A day in the life of an engineer at a biogas facility is a dynamic blend of hands-on technical work, data analysis, and collaborative problem-solving, focused on ensuring the safe and efficient conversion of organic waste into renewable energy. The specific tasks vary depending on whether the engineer is focused on operations, maintenance, or process design.

The following article is a compilation of events and experiences that are typical for this job role and was assisted by AI. The characters named are fictional.

Key Takeaways

- Biogas facility engineers start each day with rigorous safety protocols and system health checks to ensure optimal operation of anaerobic digesters

- Problem-solving skills are essential as engineers regularly face challenges with temperature control, gas quality, and feedstock management

- Working at a biogas facility combines mechanical, chemical, and environmental engineering disciplines with tangible environmental impact

- Renewable Energy Solutions' biogas facilities convert organic waste into clean energy while reducing methane emissions from landfills

- Modern biogas engineers rely on advanced monitoring systems like SCADA and specialised gas analysers to maintain efficient operations

The alarm sounds at 6:30 AM. While most people might grumble, I jump out of bed with purpose. Working as an engineer at a biogas facility isn't just a job—it's being on the frontlines of the renewable energy revolution.

My name is Alex, and I've been employed in this role for the past four years, helping to transform organic waste into clean, renewable energy. Our facility processes nearly 100 tons of organic waste daily, generating enough electricity to power approximately 2,000 homes while preventing methane—a potent greenhouse gas—from escaping into the atmosphere.

The technical challenges are complex, the hours can be long, but the environmental impact makes every minute worthwhile.

Article-at-a-Glance

Biogas engineering combines aspects of mechanical, chemical, and environmental engineering into one fascinating career. We're the problem-solvers who keep these biological powerhouses running efficiently, troubleshooting everything from pipe blockages to microbial imbalances.

A typical day involves monitoring complex biological processes, analysing performance data, implementing optimisation strategies, and collaborating with operators and laboratory technicians.

It's hands-on, intellectually stimulating work that directly contributes to fighting climate change.

The Renewable Revolution: My Morning at a Biogas Plant

By 7:00 AM, I'm driving through the main gate of our rural facility, the silhouette of massive digester tanks standing tall against the morning sky. As I walk into the control cubicle beside the digester tanks, the aroma of the countryside mingles with the mild smell of biological processes at work—earthy and organic.

To me, it's the scent of progress. I note the gentle rumble of the gas engine at work, mingled with the lesser notes of pumps and mixers all doing their work, and listen for any unusual sounds that may indicate a malfunction.

This morning ritual grounds me in the physical reality of what we do: transforming what others consider waste into valuable energy.

After changing into my work gear—steel-toed boots, flame-resistant coveralls, and a hard hat—I head to the control room for the morning briefing. This daily huddle with operations staff is where we review the overnight performance reports, discuss any issues that arose during the night shift, and set priorities for the day.

Today, we're seeing fluctuations in gas production from Digester #3, and there's a scheduled delivery of food waste from a local processing plant that needs special handling due to its high fat content.

Safety Briefing: First Priority Every Day

“safety measures for anaerobic digestion …” from biogasworld.com and used with no modifications.

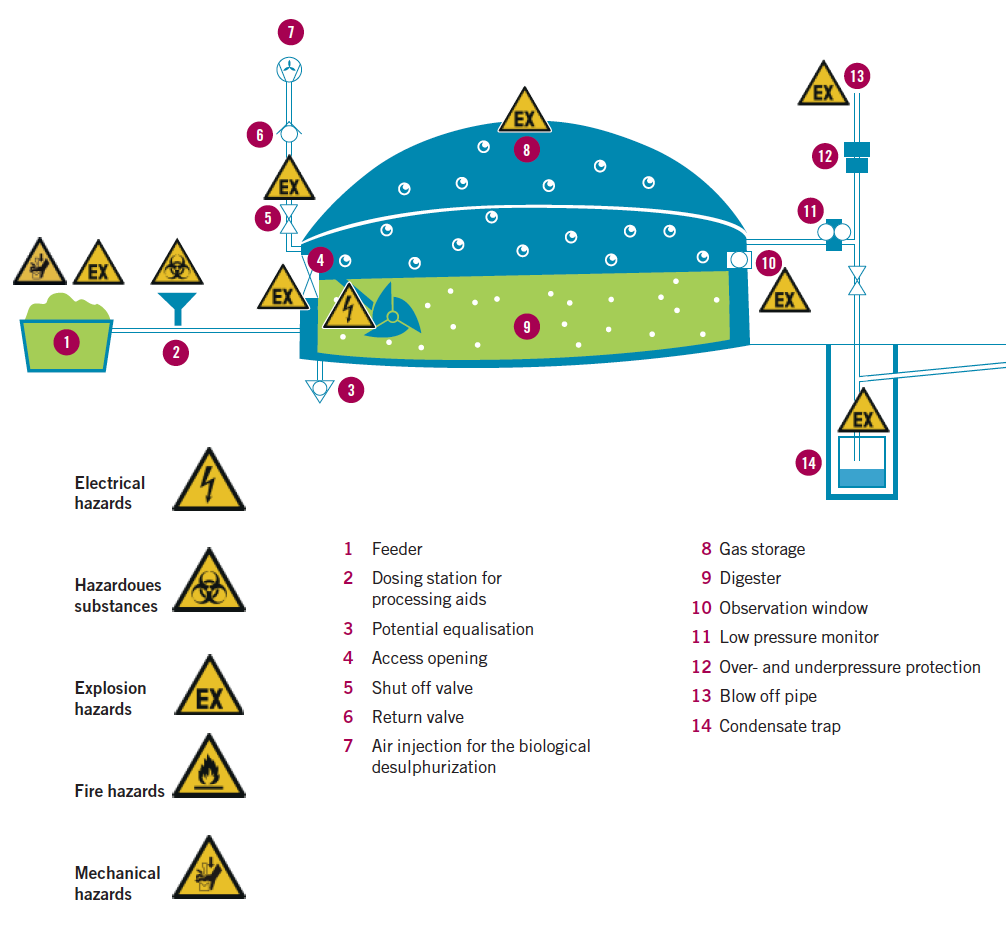

No matter what challenges await, we always start with safety. Biogas facilities have specific hazards that must be respected—explosive gases, confined spaces, and biological materials all require specialised safety protocols.

Today's safety minute focuses on proper gas monitoring procedures when entering any confined space. Even after years in the industry, these daily reminders keep safety at the forefront of our minds.

After reviewing our permit-to-work system for scheduled maintenance activities, we conduct a quick radio check. Clear communication is vital in a facility where hazardous conditions could develop rapidly. Every team member carries a multi-gas detector calibrated to alert us to potential dangers from methane, hydrogen sulfide, carbon dioxide, and oxygen deficiency.

For newcomers to the industry, the emphasis on safety can seem excessive—until you understand that biogas is primarily methane, which is both highly flammable and an asphyxiant in confined spaces.

Hydrogen sulfide, another byproduct of anaerobic digestion, is toxic even in small concentrations. Our facility has multiple safety systems, including automated gas detection, emergency shutdown sequences, and ventilation systems that activate automatically if gas levels approach concerning thresholds. Learn more about increasing biogas yield through advanced methods.

“In four years at this facility, we've had zero lost-time accidents. That's not luck—it's systematic attention to safety procedures and a culture where everyone is empowered to stop work if they spot a potential hazard.”

System Health Check: Monitoring the Digesters

![]()

“Biogas Plant Digester Monitoring – Mantech” from mantech-inc.com and used with no modifications.

With safety checks complete, my first technical task involves reviewing the overnight data from our digester monitoring systems. Our SCADA (Supervisory Control and Data Acquisition) displays show trends for temperature, pH, gas production rates, and a host of other parameters across our four primary digesters. Digester #3 indeed shows a 12% drop in gas production over the past 18 hours—not catastrophic but certainly requiring investigation.

I pull up the detailed data for Digester #3, checking temperature profiles at different points in the tank. The digester temperature should maintain a steady 38°C (100.4°F) for optimal mesophilic bacteria activity, but I'm seeing temperatures dropping to 36.2°C (97.2°F) in the lower quadrant.

This relatively small temperature difference is enough to slow bacterial activity and reduce gas production. The heating system seems to be running normally according to the control logs, which suggests we might be dealing with inadequate mixing rather than a heating issue.

Next, I check the feedstock logs. The quality and consistency of what we put into our digesters directly affect what we get out. The past week's inputs show an increasing proportion of yard waste, which has lower biogas potential than food waste and takes longer to break down. This seasonal shift in feedstock composition—common in spring—partially explains the reduced gas production, but doesn't account for the temperature variation.

| Digester Parameter | Normal Range | Current Reading | Action Required |

|---|---|---|---|

| Temperature | 37.5-38.5°C | 36.2-38.0°C | Inspect the mixing system |

| pH | 7.0-7.4 | 7.2 | Continue monitoring |

| Volatile Fatty Acids | < 2,000 mg/L | 1,850 mg/L | Continue monitoring |

| Gas Production | 950-1,100 m³/day | 862 m³/day | Investigate cause |

| Methane Content | 58-62% | 59% | No action needed |

Problem-Solving in Real Time: Engineering Challenges

Armed with the morning's data analysis, I head out to the digesters for a physical inspection. The satisfying crunch of gravel under my boots reminds me that despite all our advanced monitoring systems, there's still no substitute for boots on the ground.

I'm joined by Marco, one of our senior operators with 15 years of experience in waste management facilities. His intuitive understanding of the equipment often catches issues that our sensors might miss.

We climb the steel stairway to the top of Digester #3, where we can access the mixing system control panel and view ports. Through the reinforced glass viewing port, we can see the dark, bubbling mixture inside—a living ecosystem of microorganisms breaking down organic matter.

Marco points out that the surface movement seems sluggish compared to our other digesters, confirming my suspicion of inadequate mixing.

Temperature Control Issues in Digester #3

![]()

“anaerobic digestion temperature …” from www.sciencedirect.com and used with no modifications.

After checking the external temperature sensors with an infrared thermometer to verify our remote readings, we open the control cabinet for the mixing system. The mixing motor's current draw is within normal parameters, but the timer settings have somehow been altered.

Instead of operating for 20 minutes every hour, the mixer has been running for only 10 minutes. This reduced mixing time explains both the temperature stratification and the reduced gas production—the bacteria aren't getting optimal exposure to new feedstock.

We reset the timer to the correct settings and make a note to monitor the system closely for the next 24 hours to ensure it doesn't change again. I suspect a software glitch during our last control system update, so I'll need to check with our automation engineer later.

Marco suggests we increase mixing time temporarily to 30 minutes per hour to break up any settled layers that may have formed, which is an excellent idea.

Gas Quality Sampling and Analysis

With the mixing issue addressed, we move on to take manual gas samples from various points in our collection system. While automated analysers continuously monitor our biogas quality, periodic manual sampling provides validation and more detailed composition analysis. I use a specialised gas sampling pump that draws the biogas through a series of tubes into sealed collection vials.

Back in our small on-site laboratory, I run the samples through our gas chromatograph to determine precise methane, carbon dioxide, hydrogen sulfide, and trace gas concentrations. The results confirm that our gas quality remains excellent at 62% methane content, despite the production volume issues.

This high methane content means our gas upgrading system will operate more efficiently, requiring less energy to reach pipeline quality standards.

“Gas composition tells us as much about the health of our digesters as a blood test tells a doctor about a patient. Changes in methane or hydrogen sulfide levels can indicate biological imbalances weeks before they become serious problems.”

Troubleshooting the Feed System

The scheduled delivery of high-fat food waste arrives mid-morning, and I meet with the receiving team to develop a feeding strategy. This particular waste stream has excellent biogas potential but can cause foaming issues if added too quickly. We decide to blend it with yard waste at a 1:3 ratio and introduce it gradually over 48 hours rather than our standard 24-hour feeding cycle.

While at the receiving area, I notice that one of our screw conveyors is making an unusual noise. Preventative maintenance is crucial in biogas facilities—a small issue can quickly escalate into a facility-wide shutdown if left unchecked. After inspecting the conveyor, we found a plastic contaminant that made it through our screening process. This highlights the importance of our upcoming feedstock pre-processing upgrade project, which will improve contaminant removal and protect our equipment.

Working with our maintenance team, we safely remove the obstruction and perform a quick alignment check on the conveyor before putting it back into service. This kind of hands-on troubleshooting is a daily reality for biogas engineers—we need to understand mechanical systems as well as biological and chemical processes.

Collaboration with Operations Team

One of the most rewarding aspects of biogas engineering is the collaborative problem-solving that happens organically throughout the day. During our lunch break, I discuss the morning's challenges with our diverse team—operators from various backgrounds, our lab technician with a microbiology degree, and our electrical engineer who's working on power output optimisation. Each brings a different perspective to our challenges.

Our lab technician, Sophia, mentions that she's been tracking a slight increase in volatile fatty acids (VFAs) in Digester #3, which correlates with the reduced mixing we discovered. High VFA levels can indicate stress on the microbial community, potentially leading to digester “souring” if left uncorrected. We discuss adding calcium carbonate as a buffering agent as a precautionary measure while the mixing issue resolves itself.

The Science Behind the Systems

While many see biogas facilities as primarily mechanical operations, the reality is that we're running controlled biological reactions at an industrial scale. Understanding the microbiology is just as important as understanding pumps and valves. After lunch, I spend time reviewing our latest lab results and considering process optimisations.

Anaerobic Digestion: The Heart of Biogas Production

Our digesters rely on a four-stage biological process that converts complex organic materials into biogas. First, hydrolysis breaks down complex molecules like carbohydrates, proteins, and fats into simpler compounds. Next, acidogenic bacteria convert these simple compounds into volatile fatty acids. Then, acetogenic bacteria transform these acids into acetic acid, hydrogen, and carbon dioxide. Finally, methanogenic archaea convert these products into methane and carbon dioxide. Each stage depends on specific microbial communities that must remain in balance for optimal production.

The challenge lies in maintaining perfect conditions for these microorganisms while processing varying feedstock inputs. Even small changes in temperature, pH, or toxic compounds can disrupt the microbial balance, potentially causing a cascade of problems that could take weeks to correct.

This biological complexity makes biogas engineering particularly challenging—and fascinating. Our company has developed proprietary biological monitoring techniques that implement the FOS/TAC ratio principle to give us early warning of potential imbalances, allowing us to make proactive adjustments before production is affected.

SCADA Systems for Process Control

The brain of our operation is our SCADA (Supervisory Control and Data Acquisition) system, which provides real-time monitoring and control of every aspect of our biogas production process. Walking into our control room after lunch, I settle into my ergonomic chair facing six wide-screen monitors displaying colourful graphics of our entire facility. The system continuously collects data from hundreds of sensors throughout the plant, presenting a comprehensive picture of our operation from feedstock reception to gas compression.

Our SCADA system doesn't just passively monitor—it actively controls critical processes to maintain optimal conditions. When digester temperature begins to drift, for example, the system automatically adjusts heating elements or cooling systems to bring it back within parameters.

The system also features sophisticated alarm management that prioritises notifications based on severity and potential impact on production. This morning's mixing timer issue would have eventually triggered an alert based on temperature stratification, but our manual inspection caught it first—proving that technology and human expertise work best in tandem.

Gas Analysers and Monitoring Equipment

Perhaps the most critical monitoring equipment in our facility is our network of gas analysers. Fixed analysers continuously monitor methane, carbon dioxide, oxygen, and hydrogen sulfide levels at key points throughout our gas collection and upgrading systems. These analysers use technologies like infrared absorption spectroscopy and electrochemical sensors to provide highly accurate measurements even in the challenging environment of a biogas plant with its humidity, particulates, and corrosive compounds.

Beyond gas composition, we rely on flow meters to measure gas production rates and identify potential issues with collection efficiency. Ultrasonic flow meters provide non-invasive measurement without creating pressure drops, while thermal mass flow meters account for variations in gas density and composition. The integration of these measurements with our SCADA system gives us both real-time views and historical trends that help identify subtle degradations before they become serious problems. For those planning similar projects, a biogas plant project plan can be invaluable.

Our portable gas analysers are equally important for troubleshooting and verification. Today I used our portable gas chromatograph to verify the fixed analyser readings and look for trace compounds that might indicate developing issues.

The ability to detect parts-per-million concentrations of various gases gives us insights into biological processes occurring inside our sealed digesters without having to open them and disrupt the anaerobic environment.

“Modern biogas facilities are as much about information management as they are about biological processes. Every day, we collect millions of data points that help us make better decisions and continuously improve our operations.”

Digital Twins and Simulation Software

One of our most powerful tools isn't physically connected to the digesters at all—it's our digital twin simulation software. Using real-time and historical data from our facility, this sophisticated model can predict how changes in feedstock, mixing strategies, or temperature will affect gas production days or weeks in advance.

After addressing the mixing issue this morning, I run a simulation to predict how quickly gas production should recover and what interim adjustments might speed the recovery. The model suggests that our temporary increase in mixing time should restore full production within 36 hours, and that gradually increasing the feeding rate of our high-energy food waste could safely accelerate this recovery.

Why I Love This Job: The Bigger Picture

As the afternoon ends, I meet with our site manager to discuss the day's challenges and our upcoming projects. The mixing timer issue has been documented in our maintenance system, and we've scheduled a comprehensive review of all timer settings in the control system for next week.

Our food waste receiving went smoothly after implementing the modified feeding strategy, and gas production from Digester #3 is already showing signs of recovery. These daily victories are satisfying, but they're not what gets me out of bed at 5:30 each morning.

What truly motivates me is knowing the environmental impact of our work. Today alone, our facility prevented approximately 20 tonnes of CO₂-equivalent emissions by capturing methane that would otherwise enter the atmosphere.

We generated enough renewable electricity to power 2,000 homes without burning fossil fuels. And we diverted nearly 100 tonnes of organic waste from landfills, returning valuable nutrients to agricultural soils through our digestate fertiliser program. Few engineering careers offer such tangible environmental benefits combined with fascinating technical challenges.

- Preventing greenhouse gas emissions through methane capture

- Generating renewable energy from waste that would otherwise be landfilled

- Producing organic fertiliser that reduces dependence on synthetic alternatives

- Developing technologies that can be scaled globally to address climate change

- Working with a diverse team of specialists united by environmental goals

As I prepare to head home after checking in with the evening shift, I reflect on how biogas engineering represents the perfect intersection of environmental stewardship and technical innovation.

Each day brings new challenges that require creativity, scientific understanding, and practical problem-solving skills. For those passionate about renewable energy and sustainable resource management, I can't imagine a more rewarding career path than turning what others consider waste into clean, renewable energy.

Frequently Asked Questions

Throughout my career, I've fielded countless questions about what biogas engineers actually do and what it's like working in this growing industry. Here are answers to the most common questions I receive from students and professionals considering this career path. For more insights into the industry, explore the high-rate anaerobic digestion process and its impact on biogas production.

What qualifications do you need to become a biogas facility engineer?

Most biogas engineers hold at least a bachelor's degree in environmental, chemical, mechanical, or agricultural engineering. My own background is in civil and environmental engineering with a minor in environmental science, which provided an excellent foundation for understanding both the biological processes and the mechanical systems involved in biogas production. Many of my colleagues have similar technical backgrounds but with different specialisations that add value to our multidisciplinary team.

Beyond formal education, hands-on experience with industrial processes is invaluable. Many successful biogas engineers start in operations or maintenance roles, gaining practical knowledge of how these complex facilities function before moving into engineering positions.

Specific certifications in renewable energy systems, hazardous area classification, or industrial safety can also enhance your qualifications. Continuing education is essential in this rapidly evolving field. My membership of the Chartered Institution of Waste Management (CIWM) provides the ability to attend a range of member events. I regularly attend industry conferences and technical workshops to stay current with emerging technologies and best practices. My employer encourages my further professional development and provides me with time during the day to attend.

Perhaps most importantly, successful biogas engineers need a combination of technical expertise and problem-solving creativity. We face challenges that don't appear in textbooks and require innovative solutions developed on the fly.

A passion for renewable energy and environmental sustainability provides the motivation to persist through difficult troubleshooting scenarios, and the satisfaction of knowing your work makes a tangible difference in addressing climate change.

| Key Skills for Biogas Engineers | Relevance to Daily Work |

|---|---|

| Process Engineering | Optimising biological and mechanical systems for maximum efficiency |

| Instrumentation & Control | Monitoring and automating complex processes |

| Microbiology Basics | Understanding the biological processes that produce biogas |

| Data Analysis | Interpreting process data to identify optimisation opportunities |

| Project Management | Leading improvement projects and system upgrades |

| Safety Management | Creating and maintaining safe working environments |

What's the salary range for engineers working in biogas plants?

Biogas engineers typically earn competitive salaries that reflect their specialised expertise and the growing demand for renewable energy professionals. Entry-level engineers with bachelor's degrees generally start between $60,000 and $75,000 annually, while experienced engineers with 5+ years in the industry often earn $85,000 to $110,000.

Senior engineers and those in management positions can earn well over $120,000, particularly in regions with high concentrations of renewable energy development. Benefits packages typically include performance bonuses tied to facility output, which can add 10-15% to base compensation when production targets are met or exceeded.

Many biogas companies also offer attractive benefits like renewable energy education allowances, sustainability bonuses for reducing the facility's own carbon footprint, and opportunities to participate in international technology exchanges.

How dangerous is it to work at a biogas facility?

While biogas facilities do present specific hazards—primarily related to methane's flammability, potential for asphyxiation in confined spaces, and hydrogen sulfide toxicity—modern plants with properly implemented safety systems are remarkably safe workplaces. The rigorous safety protocols I described earlier, combined with comprehensive training and redundant monitoring systems, effectively manage these risks. In fact, the renewable energy sector as a whole has a better safety record than many traditional energy industries.

The key dangers we manage daily include explosion risks from methane accumulation, exposure to potentially harmful gases like hydrogen sulfide, biological hazards from handling waste materials, and standard industrial hazards associated with heavy equipment and pressurised systems. With proper training, equipment, and procedures, these risks are well-controlled, allowing us to maintain an excellent safety record while producing clean, renewable energy.

What's the biggest challenge in biogas engineering?

The greatest challenge in biogas engineering is maintaining consistent performance while handling highly variable feedstock inputs. Unlike fossil fuel power plants that use standardised fuels, biogas facilities process organic materials that can vary dramatically in composition, energy potential, and contaminant levels.

Food waste from different sources, agricultural residues affected by seasonal changes, and varying inputs from industrial food processing all create a constantly changing biological environment that must nonetheless produce consistent biogas output.

This variability requires biogas engineers to be exceptionally adaptable, developing feeding strategies that blend different waste streams to maintain stable digester biology. We must constantly adjust process parameters—feeding rates, mixing intensities, temperature profiles—to compensate for these changing inputs while protecting the sensitive microbial communities that actually produce the biogas. Advanced analytics help us predict how different feedstocks will perform, but there's still significant art alongside the science.

Another major challenge is optimising energy balance—ensuring that the energy required to collect, transport, and process waste materials doesn't exceed the energy value of the biogas produced.

This requires constant efficiency improvements and innovative approaches to heat recovery, process optimisation, and logistics management. Despite these challenges, well-designed biogas facilities typically achieve energy ratios of 4:1 or better—producing four units of energy for every unit consumed in operation.

How much does a biogas facility reduce carbon emissions compared to fossil fuels?

The carbon emission reductions from biogas facilities are substantial and occur through multiple pathways. First, we prevent methane emissions that would occur if organic waste were sent to landfills, where it would decompose anaerobically with much of the methane escaping to the atmosphere. Since methane is approximately 28 times more potent as a greenhouse gas than carbon dioxide over a 100-year period, this capture alone represents a significant climate benefit. Learn more about the anaerobic digestion process and its environmental impact.

Second, the renewable electricity or biomethane we produce displaces fossil fuel energy that would otherwise be required. For every megawatt-hour of electricity generated from biogas rather than coal, approximately 0.9 tonnes of CO₂ emissions are avoided.

When upgraded to pipeline-quality biomethane, our gas can directly replace natural gas in existing infrastructure, reducing emissions by about 80% compared to fossil natural gas when accounting for full lifecycle impacts. For more insights on biogas production, check out our biogas plant project plan and design.

Third, the digestate byproduct from our process serves as an organic fertiliser that displaces energy-intensive synthetic fertilisers. Manufacturing synthetic nitrogen fertiliser is particularly energy-intensive, so this replacement provides additional carbon benefits that are often overlooked in simplified analyses.