Dive into the world of food waste anaerobic digestion and learn how it tackles this pressing waste problem while powering our world in a greener way. Read more now!

Food waste isn’t just messy; it’s a growing environmental headache and a squander of resources that hits us all in the pocket. Managing this mountain of leftovers has become critical, and finding sustainable ways to deal with it is high on the agenda for businesses, cities, and environmentally conscious individuals alike.

Picture this: tons of unwanted food vanishing from sight without clogging up our landfills—sounds almost too good to be true, doesn’t it?.

The key might just lie in combining:

- something called anaerobic digestion—a clever process that munches through this waste out of sight, transforming yucky scraps into useful energy and fertiliser, with

- better organic separation processing equipment.

Both are gaining traction as a savvy solution to tackle our food waste woes while helping power our world in a greener way. This article peels back the layers of how this technology works wonders but also faces some head-scratching challenges.

Stick around—your journey into the world of turning leftovers into power is about to get interesting!

[boomdevs_toc]

Key Takeaways

- Anaerobic digestion turns food waste into energy and fertiliser, but it can be costly and complex.

- It reduces harmful gases from landfills, helping the environment.

- Different types of food waste affect how much gas you make; it’s not always the same.

- Getting rid of plastics in food scraps is important for making good biogas without trouble.

- Better depackaging equipment is available to make it possible to recycle plastics while sending optimum-quality organic waste pulp to Anaerobic Digestion plants

- New ideas, like mixing the process better, could make anaerobic digestion better and more useful.

The process of breaking down organic waste using bacteria in the absence of oxygen

Organic waste can turn into something valuable, and this is where anaerobic digestion steps in. Bacteria get to work on food scraps, plant matter, and other bits of organic stuff without any air around.

They munch away in sealed tanks called anaerobic digesters. This isn’t just a quick snack for the bacteria—it’s a step-by-step feast that turns waste into energy.

First up in their dining process is breaking things down into smaller pieces—this part is called enzymatic hydrolysis. Then they make acids out of these tiny bits during acidogenesis.

Next comes acetogenesis, where those acids change again into substances the final group of bacteria needs. In methanogenesis, these last microbes produce biogas—a mix of methane and carbon dioxide—which you can burn to make electricity or heat buildings.

What about the leftover material from this whole thing? It’s very useful. It’s a superb fertiliser for crops!

Anaerobic Digestion is the most sustainable method for managing food and green waste

Turning food and green waste into something useful can be quite a task. Anaerobic digestion steps in as a hero here. It uses bacteria to break down this kind of waste without any oxygen around.

This process is not just smart; it’s also becoming more and more popular among those who handle lots of leftovers or garden trimmings.

Here’s why people like it so much: anaerobic digestion makes biogas, which we can burn to make electricity and heat. Plus, the leftover stuff from this process can help plants grow better than many chemical fertilisers would.

Not only does this method keep waste out of landfills, but it also cuts down on gases that can hurt our planet’s climate. For folks running an anaerobic digestion plant or thinking about setting one up, using food and green trash this way is a big win for both energy-making and taking care of the Earth!

Benefits of Food Waste Anaerobic Digestion

Food waste anaerobic digestion offers several key benefits, including the reduction of greenhouse gas emissions, production of biogas and organic fertiliser, and diversion of waste from landfills.

This process contributes to sustainable energy production and helps in mitigating climate change.

Reduction of greenhouse gas emissions

Turning food waste into energy through anaerobic digestion is a smart move for the planet. It cuts down on harmful gases like methane and carbon dioxide that would escape if this waste just sat in a landfill.

You see, these gases trap heat and make the earth warmer, but when you use anaerobic digestion, you turn them into something useful instead.

This method also fits well with global goals to care for our environment. By taking food scraps and making renewable energy, we lower the impact of climate change. And it’s not just about creating less pollution; it’s about giving back to the earth by generating electricity or even vehicle fuel from what we used to throw away!

Production of biogas and organic fertiliser

Making use of food waste in anaerobic digestion creates two valuable products: biogas and organic fertiliser. The process turns leftovers into biomethane, which can be used to generate electricity or heat for buildings.

This isn’t just smart; it also cuts down on the use of fossil fuels. Now, think about the leftover solid stuff—that’s turned into a rich fertiliser. It’s full of nutrients and is great for the soil.

Farmers can swap out chemical options for this natural one, helping crops grow strong while looking after the earth. Plus, mixing AD with other processes might even boost profits and keep things efficient.

If you are thinking about setting up an AD facility, imagine turning your waste problems into energy solutions!

Diversion of waste from landfills

Keeping food waste out of landfills is a big win for both the environment and your business. Landfills are not good places for organic waste because they break down and make methane, a harmful greenhouse gas.

By using anaerobic digestion to handle food waste, you help cut down on these emissions. This smart move turns what would be trash into valuable things like biogas and fertiliser.

Anaerobic digestion plants can make energy from food that people throw away, turning a problem into an opportunity. Biogas made this way can power homes or even be sold, which helps your plant pay for itself over time.

And since fertiliser comes out of the process too, it’s like getting two products in one go! You’re not just tossing scraps; you’re investing in renewable energy and giving back to the earth by enriching soil for farms or gardens.

So far, we have talked only about the good things, but now let’s discuss the challenges that have to be overcome for truly sustainable food waste digestion at every biogas digester.

Challenges of Food Waste Anaerobic Digestion

Ensuring proper management of anaerobic digestion processes is crucial to winning the undoubted benefits.

Let’s delve into the challenges posed by:

- Complex technical requirements resulting in high initial costs,

- variability in feedstock,

- odour control methods,

- restrictive regulations on food waste feedstock importation onto farms for digester use, and

- the dangers of plastic pollution from the waste industry’s use of shredding and milling of unwanted plastic in food waste.

All must be solved before adopting a sustainable approach toward food waste anaerobic digestion but when done, the way is open for the sale of more integrated recycled products such as:

- renewable fertiliser,

- recycled plastic,

- livestock bedding, and

- fibre based and grit-and-sand based construction materials.

1. High cost and complex technical requirements

Setting up an anaerobic digestion plant comes with a hefty price tag. You’ll need to think about the cost of building the facility and buying all the right gear. But it’s not just about having the right tanks and pipes; you also have to manage things like acidity levels and possible inhibition of microorganism growth that can upset the whole process if they’re not kept in check.

Think about it as keeping a giant stomach healthy—it needs constant care, and if something goes wrong, fixing it can be expensive.

Running these plants is no walk in the park. Tricky issues often pop up, like too much VFA (volatile fatty acids) or foam messing with your operation.

Plus, you’ve got to get your waste from farms or food factories all the way to your digester—that’s more money on transport! And we haven’t even talked about foaming or making sure everything stays stable inside those big tanks—they all need smart handling and more cash outlay.

Keeping costs down while making sure your biogas system runs smoothly is a real balancing act for anyone in this game.

2. Variability in feedstock and biogas production

Some parts may break down easily and create lots of gas.

Others might not, and you get less gas than expected. This makes it hard to know how much energy you’ll actually produce.

You need the right mix for your digester to work best. Think about adding garden trimmings or other organic stuff to your food scraps. This and many other tricks known to the experts could help keep the gas flowing steadily.

Keep an eye on what goes in so that the bacteria in your system stay happy and active, making as much biogas as they can.

3. Potential for odour and pollution

Food waste anaerobic digestion has the potential to produce odours and pollute if not managed properly. The accumulation of volatile fatty acids (VFAs) and resulting process instability can contribute to these issues.

Co-digestion, which involves combining food waste with other organic materials, and the addition of micronutrients are effective strategies to mitigate the potential odour and pollution problems associated with food waste anaerobic digestion.

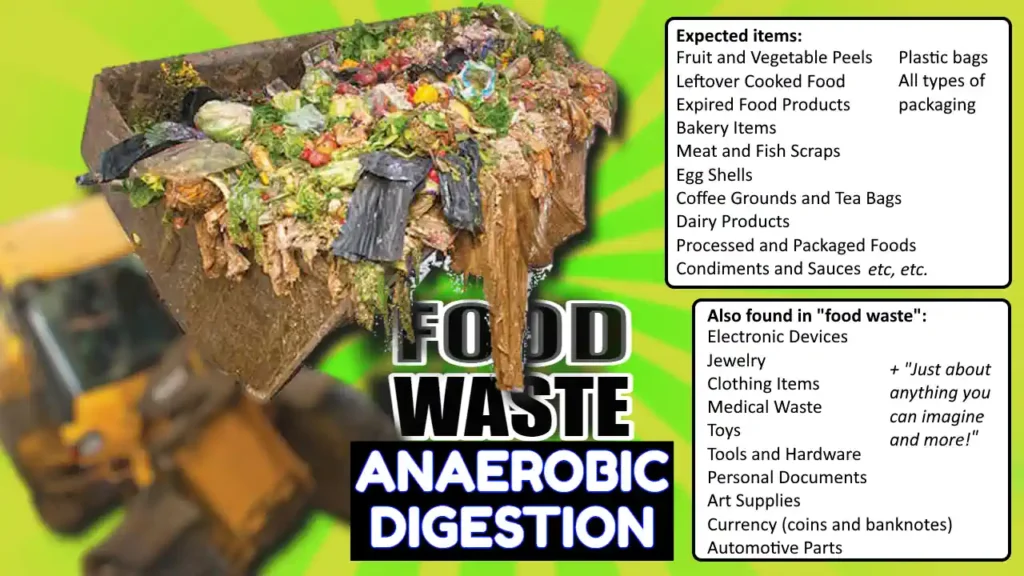

4. The hidden danger of food waste anaerobic digestion from plastics in the organic pulp used to feed the digester

Plastics that get into the organic pulp used to feed digesters can pose a significant danger to the anaerobic digestion process. Their presence can lead to contamination and inhibit biogas production, causing technical problems and impacting system stability and efficiency.

This can affect the economic viability of the system and lead to the accumulation of volatile fatty acids, ultimately affecting the stability of the anaerobic digestion process.

Plant owners and potential facility installers must be aware of this risk and take measures to ensure that plastics are effectively removed from organic waste before they enter the digester.

Not simply smashed up so small that they are seldom visible to the eye.

Advances in Depackaging Equipment

Most of the food waste depackaging and separation equipment now in use in MRFs, ERFS, and across all UK recycling centres, was once a leap forward. But, it is now recognised to be a peril because it increases the tiny plastic (microplastic) in food waste by reducing the size of each piece of plastic.

Paradoxically, although the waste industry talks about recycling plastic, by continuing to use outdated chipping, shredding, and milling equipment it is doing the opposite.

An example of a depackaging machine that overcomes these problems is the Drycake Twister™ Depackager and Separator. Developed from the start to avoid making the plastic problem worse represents an advancement over previous machines in the field of waste processing and material separation.

Drycake says that the Twister avoids creating microplastic by a combination of “batting” and “plucking” action on the non-organic reject items in the unique patented air vortex action of their device.

Plastic bottles and metal cans, etc. also arrive in the reject bins, if not whole, in large pieces recognisable by modern smart picking equipment on recycling conveyor lines. The energetic vibration occurring in the Twister actively cleans and dries them as it forcibly ejects them.

Here’s a breakdown of how Drycake Twister™ improves upon earlier technologies:

1. Improved Separation Efficiency: The Twister Depackager is designed to effectively separate organic material from its packaging in one single unit, with all forms of the rejected material discharged in a clean and dry condition.1

This is crucial in the waste processing and recycling industries, where maximizing the clean recovery of usable material is essential for it to be of adequate quality to command a high sales value. It is also both a “no-brainer” and a “win-win” situation because:

- every bit of organic material that reduces the value of the recyclable materials in food waste

- is also a loss of profitable energy-producing “calorific content” that can’t be used to produce biogas.

So, getting this right has a doubling effect on AD plant income!

2. Versatility in Handling Different Materials: This machine can handle a wide variety of materials, including packaged food waste, supermarket waste, and even food industrial products, from “spoilt” or “unsaleable” goods such as “out of date” biscuit stock to unopened packet meals.

Its ability to process diverse materials, including bottled drinks, makes it more versatile compared to previous machines that may have been limited to specific types of waste.

3. Reduced Contamination: Although we referred to this already in 1. above, it is important to stress that one of the key advancements is its ability to reduce contamination in the separated organic material. This is particularly important for applications where the organic output is used for anaerobic digestion or composting. Lower contamination means higher-quality end products and is crucial when selling plastics for recycling.

But it is possibly even more important for the cost penalty when rejects from food waste are too dirty to be sold even as a refuse-derived fuel (RDF). Sadly, that is the norm for the old-style depackaging systems still on sale today.

4. Energy Efficiency: The Twister Depackager is designed to be energy efficient, which reduces operational costs and minimizes its environmental impact. This is a significant advancement over older machines that may have been less energy efficient.

5. Ease of Maintenance and Operation: With advancements in design and technology, the Twister Depackager is easier to operate and maintain. This reduces downtime and labor costs, further enhancing its efficiency and cost-effectiveness.

6. Improved Safety Features: Modern machines, including the Twister Depackager, often incorporate better safety features to protect operators and maintenance staff. This is an important advancement, as it helps to reduce workplace accidents and injuries.

Simple, reliable equipment that is easily accessed and rapidly made safe after any maintenance is the safest.

7. Automated Controls and Monitoring: The integration of automated controls and monitoring systems allows for more precise operation and adjustments, leading to better overall performance and efficiency.

8. Environmental Impact: By improving the efficiency of waste processing and material separation, the Twister Depackager contributes to more sustainable waste management practices, which is an increasingly important consideration in modern industries.

Washing has recently been recognized as an option of last resort due to the high environmental impact of the process, incurring:

- consumption of an over-exploited resource—water

- high energy use in the aerobic water treatment necessary to recycle water on-site, or at a receiving Wastewater Treatment (Sewage) Works.

Although there has been a recent trend for other depackaging machine suppliers to include a wet water washing stage to clean the recyclables to make them, (notably the plastic resins), saleable, Drycake maintains that this stage is not necessary when using the Twister.

Overall, depackaging machines like the Drycake Twister Depackager and Separator represent a significant step forward in the technology of waste processing and material separation, offering improvements in efficiency, versatility, safety, and environmental impact.

Note 1: Processing unusually high plastic film content waste may retain variable moisture. If so, drying options exist.

5. Regulatory Constraints that limit the importation of feedstocks for use in a digester such as food waste

Strict regulations govern the importation of feedstocks for food waste anaerobic digestion. These may involve rigorous certification, inspection, and pasteurization to ensure compliance with biosecurity standards.

Moreover, some countries prioritize locally sourced materials to support circular economy initiatives and reduce transportation impacts. Compliance demands thorough documentation and verification of the origin and characteristics of imported feedstocks. This highlights the need for careful risk assessment and consideration of legal, environmental, and economic implications associated with sourcing from different regions.

These constraints emphasise the necessity for meticulous evaluation when sourcing organic materials from various geographic locations. Importing food waste alongside other farm-sourced feedstocks could result in operators being subjected to additional stringent regulatory requirements, including those such as the Animal By-Products Regulation (ABP) intended to uphold biosecurity standards.

6. Integration with other processes for value-added products

- Co-digestion of food waste with suitable co-substrates has been shown to significantly increase biogas yields and production efficiency, offering a potential avenue for enhancing the overall output of the facility while also improving its cost-effectiveness.

- The integration with other processes allows for the production of high-quality digestate, which can be used as a valuable organic fertiliser that contributes to sustainable agriculture practices and reduces reliance on synthetic fertilisers.

- Adding processes like hydrothermal liquefaction or bio-refineries to the anaerobic digestion of food waste makes it possible to get more value from the organic waste by increasing the variety of products the AD facility makes.

- Utilising biogas produced through anaerobic digestion in combined heat and power (CHP) systems provides an opportunity to generate renewable energy sources, contributing to energy security while reducing carbon footprints.

- Other product options may include:

- Sale of organic content as animal feed when processing pre-consumer bakery and biscuit wastes

- Use of the fibrous output after subsequent windrowing as livestock bedding, or for incorporation into fibre-based building products (e. g. boarding or blocks)

- While drying the digestate to use the fibre, use a wet scrubbing unit to capture the gaseous ammonia for sale as a high-grade fertiliser in addition to the liquid-phase digestate fertiliser normally used.

Potential Solutions and Future Directions

The challenges are many, but none are insurmountable.

Potential solutions and future directions for food waste anaerobic digestion include:

- integrating the process output with other systems to produce a wider range of value-added products (not least rescuing clean recyclable plastics that can be converted back to the source resin for new plastic products and sold profitably),

- researching ways to optimise feedstock and feed composition, and advancing technology for higher efficiency and cost-effectiveness.

These approaches can help overcome challenges and improve the overall sustainability of both the waste recycling centres collecting the waste, and the anaerobic digestion plant operations that digest the organic waste, to produce biogas energy.

Research on optimising feedstock and feed composition

Research on optimising feedstock and feed composition plays a crucial role in enhancing the efficiency and performance of anaerobic digestion systems. Here are key areas to focus on:

- Understanding the ideal ratio of different waste materials in feedstock

- Exploring the impact of chemical compositions on biogas productivity

- Investigating the effects of micronutrient addition on overall digestion process

- Analysing the influence of mixing ratios on biogas production

- Identifying strategies to control foaming during anaerobic digestion

- Assessing the potential benefits of co-digestion with other organic waste streams.

Advancements in technology for higher efficiency and cost-effectiveness.

Technology advancements are crucial for improving the efficiency and cost-effectiveness of food waste anaerobic digestion. These advancements can help in enhancing the process design, controlling foaming, and adding micronutrients to improve the anaerobic digestion of food waste.

Additionally, further understanding of the fundamental biological and physicochemical processes in anaerobic digestion is essential to advance the technology. Integrating food processing facilities with a biorefinery is also proposed as a solution to address challenges while increasing revenue.

Co-digestion and optimising feedstock composition through research provide valuable insights for improving the efficiency and cost-effectiveness of this renewable energy production option.

Anaerobic digestion plant owners and those considering installing an AD facility should keep abreast of these technological advancements, given their potential to enhance operational effectiveness and create new revenue streams.

Final Thoughts on the Challenges And Benefits Of Food Waste Anaerobic Digestion

In conclusion, anaerobic digestion presents both challenges and benefits in managing food waste. The strategies discussed offer practical and efficient ways to address these issues.

How might integrating food processing facilities with biorefinery processes enhance the sustainability of waste management? Applying these approaches can lead to significant improvements in environmental impact and resource utilisation.

Readers are encouraged to explore further resources for continued learning and engagement beyond this article. Reflecting on the potential impact of these strategies can inspire action towards more sustainable waste management practices.

Challenges And Benefits Of Food Waste Anaerobic Digestion – FAQs

1. What is food waste anaerobic digestion?

Food waste anaerobic digestion is a process where organic wastes, like leftover food, are broken down by bacteria in the absence of oxygen to make biogas.

2. Why is this process good for the environment?

It’s great because it turns waste that would have been landfilled into bioenergy, like natural gas and composts. This helps cut down on global warming gases.

3. Can anything go wrong with anaerobic digestion?

Yes, sometimes things like corrosion in storage tanks or too much hydrogen sulphide can cause problems. But using tough materials and good controls can help prevent this.

4. Do you get anything else besides biogas from this process?

Actually, yes! Apart from biogas, we also get digested material that can be used as fertiliser or composted to enrich soil.

5. What kind of stuff do they put into an anaerobic digester?

They use all sorts of biodegradable waste—think leftover veggies from dinner, dung from farms, or even sewage sludge!

6. Is energy made from anaerobic digestion any good compared to other types?

Indeed! The energy created here is low-carbon and renewable. It’s both cleaner-burning than fossil fuels like coal and bunker oil, genuinely lower in greenhouse gas emissions, and, as a consequence, lower in global warming.

Sounds like a load of rubbish to me—just another overhyped ‘green’ fantasy.