The smart biogas concept is a system that optimises and automates the production, monitoring, and distribution of biogas generated by anaerobic digestion by utilising sensors, data analytics, and artificial intelligence (AI).

This strategy is said to maximise energy output, lower expenses for plant operators, and improve efficiency and dependability. However, the whole of this article is based upon a very limited number of projects in the developing nations for simple manually operated biogas plants not much larger than pilot scale.

Despite all the hype about AI, it doesn't look as if much “smart biogas” is happening. So, take this article with a pinch of salt. It may yet prove to be hype!

Smart Biogas – Key Takeaways

- Based upon the publicity put out by a few start-ups, we are told that Smart biogas revolutionises renewable energy production by integrating sensors, mobile applications, and data analytics to maximise efficiency and safety. Is the big claim made by a few new AI companies

- If you believe it, advocates of these systems claim to reduce greenhouse gas emissions by up to 60% compared to traditional waste management, while creating valuable byproducts like fertiliser

- Real-time monitoring capabilities prevent methane leaks and system failures, significantly enhancing operational safety and performance

- Smart biogas technology is claimed to democratise renewable energy access across various scales, from household to commercial applications

- Its proponents claim that implementing smart biogas systems can create new revenue streams through energy production, carbon credits, and reduced waste disposal costs

Traditional biogas systems have long offered a way to convert organic waste into energy, but they've been plagued by inefficiency, safety concerns, and management challenges. It would help the AD industry greatly if AI were able to improve all these areas!

Real or Hype?

But is it all hype when AI tells us that Smart biogas systems are changing this landscape dramatically? By integrating cutting-edge technology with established biodigestion principles, these innovative systems could help to transform how we produce renewable energy from organic waste.

www.sistema.bio‘s latest smart biogas solutions are described as offering unprecedented control and efficiency gains for operations of all sizes, making renewable energy production more accessible than ever before.

The transition to smarter biogas production would represent a critical step in our renewable energy evolution. Unlike conventional systems that operate with minimal monitoring and frequent failures, could smart biogas installations leverage real-time data, automated controls, and predictive analytics to maximise output while minimising risks?

This technological leap would transform biogas from a temperamental, maintenance-heavy energy source into a reliable, high-performance renewable solution.

Revolutionary Smart Biogas Systems Transform Waste Into Clean Energy

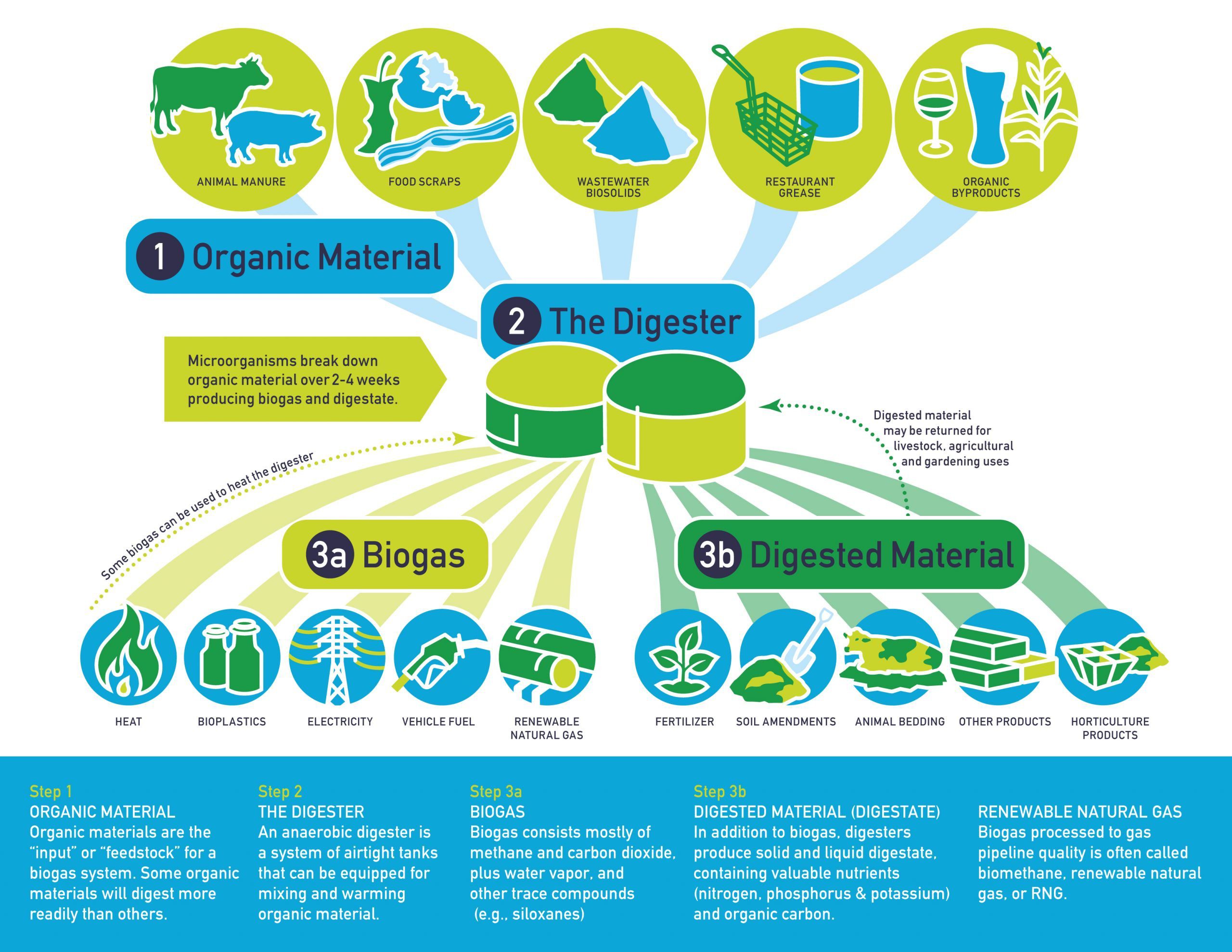

Smart biogas systems represent the next generation of organic waste-to-energy technology. At their core, these systems harness the natural biological process of anaerobic digestion—where microorganisms break down organic materials in oxygen-free environments to produce biogas.

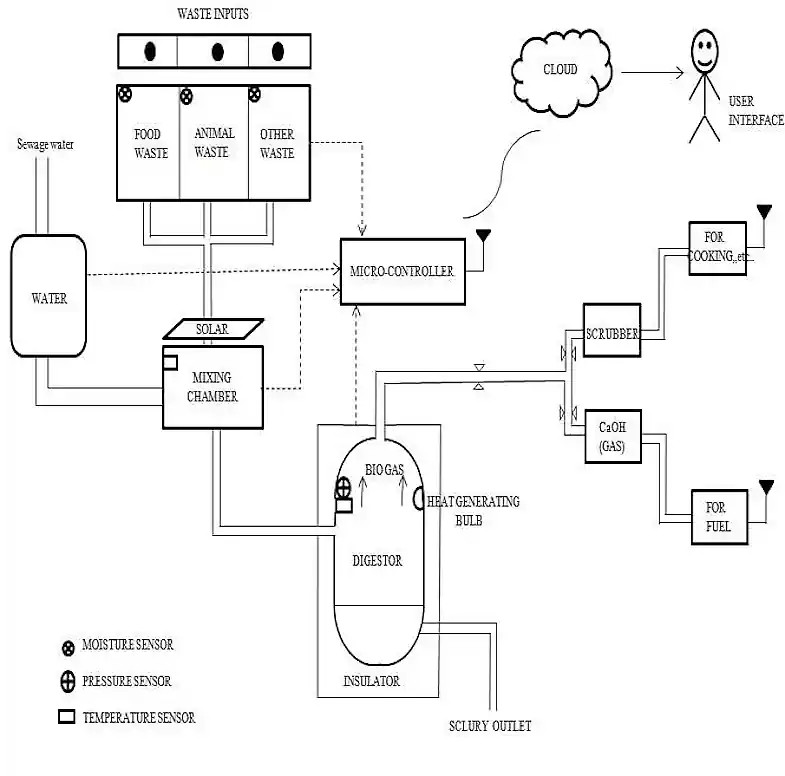

What makes these systems “smart” will be the integration of digital technology, sensors, and automation that optimise every aspect of this process. From monitoring methane content to regulating temperature and pressure, smart systems could ensure peak performance while providing unprecedented visibility into system operations.

“Smart Meters for Biogas Companies …” from cleancooking.org and used with no modifications.

The transformation begins with sophisticated monitoring capabilities that were previously seldom available. If adequate investment in automation were to be made, temperature, pressure, gas composition, pH levels, and substrate flow would be continuously measured by strategically placed sensors.

The real-time data collection proposed would create, when analysed by AI, a comprehensive picture of digester health and performance, allowing for immediate adjustments when conditions drift from optimal ranges. The result would be significantly higher biogas yields— claimed to be typically 15-30% more gas production from the same amount of feedstock compared to traditional systems.

Furthermore, the AI is claimed to enable smart biogas systems to dramatically reduce the safety risks associated with traditional biodigesters. Methane leaks, pressure buildup, and other potentially dangerous conditions are detected instantly, triggering automatic safety protocols before hazardous situations develop.

An enhanced safety profile would make biogas technology accessible to users without specialised technical training, expanding the potential adoption in both rural and urban settings across diverse applications.

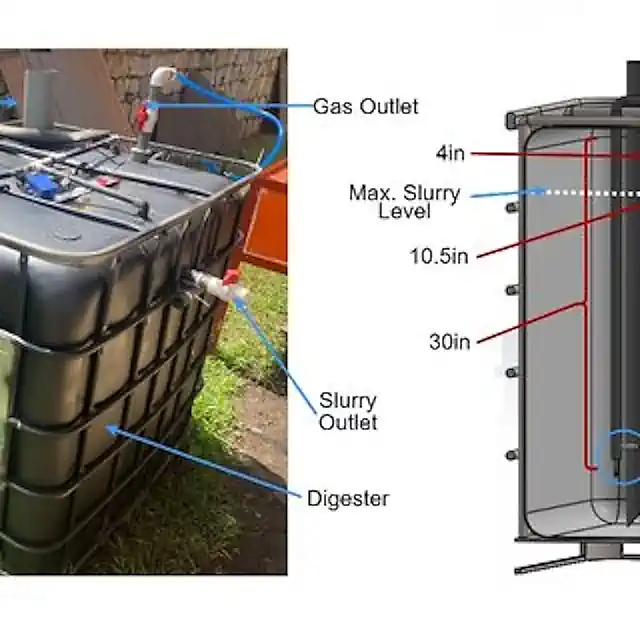

“smart biogas digester as used in research…” from www.researchgate.net and used with no modifications.

Complete Smart Biogas System Components

A comprehensive smart biogas system integrates several key components that work together to transform organic waste management.

The foundation remains the biodigester—the sealed tank where anaerobic digestion occurs—but the similarities with traditional systems might largely end there.

Modern smart systems will, we are told, incorporate a network of advanced components that enable precise control, monitoring, and optimisation at every stage of the biogas production process.

Advanced Sensors and Monitoring Technology

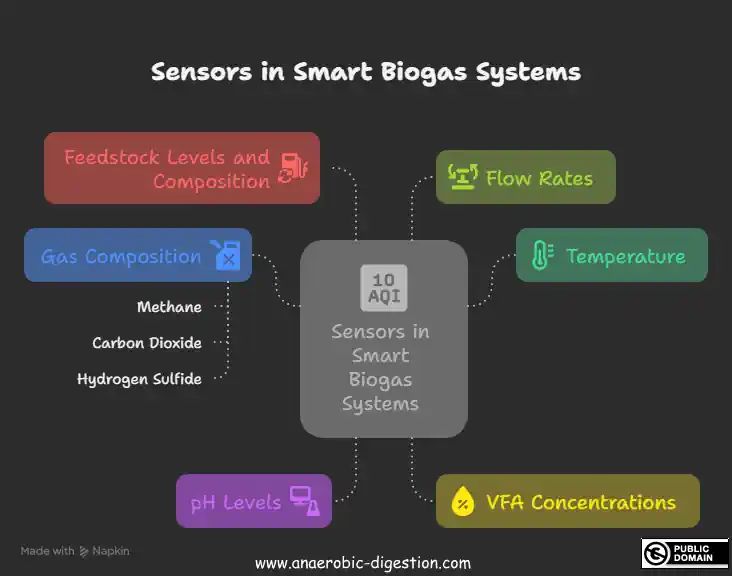

The intelligence of smart biogas systems begins with their sophisticated sensor arrays. These high-precision instruments continuously monitor critical parameters throughout the system.

Temperature sensors track the internal environment of the digester, ensuring optimal conditions for the microorganisms responsible for breaking down organic matter.

Pressure sensors detect potentially dangerous buildups within the system, automatically triggering release mechanisms when necessary.

Gas composition analyzers provide real-time data on methane concentration, CO2 levels, and trace gases, enabling precise quality assessment of the biogas being produced.

Sensors will also monitor pH levels and volatile fatty acid concentrations, critical indicators of digester health that previously required manual laboratory testing. Flow meters track the movement of substrates and gas throughout the system, providing valuable data on production rates and efficiency.

The comprehensive monitoring network will need to be well-maintained if it is going to be of any use and serve as the system's nervous system. It will involve gathering thousands of data points daily to form the basis for automated adjustments and optimisation using AI apps.

That data will only be useful if the probes that collect the data are calibrated and operating correctly at all times. That will be very difficult to achieve in the tough environment of a digester.

Smartphone Integration and Mobile Applications

One of the most transformative aspects of smart biogas systems is likely to be their integration with mobile technology.

User-friendly applications will be built to transform complex biogas operations into accessible dashboards that can be monitored and controlled from anywhere with internet connectivity.

But how this claim can be cited as an advance is nonsense because intuitive interfaces have for many years been available to display:

- real-time system status,

- production metrics, and

- historical performance data in easy-to-understand visualisations.

System owners can already receive instant alerts about potential issues, make remote adjustments to operating parameters, and even schedule feedstock additions or maintenance activities through their smartphones. For more insights on the biogas industry, explore Stortec's involvement in the Australian biogas market.

“The mobile integration Ai will bring will extend beyond mere convenience—it fundamentally changes who can successfully operate biogas systems. Technical barriers that once limited biogas adoption to those with specialised knowledge have been replaced with intuitive interfaces that guide users through optimal operation procedures.”

said an AI systems seller

It is a great idea that democratisation of renewable energy management aligns perfectly with global efforts to expand clean energy access, particularly in regions where traditional energy infrastructure is limited or unreliable.

But it is not new and does not need AI to accomplish it.

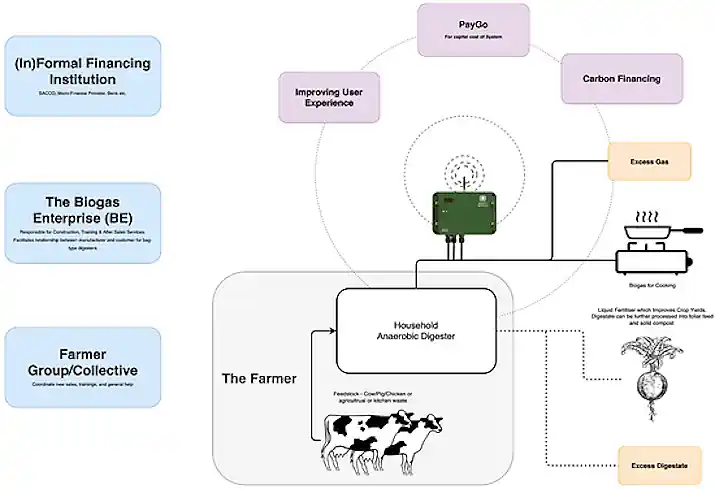

“African Smart Biogas Systems” from www.mdpi.com and used with no modifications.

In this system, it is assumed that the AI is in the Green Box and will learn from the data it receives how to optimise the biogas output. The AI will be able to learn the best parameters for optimised biogas output and convey those to the plant operator as clear instructions.

Automated Safety Features

It is hoped that safety will be improved in smart biogas systems through multiple layers of automated protection. Gas leak detection systems might continuously monitor for methane emissions, triggering immediate alerts and safety protocols if leaks are detected.

Pressure relief valves could be arranged to automatically activate when internal pressure exceeds safe thresholds, preventing dangerous buildup that could lead to system rupture. Temperature regulation systems would be able to maintain optimal ranges, preventing both freezing in cold climates and overheating that could damage the microbial communities essential to digestion.

Emergency shutdown capabilities built into the AI could quickly secure the entire system in case of critical failures, minimising risk to operators and the surrounding environment. For systems connected to appliances or generators, flame detection and carbon monoxide monitoring provide additional safety layers to protect end-users. These comprehensive safety features represent a significant advancement over traditional biogas systems, which often relied solely on manual inspection and lacked real-time monitoring capabilities.

Beyond immediate safety concerns, smart systems would also include predictive maintenance algorithms that identify potential issues before they become problematic. By analysing patterns in sensor data, these systems can detect gradual changes that might indicate developing problems, from wearing components to biological imbalances in the digestion process.

This predictive approach could dramatically reduce system downtime and extend equipment lifespan, improving the overall economics of biogas adoption.

Data Analytics and Performance Optimisation

The true power of smart biogas systems emerges through advanced data analytics capabilities.

Every data point collected by the sensor network would feed into sophisticated algorithms that continuously analyse system performance. These analytics engines identify efficiency patterns, detect anomalies, and generate actionable insights that would be impossible to discern through manual monitoring.

Historical performance data would also be analysed alongside current operations to identify optimal conditions for specific feedstock types and seasonal variations.

Machine learning algorithms would progressively be able to refine these models, enabling the system to become more efficient over time. For large-scale operations, this can translate to thousands in additional revenue annually through increased gas production efficiency.

The analytics platform can also generate comprehensive reports that simplify regulatory compliance and carbon credit verification processes, reducing administrative burdens for system operators. Learn more about the smart biogas system and its impact on renewable energy.

7 Major Environmental Benefits of Smart Biogas Systems

Smart biogas technology could deliver profound environmental benefits that extend far beyond renewable energy production.

These systems might represent a holistic solution to multiple environmental challenges, addressing waste management, emissions reduction, and resource conservation simultaneously.

The integration of smart technology promises to magnify these benefits by optimising processes that were previously inefficient or inconsistent.

1. Significant Reduction in Greenhouse Gas Emissions

Smart biogas systems would dramatically reduce greenhouse gas emissions through multiple pathways.

By capturing methane that would otherwise be released during the natural decomposition of organic waste, these systems prevent a potent greenhouse gas from entering the atmosphere.

Methane has 28-36 times the global warming potential of CO2 over a 100-year period, making its capture particularly valuable for climate mitigation efforts. The precision monitoring in smart systems could ensure near-complete capture of these emissions, with leak detection capabilities that minimise fugitive releases.

Furthermore, the energy produced would replace fossil fuels in various applications from cooking and heating to electricity generation, creating a double emissions reduction benefit.

Some studies have shown that well-managed biogas systems can reduce greenhouse gas emissions by 60-80% compared to conventional waste management and energy production methods.

“1. working of smart Biogas plant …” from www.researchgate.net and used with no modifications.

2. Effective Organic Waste Management

The foundation of biogas production is organic waste management, and smart systems could excel at processing diverse waste streams that would otherwise create disposal challenges.

Food waste, agricultural residues, animal manure, and certain industrial organic byproducts are all valuable feedstocks for smart biogas systems. The intelligent feeding systems hold the prospect of blending these materials in optimal ratios, accommodating seasonal variations in waste availability without compromising system performance.

This diversion of organic materials from landfills and conventional waste processing facilities promises multiple environmental benefits. It reduces methane emissions from landfills, decreases leachate that can contaminate groundwater, and eliminates the energy consumption and emissions associated with waste transportation and processing.

For municipalities and agricultural operations, smart biogas systems could transform waste management from an environmental liability into a renewable energy asset.

3. Decreased Reliance on Fossil Fuels

Biogas produced through smart systems will directly displace fossil fuels across multiple applications. When purified to biomethane standards, it becomes indistinguishable from natural gas and can utilise existing gas infrastructure for distribution.

This renewable gas can fuel cooking stoves, heating systems, vehicles, and power generators with minimal modifications to existing equipment. Unlike intermittent renewable sources like solar and wind, biogas production is continuous and can be stored, making it an excellent complement to other renewable energy systems.

Advanced biogas upgrading modules integrated with smart systems can potentially produce biomethane that meets stringent quality standards for injection into natural gas grids or use as vehicle fuel.

The continuous optimisation of the digestion process would ensure maximum energy recovery from feedstocks, enhancing the fossil fuel displacement potential of every ton of organic matter processed.

4. Reduced Deforestation Pressure

In many developing regions, biomass fuels like wood and charcoal remain primary cooking and heating energy sources, driving deforestation and associated environmental degradation.

Smart biogas systems provide an accessible alternative that can be produced locally from readily available organic materials. The reliability improvements achieved through smart monitoring and control make biogas a viable replacement for traditional biomass fuels, directly reducing pressure on forest resources.

The smartphone integration of modern biogas systems is particularly valuable in this context, as it allows users without technical expertise to successfully operate and maintain their systems.

This accessibility expands the potential adoption in regions where deforestation pressure is highest. Case studies from East Africa demonstrate that communities adopting smart biogas technology can reduce wood fuel consumption by 60-90%, directly translating to forest conservation benefits.

“Biogas to Help Curb Deforestation …” from www.nytimes.com and used with no modifications.

5. Improved Soil Health Through Digestate Application

The nutrient-rich digestate produced as a byproduct of biogas generation serves as an exceptional organic fertiliser that builds soil health while reducing dependency on synthetic alternatives. Smart biogas systems monitor the composition of this digestate, ensuring optimal nutrient content and identifying any potential contaminants.

A few advanced systems include digestate processing modules that can customise the nutrient profile for specific crop applications, maximising agricultural benefits.

Regular application of digestate improves soil structure, water retention capacity, and microbial activity while building organic carbon content. These soil health improvements enhance climate resilience in agricultural systems while potentially increasing crop yields.

The closed-loop nature of this process—where food production waste becomes an input for new food production—exemplifies sustainable agricultural practices, and smart biogas systems would facilitate this.

6. Water Conservation and Quality Protection

Smart biogas systems can contribute significantly to water conservation and quality protection efforts.

By treating organic wastes that might otherwise contaminate water bodies, these systems may be able to prevent nutrient runoff that causes eutrophication and algal blooms. The controlled anaerobic digestion process neutralises many pathogens that could present water quality risks, reducing potential contamination sources.

Smart biogas implementations may also be developed to include water recovery systems that capture and treat wastewater from the digestion process. This recovered water can be reused for irrigation or cleaning operations, reducing freshwater demands.

The comprehensive monitoring capabilities of smart systems are ideal to ensure that any water released from the biogas production process meets environmental standards, protecting surrounding water resources from potential impacts.

“Benefits of Biogas | American Biogas …” from americanbiogascouncil.org and used with no modifications.

7. Circular Economy Promotion

Perhaps the most profound environmental benefit of smart biogas systems is their embodiment of circular economy principles. These systems transform what was once considered waste into multiple valuable resources—energy, fertilizer, and in some cases, recovered water and CO2.

The intelligence built into smart systems maximises the recovery and utilisation of these resources, ensuring that little is wasted. This closed-loop approach represents a fundamental shift from linear “take-make-dispose” models toward regenerative systems that preserve value and minimise environmental impact.

Energy Cost Savings and Return on Investment

Smart biogas systems may be able to deliver substantial energy cost savings by producing renewable gas for on-site use or sale to external markets. For agricultural operations, industrial facilities, and even residential users, this translates to reduced energy bills and greater independence from volatile utility prices.

The intelligent operation of smart systems maximises gas production while minimising inputs, improving the financial return per unit of feedstock processed. Advanced systems can adjust operation based on energy price signals, prioritising gas production during peak price periods to maximise economic returns.

Learn more about the challenges facing the biogas sector.

Energy Cost Savings and Return on Investment

The ROI timeline for smart biogas systems might be improved dramatically compared to conventional digesters. While traditional systems might require 7-10 years for payback, well-implemented smart systems might achieve ROI in 3-5 years, depending on local energy prices and available incentives.

This accelerated return is primarily driven by the 15-30% increase in gas production efficiency and the 40-60% reduction in operational failures that smart monitoring provides.

For commercial installations, this can translate to hundreds of thousands in additional lifetime revenue compared to conventional biogas systems of similar capacity.

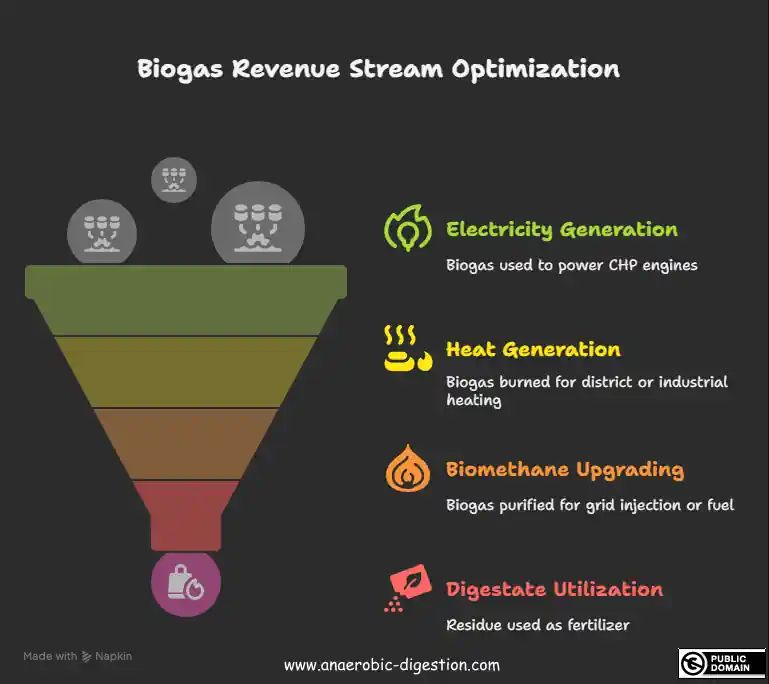

New Revenue Streams From Biogas and Byproducts

Smart biogas systems would create multiple revenue streams beyond basic energy production. Upgraded biogas can be refined to biomethane standards and sold as renewable natural gas (RNG) at premium prices to utilities or as vehicle fuel. The nutrient-rich digestate byproduct has substantial value as organic fertiliser, often commanding 30-50% higher prices than conventional compost due to its superior nutrient profile and consistent quality. In some advanced implementations, CO₂ separated during biogas upgrading can be captured and sold to greenhouse operations or food processing facilities.

The analytics capabilities of smart systems can ensure consistent quality of these products, maximising their market value. Remote monitoring allows operators to certify production methods and output quality, accessing premium markets that demand verified sustainable products.

For agricultural operations, this often means transforming waste management from a cost centre to a profit centre—a dramatic shift in operational economics.

Carbon Credit Opportunities

Smart biogas systems unlock significant carbon finance opportunities that remain largely inaccessible to traditional digesters. The precise monitoring and verification capabilities provide the data integrity required by carbon markets to quantify emission reductions. These systems can track methane capture from waste that would otherwise release greenhouse gases, document fossil fuel displacement through renewable energy production, and measure nitrous oxide emission reductions from improved fertiliser management using digestate. Learn more about how smart biogas systems are revolutionising renewable energy.

The digital record-keeping and verification inherent in smart systems significantly reduce the transaction costs associated with carbon credit certification. Some advanced platforms include built-in carbon accounting modules that automatically generate the documentation required for major carbon markets. Depending on location and applicable carbon pricing mechanisms, these credits can contribute an additional 10-25% revenue stream beyond direct energy and byproduct sales, substantially improving project economics.

Reduced Waste Disposal Costs

For many operations, particularly food processing facilities and agricultural enterprises, waste disposal represents a significant expense that smart biogas systems can dramatically reduce or eliminate.

Tipping fees, transportation costs, and regulatory compliance expenses associated with organic waste disposal can be substantial, often reaching tens of thousands annually for medium-sized operations. By processing these materials onsite through anaerobic digestion, smart biogas systems transform a financial liability into an energy asset.

The intelligent feeding systems in advanced biogas installations can handle variable waste streams and volumes, maximising this cost-saving benefit. The real-time monitoring ensures optimal digestion even as input characteristics change, maintaining process stability that conventional systems struggle to achieve with inconsistent feedstocks.

For operations like dairy farms, food processors, and beverage manufacturers, this waste disposal cost avoidance may often represent the largest single economic benefit of smart biogas implementation.

Smart Biogas Technology Across Different Scales

One of the most compelling aspects of smart biogas technology is its adaptability across vastly different scales and contexts. From household systems processing kitchen scraps to industrial installations handling tons of organic material daily, the core technology scales effectively while maintaining efficiency advantages.

This scalability makes biogas uniquely positioned to address energy challenges across diverse socioeconomic contexts, from rural developing regions to advanced industrial operations.

Household Systems: Features and Applications

Household smart biogas systems represent a technological breakthrough in distributed renewable energy generation. These compact units process 5-20 kg of organic waste daily from kitchen scraps, garden waste, and, in rural settings, small amounts of animal manure.

Modern smart household systems typically feature simplified sensor arrays focusing on critical parameters like gas production, pressure, and basic system health indicators. The smartphone interface provides intuitive guidance for feeding schedules, maintenance reminders, and troubleshooting assistance, making operation accessible to users without technical backgrounds. For more insights, explore this article on smart biogas systems.

The applications of household systems extend beyond simple cooking gas production. Many systems integrate with small generators for backup electricity, water heating elements for thermal energy recovery, and automated digestate collection for garden fertilisation.

The intelligent control systems optimise gas utilisation across these applications based on household needs and patterns. For urban households, these systems offer a powerful tool for reducing waste sent to landfills while producing renewable energy and high-quality fertiliser for urban gardening initiatives.

Case Study: Urban Household in Nairobi

The Kimani family installed a 2m³ smart biogas system connected to their kitchen waste stream and garden. Using only household organic waste, the system produces 1-1.5m³ of biogas daily—enough for 3-4 hours of cooking. The smartphone application helped optimize their feeding schedule, increasing gas production by 35% compared to initial output. The digestate fertilizer has eliminated their need for purchased garden inputs, while reducing their municipal waste by 60%. Total payback period: 2.3 years.

Community-Scale Implementation Success Stories

Community-scale smart biogas systems serve neighbourhoods, villages, or institutional settings like schools and hospitals. These mid-sized installations typically process 100-500 kg of organic material daily, generating enough energy to meet significant portions of community needs. The smart technology at this scale becomes particularly valuable for load balancing and resource allocation. Advanced systems include energy distribution management that prioritises critical uses during peak demand periods and stores excess production during low-demand times.

Success stories from community implementations highlight both the technical and social benefits of these systems. In rural communities, centralised biogas plants have transformed energy access while creating local employment opportunities for system operation and maintenance. The smartphone interfaces enable community-based management with remote expert support when needed, building local capacity while ensuring optimal system performance. The transparent monitoring also facilitates fair distribution of both responsibilities (feedstock contribution) and benefits (energy and fertiliser allocation) among community members.

Educational institutions implementing smart biogas technology have created powerful learning opportunities alongside practical energy solutions. Schools and universities use system data for environmental science education, technical training, and sustainability demonstrations. The real-time monitoring and historical data archives provide rich resources for research and education that extend the benefits beyond direct energy production.

Commercial and Agricultural Applications

Food and beverage processing facilities represent another success story in commercial biogas implementation. These operations generate consistent organic waste streams ideal for anaerobic digestion. Smart systems help manage variable production schedules by adjusting digestion parameters to accommodate changing waste volumes.

The energy produced often directly supports processing operations, creating partial energy independence that provides both cost savings and production security during grid disruptions.

East African Household Transformations

In East Africa, household smart biogas systems have revolutionised energy access for thousands of families previously dependent on wood fuel and charcoal. In Kenya's rural communities, smart biogas systems processing cow dung and kitchen waste produce 1-2 cubic meters of biogas daily—sufficient for 4-5 hours of cooking and evening lighting.

The smartphone applications have proven particularly valuable in these settings, where technical expertise is limited but mobile phone penetration is high. Users receive feeding reminders, maintenance alerts, and optimisation suggestions through simple interfaces that have dramatically improved system performance compared to earlier biogas implementations.

The health impacts have been particularly significant, with households reporting 80-90% reductions in indoor air pollution after transitioning from wood stoves to biogas. Women and children, who traditionally bear the burden of firewood collection, save 10-15 hours weekly, time now redirected to education, income-generating activities, and community engagement.

The digestate fertiliser has improved agricultural productivity on small farms, with crop yield increases of 15-30% commonly reported after applying this nutrient-rich byproduct.

Community Biogas Projects Powering Villages

Community-scale smart biogas projects will have the potential to transform entire villages from energy poverty to renewable energy abundance.

In western India, a village-scale 60m³ biodigester processes agricultural residues and community organic waste to generate electricity for 75 households. The smart monitoring system ensures optimal performance while providing transparent energy distribution tracking that has built community trust in the shared resource. Mobile alerts notify community members of feeding schedules and available energy capacity, creating a democratic management system that has proven remarkably resilient.

Beyond direct energy benefits, these community systems have created new economic opportunities. Local entrepreneurs have established businesses utilizing the reliable energy supply, from phone charging services to small-scale food processing operations.

The community management of these systems has strengthened local governance structures and built technical capacity that extends to other development initiatives. The projects demonstrate how smart biogas technology can serve as a foundation for broader rural development outcomes when implemented with attention to both technical and social dimensions.

How To Get Started With Smart Biogas Systems

Implementing smart biogas technology requires thoughtful planning and assessment to maximise benefits for your specific context.

The process begins with understanding your resource potential and ends with a fully functional system generating renewable energy, fertiliser, and environmental benefits. The smart components significantly simplify this journey compared to traditional biogas implementations, providing guidance and optimisation at each step.

Assessing Your Biogas Potential

The first step toward successful smart biogas implementation is conducting a thorough assessment of your organic resource availability and energy needs. This evaluation should quantify all potential feedstocks—kitchen waste, agricultural residues, landscaping materials, animal manure, or industrial organic byproducts—available on a consistent basis.

Smart assessment tools can help predict biogas yields from these materials based on their composition and quantity, providing realistic expectations for energy production potential. For more insights, consider exploring the smart biogas system revolution in renewable energy.

- Document daily or weekly organic waste generation across all sources

- Analyse seasonal variations in feedstock availability

- Evaluate current energy consumption patterns and costs

- Identify space availability for system installation

- Consider local climate conditions that may impact system design

This assessment should also examine energy consumption patterns to determine how biogas production aligns with usage needs. For operations with consistent energy demands throughout the day, direct biogas utilization may be optimal. For those with variable demand, considering gas storage or electricity generation with battery storage might maximise benefits. Smart biogas systems can help model these scenarios based on your specific patterns, identifying the optimal configuration.

Local regulations regarding waste handling, energy production, and air/water quality impacts should be thoroughly researched during this assessment phase. Many jurisdictions offer streamlined permitting for small to medium biogas installations, particularly those processing agricultural wastes or food scraps.

The monitoring capabilities of smart systems often simplify regulatory compliance, as they provide verifiable data on system performance and environmental parameters.

Choosing The Right System Size and Components

Selecting the appropriate system size and configuration is critical for both performance and economic returns. Undersized systems may not process all available feedstock, limiting energy production potential. Oversized systems represent unnecessary capital investment and may operate inefficiently with insufficient feedstock.

Smart sizing tools use the assessment data to recommend optimal digester volumes based on feedstock availability, desired gas production, and space constraints. For more insights on the biogas industry, explore Stortec's involvement in the Australian biogas market.

Component selection should be guided by your specific needs and operating context. For remote locations, robust systems with minimal maintenance requirements may be preferable even if slightly less efficient. For operations with technical staff available, more sophisticated systems with advanced features might maximise performance.

The smart control systems should match user capabilities and preferences, with interface options ranging from simple mobile applications to comprehensive desktop management platforms for larger installations. For those interested in exploring advanced features, lab tech advancements play a significant role in the future of sustainable anaerobic digestion systems.

Finding Financing Options and Support Programs

Financing smart biogas systems has become increasingly accessible through diverse mechanisms targeting renewable energy and sustainable waste management. Traditional options include bank loans, equipment leasing, and internal capital expenditure for businesses with available funds.

However, specialised green financing programs often offer more favourable terms for biogas projects, including longer repayment periods and reduced interest rates that better align with the technology's lifetime returns.

Many regions offer substantial incentives that can dramatically improve project economics. These include investment tax credits, production incentives for renewable energy, waste diversion credits, carbon offset payments, and accelerated depreciation allowances.

Agricultural operations may access additional funding through environmental improvement programs targeting nutrient management and water quality protection. The detailed monitoring data from smart systems simplifies verification for these programs, maximising accessible incentives.

Future Directions: What's Next For Smart Biogas Technology

Smart biogas technology continues to evolve rapidly, with innovations enhancing both performance and accessibility. Integration with other renewable energy systems represents one of the most promising development areas.

Hybrid systems combining biogas with solar and battery storage create resilient microgrids that maintain continuous energy availability despite the intermittent nature of solar generation. The intelligent control systems balance these resources, optimising economic and environmental performance across the integrated system.

Artificial intelligence advancements are revolutionising biogas operation through deeper pattern recognition and predictive capabilities. Next-generation systems will incorporate machine learning algorithms that identify subtle relationships between operating parameters, feedstock characteristics, and performance outcomes.

These systems will anticipate potential issues days or weeks before they manifest, enabling preventive interventions that maintain peak performance. For multi-digester operations, AI will optimise feeding schedules and substrate mixing to maximise overall energy production while maintaining process stability.

- Enhanced biogas upgrading technologies for cost-effective biomethane production at smaller scales

- Integrated nutrient recovery systems that produce customised fertiliser products from digestate

- Blockchain-based tracking for transparent carbon credit verification and renewable gas certification

- Miniaturised sensor technology reduces costs while improving monitoring precision

- Automated substrate preprocessing systems optimising feedstock for maximum methane potential

Biogas-powered transportation represents another exciting frontier, particularly for agricultural and waste management operations with captive fleets. Compressed biomethane can power trucks, tractors, and other vehicles with minimal modifications, creating a closed-loop system where waste collection vehicles run on fuel generated from the materials they collect. The smart monitoring systems ensure gas quality meets vehicle specifications while optimising purification processes to minimise energy losses.

As climate change concerns intensify, smart biogas systems are positioned to play an expanding role in global sustainability efforts. Their unique ability to address multiple environmental challenges simultaneously—renewable energy production, organic waste management, and soil health improvement—aligns perfectly with integrated approaches to climate resilience.

The accessibility improvements through smart technology democratise these benefits, making biogas viable across diverse socioeconomic contexts from rural villages to urban centres and industrial facilities.

Frequently Asked Questions (FAQ)

Smart biogas systems represent a significant technological advancement, but potential adopters often have questions about practical implementation aspects. The following FAQs address common inquiries about system requirements, operation, and performance based on real-world implementations across various scales and contexts. For a deeper understanding, you can explore how smartphone integration is revolutionising renewable energy.

How much organic waste is needed to produce useful amounts of biogas?

Organic waste requirements vary by application, but even small quantities can produce meaningful biogas amounts. A typical household of 4-5 people generates 1-2 kg of kitchen waste daily, which, combined with garden waste, can produce 0.4-0.6 m³ of biogas—sufficient for 1-2 hours of cooking. Small farms with just 2-3 dairy cows can generate 2-3 m³ daily, enough for cooking, lighting, and potentially small generator operation. Commercial operations processing 1 ton of food waste daily can typically generate 150-200 m³ of biogas, equivalent to 300-400 kWh of energy.

The smart components significantly improve these yields compared to traditional systems. Optimisation algorithms can increase gas production by 15-30% from identical feedstock amounts by maintaining ideal conditions and identifying the best feeding schedules. For smaller installations, this efficiency improvement often makes the difference between marginal and substantial energy production, expanding the viability of biogas to operations with limited waste streams.

What makes smart biogas systems different from traditional biodigesters?

The fundamental difference between smart and traditional biogas systems lies in their monitoring, control, and optimisation capabilities. Traditional digesters operate largely as “black boxes” with minimal insight into internal conditions and processes. Operators must rely on external observations and periodic manual tests to assess system health, often detecting problems only after significant performance degradation. Smart systems transform this paradigm through continuous monitoring of critical parameters, automated control mechanisms, and data-driven optimisation that maximises performance while preventing failures before they occur.

Can smart biogas systems operate in cold climates?

Smart biogas systems can operate effectively in cold climates through intelligent temperature management and insulation strategies. Unlike traditional digesters that struggle in low temperatures, smart systems incorporate several adaptations for cold-weather operation. Insulation requirements are precisely calculated based on local climate data, preventing heat loss during the winter months.

Many systems include solar thermal collectors or biogas-powered heating circuits that maintain optimal internal temperatures despite cold external conditions. The monitoring system tracks temperature gradients throughout the digester, identifying potential cold spots before they impact biological processes. For more insights on how biogas is being utilised in various climates, check out Stortec in the Australian biogas market.

What are the maintenance requirements for smart biogas systems?

Maintenance requirements for smart biogas systems are predicted to be significantly reduced compared to traditional digesters, primarily due to preventive monitoring and automated diagnostics.

Routine maintenance typically includes periodic sensor calibration (often automated or remotely assisted), inspection of mechanical components like mixers and pumps, and occasional cleaning of gas filters.

The smart system schedules these activities based on actual operating conditions rather than arbitrary timeframes, optimising maintenance frequency to minimise both downtime and unnecessary servicing.

For more insights, explore the US biogas capture techniques and their role in enhancing system efficiency.

How do smart biogas systems integrate with existing energy infrastructure?

Smart biogas systems offer flexible integration options with existing energy infrastructure across various scales. At the household level, simple connections to cooking stoves, water heaters, or small generators require minimal modifications to existing setups.

Conclusion

Biogas technology is rapidly advancing, providing sustainable solutions for waste management and renewable energy production. By utilising organic waste materials, biogas systems convert waste into valuable energy, reducing greenhouse gas emissions and reliance on fossil fuels.

This process not only supports environmental sustainability but also offers economic benefits by generating energy that can be used locally. For instance, US biogas capture initiatives demonstrate the potential for large-scale biogas production to contribute to energy independence and environmental goals.

The development of smart biogas holds huge potential to accelerate this process.