducing the risk of nutrient leaching into groundwater or surface water bodies—a major environmental concern in many agricultural regions.

Financial Advantages That Make Anaerobic Digestion Plants Worth It

Beyond environmental benefits, anaerobic digestion offers compelling economic advantages that have driven rapid adoption in many regions. The financial case for AD continues to strengthen as energy prices rise, waste disposal costs increase, and carbon pricing mechanisms expand.

Energy Sales Revenue Streams

The most obvious revenue source for AD plants comes from energy production, whether sold as electricity, heat, or biomethane. Many countries offer premium rates for biogas-generated electricity through feed-in tariffs or renewable portfolio standards, enhancing project economics. The stable, predictable nature of biogas production allows for reliable income forecasting, unlike some other renewable energy sources.

CHP (combined heat and power) systems maximise revenue by generating both electricity for sale to the grid and heat that can be used on-site or sold to nearby facilities through district heating networks. In cold climates, this thermal energy can be particularly valuable during winter months. When upgraded to biomethane, the gas can access premium markets as renewable natural gas (RNG) for pipeline injection or transportation fuel, often commanding prices several times higher than conventional natural gas.

Energy security represents another financial benefit that's harder to quantify but increasingly valued. On-site generation provides resilience against grid outages and energy price volatility, particularly important for critical facilities like hospitals or food processing plants.

“Biogas Market Revenue to Attain USD 271 …” from www.precedenceresearch.com and used with no modifications.

Waste Management Cost Savings

For many AD plant operators, avoiding waste disposal costs represents a significant financial benefit. As landfill tipping fees continue to rise—exceeding $100 per ton in some regions—diversion of organic waste to anaerobic digestion creates immediate savings.

Some AD facilities charge their own tipping fees to waste producers, essentially being paid twice for the same material: once for taking it and again for the energy produced.

These “gate fees” can provide 30-50% of total revenue for some commercial AD plants, creating a diversified income stream that helps buffer against energy price fluctuations.

The economics become particularly favourable when processing wastes that would otherwise require costly special handling, such as high-strength food processing wastewaters or FOG (fats, oils, and grease) from restaurants.

On-farm digesters offer additional operational savings through improved manure management, odour reduction, and pathogen control. These benefits, while sometimes difficult to monetise directly, can significantly enhance farm operations and community relations. For more information on how farm digesters contribute to reducing greenhouse gas emissions, explore further insights.

Government Incentives and Carbon Credits

Many jurisdictions offer substantial incentives for anaerobic digestion projects, recognising their multiple environmental benefits. These may include investment tax credits, accelerated depreciation, loan guarantees, grants, and renewable energy certificates. The combination of these incentives can dramatically improve project economics and reduce payback periods.

Carbon credits or offset markets provide another potential revenue stream as AD projects reduce greenhouse gas emissions in multiple ways. Projects can generate credits through methane emissions avoidance (diverting organics from landfills), fossil fuel displacement (renewable energy generation), and, in some cases, through improved fertiliser management using digestate. As carbon markets mature and credit prices increase, this revenue stream is expected to become increasingly significant for AD operators.

Nutrient trading programs are emerging in some watersheds with water quality concerns, potentially creating additional value for the careful nutrient management enabled by digestate use. These programs allow facilities to generate credits for reducing nutrient runoff, which can then be sold to other dischargers facing more expensive treatment options.

“US Government Incentives for Anaerobic …” from sksgreen.com and used with no modifications.

Types of Anaerobic Digestion Plant Systems for Different Needs

Anaerobic digestion technology has evolved into diverse system configurations to accommodate various feedstocks, scales of operation, and operational priorities. Understanding these different approaches helps in selecting the most appropriate system for specific applications.

Wet vs. Dry Systems: Choosing Based on Your Feedstock

Wet digestion systems operate with total solids content typically below 15%, creating a pumpable slurry inside the digester. These systems excel at processing liquid wastes like manure, food processing wastewater, and sewage sludge. Their advantages include easier mixing, more uniform conditions, and well-established operational track records. However, they require more water and larger tank volumes compared to dry systems.

Dry digestion systems handle materials with 20-40% solids content, such as yard waste, crop residues, and food waste, with minimal dilution. These systems typically use less water, require smaller digester volumes, and produce less wastewater requiring treatment. The trade-offs include more complex material handling systems, less uniform digestion, and, in some cases, lower biogas yields per unit of volatile solids. For instance, utilising a food waste depackager can enhance the efficiency of handling food waste in these systems.

Hybrid systems combining elements of both approaches have emerged to process mixed waste streams or to optimise different stages of the digestion process. The choice between wet, dry, or hybrid systems depends primarily on feedstock characteristics, water availability, and space constraints.

![]()

“Dry and Wet Anaerobic Digestion Systems …” from biogasworld.com and used with no modifications.

Single-Stage vs. Multi-Stage Digesters

Single-stage digesters conduct all biological processes in one vessel, offering simplicity, lower capital costs, and reduced maintenance requirements. These systems work well for homogeneous feedstocks with consistent characteristics and represent the majority of operational AD plants worldwide. Their simplicity makes them particularly suitable for smaller operations with limited technical support.

Multi-stage systems separate the digestion process into two or more tanks optimised for different biological phases. This approach can increase overall efficiency, improve stability when processing challenging feedstocks, and provide greater operational control. The initial hydrolysis and acidogenesis stages occur in the first reactor under optimal conditions for those microbes, while methanogenesis happens in subsequent reactors with different pH and temperature settings. For instance, the Landia's GasMix system has been effectively installed to enhance the efficiency of such anaerobic digestion processes.

For facilities processing diverse or variable feedstocks, multi-stage systems offer significant advantages in process stability and biogas yields, often justifying their higher capital costs and operational complexity. Some advanced systems incorporate as many as four separate stages to maximise efficiency and control.

Batch vs. Continuous Flow Operations

Batch digesters are loaded with feedstock all at once, sealed, and left to digest for a set period before being emptied and reloaded. This approach offers simplicity, lower capital costs, and good performance with high-solids feedstocks. Batch systems work well for seasonal operations or where feedstock availability fluctuates, as they can easily be scaled by adding more digester units.

Continuous flow digesters receive regular feedstock additions while simultaneously removing an equal amount of digested material. This creates steady biogas production and operational conditions, maximising efficiency and simplifying downstream energy utilisation. Most commercial-scale operations use continuous systems to optimise biogas production and streamline operations, particularly when consistent feedstock supplies are available.

Some facilities employ sequential batch reactors or other hybrid approaches to combine the advantages of both methods. These systems can accommodate feedstock variability while maintaining relatively consistent biogas production by staggering the operation of multiple batch digesters.

Efficiency Factors: Getting the Most from Your AD Plant

Maximising the efficiency of anaerobic digestion plants requires careful attention to numerous operational factors. Small adjustments in these areas can yield significant improvements in biogas production, system stability, and overall economic performance.

Temperature Control and Monitoring

Temperature significantly impacts microbial activity and thus biogas production rates. Most commercial digesters operate in either the mesophilic range (95-105°F/35-40°C) or thermophilic range (125-135°F/50-57°C), with each offering distinct advantages. Mesophilic systems provide greater stability and resilience to operational fluctuations, while thermophilic systems offer faster digestion rates, higher biogas yields, and improved pathogen reduction. For those interested in maximising methane production, exploring sludge anaerobic digestion techniques can offer further insights.

Maintaining consistent temperature throughout the digester is equally important, as temperature fluctuations can stress microbial communities and reduce performance. Advanced systems employ multiple temperature sensors, heated mixing systems, and insulated tanks to ensure uniform conditions. Some facilities recover waste heat from CHP engines to maintain digester temperature, improving overall energy efficiency.

Seasonal variations present challenges for temperature maintenance, particularly in colder climates where heat demands increase during winter months. Proper insulation, underground construction, and heat recovery systems help mitigate these challenges while minimising parasitic energy loads.

Feedstock Mixing for Optimal Biogas Production

Strategic mixing of different feedstocks—known as co-digestion—can significantly enhance biogas production and system stability. Combining carbon-rich materials (like crop residues) with nitrogen-rich wastes (like manure or food waste) optimises the carbon-to-nitrogen ratio, typically targeting 20:30 for best results. This balance prevents ammonia inhibition while ensuring sufficient nitrogen for microbial growth.

Co-digestion can increase biogas yields by 25-400% compared to mono-digestion of the same materials, making it one of the most cost-effective optimisation strategies. Many successful facilities have developed specific “recipes” that blend available feedstocks to maximise methane production while maintaining process stability. Advanced facilities may adjust these blends seasonally or even daily based on available materials and system performance metrics.

Beyond C:N ratios, operators must consider other feedstock characteristics, including biodegradability, moisture content, particle size, and potential inhibitory compounds. Modern facilities often employ laboratory testing and predictive models to optimise feedstock combinations before full-scale implementation.

Retention Time Optimisation

Hydraulic retention time (HRT)—the average time material spends in the digester—directly impacts both biogas yield and digester size requirements. Longer retention times generally increase total biogas yield per unit of feedstock but require larger digesters for the same throughput. Finding the optimal balance between maximising gas production and minimising capital costs is critical for economic performance.

Different feedstocks require different retention times for optimal digestion. Easily degradable materials like food waste may reach 80-90% of their methane potential in 15-20 days, while fibrous materials like crop residues might require 30-60 days for maximum yield. System designers must consider these characteristics when sizing digesters and establishing operating protocols. For more information on anaerobic digestion, you can explore the environmental benefits of anaerobic digestion.

Advanced digester designs incorporate features to increase the solids retention time (SRT) independently of the hydraulic retention time. These might include recirculation systems, biomass retention mechanisms, or two-stage designs that allow microorganisms to remain in the system longer than the liquid fraction, improving overall efficiency and stability.

Preventing Inhibition and System Failures

Maintaining microbial health is fundamental to successful anaerobic digestion operations. Several factors can inhibit microbial activity, including ammonia accumulation, hydrogen sulfide buildup, volatile fatty acid imbalances, heavy metals, antibiotics, and disinfectants. Regular monitoring of key parameters—pH, volatile fatty acids, alkalinity, and biogas composition—provides early warning of potential problems.

Operational strategies to prevent inhibition include gradual introduction of new feedstocks, maintaining adequate alkalinity as a buffer against pH changes, and avoiding materials known to contain inhibitory compounds. Some facilities implement biological additives or trace element supplementation to enhance microbial performance, particularly when processing challenging feedstocks or pushing systems to higher loading rates.

Real-World Success: Inspiring AD Plant Case Studies

Across the globe, thousands of anaerobic digestion facilities demonstrate the versatility and effectiveness of this technology. These real-world examples provide valuable insights into successful implementation strategies and the diverse benefits realised in different contexts.

From small-scale rural digesters providing cooking fuel in developing countries to massive industrial biogas plants processing thousands of tons daily, the technology has proven adaptable to vastly different operating environments, feedstocks, and objectives. These success stories highlight both the technical feasibility and the multifaceted benefits of anaerobic digestion implementations.

Farm-Based Digesters Transforming Agricultural Waste

Fair Oaks Farms in Indiana operates one of North America's largest on-farm digestion systems, processing manure from 36,000 dairy cows to generate 1.2 megawatts of electricity, compressed natural gas for their vehicle fleet, and bedding material for their barns. The system dramatically reduces odour issues, improves nutrient management, and creates significant cost savings while providing educational opportunities for the farm's 500,000 annual visitors.

Municipal Anaerobic Digestion Plants – Processing Food and Sewage Waste

The East Bay Municipal Utility District in Oakland, California, pioneered food waste co-digestion at wastewater treatment plants in the United States. By adding food waste to their existing sewage digesters, they increased biogas production by over 200%, generating enough renewable electricity to power both their wastewater treatment operations and sell excess to the grid. The facility now processes over 40 tons of food waste daily from local restaurants, grocery stores, and food processors.

Similarly, the Tilburg waste-to-energy plant in the Netherlands processes 52,000 tons of source-separated organic municipal waste annually, producing enough biomethane to supply 5,000 households while also generating high-quality compost from the digestate. The facility represents a cornerstone of the city's circular economy initiatives, converting a costly waste stream into valuable products.

- Reduces greenhouse gas emissions by 14,000 tons CO2-equivalent annually

- Displaces approximately 2.8 million cubic meters of natural gas

- Produces 8,500 tons of certified organic compost

- Creates local employment and technical training opportunities

These municipal examples demonstrate how anaerobic digestion can integrate into broader waste management and renewable energy strategies, creating multiple value streams from materials previously seen simply as disposal challenges.

Industrial Applications in Food Processing Facilities

Anheuser-Busch operates anaerobic digesters at most of its breweries, processing wastewater and beer production residuals to generate biogas that supplies up to 20% of each facility's thermal energy needs. Their Bio-Energy Recovery System (BERS) at the New York brewery reduces wastewater strength by 80-85% while generating 30% of the plant's fuel requirements, demonstrating how food and beverage producers can convert production byproducts into valuable energy.

Start Your Anaerobic Digestion Journey: Next Steps

Implementing anaerobic digestion technology requires careful planning and consideration of numerous factors, from feedstock availability and composition to energy utilisation options and digestate management. A feasibility study represents the essential first step, evaluating site-specific factors and establishing realistic performance and financial projections. This assessment should include comprehensive feedstock analysis, preliminary system design, capital and operating cost estimates, and financial modelling under various scenarios.

Regulatory requirements vary significantly by location, potentially including permits for air emissions, solid waste handling, water discharge, and renewable energy interconnection. Early engagement with relevant authorities helps identify requirements and potential incentives that could impact project viability. Many jurisdictions offer specialised assistance for renewable energy projects, including expedited permitting pathways and technical support services.

Frequently Asked Questions About Anaerobic Digestion Plants

As anaerobic digestion continues gaining popularity, project developers and potential adopters commonly raise several questions about implementation, operations, and economics. These insights help clarify key considerations for those exploring this technology.

How much does it cost to build an anaerobic digestion plant?

Capital costs for anaerobic digestion facilities vary widely based on scale, technology type, feedstock characteristics, and location. Small farm-based systems processing manure from 500 dairy cows typically cost $600,000-$1.5 million, while commercial-scale facilities processing 50,000+ tons of food waste annually can require $20-40 million in capital investment. Cost efficiency improves significantly with scale, with per-ton processing capacity costs decreasing as system size increases.

Key factors affecting capital costs include site preparation requirements, digester technology selection, biogas utilisation equipment, and interconnection infrastructure. Pre-treatment systems for challenging feedstocks, digestate processing equipment, and odour control measures can add significant costs but may be essential depending on feedstock characteristics and site location. Most projects achieve payback periods of 5-10 years, with government incentives potentially reducing this timeframe substantially.

- Farm-scale systems: $3,000-$6,000 per cow (dairy) or $400-$800 per kW of electrical capacity

- Commercial food waste facilities: $200-$500 per annual ton of processing capacity

- Wastewater treatment plant digesters: $3-8 million per million gallons daily (MGD) of capacity

- Biomethane upgrading equipment: $1-3 million per million cubic feet daily of capacity

Operating costs typically range from $40-100 per ton processed, including labour, maintenance, utilities, and administrative expenses. These costs can be offset by tipping fees, energy sales, and digestate valorisation, creating positive operating margins for well-designed facilities.

What types of waste can be processed in an anaerobic digester?

Virtually any organic material can be processed through anaerobic digestion, though biodegradability and methane potential vary significantly. High-performing feedstocks include food waste, food processing byproducts, fats/oils/greases, brewery and distillery wastes, and animal manures. More challenging materials include lignocellulosic wastes like crop residues, yard trimmings, and woody biomass, which may require pre-treatment to enhance digestibility or longer retention times to achieve acceptable conversion rates.

How long does the anaerobic digestion process take?

The time required for complete digestion depends on numerous factors, including temperature regime, feedstock characteristics, digester design, and desired gas yield. In commercial mesophilic systems (95-105°F), retention times typically range from 15-40 days, with easily degradable feedstocks like food waste requiring shorter periods than fibrous materials like crop residues. Thermophilic systems (125-135°F) generally achieve faster conversion rates, potentially reducing retention times by 30-50% compared to mesophilic operation.

Anaerobic digestion plant system designers must balance retention time against digester volume requirements, as longer retention times necessitate larger tanks for the same throughput capacity. Many commercial facilities optimise for 80-90% of maximum theoretical gas yield rather than 100%, as the incremental gas production from extended retention times rarely justifies the additional capital cost of larger digesters.

Can small farms benefit from anaerobic digestion technology?

Absolutely! While large-scale commercial digesters receive most media attention, smaller systems can provide significant benefits for farms with as few as 100-200 dairy cows or equivalent manure production from other livestock. Simplified plug-flow or covered lagoon digesters offer lower capital costs suitable for smaller operations, while co-digestion with off-farm organic wastes can improve gas yields and potentially generate tipping fee revenue to enhance project economics.

What maintenance is required for an anaerobic digestion plant?

Proper maintenance is critical for reliable AD plant operation and typically includes daily visual inspections, weekly equipment checks, monthly calibration of monitoring systems, and quarterly servicing of major components like pumps, mixers, and gas handling equipment.

CHP Engine Maintenance

CHP engines require more frequent maintenance, typically after every 1,500-2,000 operating hours, including oil changes, spark plug replacement, and emissions testing. Many facilities employ preventative maintenance schedules based on equipment manufacturer recommendations and operating experience.

| Anaerobic Digestion Plant – Maintenance Task | Frequency | Importance |

|---|---|---|

| Monitor biogas production and composition | Daily | Critical |

| Check digestate quality parameters | Weekly | High |

| Inspect mixing systems | Weekly | High |

| Clean biogas conditioning systems | Monthly | High |

| CHP engine maintenance | 1,500-2,000 hours | Critical |

| Pump maintenance | Quarterly | Medium |

| Calibrate monitoring instruments | Quarterly | Medium |

| Clean heat exchangers | Annually | Medium |

Operational monitoring systems have become increasingly sophisticated, with many modern facilities employing continuous parameter measurement, data logging, and remote monitoring capabilities. These systems can provide early warning of potential issues, allowing operators to make adjustments before problems affect system performance or damage equipment. For instance, biogas production requires precise monitoring to ensure efficiency and safety.

Staff Training in Operating Anaerobic Digestion Plants

Staff training represents another critical aspect of successful operations, ensuring operators understand both the biological processes and mechanical systems. Many technology providers offer comprehensive training programs and ongoing technical support to maximize system performance and reliability.

Anaerobic digestion plants represent one of our most versatile and multifaceted renewable energy technologies, simultaneously addressing waste management challenges, energy needs, and agricultural sustainability. As the technology continues to mature and deployment expands, these systems will play an increasingly important role in our transition to a circular, low-carbon economy.

Anaerobic Digestion Plants – Conclusion

For communities, businesses, and agricultural operations seeking sustainable waste management solutions with multiple benefits, anaerobic digestion offers a proven approach with environmental and economic advantages. With proper planning, design, and operation, these facilities can provide decades of reliable service while contributing to broader sustainability goals.

For more information on implementing anaerobic digestion technology for your specific needs, Veolia's environmental solutions team provides comprehensive consultation, engineering, and operational support services to ensure successful project outcomes.

Anaerobic digestion plants play a crucial role in waste management by converting organic waste into biogas and digestate. These plants are essential for reducing landfill waste and generating renewable energy. The process involves the breakdown of organic material by microorganisms in the absence of oxygen, producing methane-rich biogas that can be used for electricity and heat. For more detailed insights on the process and benefits, you can explore maximising methane production in anaerobic digestion.

[Article first published in December 2011. Updated, fully rewritten – Aug 2025.]

Subject: Inquiry Regarding Modular Biogas Plant Design for Upgrading and Bottling

Dear Sir/ Madam,

Greetings from Zambia. I am reaching out to inquire about companies capable of designing a modular biogas plant tailored for biogas upgrading and bottling.

Our project aims to produce biogas using waste from abattoirs and vegetable markets, with the upgraded biogas designated for distribution to boarding schools in Eastern Zambia. This initiative seeks to provide a clean energy source for cooking and heating, thus reducing these schools’ reliance on wood fuel—a significant contributor to deforestation in the region.

Your assistance in guiding us to potential resources or providers who can support this endeavor would be greatly appreciated.

Warm regards,

Lazarous Chewe

I did try to reply but your email bounced and the website you gave did not exist.