To increase biogas yield and methane content using both acetoclastic and hydrogen-oxidizing (hydrogenotrophic) methanogens, recent research has shown that you must first optimise operational conditions and potentially raise gas output further by employing in-situ biological upgrading techniques through microorganism regular culture dosing.

Key Takeaways for Upping Yields with Acetolactic Methanogens & Hydrogen-Oxidizing Methanogens

- Optimizing methanogenic communities can increase biogas yields by up to 95% through specialized microbiological pathways

- Acetoclastic and hydrogenotrophic methanogens work in synergy, with the former converting acetic acid and the latter converting CO₂ and H₂ to methane

- Temperature control between 35-55°C and pH management between 6.8-7.5 are critical factors for maximum methanogen activity

- Bioaugmentation with specialized methanogen cultures can jumpstart failing digesters and enhance overall system performance

- BioEnergy Solutions offers comprehensive methanogen optimization services that can transform underperforming biogas plants into high-yield renewable energy producers

Boost Your Biogas Production by 30-95% With Methanogen Optimization

“anaerobic digesters …” from www.biologicalwasteexpert.com and used with no modifications.

Biogas yields can skyrocket when you understand the microorganisms driving the process. For years, many biogas plant operators have focused on feedstock and mechanical systems while overlooking the powerhouse microbes that actually create methane.

By optimizing conditions for acetoclastic and hydrogenotrophic methanogens, plants consistently achieve 30-95% higher biogas yields with minimal additional investment.

BioEnergy Solutions specializes in methanogen optimization techniques (possibly Acetolactic Methanogens & Hydrogen-Oxidizing Methanogens) that transform underperforming digesters into high-yield renewable energy producers.

The Two Powerhouse Methanogens That Transform Waste Into Energy

“Methanosarcina – Wikipedia” from en.wikipedia.org Acetolactic Methanogens and used with no modifications.

“Methanosaeta spp …” from www.sciencedirect.com and used with no modifications.

Within your biogas reactor, two distinct groups of methanogens work tirelessly to convert organic waste into valuable methane. Acetoclastic methanogens, including Methanosarcina and Methanosaeta species, are responsible for processing acetic acid, converting it directly into methane and carbon dioxide.

These organisms typically account for about 70% of methane production in conventional digesters. Meanwhile, hydrogenotrophic methanogens like Methanobacterium and Methanoculleus species consume hydrogen and carbon dioxide to produce additional methane, potentially increasing overall biogas methane content to as high as 95%.

The balance and health of these microbial communities determine your system's ultimate performance and profitability.

Why Most Biogas Plants Operate Below Their Potential

The majority of biogas plants worldwide operate at 50-70% of their biological potential due to suboptimal methanogen conditions.

Common issues include improper temperature control, pH imbalances, trace element deficiencies, and inefficient reactor designs that limit gas transfer. Many operators make the mistake of addressing symptoms (like low gas production) rather than root causes (methanogen limitations).

In a three-year study of 87 commercial biogas plants, researchers found that simple methanogen optimization techniques increased production by an average of 43% without requiring major capital investments. The good news is that these microbial communities can be optimized relatively quickly once you understand their specific requirements.

“Understanding the microbial ecology of digesters isn't just academic—it's the key to unlocking millions of cubic meters of additional renewable energy from existing infrastructure. When methanogens thrive, biogas systems deliver their full potential.”

— Dr. Maria Schmidt, Microbial Biotechnology Institute, Acetolactic Methanogens & Hydrogen-Oxidizing Methanogens

How Acetoclastic and Hydrogenotrophic Methanogens Create Biogas

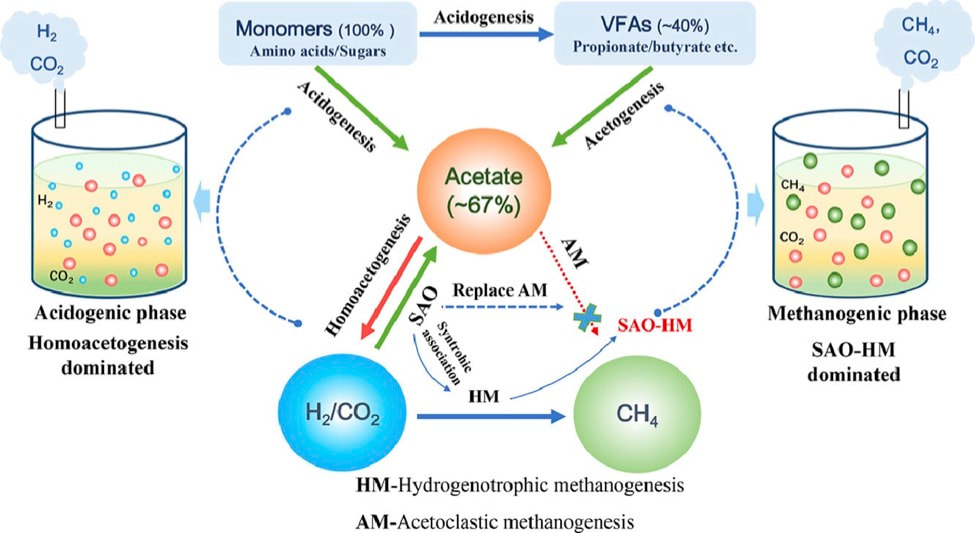

The transformation of organic waste into biogas relies on a complex microbial ecosystem where methanogens play the starring role in the final, methane-producing stage.

Understanding how these specialized microorganisms (Acetolactic Methanogens & Hydrogen-Oxidizing Methanogens) function is essential for maximizing biogas yields and creating more sustainable energy systems. While traditional approaches have often treated digesters as “black boxes,” advanced biogas operations now recognize that targeted methanogen management delivers remarkable production increases.

Acetoclastic Methanogens: The Acetic Acid Converters

Acetoclastic methanogens perform a remarkably efficient metabolic feat: they split acetic acid (CH₃COOH) into methane (CH₄) and carbon dioxide (CO₂).

This direct conversion pathway produces approximately 70% of the methane in most conventional digesters, making these microorganisms the primary workhorses in biogas production.

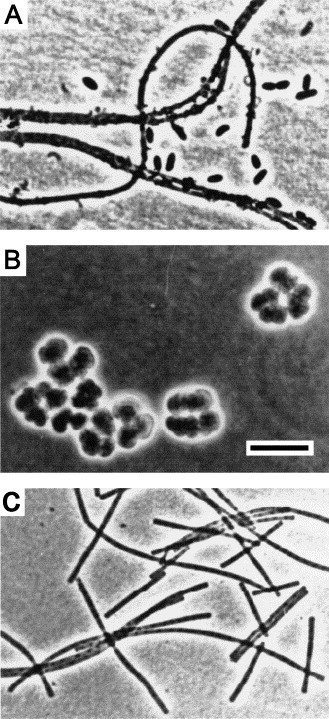

The two major genera responsible for this process are Methanosarcina and Methanosaeta, with distinct characteristics that affect digester performance.

Methanosarcina species grow relatively quickly and tolerate higher concentrations of acetic acid, making them dominant in digesters with higher organic loading rates and shorter retention times. Their ability to form clusters provides some protection against environmental stressors.

In contrast, Methanosaeta species grow more slowly but can utilize acetic acid at much lower concentrations, allowing them to thrive in digesters with more stable, lower-loading conditions. Their filamentous growth pattern contributes to granule formation, improving biomass retention in the system.

The enzymatic pathway used by these organisms involves the conversion of acetate to acetyl-CoA, followed by a series of reactions utilizing the enzymes carbon monoxide dehydrogenase and methyl-coenzyme M reductase.

These biochemical processes require specific cofactors including nickel, cobalt, and iron—explaining why trace element deficiencies can dramatically reduce biogas production even when all other conditions seem optimal.

For more insights on the factors affecting biogas production, you can explore the rate-limiting step in anaerobic digestion.

Hydrogenotrophic Methanogens: The CO₂ and H₂ Specialists

“hydrogenotrophic methanogenic cultures …” from commons.wikimedia.org and used with no modifications.

Hydrogenotrophic methanogens utilize a different metabolic pathway, consuming hydrogen (H₂) and carbon dioxide (CO₂) to produce methane. These remarkable microorganisms play a crucial role in maintaining the anaerobic ecosystem by preventing hydrogen accumulation, which would otherwise inhibit fermentative bacteria.

Common species include Methanobacterium, Methanoculleus, and Methanospirillum, each with slightly different optimal conditions but all contributing to enhanced methane production.

The hydrogenotrophic pathway involves the reduction of CO₂ with hydrogen as an electron donor through a series of enzymatic reactions.

This process requires specific enzymes like formylmethanofuran dehydrogenase and methyl-coenzyme M reductase.

By converting CO₂ (a relatively low-value gas) into CH₄ (high energy content), these methanogens effectively upgrade the quality and energy value of your biogas. When conditions are optimized, they can increase the methane concentration from the typical 50-65% to over 90%, approaching the quality of natural gas.

The Critical Synergy Between These Microbial Communities

The most productive biogas systems maintain a healthy balance between acetoclastic and hydrogenotrophic methanogens.

These communities don't operate in isolation but form part of a complex syntrophic network with fermentative and acetogenic bacteria. When hydrogen partial pressure is maintained at optimal levels (typically below 10⁻⁴ atmospheres), both pathways operate efficiently. Imbalances, however, can cascade through the entire microbial community, reducing yields dramatically.

In well-balanced systems, hydrogenotrophic methanogens consume hydrogen, keeping concentrations low. This creates favourable thermodynamic conditions for acetogenic bacteria to convert volatile fatty acids into acetic acid, which acetoclastic methanogens then convert to methane.

This delicate balance explains why seemingly minor changes in digester conditions can have outsized impacts on biogas production. Modern biogas optimization strategies therefore focus on maintaining this syntrophic harmony rather than addressing individual microbial groups in isolation.

5 Proven Techniques to Enhance Methanogen Activity

Unlocking the full potential of your biogas system requires strategic management of environmental conditions to enhance methanogen activity.

These specialized techniques focus on creating the ideal environment for these microorganisms to thrive, converting more organic matter into valuable methane.

Each approach targets specific limitations in conventional digester operations, addressing the unique requirements of both acetoclastic and hydrogenotrophic methanogens.

1. Optimize Temperature Conditions (35-55°C)

Temperature control is perhaps the most critical factor in methanogen performance. Mesophilic digesters operating at 35-40°C generally support diverse methanogenic communities with good stability, while thermophilic systems at 50-55°C can achieve higher conversion rates but with less microbial diversity and greater sensitivity to fluctuations.

Research shows that temperature stability is often more important than the absolute temperature—even small fluctuations of 2-3°C can reduce methanogen activity by 30% or more. Implement precise temperature control systems with redundant heating mechanisms and insulation to maintain optimal conditions year-round.

For maximum stability, many commercial operations now use double-walled digesters with glycol circulation systems that provide uniform temperature distribution throughout the digester volume.

2. Maintain Ideal pH Balance (6.8-7.5)

Methanogens are highly sensitive to pH changes, with optimal activity occurring in the narrow range of 6.8-7.5. Below pH 6.5, methanogenic activity declines rapidly, while above pH 8.0, ammonia toxicity becomes problematic.

Regular monitoring and pH control are essential, particularly when processing protein-rich feedstocks that release ammonia or easily degradable materials that can cause volatile fatty acid accumulation.

Implement automated pH monitoring systems with appropriate buffering capabilities, such as controlled lime or sodium bicarbonate addition systems. Many successful operators maintain alkalinity between 3,000-5,000 mg/L as CaCO₃ to provide sufficient buffering capacity against pH fluctuations.

3. Add Trace Elements (Nickel, Cobalt, Iron)

Methanogens require specific trace elements for their enzyme systems to function properly. Nickel, cobalt, iron, selenium, molybdenum, and tungsten are particularly critical for methane-producing enzymes.

Deficiencies in these micronutrients often limit biogas production even when all other conditions are optimal. Regular supplementation with carefully formulated trace element mixtures can increase methane yields by 15-30% in deficient systems.

The most effective supplementation strategies involve regular low-dose additions rather than infrequent large doses, allowing steady incorporation into the microbial biomass without reaching potentially toxic concentrations.

A commercial-scale study across 42 biogas plants demonstrated that targeted trace element supplementation increased methane yields by an average of 24%, with the greatest improvements seen in plants processing mono-feedstocks like corn silage or food waste.

The return on investment for trace element supplementation programs typically exceeds 500%, making this one of the most cost-effective optimization strategies available.

4. Control Feeding Rates and Organic Loading

The rate at which organic material is fed into digesters directly impacts methanogen performance. While higher loading rates might seem to promise more biogas, overloading quickly leads to process imbalances as acid-producing bacteria outpace the slower-growing methanogens.

Modern feeding strategies emphasize consistent, frequent feeding at appropriate organic loading rates (typically 2-4 kg VS/m³/day for mesophilic systems and 4-6 kg VS/m³/day for thermophilic systems).

Automated feeding systems that provide small, frequent feeds throughout the day rather than one or two large feeds have consistently shown 10-20% higher methane yields by maintaining more stable digester conditions.

Progressive operators implement adaptive feeding programs that adjust loading rates based on real-time monitoring of process indicators like volatile fatty acid concentrations, gas production rates, and pH values.

This responsive approach maintains optimal conditions for methanogenic activity regardless of variations in feedstock composition or environmental conditions.

5. Implement Hydrogen Injection for Hydrogenotrophic Boost

One of the most innovative approaches to increasing methane yields involves targeted hydrogen injection to stimulate hydrogenotrophic methanogens.

By providing additional hydrogen (often produced through renewable electricity via electrolysis), these methanogens can convert more CO₂ into CH₄, effectively upgrading biogas in-situ. This approach can increase methane content from the typical 55-65% to over 95%, while simultaneously reducing carbon dioxide emissions.

Pilot studies have demonstrated methane content increases of up to 40 percentage points through optimized hydrogen injection systems, though careful control is necessary to prevent inhibitory hydrogen concentrations or pH shifts from rapid CO₂ consumption.

Biogas Reactor Design Modifications That Maximize Methanogen Performance

Beyond operational parameters, the physical design of biogas reactors plays a crucial role in methanogen performance. Advanced reactor designs incorporate features specifically engineered to create optimal conditions for methane-producing microorganisms.

These design elements focus on enhancing contact between microbes and substrates, improving gas transfer, and maximizing biomass retention to achieve higher conversion efficiencies.

For instance, the UASB reactor design is known for its efficiency in treating wastewater while generating renewable biogas.

The most successful biogas operations now incorporate multiple design innovations rather than relying on conventional completely mixed reactor designs.

By understanding the specific requirements of different methanogenic communities, these advanced systems create specialized microenvironments that maximize the activity of both acetoclastic and hydrogenotrophic pathways simultaneously, significantly outperforming traditional approaches.

Two-Stage Digestion Systems

Two-stage digestion separates the acidogenic and methanogenic phases into distinct reactors, creating optimized conditions for each microbial group.

The first reactor operates at lower pH (5.5-6.5) and shorter retention times to maximize hydrolysis and acidification, while the second maintains ideal methanogenic conditions (pH 7.0-8.0) with longer retention times.

This configuration can increase methane yields by 15-30% compared to single-stage systems when processing readily degradable feedstocks. The separation prevents inhibitory conditions caused by rapid acidification and allows the development of specialized methanogen communities in the second reactor.

Modern two-stage systems often incorporate specific retention mechanisms in the methanogenic reactor, such as fixed film media or granular sludge beds, to maintain high concentrations of slow-growing methanogens.

Agricultural Waste Digester: 45% Yield Increase

A dairy farm in Wisconsin implemented a comprehensive methanogen optimization program for their 500,000-gallon digester processing manure from 2,000 cattle.

After establishing baseline performance, they introduced trace element supplementation, precise temperature control, and a specialized methanogen inoculum rich in hydrogenotrophic species. Within six weeks, biogas production increased by 28%, and by the three-month mark, they achieved a sustained 45% increase in methane yield.

The additional 980 m³ of methane daily generated approximately $215,000 in additional annual revenue through their combined heat and power system.

The key to their success was maintaining stable operational parameters: temperature variation was kept within ±0.5°C of their 38°C target, pH remained between 7.2-7.4, and a custom-formulated trace element mixture containing nickel, cobalt, selenium, and molybdenum was added weekly.

Microscopic examination revealed a significant increase in the diversity and abundance of both Methanosarcina and Methanobacterium species, indicating successful enrichment of both acetoclastic and hydrogenotrophic pathways.

Notably, the system showed improved resilience to feeding fluctuations, maintaining stable gas production despite variations in manure composition.

Municipal Wastewater Treatment: 38% More Methane

The Jefferson County Water Authority upgraded their anaerobic digestion system treating primary and waste activated sludge by implementing targeted bioaugmentation and hydrogen injection.

They selected a specialized methanogen consortium dominated by hydrogen-utilizing species including Methanoculleus bourgensis and Methanothermobacter thermautotrophicus.

After acclimation, they gradually introduced small amounts of hydrogen gas through fine-bubble diffusers in a side-stream recirculation loop, carefully monitoring dissolved hydrogen to prevent inhibition.

The results exceeded expectations, with methane yields increasing by 38% and methane concentration in the biogas rising from 63% to 86%.

The facility now produces enough additional biomethane to power all the treatment plant's electrical needs, eliminating their previous electricity purchases. Process stability also improved significantly, with volatile solid destruction increasing from 52% to 71%.

The payback period for the system modifications was just 14 months, and the plant now serves as a demonstration site for other utilities considering similar upgrades.

Their operating data shows that the hydrogen injection system consumed 0.43 kWh of electricity per additional cubic meter of methane produced, representing an energy return on investment of approximately 6:1.

Food Industry Waste: Doubling Gas Production

A fruit juice producer in California faced challenges processing their high-sugar waste streams in a conventional, completely mixed digester. Rapid acidification consistently inhibited methanogen activity, resulting in unstable operation and low biogas yields.

After consulting with microbial specialists, they implemented a two-stage digestion system with a controlled acidogenic first stage (pH 5.5-6.0) followed by a methanogenic second stage with granular sludge bed technology to retain slow-growing methanogens.

“The transformation was remarkable. Our previous single-stage system struggled to handle load variations, frequently resulting in souring and methane production crashes. The two-stage approach with specialized methanogen retention has not only doubled our gas production but virtually eliminated the process instability we battled for years.”

– Carlos Menendez, Environmental Director, SunFresh Beverages

The facility now processes 120 tons of waste daily while producing twice the methane volume compared to their previous system.

The methane content increased from 58% to 74% without additional upgrading steps. Microbial analysis confirmed a significant shift in the methanogen community, with greater abundance and diversity of both acetoclastic and hydrogenotrophic species.

The success hinged on creating separate optimized environments: the first stage maximized conversion of sugars to organic acids while the second stage maintained ideal conditions for different methanogen groups with hydraulic retention times of 20 days and excellent biomass retention.

Particularly notable was the system's ability to handle seasonal variations in waste composition without performance decline.

The specialized second-stage reactor maintained a high concentration of acclimated methanogens (15 g/L of volatile suspended solids) compared to just 3 g/L in their previous configuration.

This biomass richness provided the metabolic capacity to rapidly convert incoming organic acids to methane, preventing accumulation and subsequent inhibition.

Turn Your Biogas Into Biomethane: Upgrading for Maximum Value

The true value of biogas emerges when it's upgraded to biomethane quality (>95% CH₄), allowing for grid injection, vehicle fuel use, or chemical feedstock applications.

While traditional upgrading methods like pressure swing adsorption or water scrubbing are common, biological upgrading through enhanced methanogen activity represents a more elegant, efficient approach.

By harnessing hydrogenotrophic methanogens' ability to convert CO₂ directly to CH₄, operators can simultaneously increase gas volume, energy content, and remove impurities through biological processes that avoid chemical consumables and high energy inputs.

Hydrogenotrophic CO₂ Conversion to CH₄

The biological upgrading of biogas leverages hydrogenotrophic methanogens' natural ability to consume CO₂ and H₂ to produce CH₄. This process can be implemented as either an in-situ approach (hydrogen injection directly into the anaerobic digester) or ex-situ (in separate reactors optimized for hydrogenotrophic activity).

The methanation reaction (CO₂ + 4H₂ → CH₄ + 2H₂O) effectively converts what would be a waste gas (CO₂) into additional methane, increasing both gas quality and quantity simultaneously.

Advances in reactor design have addressed the primary challenge of hydrogen gas transfer into the liquid phase, with specialized high-mass transfer systems achieving over 98% hydrogen utilization efficiency and methane contents exceeding 97%.

The most successful implementations use enriched cultures of thermophilic hydrogenotrophic methanogens like Methanothermobacter species, which demonstrate conversion rates up to 6 times faster than mesophilic communities.

Biological vs. Physical Upgrading Methods

Biological upgrading through methanogen enhancement offers several advantages over traditional physical/chemical methods.

While conventional upgrading typically consumes 0.25-0.3 kWh per cubic meter of biogas processed and removes CO₂ as a waste stream, biological approaches convert that CO₂ into additional methane with energy consumption as low as 0.15 kWh per cubic meter.

The biological process also naturally removes hydrogen sulfide and other contaminants, as these compounds are metabolised by specialised microorganisms present in the methanogenic community.

For operations already investing in digester optimisation, the incremental cost to achieve biomethane quality gas through biological means is significantly lower than installing separate conventional upgrading equipment.

Additionally, the biological approach aligns perfectly with circular economy principles, as it transforms waste components into valuable products rather than simply separating and disposing of unwanted fractions. For more insights, explore biogas generators and the future of waste-to-energy.

Your Next Steps to Higher Biogas Yields

Implementing a methanogen optimization strategy requires a systematic approach starting with baseline assessment. Begin by conducting a comprehensive analysis of your current digester performance, including methane yield, biogas composition, and digester microbiology.

This baseline data will help identify specific limitations and opportunities in your system. Next, implement fundamental improvements in temperature stability, pH control, and trace element supplementation before moving to more advanced interventions like bioaugmentation or hydrogen injection.

Continuous monitoring using both traditional process parameters and advanced molecular techniques allows for data-driven decision-making as your optimisation program progresses.

For operators serious about maximising their biogas potential, BioEnergy Solutions offers comprehensive methanogen optimisation programs tailored to specific digesters and feedstocks.

Their multidisciplinary approach combines microbiology, process engineering, and practical operational experience to achieve breakthrough performance improvements. Whether you're operating a small farm digester or an industrial-scale biogas facility, understanding and optimising your methanogen communities represents the most cost-effective pathway to increased renewable energy production and improved financial returns from your biogas assets.

Frequently Asked Questions About – Acetolactic Methanogens and Hydrogen-Oxidising Methanogens

Operators considering methanogen optimisation often have common questions about implementation, costs, and results. The following answers address the most frequently asked questions based on extensive field experience and research data from hundreds of successful biogas enhancement projects worldwide.

How quickly can I expect to see results after optimising for methanogens?

Results typically appear in three phases: initial improvements in 2-3 weeks (10-15% yield increase) as existing methanogens respond to improved conditions, intermediate gains at 6-8 weeks (20-30% increase) as microbial populations shift toward more efficient communities, and full optimization results after 3-6 months (30-95% increase) when robust, specialized methanogen communities are fully established.

The timeline varies based on initial digester conditions, with stressed or inhibited systems often showing the most dramatic early improvements.

Temperature optimisation and trace element supplementation typically produce the fastest results, while community restructuring through bioaugmentation or process modifications requires more time for complete adaptation.

What feedstocks work best with acetoclastic vs. hydrogenotrophic methanogens?

Acetoclastic methanogens thrive in digesters processing carbohydrate-rich feedstocks like food waste, crop residues, and some industrial wastewaters that produce significant amounts of acetic acid during fermentation.

Hydrogenotrophic methanogens perform particularly well with protein-rich substrates like animal manures, slaughterhouse waste, and certain industrial byproducts that generate higher hydrogen levels during degradation.

However, most commercial digesters benefit from balanced communities of both methanogen types. Multi-feedstock digesters generally develop more diverse methanogen populations naturally, while mono-digestion systems often require more active management to maintain optimal microbial balance.

For maximum performance with any feedstock, the key is matching operational parameters and supplementation strategies to support the specific methanogen communities best suited to your substrate characteristics.

How much does it cost to implement hydrogen injection for biogas upgrading?

Hydrogen injection systems typically cost between $400,000 and $1.5 million for medium-sized digesters (500-2,000 m³), with costs scaling based on capacity and configuration. The main components include hydrogen generation (typically electrolysis), gas storage, injection systems, and control equipment. Operating costs average $0.10-0.20 per additional cubic meter of methane produced, primarily from electricity consumption for hydrogen production.

The economics work best when using surplus renewable electricity during low-demand periods, effectively storing electrical energy as methane. For a typical 1 MW biogas plant, a well-designed hydrogen injection system can increase methane production by 30-50%, representing additional annual revenue of $200,000-400,000 at current natural gas prices.

Most systems achieve payback periods of 3-5 years under current market conditions, with shorter paybacks in regions with high natural gas prices or generous biomethane incentives.

Can methanogen optimisation work in small-scale digesters?

Absolutely. Small-scale digesters (under 100 m³) often benefit the most from methanogen optimization, as they typically experience more variability and have less professional operational oversight than large commercial facilities. The basic principles remain the same regardless of size: stable temperature, appropriate pH, adequate trace elements, and balanced feeding.

For small systems, simplified approaches like pre-packaged trace element mixtures, basic temperature control improvements, and careful feeding management can increase yields by 25-40% with minimal investment. Small-scale operators should focus first on creating stable conditions before considering more advanced interventions.

Many small digesters have achieved excellent results using passive approaches such as improved insulation, simple automated feeding systems, and periodic additions of methanogen-rich materials from well-functioning digesters.

While advanced technologies like hydrogen injection may not be economically viable at very small scales, most other methanogen optimisation strategies scale down effectively.

In fact, small systems can sometimes implement changes more quickly due to their shorter hydraulic retention times and simpler configurations. The key difference is that small operators should emphasise robustness and simplicity over maximum theoretical performance, creating systems that deliver consistent results with minimal maintenance requirements.

For more information on optimising these systems, you might find this article on high-rate anaerobic digestion processes helpful.

What are the signs that my digester has healthy methanogen populations?

Healthy methanogen populations manifest through several observable indicators. First, stable gas production with methane content consistently above 55% indicates active methanogenic conversion. A balanced volatile fatty acid profile with total VFA concentration below 2,000 mg/L and a ratio of acetic acid to propionic acid greater than 2:1 suggests effective methanogen activity.

Microscopically, samples should reveal diverse morphologies of methanogens, including characteristic cocci (Methanosarcina), filaments (Methanosaeta), and rods (Methanobacterium). Under fluorescence microscopy, abundant blue-green autofluorescence indicates high methanogen counts, as their unique coenzyme F420 naturally fluoresces under UV light.

Process indicators of healthy methanogen activity include rapid recovery after feeding (minimal pH drops), high volatile solids destruction (>60% for easily degradable substrates), and resilience to minor operational fluctuations.

Many operators now use quantitative PCR techniques to directly measure the abundance of key methanogen groups, with healthy digesters typically showing 10⁷-10⁸ copies of methanogen-specific genes per gram of digester content.

Regular monitoring of these parameters provides early warning of methanogen inhibition, allowing for prompt intervention before significant performance decline occurs.

Remember that a truly optimised digester maintains balance across multiple methanogen groups. An overabundance of a single species often indicates sub-optimal conditions, forcing adaptation rather than truly favourable conditions.

The most productive systems show rich diversity within both acetoclastic and hydrogenotrophic functional groups, creating metabolic redundancy that enhances stability and performance across varying operating conditions.

By implementing the strategies outlined in this article, biogas producers can significantly enhance methane yields through optimised methanogen activity.

Whether you're operating an agricultural waste digester, municipal facility, or industrial biogas plant, the microbiology-first approach to system optimisation represents the most cost-effective pathway to increased renewable energy production from existing assets.

Biogas production is an important process for renewable energy generation. One of the methods to enhance biogas yield is through the use of acetolactic methanogens and hydrogen-oxidising methanogens.

These microorganisms play a crucial role in breaking down organic matter, resulting in increased methane production. For those interested in exploring more about high-rate anaerobic digestion processes, understanding the interaction of these methanogens can provide valuable insights.