We will explain how biogas production has always been a Carbon Capture Technology since the first biomethane plant was built. In fact, the anaerobic digestion upgrading process cannot help but capture carbon (while separating the C02 from the methane in biogas) and this is now transforming the UK's CO2 produced for use in industrial applications.

Read how anaerobic digestion is the best Carbon Capture Technology via biogenic CO2 production, for helping the nation comply with the UK's net-zero goals by 2050. Explore how biogas biomethane plant facilities are revolutionizing carbon capture simply by making use of their inherent CO production.

They are offering sustainable solutions for industrial CO2 demand available right now, while contributing more to the UK's net-zero goals by than “Big Oil's” long-promised sequestration capacity.

Introducing AD Carbon Capture Technology

In the race to combat climate change and achieve net-zero emissions, an innovative Carbon Capture Technology solution has emerged from an unexpected source: anaerobic digestion (AD) facilities.

These plants, traditionally known for processing organic waste and generating renewable energy, are now at the forefront of sustainable carbon capture technology. With the UK's ambitious target to achieve net-zero emissions by 2050, AD facilities are proving to be crucial players in both waste management and carbon capture sectors.

Understanding Anaerobic Digestion and Biogenic Carbon

The Natural Carbon Cycle

At its core, anaerobic digestion represents a natural carbon cycle that begins with organic feedstocks. These materials, rich in biogenic carbon, undergo a sophisticated biological process that yields two primary sustainable products: biogas and biofertilizer.

The biogas component consists of approximately 55% biomethane and 45% bio-CO2. These are separated during the process of upgrading biogas to biomethane creating a carbon-neutral cycle that effectively captures and processes atmospheric carbon.

Biomethane: The Biogas Upgrading Revolution

The transformation of raw biogas into usable products marks a significant technological achievement in the AD industry. Through a process known as biogas upgrading, facilities separate the gaseous mixture into its component parts. The resulting biomethane can be injected into the national gas grid, while the concentrated stream of bio-CO2 presents numerous opportunities for capture and utilization.

Current State of AD-Based Carbon Capture

UK Infrastructure Overview

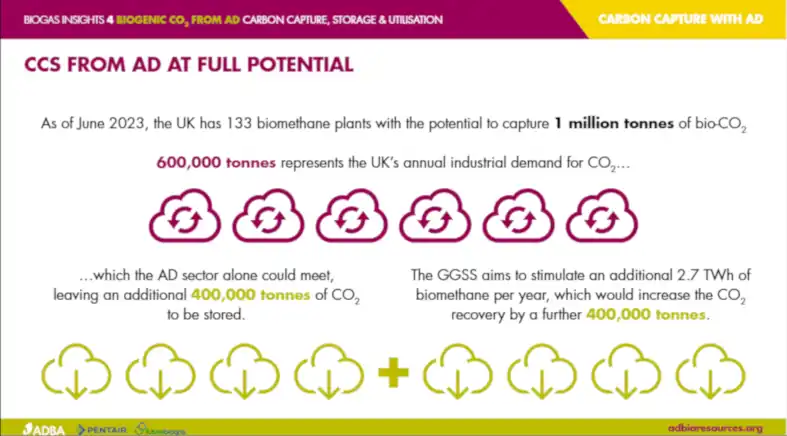

As of June 2023, the United Kingdom boasted an impressive network of 133 biomethane plants, collectively capable of producing approximately 1 million tonnes of bio-CO2 annually (Source: ADBA). These facilities are strategically distributed across the country, with 120 plants processing municipal, industrial, and agricultural feedstocks, while 13 specialized facilities handle wastewater treatment.

Production Capacity Analysis

The current AD Carbon Capture Technology infrastructure record demonstrates remarkable efficiency in bio-CO2 production:

- Municipal, industrial, and agricultural plants already generate over 897,000 tonnes per annum, with an average plant production of 7,500 tonnes

- Wastewater treatment facilities contribute an additional 157,000 tonnes annually, averaging 12,000 tonnes per plant

Industrial Applications and Market Demand

Market Overview

The UK industrial sector currently has a demand for approximately 600,000 tonnes of CO2 annually, with the food and beverage industry consuming 50-60% of this supply. This creates a unique opportunity for AD facilities, which can produce nearly double the current industrial demand through their existing infrastructure.

Supply Chain Resilience is Where Carbon Capture Technology Wins

Recent global events have highlighted vulnerabilities in traditional CO2 supply chains. The AD sector offers a decentralized, resilient alternative to conventional sources. With facilities distributed across the UK, AD plants can provide localized CO2 supply, reducing transportation costs and enhancing supply security.

Carbon Capture Technology and Implementation

Natural Carbon Capture Methods

Nature is very good at capturing carbon dioxide. It has a system known as photosynthesis that is pretty darn good at capturing CO2!

Modern AD facilities with carbon capture technology in-house employ sophisticated carbon capture technologies that achieve capture rates (from organic feedstocks) exceeding 80%.

These systems utilize a combination of filtering, washing, distillation, compression, and cooling processes to produce high-purity CO2 suitable for industrial applications.

Storage and Transportation Solutions

The AD Carbon Capture Technology industry has developed efficient solutions for CO2 storage and transportation. A typical gas transportation truck can carry approximately 20 tonnes of compressed CO2, and 78 UK biomethane plants have the capacity to fill at least one truck per day, ensuring reliable distribution networks.

Regulatory Framework and Standards

AD Carbon Capture Technology Compliance Requirements

AD facilities must adhere to strict regulatory standards, particularly RPS 255, which governs the treatment of food and industrial-grade CO2. Key requirements include:

- Maintaining specific capture rates

- Implementing robust monitoring systems

- Following strict storage protocols

- Meeting quality standards for different applications

Industry Standards

The sector operates under multiple quality standards:

- BSI 4105:1990 for industrial applications

- EIGA Doc 70/17 for food and beverage grade CO2

- ISBT BVG-00001 for beverage-specific applications

Environmental Impact and Benefits of AD-Based Carbon Capture: A Detailed Analysis

The environmental implications of anaerobic digestion (AD) based carbon capture extend far beyond simple CO2 reduction. The comprehensive analysis that follows examines the multi-faceted environmental benefits and potential impacts of implementing AD carbon capture systems at scale.

Greenhouse Gas Removal Potential

Current Capacity Analysis

The UK's existing AD infrastructure demonstrates significant greenhouse gas removal potential:

| Facility Type | Annual Capacity |

|---|---|

| Existing biomethane plants | 1.0 MT |

| Existing AD plants (including CHPs) | 2.5 MT |

| Potential capacity by 2030 | 8.3 MT |

Projected Impact on UK Emissions

By 2030, full deployment of AD carbon capture could:

- Reduce UK carbon emissions by 6%

- Save 23 MtCO2eq of GHG emissions annually

- Process 170 million tonnes of organic waste

- Provide 54.5 TWh of energy

Atmospheric Carbon Removal Mechanisms

AD facilities contribute to atmospheric carbon removal through three primary pathways:

- Direct Capture (DAC)

- Removal of CO2 during biogas upgrading

- Concentration levels 1000x greater than direct air capture

- Enhanced efficiency due to controlled environment

- Indirect Sequestration

- Carbon storage in digestate when used as fertilizer

- Soil carbon enhancement through improved agricultural practices

- Reduced emissions from conventional fertiliser production

- Displacement Effects

- Replacement of fossil-derived CO2 in industrial processes

- Reduction in transportation emissions through localized supply

- Avoidance of emissions from alternative waste treatment methods

Carbon Footprint Reduction

Life Cycle Analysis

A comprehensive life cycle analysis reveals multiple areas of carbon reduction potential:

| Reduction Mechanism | Annual Impact |

|---|---|

| Direct CO2 capture | 1.0 MT |

| Fossil fuel displacement | 0.8 MT |

| Transport emissions reduction | 0.3 MT |

| Fertilizer displacement | 0.5 MT |

| Soil carbon enhancement | 0.2 MT |

| Total Potential Impact | 2.8 MT |

Supply Chain Optimization

Localized AD facilities offer significant transportation-related emissions reductions:

- Average reduction of 75km in CO2 transportation distance

- 50% decrease in transportation-related emissions

- Elimination of empty return journeys in CO2 delivery

Industrial Process Integration

Integration with industrial processes yields additional environmental benefits:

- Reduced energy consumption in CO2 purification

- Lower cooling requirements due to process integration

- Improved overall system efficiency

Ecosystem Benefits

Soil Health Enhancement

AD systems contribute to soil ecosystem health through:

- Improved soil structure from digestate application

- Enhanced water retention capabilities

- Increased soil organic carbon content

- Reduced chemical fertilizer dependency

Water System Impact

Positive effects on water systems include:

- Reduced nutrient runoff compared to raw organic waste

- Lower water consumption in CO2 production

- Improved water quality through proper waste management

Biodiversity Considerations

Implementation of AD systems affects local biodiversity through:

- Reduced landfill requirement

- Improved soil microbiome health

- Enhanced habitat preservation through reduced land use

Circular Economy Integration

Resource Recovery

AD systems excel in resource recovery:

| Resource Type | Recovery Rate |

|---|---|

| Organic nutrients | 95% |

| Water | 85% |

| Biogas | 98% |

| CO2 | 80% |

Waste Reduction Impact

Comprehensive waste reduction achievements:

- Processing of 170 million tonnes of organic waste annually

- Diversion of waste from landfills

- Reduction in methane emissions from decomposition

- Creation of valuable by-products

Environmental Risk Mitigation

Safety Considerations

Environmental safety measures include:

- Contained processing systems

- Regular monitoring and maintenance

- Emergency response protocols

- Environmental impact assessments

Long-term Environmental Monitoring

Ongoing assessment of:

- Soil quality in digestate application areas

- Local air quality impacts

- Groundwater protection measures

- Ecosystem health indicators

Future Environmental Potential

Technology Development

Emerging technologies promise enhanced environmental benefits:

- Improved capture efficiency

- Reduced energy consumption

- Enhanced resource recovery

- Better process integration

Policy Integration

Environmental policy alignment opportunities:

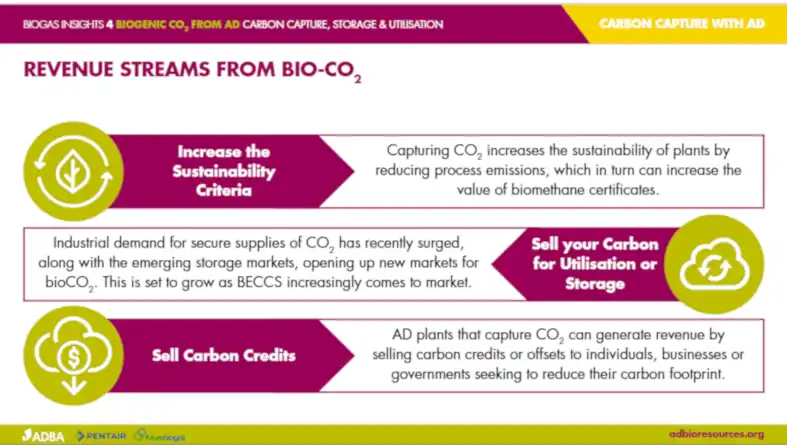

- Carbon credit systems via the UK ETS (at a future date unknown) when AD is recognised for its true worth by the UK government

- Renewable energy incentives

- Waste management regulations

- Agricultural policy integration

The environmental benefits of AD-based carbon capture extend far beyond simple carbon reduction. The system provides a comprehensive solution to multiple environmental challenges, from waste management to soil health enhancement. With proper implementation and continued technological development, AD systems represent a crucial component in achieving broader environmental sustainability goals.

Recommendations

- Increased monitoring of environmental impacts

- Development of standardized assessment methods

- Integration with existing environmental protection frameworks

- Enhanced focus on ecosystem service benefits

- Continued research into optimization opportunities

This analysis demonstrates that AD-based carbon capture systems offer substantial environmental benefits while providing essential services in waste management and resource recovery. The technology's ability to address multiple environmental challenges simultaneously makes it a valuable tool in the transition to a more sustainable future.

Natural Carbon Capture Technology: How Anaerobic Digestion Captures Carbon – Conclusion

Anaerobic digestion represents a transformative approach to carbon capture, offering a sustainable solution to industrial CO2 demand while contributing to climate change mitigation.

With current facilities capable of producing twice the UK's industrial CO2 demand and significant potential for expansion, the AD sector is poised to play a crucial role in achieving net-zero emissions while providing valuable products for various industries.

The combination of environmental benefits, economic opportunities, and technological advancement positions AD-based carbon capture as a key component in the UK's sustainable industrial future. As regulations evolve and markets mature, this sector will continue to grow in importance, offering increasingly sophisticated solutions to the challenge of carbon capture and utilization.