Biogas yield analysis evaluates the amount of biogas (primarily methane and carbon dioxide) produced from a specific feedstock during anaerobic digestion, using metrics like biogas potential (theoretical maximum) and actual yield (real-world production).

Biogas yield analysis is essential for optimising biogas production. Its use will identify suitable feedstocks of which food waste is of increasing importance, and understand how variables such as temperature, retention time, feedstock composition, and microbial activity influence performance. Tools like Biogas Potential (BMP) tests provide a benchmark

Biogas Yield Analysis – Key Takeaways

- Food waste can generate up to 0.65 m³ of biogas per kg of dry matter, making it one of the most efficient organic feedstocks for renewable energy production.

- Optimising temperature (35-55°C), pH (6.8-7.2), and carbon-to-nitrogen ratio (20-30:1) can increase biogas yields by up to 40%.

- Pretreatment methods like mechanical shredding and thermal hydrolysis can break down complex molecules, increasing biodegradability and methane content by 15-25%.

- Co-digestion with complementary substrates such as agricultural waste can balance nutrients and increase biogas yields by 50-200% compared to mono-digestion.

- Drycake Twister™ provides depackaging systems to help maximise biogas production from food waste while reducing operational costs and environmental impact.

Transforming Food Waste into Clean Energy: The Biogas Opportunity

Food waste represents both a global challenge and a remarkable opportunity. When diverted from landfills and processed through anaerobic digestion, this abundant resource transforms into renewable biogas energy. The potential is enormous—a proper biogas system can convert virtually any food waste stream into clean, versatile fuel while simultaneously addressing waste management challenges and reducing greenhouse gas emissions.

At Landia, they've seen firsthand how optimising biogas production systems can dramatically improve both environmental outcomes and financial returns. Our research shows that many operations are achieving only 40-60% of their theoretical maximum yields, highlighting the significant opportunity for improvement through evidence-based optimisation techniques.

The Food Waste Crisis in Numbers

The scale of food waste globally is staggering. Approximately one-third of all food produced for human consumption—about 1.3 billion tons annually—is lost or wasted. This waste contributes roughly 8% of global greenhouse gas emissions, with methane from decomposing organic matter in landfills being particularly problematic due to its potency as a greenhouse gas (25 times more powerful than CO₂). In the United States alone, more than 63 million tons of food waste is generated annually, with over 54% still ending up in landfills rather than being recycled or recovered.

Food waste composition varies widely by source, but typically contains 70-90% moisture, 15-25% organic matter, and high concentrations of easily degradable materials like carbohydrates, proteins, and lipids. These characteristics make food waste an ideal feedstock for anaerobic digestion. But, without biogas yield analysis, it is unlikely that digester operators will ever consistently achieve theoretical methane yields that significantly exceed those of many other organic waste streams, including agricultural residues and manure.

Energy Potential: What 1 Ton of Food Waste Can Generate

Energy Potential from 1 Ton of Food Waste

Biogas Production: 100-200 m³

Methane Content: 50-70% (60% average)

Energy Value: 2,000-4,000 kWh

Equivalent to: 200-400 liters of diesel fuel

Electricity Generation: 600-1,200 kWh

CO₂ Emissions Avoided: 0.5-1.0 tons

The energy potential from food waste varies based on composition, but the figures above represent typical values from mixed food waste streams. Higher fat content can significantly increase yields, with some restaurant and food processing wastes generating up to 25% more energy. This substantial energy value explains why optimising biogas yields has become a focus for waste management facilities, municipalities, and food industry stakeholders seeking both environmental and economic benefits.

The Science of Biogas Production from Food Waste

Understanding the biochemical processes behind biogas formation is essential for maximising yields. Anaerobic digestion is essentially a series of biological processes in which microorganisms break down biodegradable material in the absence of oxygen. The efficiency of this process depends on numerous factors, including feedstock characteristics, microbial activity, and environmental conditions within the digester.

1. The Four-Stage Anaerobic Digestion Process

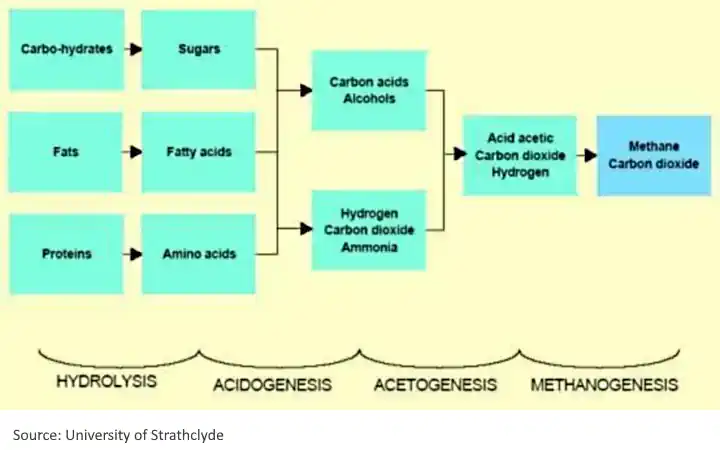

Biogas production occurs through a four-stage process, each driven by different groups of microorganisms working in a synchronised ecological system. The first stage, hydrolysis, breaks down complex organic polymers (carbohydrates, proteins, and lipids) into simpler compounds like sugars, amino acids, and fatty acids. This stage often becomes the rate-limiting step for food waste with high cellulose or lignin content.

The second stage, acidogenesis, converts these simpler compounds into volatile fatty acids (VFAs), alcohols, hydrogen, and carbon dioxide. During the third stage, acetogenesis, these intermediate products are further transformed into acetic acid, hydrogen, and carbon dioxide. The final stage, methanogenesis, is where specialised archaea convert these compounds primarily into methane and carbon dioxide, forming biogas.

Each stage must function optimally and in balance with the others to achieve maximum biogas yields. Disruption in any one phase can create a cascade effect that reduces overall system performance. Monitoring intermediate products, particularly VFAs, provides valuable insights into process stability.

2. Microorganisms That Drive Biogas Generation

The anaerobic digestion process relies on diverse microbial communities working synergistically. Primary fermentative bacteria handle hydrolysis and acidogenesis, while secondary fermenters perform acetogenesis. Methanogenic archaea, which conduct the final conversion to methane, are particularly sensitive to environmental conditions and require careful management.

These methanogens fall into two main groups: acetoclastic methanogens that convert acetic acid to methane (responsible for approximately 70% of methane production) and hydrogenotrophic methanogens that convert hydrogen and carbon dioxide to methane. The balance between these groups affects both the quantity and quality of biogas produced, with optimal microbial diversity leading to more resilient systems and higher methane content.

Certain food waste characteristics can inhibit microbial activity. High concentrations of ammonia from protein-rich wastes, sulfides from sulfur-containing amino acids, or sodium from certain processed foods can all inhibit methanogenic activity if not properly managed. Developing and maintaining a robust, adapted microbial community is therefore crucial for maximising biogas production from variable food waste streams.

3. Biogas Composition and Energy Content

Biogas from food waste typically contains 50-70% methane, 30-45% carbon dioxide, and trace amounts of other gases, including hydrogen sulfide, ammonia, and water vapour. The methane concentration directly determines the energy value, with each percentage point increase in methane content raising the energy value by approximately 10%. High-quality biogas with 65% methane content has an energy value of approximately 23 MJ/m³ (6.5 kWh/m³), comparable to about 0.6 litres of diesel fuel.

The presence of impurities can significantly impact both biogas quality and system performance. Hydrogen sulfide, even at low concentrations, is particularly problematic as it causes corrosion in engines, pipelines, and other equipment. Water vapour reduces the calorific value and can condense in pipelines, while ammonia can cause nitrogen oxide emissions during combustion. Most commercial biogas operations incorporate conditioning systems to remove these impurities, with technologies ranging from simple condensation traps to advanced biological filtration systems.

4. Critical Factors That Determine Biogas Yields

Maximising biogas yields from food waste requires careful management of multiple interdependent operational parameters. Among these, temperature, pH, retention time, and nutrient balance have the most significant impact on process efficiency and stability. When properly optimised, these factors can increase biogas production by 30-50% compared to poorly managed systems, making the difference between financial viability and operational losses. For a deeper understanding of these parameters, you can explore this comprehensive study on biogas production.

5. Temperature Ranges and Their Effects

Anaerobic digestion occurs across three main temperature ranges, each supporting different microbial communities with distinct characteristics. Psychrophilic digestion (below 25°C) offers simplicity and low energy requirements but results in slow reaction rates and lower gas yields, typically 30-50% less than higher-temperature operations. Mesophilic digestion (35-42°C) represents the most common operating range due to its good balance of stability, gas production, and energy requirements. At the higher end, thermophilic digestion (50-57°C) can increase reaction rates and pathogen destruction but demands more precise control and greater energy input for heating.

Temperature stability is just as important as the absolute value. Methanogens are particularly sensitive to temperature fluctuations, with variations of more than ±2°C potentially reducing activity by up to 30%. Most commercial systems incorporate heating systems with automated temperature control, often utilising a portion of the biogas produced to maintain optimal conditions. Insulation quality and mixing efficiency both play important roles in maintaining temperature uniformity throughout the digester volume.

6. Optimal pH Levels for Maximum Production

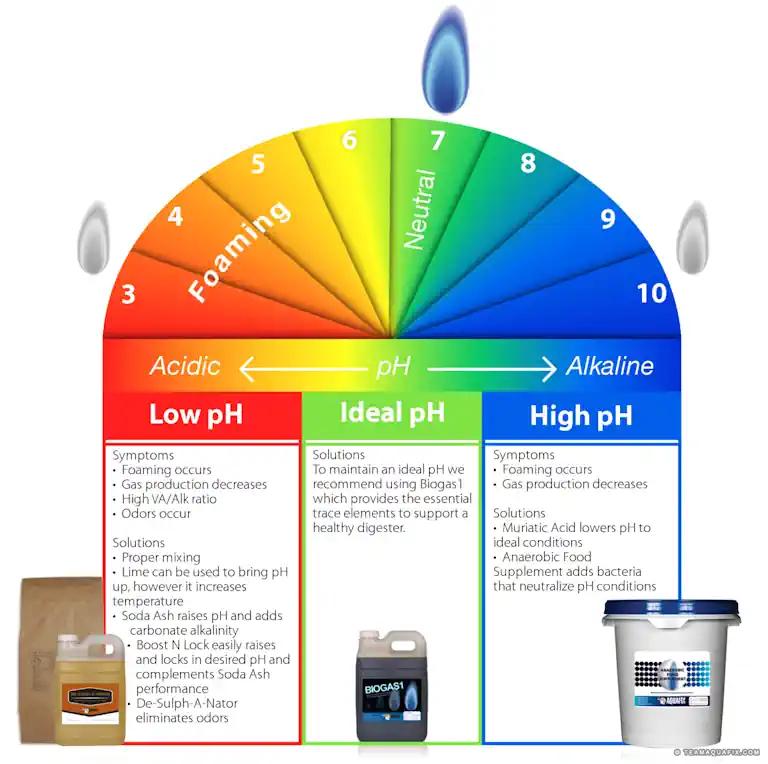

pH control is critical for maintaining microbial activity, with methanogens being particularly sensitive to acidic conditions. While hydrolytic and acidogenic bacteria function effectively at pH 5.5-6.5, methanogens require a narrower range of pH 6.8-7.2 for optimal activity. Systems processing food waste often struggle with pH stability due to the rapid generation of volatile fatty acids during the initial digestion phases, which can lower pH and inhibit methanogenesis if not properly managed.

Effective pH management strategies include careful feeding rate control to prevent organic overloading, co-digestion with alkaline substrates like manure or biosolids, and the addition of buffering agents such as sodium bicarbonate, lime, or sodium hydroxide. Continuous monitoring systems with automatic pH correction have become standard in commercial facilities, allowing immediate response to developing imbalances before they significantly impact methane production.

“Anaerobic Digester Issues …” from teamaquafix.com and used with no modifications.

7. Retention Time: Finding the Sweet Spot

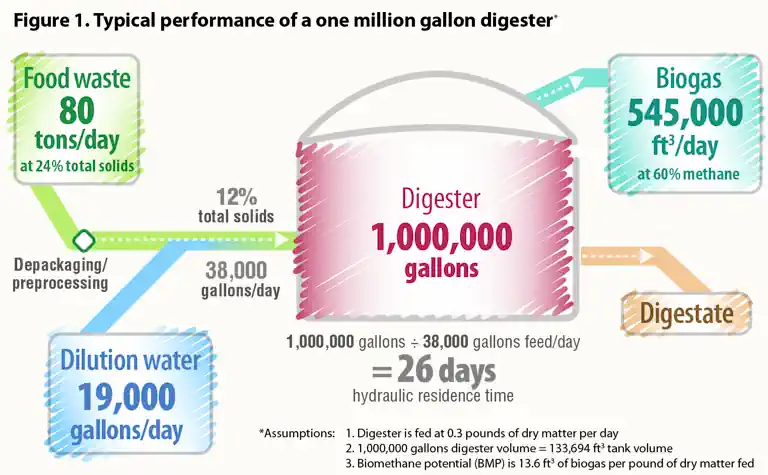

Hydraulic Retention Time (HRT) represents the average time that substrate remains in the digester, while Solid Retention Time (SRT) indicates how long the active biomass stays in the system. Both parameters must be optimised to ensure complete degradation while maintaining efficient digester utilisation. For food waste, typical HRT ranges from 15-30 days in mesophilic systems and 10-18 days in thermophilic operations. For more detailed insights, consider exploring this research article on retention time optimisation.

The relationship between retention time and biogas yield follows a diminishing returns curve, with approximately 80% of the potential methane produced within the first half of the optimal retention period.

Shorter retention times increase throughput but risk incomplete digestion and reduced yields, while excessive retention times reduce volumetric efficiency without proportional yield increases. Advanced digester designs often incorporate biomass retention mechanisms that allow shorter HRTs while maintaining adequate SRTs for the slower-growing methanogenic organisms.

“101 For Digester Sizing And RNG …” from www.biocycle.net and used with no modifications.

8. Carbon-to-Nitrogen Ratio Optimisation

The carbon-to-nitrogen (C/N) ratio significantly impacts digestion efficiency and system stability. The optimal range for anaerobic digestion typically falls between 20:1 and 30:1, balancing carbon availability for energy with nitrogen for microbial growth. Food waste often exhibits lower C/N ratios (typically 14-18:1) due to high protein content, potentially leading to ammonia inhibition during digestion.

Strategies to optimise C/N ratios include selective waste segregation, targeted collection programs, and most commonly, co-digestion with carbon-rich substrates. Materials like garden waste, straw, paper products, or wood chips can be strategically blended with food waste to achieve ideal nutrient balances. Many commercial operations maintain multiple feedstock sources and adjust mixing ratios based on regular compositional testing to maintain optimal C/N ratios throughout seasonal variations in waste composition.

9. Mixing Techniques That Boost Efficiency

Effective mixing is essential for maintaining process stability and maximising biogas yields from food waste. Proper agitation ensures uniform distribution of substrate, microorganisms, and heat while preventing stratification, floating layers, and dead zones within the digester. Research indicates that optimised mixing can increase biogas production by 10-15% compared to poorly mixed systems, while also reducing the risk of process upsets.

The most common mixing technologies include mechanical agitation (paddle, propeller, or draft tube mixers), hydraulic mixing (recirculation pumps), and pneumatic mixing (biogas injection). Each approach offers different advantages in terms of energy efficiency, maintenance requirements, and effectiveness with varying substrate viscosities. The choice of mixing strategy should be tailored to specific digester design, substrate characteristics, and operational goals, with most commercial facilities employing programmable mixing cycles rather than continuous agitation to reduce energy consumption.

Food Waste Characteristics and Their Impact on Biogas Output

Not all food waste is created equal when it comes to biogas potential. Composition varies dramatically based on source, collection methods, and pre-consumer versus post-consumer origin, significantly affecting biodegradability and methane yields. Understanding these variations allows for strategic feedstock management and realistic performance expectations when designing or operating biogas facilities.

1. High-Yield vs. Low-Yield Food Waste Types

Fats, oils, and simple carbohydrates generally produce the highest methane yields due to their chemical composition and ease of biodegradation. Waste streams from bakeries, confectioneries, and dairy processing typically generate 15-25% more biogas than average mixed food waste. In contrast, materials high in complex carbohydrates and lignin—such as certain fruits and vegetables with tough skins or woody components—produce significantly lower yields without adequate pretreatment.

Protein-rich waste streams present a complex case, offering high theoretical methane potential but potentially causing inhibition through ammonia release during degradation. Restaurant waste containing significant amounts of meat and dairy can produce excellent biogas yields but requires careful process management to prevent ammonia toxicity. Many successful operations strategically blend different waste types to balance these characteristics, maintaining high energy potential while minimising inhibitory effects.

2. Moisture Content and Its Role in Digestion

Moisture content significantly impacts digestion efficiency and technology selection for food waste processing. Wet digestion systems (total solids <15%) offer excellent mass transfer and process stability but require larger digester volumes and generate more liquid effluent, requiring management. Semi-dry (15-20% total solids) and dry digestion systems (20-40% total solids) reduce volume requirements and wastewater generation but may experience mass transfer limitations and require more robust handling equipment.

Food waste typically contains 70-90% moisture, making it naturally suited for wet digestion processes. However, dewatering or mixing with drier co-substrates may be advantageous in certain scenarios, particularly when digestate management poses challenges or when using plug-flow or garage-type digesters. The optimal approach depends on regional factors, including climate, available infrastructure, and end-use applications for both biogas and digestate.

3. Dealing with Fats, Oils, and Greases

Fats, oils, and greases (FOG) present both an opportunity and a challenge in food waste digestion. With theoretical methane yields up to 1,000 L/kg VS—nearly double that of carbohydrates—FOG can dramatically boost biogas production when properly managed. However, these materials can also cause operational issues, including poor mixing, pipe blockages, and the formation of floating layers that reduce effective digester volume.

Successful FOG integration strategies include gradual acclimatisation of microbial communities, maintaining FOG concentrations below 30% of total feedstock, and ensuring adequate mixing. Many commercial operations utilise specialised pre-mixing systems that create stable emulsions before introducing FOG into the main digester. Long-chain fatty acids (LCFAs) released during FOG breakdown can temporarily inhibit methanogenesis, so feeding patterns may require adjustment to prevent accumulation beyond inhibitory thresholds of 1.0-1.5 g/L.

Pretreatment Methods That Increase Biogas Production

Pretreatment technologies can significantly enhance biogas yields from food waste by addressing its inherent limitations. These processes improve biodegradability by breaking down complex structures, increasing surface area for microbial attack, and releasing nutrients that would otherwise remain inaccessible. Well-designed pretreatment systems can increase methane yields by 15-40% while also improving digester stability and reducing retention time requirements.

1. Mechanical Pretreatment Techniques

Mechanical pretreatment primarily aims to reduce particle size and increase surface area available for microbial degradation. Technologies range from simple grinding and shredding to more sophisticated ultrasonic and high-pressure homogenization systems. For food waste, particle size reduction to 10-20 mm typically provides optimal results, balancing increased biodegradability with energy consumption and equipment wear.

Beyond size reduction, mechanical separation can remove contaminants like plastics, metals, and glass that frequently contaminate collected food waste. Sophisticated separation systems utilising magnets, eddy current separators, ballistic separators, and optical sorting technologies can achieve contamination levels below 0.5% by weight, meeting even strict quality standards for digestate. The investment in effective separation technology typically pays for itself through reduced maintenance costs and improved digester performance.

2. Thermal Hydrolysis: Breaking Down Complex Molecules

Thermal hydrolysis subjects food waste to high temperatures (typically 140-180°C) and pressure (4-8 bar) for short periods (20-30 minutes) followed by rapid decompression. This process ruptures cell structures, solubilises complex organic matter, and significantly improves biodegradability. Studies show that properly optimised thermal hydrolysis can increase methane yields from food waste by 15-25% while reducing required digestion time by up to 50%.

The benefits of thermal hydrolysis extend beyond increased gas yields. The high-temperature process ensures pathogen destruction, producing Class A biosolids suitable for unrestricted agricultural use. Additionally, the improved dewatering characteristics of the resulting digestate can reduce volume by 30-40%, significantly lowering transportation and disposal costs. While thermal hydrolysis systems require substantial capital investment and energy input, the combination of increased revenue and reduced operating costs typically delivers payback periods of 3-5 years for large-scale operations.

3. Chemical Pretreatment Options

Chemical pretreatment methods utilise acids, bases, or oxidising agents to modify the structure and chemistry of food waste components. Alkaline pretreatment using sodium or potassium hydroxide (at concentrations of 1-8% and temperatures of 60-100°C) effectively solubilises proteins and carbohydrates while also providing pH buffering benefits within the digester. Acid pretreatment, typically with sulfuric or hydrochloric acid, is particularly effective for breaking down cellulosic materials but requires neutralisation before digestion.

Oxidative pretreatment using ozone, hydrogen peroxide, or Fenton's reagent can break down recalcitrant compounds and increase biodegradability, though these methods are more commonly applied to industrial food processing wastes containing complex organic pollutants. The selection of chemical pretreatment methods should balance effectiveness against costs, safety considerations, and potential downstream impacts on digester biology and digestate quality.

4. Enzymatic Treatments for Enhanced Breakdown

Enzymatic pretreatment employs specific enzymes like amylases, proteases, and lipases to catalyse the breakdown of starches, proteins, and fats in food waste. This approach offers high specificity, operates under mild conditions (typically 40-60°C and pH 4.5-7.5), and avoids the energy inputs and potential inhibitory byproducts associated with harsher pretreatment methods. Commercial enzyme preparations can increase methane yields by 10-15% while simultaneously reducing viscosity and improving mixing efficiency.

The economic viability of enzymatic pretreatment depends largely on enzyme costs versus performance benefits. Recent advances in enzyme production technology and the development of more stable, higher-activity formulations have significantly improved this balance. Many commercial operations now implement enzyme dosing systems that adjust concentrations based on feedstock characteristics and performance metrics, optimising cost-benefit ratios across varying operating conditions.

Co-digestion Strategies for Optimal Performance

Co-digestion—the simultaneous digestion of food waste with complementary substrates—has emerged as one of the most effective strategies for maximising biogas yields and process stability. Well-designed co-digestion programs can increase methane production by 50-200% compared to mono-digestion of food waste, while also addressing challenges related to nutrient imbalances, inhibitory compounds, and seasonal variability in waste composition.

1. Ideal Co-substrates for Food Waste

The most beneficial co-substrates complement food waste's characteristics by addressing its limitations. Agricultural residues like corn stover, wheat straw, and rice husks provide carbon to balance food waste's high nitrogen content, while manure offers buffering capacity, trace elements, and diverse microbial communities that enhance stability. Wastewater treatment biosolids provide alkalinity and can improve dewatering characteristics, though potential heavy metal content requires monitoring.

Industrial organic wastes from food processing, beverage production, and pulp/paper industries often offer high energy potential and can be excellent co-substrates when properly characterised and introduced at appropriate ratios. Regional availability and transportation costs typically dictate co-substrate selection in commercial operations, with most facilities utilising multiple options to maintain flexibility. Many successful biogas plants have developed “recipes” for different seasons and waste streams, adjusting co-digestion ratios based on regular compositional analysis. For more information on the potential of biogas, check out why biogas is considered an excellent fuel.

2. Mixing Ratios That Maximise Methane Content

Optimal mixing ratios depend on the specific characteristics of both food waste and co-substrates, but research and operational experience provide useful guidelines. For food waste and dairy manure co-digestion, ratios between 1:1 and 3:1 (food waste: manure, volatile solids basis) typically maximise methane yield while maintaining process stability. When using carbon-rich agricultural residues, ratios typically range from 2:1 to 5:1 (food waste: residue) depending on the C/N ratio of the specific materials.

The benefits of proper mixing ratios extend beyond simple yield improvements. Strategically designed co-digestion programs can reduce hydrogen sulfide content in biogas, improve digestate quality, and enhance system resilience against variations in feedstock characteristics. Many commercial operations now employ automated feeding systems that can adjust ratios based on real-time monitoring data, maintaining optimal performance despite variations in incoming waste streams.

4. Balancing Nutrients Through Co-digestion

Beyond the carbon-to-nitrogen ratio, co-digestion can address other critical nutrient requirements for optimal anaerobic digestion. Trace elements, including iron, nickel, cobalt, molybdenum, selenium, and tungsten, serve as cofactors for enzymes involved in methanogenesis and can become limiting in mono-digestion systems. Manure typically provides these elements in sufficient quantities, while agricultural and food processing wastes may require supplementation.

Successful co-digestion also balances macro-nutrients, including phosphorus, potassium, and sulfur, affecting both process performance and digestate value as fertiliser. Operations processing primarily food waste often monitor these parameters regularly and may rotate between different co-substrates to maintain optimal nutrient profiles. This balanced approach not only maximises biogas production but also enhances digestate quality, potentially creating a valuable secondary revenue stream through fertiliser sales.

Monitoring and Control Systems for Biogas Yield Analysis and Process Optimisation

Effective monitoring and control systems represent the difference between theoretical and achievable biogas yields in real-world operations. By providing timely information about process conditions and enabling rapid response to developing imbalances, these systems allow operators to perform a rigorous biogas yield analysis and maintain optimal conditions despite variations in feedstock and environmental factors. Investments in monitoring technology typically deliver returns through increased gas production, reduced downtime, and lower maintenance costs. For more information on optimising biogas systems, explore services helping generators optimise their assets.

Essential Parameters to Track Daily

Successful biogas operations monitor a core set of parameters at frequencies matched to their variability and impact.

- Temperature,

- pH,

- gas production rate, and

- methane content, should be measured continuously or at a minimum daily.

Monitoring at this frequency level means that deviations can indicate developing problems before they significantly impact performance. Volatile fatty acids (VFAs) and alkalinity represent critical early warning indicators, with the VFA/alkalinity ratio ideally maintained below 0.3-0.4 for stable operation.

More comprehensive biogas yield analysis, including:

- ammonia nitrogen,

- volatile solids reduction, and

- specific VFA composition,

typically occurs weekly or monthly to track longer-term trends.

Modern monitoring systems increasingly incorporate online sensors for real-time data collection, with gas analysers, pH probes, temperature sensors, and flow meters providing continuous information streams.

Advanced facilities may also utilise;

- spectroscopic techniques like near-infrared (NIR) or Raman spectroscopy to measure organic acid profiles,

- dry matter content, and even

- feedstock composition without laboratory analysis.

These systems enable proactive process control rather than reactive problem-solving, significantly improving overall performance. For more insights, learn about what a biogas reactor is and how it integrates with modern monitoring systems.

Warning Signs of Process Imbalance

Early detection of developing process imbalances allows for corrective action before severe inhibition occurs. Declining gas production coupled with decreasing methane percentage often indicates acidification from organic overloading, while rising pH and ammonia levels signal potential ammonia inhibition. Changes in gas production without corresponding changes in feeding rates may indicate temperature fluctuations, mixing problems, or biomass washout.

The progression of volatile fatty acids provides particularly valuable diagnostic information. Acetic acid accumulation often precedes more serious acidification, while propionic acid accumulation above 1,000 mg/L indicates significant inhibition of secondary fermenters.

Rising levels of butyric and valeric acids typically signal more severe imbalances requiring immediate intervention.

Establishing operation-specific baselines and biogas yield analysis often proves more valuable than absolute values, as stable systems can adapt to conditions that would cause failure in less established processes. For a comprehensive understanding of these processes.

Automation Tools for Small and Large-Scale Operations

Automation systems ranging from basic programmable logic controllers (PLCs) to sophisticated supervisory control and data acquisition (SCADA) platforms have become standard in commercial biogas operations.

These systems manage feeding schedules, mixing cycles, temperature control, and gas handling while providing operators with biogas yield analysis visualisation tools to monitor performance trends.

The more advanced installations incorporate feed-forward control strategies that adjust operational parameters based on feedstock characteristics before problems develop.

For smaller operations, affordable monitoring and control solutions have emerged that provide core functionality without the expense of full industrial automation.

Cloud-based monitoring platforms allow remote system supervision from mobile devices, while open-source control systems and modular components enable customisation to specific needs.

Even simple automation of biogas yield analysis to control feeding schedules and basic parameter logging can significantly improve performance by ensuring consistent operation and enabling data-driven decision making.

Real-World Yield Data: What's Actually Achievable

While theoretical calculations and laboratory studies provide important benchmarks, real-world performance data offers the most reliable guide for planning and operating food waste digestion systems.

Operational yields typically range from 70-90% of theoretical maximums due to practical limitations, including heterogeneous feedstock, unavoidable heat losses, and the need to maintain process stability margins.

Understanding these realistic expectations helps avoid overdesigned systems and unrealistic financial projections.

Typical Biogas Yields from Different Food Waste Sources

| Food Waste Source | Biogas Yield (m³/ton wet weight) | Methane Content (%) | Energy Value (kWh/ton) |

|---|---|---|---|

| Restaurant Waste | 150-300 | 55-70 | 800-1,800 |

| Supermarket Waste | 100-200 | 50-65 | 500-1,300 |

| Food Processing Waste | 70-250 | 60-75 | 450-1,600 |

| Residential Food Waste | 80-160 | 50-60 | 400-900 |

| Bakery Waste | 250-550 | 50-55 | 1,200-2,800 |

Comparing Small vs. Commercial-Scale Performance

Scale significantly impacts achievable biogas yields, with larger systems typically achieving 15-25% higher production rates than small-scale operations processing similar feedstocks.

This performance gap stems from several factors: larger systems maintain more stable conditions through thermal mass and dilution effects, employ more sophisticated monitoring and control systems, and often utilise more effective pretreatment technologies. Commercial operations also benefit from economies of scale in staffing, allowing for 24/7 monitoring and specialised expertise in process optimisation.

However, smaller systems offer advantages in feedstock quality control, system responsiveness, and operational flexibility. Many small farm-based digesters achieve excellent performance by focusing on high-quality feedstocks, biogas yield analysis, careful management, and integrated energy utilisation.

Technological advances, including modular designs, simplified automation systems, and standardised components, have significantly narrowed the performance gap in recent years, making small-scale digestion increasingly viable for distributed applications.

Biogas Yield Analysis to Accommodate Seasonal Variations in Biogas Production

Seasonal factors can cause biogas yield variations of 10-30% in systems processing food waste, particularly those utilising outdoor components or accepting seasonally variable feedstocks.

Winter conditions present challenges through increased heating requirements and potential feedstock temperature depression during delivery and storage. Summer peaks in fruit and vegetable waste can alter C/N ratios and increase acidity, requiring adjustment of operating parameters to maintain stability.

Successful operations plan for these variations through using their biogas yield analysis to guide flexible co-substrate strategies, adjustable feeding rates, and adequate gas storage capacity to buffer production fluctuations.

Many facilities maintain slightly conservative loading rates during stable periods, creating capacity reserves for challenging conditions.

Climate-controlled receiving areas and insulated digestion systems significantly reduce seasonal performance variations, though their implementation economics depend on local climate severity and energy costs.

Troubleshooting Common Biogas Production Problems

Even well-designed biogas systems encounter operational challenges that can reduce yields and threaten stability. Most issues stem from common root causes, including organic overloading, nutrient imbalances, inhibitory compounds, equipment failures, or operational errors.

A systematic troubleshooting approach combining monitoring data with biogas yield analysis, process knowledge, and corrective action protocols helps resolve problems quickly while minimising performance impacts.

Addressing Low Gas Production

Declining biogas production often signals process imbalances requiring prompt intervention. Organic overloading, characterised by VFA accumulation and declining pH, typically requires temporary feeding reductions of 30-50% until stability returns.

Nutrient limitations may be addressed through targeted supplementation, with particular attention to micronutrients including iron (10-100 mg/L), nickel (0.1-1.0 mg/L), and cobalt (0.05-0.5 mg/L) that are essential for methanogenic activity.

Temperature variations beyond the optimal range for the resident microbial community can significantly reduce activity, with mesophilic systems particularly sensitive to temperatures below 30°C or above 42°C.

Toxicity from hydrogen sulfide, ammonia, heavy metals, or disinfectants requires identification and mitigation through dilution, antagonistic ion addition, or specific binding agents, depending on the specific inhibitor.

Biogas yield analysis should prevent biomass washout from excessive hydraulic loading, but if it occurs may necessitate reduced throughput or recovery through retained digestate recycling.

To understand and also cure underperforming biogas plants, check out our ebook here.

Preventing and Resolving System Blockages

Food waste digestion systems are particularly vulnerable to physical blockages from packaging materials, cutlery, bones, and other non-digestible contaminants. Effective pre-screening systems the Dycake Twister Depackaging and Separation System with Seditank, can remove these materials.

Providing strategic placement of cleanouts, rodding ports, and access hatches at potential blockage points allows for maintenance without a complete system shutdown.

The additional investment in a system such as the Drycake Seditank® will prevent internal sedimentation of inorganic materials, including sand, egg shells, bone fragments, and soil, which can gradually reduce effective digester volume and damage pumps and mixers.

Many facilities incorporate plastic to grit removal systems, like the Seditank, in pre-processing areas and schedule periodic partial draindown for sediment removal.

Struvite (magnesium ammonium phosphate) precipitation on pipes, pumps, and heat exchangers presents another common challenge, particularly in systems with elevated ammonia and phosphate levels.

Regular cleaning protocols, pH management, and in some cases chemical additives like ferric chloride can control struvite formation and maintain system hydraulic capacity.

Sources: