Leading digestate separator manufacturer Borger UK hires out digestate separation trailers. This innovative development is capable of providing enhanced digestate value for biogas operators without the need to invest in a fixed separation facility. Regular visits to biogas plants in the UK by a digestate separation service allows stored biogas plant output to be processed when necessary.

The digestate trailer hire business is growing as UK agricultural and food waste biogas plants multiply.

According to the trade association for the biogas industry (ADBA), there will soon be 1,000 operational biogas plants in the UK.

In Germany, where there are in excess of 9,000 of these plants in operation already. There too specialist digestate separation contracting businesses have already emerged.

This new business model offers a commercially viable service tapping into the growing market for:

- processing accumulated digestate slurry (raw from the digester and including both liquid and fibrous/solids),

- into a digestate product that can be sold as a sustainable natural fertiliser.

On occasions the fibrous material produced by the Borger separator may be used as a valuable livestock bedding.

Digestate Separation contracting will be increasingly viable sooner than most people realise as pressure mounts to increase biogas plant development. One reason for this is to accelerate the decarbonisation of transport vehicles, for which biogas upgraded methane is proving the firm favourite fuel.

What are Digestate Separation Trailers?

Digestate separation trailers are large flatbed truck trailers that have been fitted out to hold up to 6 digestate separator units, with a common fibre discharge conveyor. They provide a high throughput digestate slurry processing facility when parked-up next to the digestate fibre storage bay at any AD plant, and connected to an electric power source.

A few minutes after arrival, and once connected to a slurry source, the Borger separators can be fired up using their own built-in pumps to convey the slurry to the trailer for separation. The digestate-separation trailer-operative will be trained in best practise digestate processing.

The benefits of mobile for AD plant operators which include:

- They need no expertise in digestate processing

- They don't need any training in digestate separator equipment operation or maintenance.

The biogas plant operator can view the cost of the separation contractor's work as self-funding from the revenue generated from the value added to the digestate, or at worst reduced digestate disposal costs.

After anything, from a few hours to a day, the Digestate Separation Trailer moves on to another AD plant to repeat the operation on the mixed pumped digestate discharged daily from the biogas digester. Investment in the separator equipment gains maximum return on investment and the Digestate Separation Trailer operators provide much-needed assistance with digestate processing.

Why Do Biogas Plants Need Biogas Plant Digestate Separators?

If biogas plant operators can improve the quality of their digestate solids by complying with the WRAP PAS110 Standard their composted solid digestate can be sold at a profit. So, this raises the intriguing opportunity of a new breed of farm contracting businesses in countries and regions where biogas plant adoption is high.

Digestate must fulfil the standards outlined in the Quality Protocol and BSI PAS110 specification (England and Wales) or the SEPA position statement (Scotland), in order to be sold as a biofertilizer.

PAS110 establishes minimum quality requirements for entire digestate, separated fibre, and separated liquor generated from source-segregated biowaste.

There is no requirement that items be dried or dewatered precisely so the extent to which this is done relates to the renewable fertilizer product's intended market.

Converting Digestate Disposal from an Expense to an Asset

Disposal of digestate is generally a business expense for bigger AD plant operators (especially for non-farm based commercial and industrial locations).

When digestate is sold offsite, WRAP surveys show an average price of £3.73 per tonne, with comparable studies showing prices as high as £5 per tonne. Data on this is scarce and commercially sensitive.

An NNFCC report says that some industry literature claims that digestate driers' agents will buy back granulated quality digestate from industrial processors for £25 per tonne or more, but this is difficult to verify. It's also unclear, they say, whether this is related to leased turn-key offerings, in which an RHI payment is claimed by the digestate driers' owner and site owners/operators simply supply feedstock.

However, digestate separation into the liquid with close to no plastic content and a solid fraction is an essential prerequisite to PAS110 compliance. The solid fraction containing plastic residues are subsequently screened (or processed by a plastics separator) for plastics separation and another unwanted content removal.

Growth in the Market for Digestate for Sale

There is now still only a limited market for digestate for sale in the UK as a Green Fertilizer Product, but it's growing.

Currently, a substantial percentage of the digestate is given out for free. In other cases, anaerobic digestion facility operators pay to have it removed (to cover transport and spreading costs).

Until now, in the UK the great majority of digestate has been utilised on agricultural land or in low-value horticultural applications. But the number of AD plant operators processing digestate has increased as the industry has developed.

At some point, the pressure for renewable fertiliser to replace synthetic fertilizers and reduce the carbon footprint of farming will force agriculture to find ways of using digestate to replace synthetic (mined/ chemical) fertilizers. There is also evidence that transitions of this sort can be quite rapid.

As any keen gardener will have noticed over the last 2 years the proportion of peat-based garden compost on offer at Garden Centres versus composted green waste has seen a rapid reversal.

Whereas before the covid pandemic struck most garden compost on sale was peat-based, now less than 2 years later in England, the majority are now recycled garden green-waste based products.

The Development of Digestate Separator Technology

The search for compliance with PAS110 has led to a demand for biogas digestate separators which equipment suppliers such as Borger have risen to the challenge to provide.

Borger and their competitors have brought forward today's proven generation of highly efficient separators.

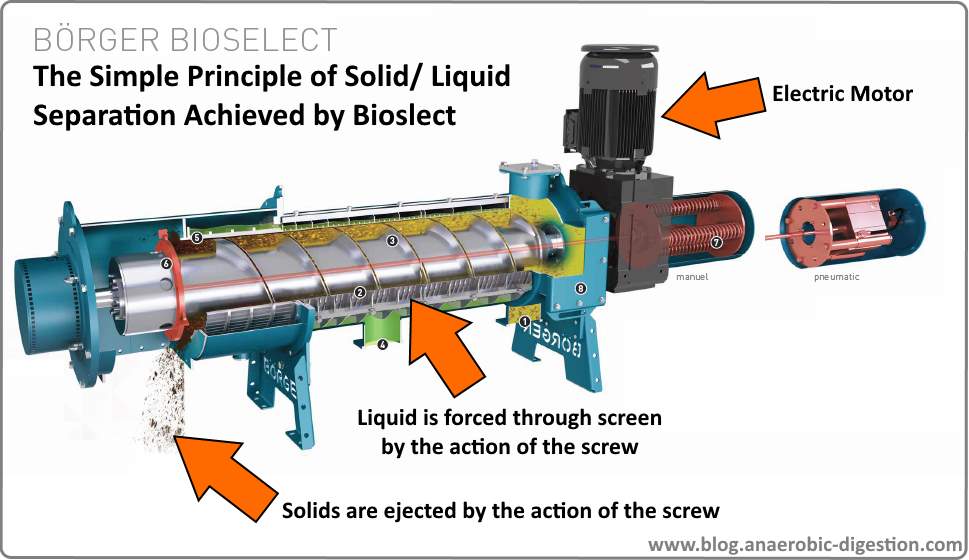

These are a clever combination of lobe-pumps, with progressive cavity straining devices using wedge wire screen technology. The very latest models have even been made more reliable by a more robust proprietary pre-dewatering stage before the wedge wire filtration starts.

Land Spreading

Because land-spreading is the most frequent method of digestate usage, the justification for biogas plant operators for exploring further processing alternatives will be based on the availability of land to spread digestate. Where sufficient land is available the higher costs of optimising storage, transport, and spreading using separator technology will be balanced against the cost of processing.

Permissible Spreading Rates

However, even on large farms, permissible spreading rates are limited both annually and long term by concerns about the build-up of contaminants in the digestate such as dissolved heavy metals. This means that long-term alternative disposal routes for digestate will increasingly have to be found even for large farm AD plant operators.

At the same time, the cost of separation is falling with continuous equipment improvements being offered by the manufacturers as a proportion of profits is poured back as further development money.

However, many AD facility owners will not want to invest in Digestate Separator Technology, and that's where the opportunity will arise for a new breed of separator equipped roving contractors!

Current Generation of Digestate Separator Technology

An example of what is possible today is well illustrated by the Borger Bioselect Range of Biogas Separators.

The dry solids content of the Bioselect is completely adjustable between 12% and 38% in four sizes, with maximum capacities ranging from 25 to 150 m3/h (110 to 660 GPM).

The perforation-proof separation technique is available as a fixed or mobile device. The device is extremely energy efficient and has great wear resistance.

Travelling Digestate Separator Trailers to Become as Common on Country Roads as Crop Sprayers?

Launching a mobile biogas digestate separator business based upon up to 6 Bioselect separators mounted on one HGV trailer is an excellent entrepreneurial opportunity. The aim is for the digestate processing contractor to roll up with a separator trailer:

- connect to a 3-phase electric power supply

- couple up a digestate source to its pump and an outlet for the liquid digestate portion

- swing out a conveyor belt to drop the dry material into a fibrous solid digestate storage bay

- connect the purified liquid digestate output to a suitable storage tank.

The UK has yet to see such services being offered by itinerant digestate processing contractors. But we do predict that once a critical level of anaerobic digestion process plants has been brought into operation this discipline will emerge, as it has in Germany.

It would be a very big stretch to imagine those digestate separators will ever become as common as fertilizer rigs on the country roads. But, who knows? At the current rate of global warming, it would seem that many new “green” things will be happening that nobody would have imagined just a few years ago.

5 Tips for People Planning to Start a Mobile Biogas Digestate Separation Business

This is a company that will tour a country, state, or area with its “separator trailers,” travelling between biogas facilities and supporting their clients on-site by ensuring the exported treatment is of consistently high quality.

Prior to establishing the firm, it will be critical to plan everything out well.

1. Many agricultural AD plant operators lack the necessary equipment for digestate separation and are hesitant to invest in their own until they have successfully produced useful digestate fertiliser.

However, startup founders must exercise caution while drafting their company strategies, devoting many hours to the finer points of their startup strategy.

2. A vital component of a new “Digestate Separation Trailers” firm's business plan is a comprehensive yet succinct industry study. Sector analysis, in most situations, analyses the possibilities and risks that comparable firms face throughout the industry.

To succeed, you'll need to avoid typical industry analysis blunders and correctly depict your business in the context of the industry.

3. It's a good idea to figure out how much competition you'll have before starting a “Digestate Separation Trailers” business in your county or region. Pick up the phone and call those businesses to discuss your goals. They can only refuse to disclose information in the worst-case scenario, but most will be helpful.

Is there enough of a market for “Digestate Separation Trailers” in the area? If not, you must be certain that you are doing things far better than your rivals and that you have a unique value to provide in order to beat out competitors for available employment.

4. Locate vendors for the various separation and pumping equipment you'll want. Before you buy anything, make sure you compare prices. If you buy the majority of your equipment from one source or manufacturer, you can save money.

5. Employ qualified mechanics and technicians who have worked on comparable process equipment before. If you want to establish a good reputation, your employees must be experts in their fields.

Of course, all “Digestate Separation Trailers” companies must follow all federal, state, and municipal health and safety standards, as well as operate their equipment in accordance with the AD Plant Operating Permits.

Failure to comply may not result in your firm being shut down immediately, but a negative reputation may limit your commercial prospects in this relatively small region.

Remember that in the biogas sector, word-of-mouth will be critical to your success.

Frequently Asked Questions (FAQ)

Q1: What is digestate separation, and why is it important? Digestate separation is the process of dividing biogas plant output (digestate) into its solid and liquid fractions. It’s essential because it helps AD (Anaerobic Digestion) operators comply with PAS110 standards, reduce disposal costs, and potentially generate revenue by selling separated fibre as a sustainable fertilizer.

Q2: How do digestate separation trailers work? A digestate separation trailer arrives at an AD plant and connects to a power source and a slurry feed. The built-in pumps transfer digestate into separator units (often wedge-wire or similar technologies) that remove solids from the liquid fraction. Once processed, the trailer conveyors discharge the fibrous solids into a storage bay while the cleaned liquid goes into a separate tank.

Q3: What are the benefits of hiring a digestate separation contractor? No Equipment Investment: AD operators don’t need to purchase or maintain costly separation machinery. Expertise On-Demand: Contractors bring trained technicians who understand how to maximize output quality. Revenue Potential: Quality-separated digestate can meet PAS110 requirements, allowing it to be sold as a biofertilizer. Flexibility: Contractors move from site to site, offering services only when needed. Q4: Why is PAS110 compliance so important for digestate? PAS110 sets the minimum quality standards for digestate (whole, separated fibre, and separated liquor). Meeting PAS110 ensures the separated product can be sold or distributed legally as a biofertilizer in England and Wales (and similarly under SEPA in Scotland). It reduces contamination risks and increases market acceptance.

Q5: Is there a market for selling digestate in the UK? Currently, the UK market for digestate as a green fertilizer product is limited but growing. Most digestate is spread on land at little or no profit. However, as the demand for renewable fertilizer rises—driven by sustainability goals and rising synthetic fertilizer costs—more AD operators are expected to process digestate for commercial sale.

Q6: How could a mobile digestate separation business succeed? Market Research: Understand local demand, existing competition, and the number of AD plants in the region. Equipment & Suppliers: Choose reliable separators and pumps. Borger’s BioSelect range is one example. Skilled Staff: Employ technicians experienced in separator operations and maintenance. Compliance & Reputation: Follow environmental regulations and maintain a strong reputation through quality service—word-of-mouth is vital in the AD industry. Q7: Will digestate separation trailers become more common? As more biogas plants come online and sustainability pressures increase, it’s likely that specialized mobile separation services will grow. While it may be ambitious to say they’ll be as common as traditional fertilizer rigs, Germany’s example (with over 9,000 AD plants) shows a clear path toward thriving digestate processing contractors.

Have more questions? Feel free to get in touch or leave a comment below to continue the discussion on digestate separation and biogas plant operations!

[First published 18 September 2021. Updated 14 March 2025.]

Please keep me updated