Is it possible that a new French biogas liquefaction technology might prove to be a game changer for small-scale AD plants? Read on to find out more.

Learn about the process of converting biogas into liquid biomethane and its importance in the biogas industry.

The burgeoning biogas industry holds immense potential for renewable energy generation and waste management, particularly in the agricultural sector. However, it can be hard for small-scale and medium-sized AD Plants traditional biogas utilization methods present significant challenges for small and remote farms.

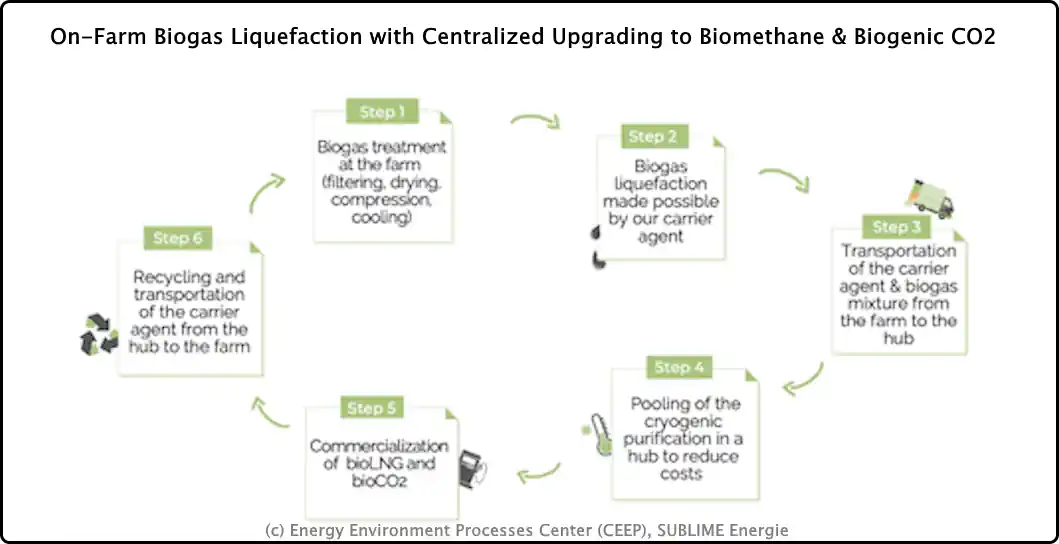

SUBLIME Energie's innovative on-farm biogas liquefaction technology offers a compelling solution, unlocking new opportunities in centralised upgrading to biomethane, at the gas grid access point for these under-represented players.

What is Biogas Liquifaction?

The process involves cooling the biogas to a temperature of -162 °C to produce liquefied biogas. At this temperature, the gas undergoes a transformation into a liquid that lacks odour and is transparent.

Nitrogen is commonly employed as a refrigerant for scientific study to liquefy biogas, owing to the low boiling point of nitrogen at -197 °C.

Biogas liquefaction has previously only been carried out as part of the upgrading process in which the biogas is separated into almost pure methane without the other gases found in biogas, such as CO2.

The Struggles of Small-Scale AD Plants

Despite holding over 80% of the biomass resources, smaller farms are often excluded from the biogas revolution due to limitations inherent to existing technologies:

- Electricity-generation using a gas engine: The conventional method that uses a reciprocating internal combustion engine, to make and export electricity to the power grid suffers from low engine efficiency, resulting in limited profitability.

- Biomethane Injection: Grid injection necessitates expensive purification and connection infrastructure, making it unviable for low flow rates typical of small farms.

These restrictions need to be addressed by governments if the global community is not going to leave a vast potential of nearly 26 TWh of renewable energy untapped by 2050.

SUBLIME Energie: Democratizing Biogas Production

SUBLIME Energie addresses these hurdles with a unique on-farm biogas liquefaction process. Their patented technology overcomes the technical barriers associated with liquefaction of a biogas mixture (typically 60% CH4 and 20% CO2) by introducing a carrier agent, enabling efficient liquefaction at low flow rates.

Promising Technological Advancements

The company has successfully completed a proof-of-concept (POC) in 2020 and is a demonstrator at the prestigious CEEP facility. This demonstrator achieved key milestones:

- Liquefaction of a ternary biogas mixture with a predefined final composition.

- Separation of purified methane and CO2 for valorization as BioLNG (liquefied biomethane) and BioCO2.

These promising results pave the way for a second demonstrator planned for 2025, followed by the first commercial deployment by the end of 2026.

Environmental and Economic Benefits

SUBLIME Energie's solution offers a multitude of environmental and economic advantages:

- Decarbonization: By capturing methane, a potent greenhouse gas, it significantly reduces emissions from the agricultural sector.

- BioLNG Production: BioLNG, a mature fuel for heavy-duty vehicles, offers an 85% lifecycle GHG reduction compared to diesel.

- BioCO2 Capture: Carbon captured CO2 (also known as biogenic CO2 finds application in various industries, replacing fossil-derived CO2 and potentially enabling geological storage solutions.

- Circular Economy: The process adheres to circular economy principles with systematic carrier agent recycling.

- Reduced Fertilizer Costs: The digestate byproduct can replace up to 95% of fossil fertilizers, lowering production costs and associated emissions.

Empowering Farmers and Strengthening Communities

SUBLIME Energie's technology empowers farmers by:

- Providing additional income streams through profitable on-farm biogas production.

- Reducing initial investment and entry barriers for adopting biogas technology.

- Lowering dependence on fossil fuels through digestate-based fertilizer use.

Furthermore, this approach fosters:

- Farm modernization and increased attractiveness for future generations.

- Creation of local, non-relocatable jobs in project implementation and operation.

- Enhanced resilience of farms in remote areas by promoting local production and energy independence.

Strengthening the Biogas Ecosystem: Collaboration through Liquefaction

The economic viability of SUBLIME Energie's technology is further amplified by its potential for collaborative transport and centralized upgrading. Here's how biogas plant operators can benefit from this approach:

- Cost-Effective Transportation: Biogas in its gaseous state occupies significant volume. Liquefaction dramatically reduces this volume, allowing for more biogas to be transported per vehicle. This translates to lower transportation costs for individual plant operators, especially for those in remote locations facing high gas pipeline connection fees.

- Pooling Resources for Upgrading: Upgrading biogas to biomethane requires expertise and substantial infrastructure investment. Centralized upgrading facilities can leverage economies of scale, making the process more efficient and cost-effective for individual plant operators. Biogas plant operators can group together to create a consortium that delivers their partly purified liquified biogas to a central upgrading facility. This eliminates the need for each plant to invest in its own expensive upgrading equipment.

- Focus on Core Competency: By offloading the upgrading process to a central facility, individual plant operators can focus their resources on optimizing biogas production through efficient feedstock management and digester operation. This specialization allows them to become more efficient biogas producers.

Conclusion – Biogas Liquifaction for Centralised Upgrading to Biomethane

SUBLIME Energie's on-farm biogas liquefaction technology presents a paradigm shift for small-scale AD plants.

By overcoming the limitations of traditional methods, it unlocks the vast potential of biogas production in the agricultural sector. This innovation not only contributes to environmental sustainability but also fosters economic development and strengthens rural communities.

As the technology matures and deployments commence, SUBLIME Energie's solution may, just possibly, revolutionize the biogas landscape, creating a more inclusive and prosperous future.

More About Biogas Liquefaction

Biogas liquefaction is the process of transforming biogas, which is typically in a gaseous state, into a liquid form. This liquid form is called Liquefied Biogas (LBG) or Bio-LNG. Here's a breakdown of the key aspects:

Biogas: Biogas is a renewable energy source produced by the anaerobic digestion (decomposition in an oxygen-free environment) of organic matter like manure, food waste, and agricultural residues. It's a mixture of gases, primarily methane (CH4) and carbon dioxide (CO2), with smaller amounts of other gases like nitrogen and hydrogen sulfide.

Liquefaction: Liquefaction refers to the process of converting a gas into a liquid state. This is achieved by subjecting the gas to a combination of high pressure and low temperatures. In the case of biogas, the specific conditions required for liquefaction depend on the composition of the gas mixture.

Benefits of Biogas Liquefaction:

- Increased Energy Density: Liquefaction significantly increases the energy density of biogas. In simpler terms, a smaller volume of LBG holds the same amount of energy as a much larger volume of gaseous biogas. This makes transportation and storage of biogas more efficient and cost-effective.

- Easier Transportation: Gaseous biogas requires extensive pipeline infrastructure for transportation over long distances. LBG, on the other hand, can be transported efficiently using trucks or cryogenic containers, similar to Liquefied Natural Gas (LNG).

- Grid Independence: Biogas liquefaction allows for the utilization of biogas even if the location lacks a connection to the natural gas grid. LBG can be used directly as a transportation fuel or injected into the grid after further purification.

Challenges of Biogas Liquefaction:

- Cost: The process of liquefaction requires specialized equipment and energy, which can increase the overall cost of biogas production.

- Technical Complexity: Biogas liquefaction is a complex process with specific technical requirements for pre-treatment and composition control.

- Energy Consumption: The cooling process for liquefaction itself consumes energy, which needs to be factored into the overall environmental impact.

Overall, biogas liquefaction offers a promising solution for unlocking the full potential of biogas as a renewable energy source.

By overcoming the limitations associated with gaseous biogas, liquefaction can contribute to a more sustainable and efficient energy future.

FAQs about On-Farm Biogas Liquefaction Technology with Centralised Upgrading to Biomethane for Grid Injection

FAQ List: On-Farm Biogas Liquefaction with SUBLIME Energie's Technology

- On-Farm Biogas Liquefaction with SUBLIME Energie's Technology

- This FAQ section addresses frequently asked questions regarding SUBLIME Energie's innovative on-farm biogas liquefaction technology and its applications.

What is biogas?

Biogas is a renewable energy source produced from organic materials. It has numerous benefits for the environment and energy sector.

What is the liquefaction process?

The liquefaction process involves converting biogas methane content into liquid form through various technological methods.

Why is liquefaction important?

Liquefied biogas offers several advantages and applications in different industries, along with environmental benefits.

How does the liquefaction process work?

Discover the detailed steps and technologies involved in converting biogas methane into liquid form.

What are the challenges of liquefying biogas?

Explore the common obstacles faced in biogas liquefaction and potential solutions to overcome them.

What are the potential uses of liquefied biogas?

Scroll up and read this article to learn about the industrial and transportation applications of liquefied biogas, along with emerging trends in its utilization.

How can companies benefit from biogas liquefaction?

Scroll up and read this article to find out the economic advantages and regulatory incentives for companies to invest in biogas liquefaction, with real-world case studies.

What are the challenges faced by small-scale biogas plants for utilizing biogas?

Small-scale biogas plants often struggle with limited profitability due to:

- Low engine efficiency associated with electricity-generation, a traditional biogas utilization method.

- High costs of purification and connection infrastructure required for biomethane injection into the gas grid.

How does SUBLIME Energie's technology address these challenges?

SUBLIME Energie's technology offers a solution through on-farm biogas liquefaction. Their patented process overcomes technical limitations by introducing a carrier agent, enabling efficient liquefaction of biogas at low flow rates typical of small farms.

What are the environmental benefits of SUBLIME Energie's technology?

The technology offers several environmental advantages:

- Reduces greenhouse gas emissions: By capturing methane from livestock effluents, it helps decarbonize the agricultural sector.

- Promotes BioLNG production: BioLNG, a fuel derived from liquefied biomethane, offers significant lifecycle GHG reductions compared to diesel.

- Enables BioCO2 capture: Captured CO2 finds application in various industries, replacing fossil-derived CO2 and potentially enabling geological storage solutions.

- Supports a circular economy: The process adheres to circular economy principles with systematic carrier agent recycling.

How does SUBLIME Energie's technology benefit farmers?

Answer: Farmers benefit from:

- Additional income streams through profitable on-farm biogas production.

- Reduced initial investment and entry barriers for adopting biogas technology.

- Lower dependence on fossil fuels through the use of digestate for fertilizer.

Question: Can SUBLIME Energie's technology be combined with existing biogas infrastructure?

Answer: Yes. Liquefaction allows for cost-effective transport of biogas to central upgrading facilities. This approach offers several advantages:

- Reduced transportation costs due to lower volume of liquified biogas.

- Economies of scale for centralized upgrading making the process more efficient.

- Allows farmers to focus on core competency of biogas production.