Biogas production from sewage sludge is likely to become more common at ever-smaller sewage treatment plants. One of the leading companies that will achieve this for their clients is Weltec Biopower.

Weltec Biopower is one of the AD firms using its biogas technology and making a big step into the wastewater treatment works industry. Their well-respected biogas technology is offered for smaller local Sewage Works. The well established German biogas specialist has announced, their latest achievement in biogas production from sewage (WWTW) sludge (as described below).

Biogas production for WWTW sludge treatment and disposal has been a growing success story at the very largest sewage treatment works in many countries, for many years now. Globally, there is a large uptake of AD technology at STWs, often with the inclusion of biomethane (biogas purification) upgrades for large city wastewater treatment plant digesters. But, why not generate more biogas throughout all of a water utility's sewage works infrastructure?

In order to explain, let us first explain the basics involved in the production of biogas:

Biogas

Biogas is a mixture of chemicals produced from wastes mainly from methane and carbon dioxide and is usually made of sewage and other waste. These are renewable sources.

Biogas may be created from anaerobic digestion with anaerobic organisms inside of anaerobic digesters, biodigesters or bioreactors. Biogas has the potential to contain sulfide, water, sulphuric and siloxanes mainly from methanes. Methane and hydrogen are combustible with oxygen.

Organic waste can be collected and used to produce biogas, a renewable source of energy, to minimise greenhouse gas emissions and the danger of pollution to rivers.

As a result of anaerobic digestion, biogas production is more environmentally friendly than the generation of fossil fuel.

Biogas combustion results in a net reduction in greenhouse gas emissions since methane is over 80 times more effective at trapping heat in the atmosphere than carbon dioxide.

Biogas Production Process Explained

It's good to be able to tell you that biogas is produced largely without burning fossil fuel; it's less harmful to the environment and produces fewer greenhouse gases than fossil fuels do. For example, you digest the organic fraction which would otherwise end up as garbage sent to a landfill, or you use WWTW sludge and convert the waste into energy—like liquid fuel that can be used to heat food. Initially, the idea seems complicated to most people but it can work really well.

How is biomass converted into biogas? You should be aware that the process of producing biogas from biomass occurs naturally in swamps and at the bottom of oceans, rivers, and lakes where organic residues are exposed to anaerobic conditions.

How is biogas produced? When bacteria digest organic matter (biomass) in the absence of oxygen, biogas is produced. This is known as anaerobic digestion. It occurs naturally anywhere from the digestive tract to the depths of effluent ponds and can be replicated artificially in digesters, which are engineered containers.

Biogas Production

In biogas production, anaerobic processes typically involve several steps and are used to progressively transform organic materials into low molecular weight by the action of a whole host of bacterial strains, and archaea.

Biogas can be produced from animal and plant waste. They are processed as a liquid or as a slurry mixed with water in anaerobic digesters. Anaerobic digesters are typically made up of a feedstock source holder, a digestion tank, a biogas recovery unit, and heat exchangers to keep the temperature required for bacterial digestion constant.

What types of waste can be used to produce biogas? Biogas can be produced from a wide range of waste materials, including animal manure, municipal trash/waste, plant material, food waste, and sewage. What gases are present in biogas?

What is biogas?

Biogas is a renewable energy that is produced through the breakdown of organic materials. This product is widely used for fuel for vehicles as well as heating power.

Anaerobic digesters are used by wastewater treatment plants, some dairy farms and animal enterprises to produce biogas from manure and old bedding material.

Unlike natural gas, which is a fossil fuel, biogas is a renewable energy source that is created organically through anaerobic digestion. Leper colonies in India have been using anaerobic digestion plants since at least 1859 when one was built in Bombay.

Types of biogas

The major “elements” in biogas are methane and carbon dioxide between 50 and 60%. In varying amounts, biogas contains sulphur dioxide, a mixture of sulphate, sulphate sulfate, and silicium a.

By eliminating carbon dioxide and impurities of biogas a person can produce biomethane that resembles fossil gas. So the food can be cooked and reheated. In addition, compressed biomass gas is used in vehicles that help to lower the emissions of greenhouse gases.

Methane has recently been upgraded as a dangerous contributor to climate change. Until recently it was only thought to be 21 times the ability to contribute to climate change as carbon dioxide. However, scientists revised that recently from new research to over 80 times more damaging. Rather than allowing natural putrefaction methane to escape into the atmosphere, it makes sense to capture and burn it. Methane is converted into heat and carbon dioxide during combustion. This allows you to harvest the energy content of the gas while also reducing the impact on climate change.

What is the process of making biogas?

The engineering for generating the biogas is called anaerobic digestion and is less damaging to the environment than the process using fossil fuels. The bacteria break down organic material without oxygen – an event that is often called decomposition or fermenting. The fermentation process involves three stages to transform organic material into biogas.

Biogas generation using the anaerobic digestion process involves the biological degradation of organic matter. The biogas production process is the same for all types of biogas, and it relies entirely on natural chemical reactions.

Bacteria first degrade carbohydrates, and then acidogenic bacteria convert sugars and amino acids into carbon dioxide, organic acids, hydrogen, and ammonia. These organic acids are transformed in the third stage until methanogens can finally break the components down in the fourth stage and obtain methane and carbon dioxide. The average energy potential per tonne of waste is close to 2 gigatonnes (1,895,634 BTU).

How is biogas produced from biomass?

When you put organic waste (biomass) in a digester, bacteria are able to break it down and turn it into biogas. It may easily replicate in artificial environments referred to as digester processes. This is a manufactured container that allows bacteria to freely work without oxygen to breathe. Biofuels used for biogas include food waste and animal manure.

We can get biogas without combusting anything, which implies that the manufacturing method has a limited environmental impact and doesn't produce large levels of greenhouse gas emissions like fossil fuels.

Microbes that feed on the biomass perform the most important part in the biogas production process.

Is Biogas from Sewage Viable?

There is no reason not to treat all sewage works sludge to make biogas, and use the energy wisely to power wastewater treatment with power to spare. The only likely limit to the rate of progress in raising the level of biogas production from WWTW sludge will be the need to finance the up-front capital/ construction costs on new water treatment sludge digestion facilities. It will also be important to train more anaerobic digestion plant operating staff.

Heating digesters by hydrolysis with biogas from AD accelerates the anaerobic digestion process and eliminates germs; some sewage treatment and industrial facilities also use it to create power to use at the facility or sell. The EIA predicted that 61 of these waste treatment facilities will generate roughly 1 billion kilowatt-hours of power in the United States by 2020.

Using the biogas production process to generate power, heat, or car fuel is a sustainable energy source that can help reduce reliance on foreign oil imports, reduce greenhouse gas emissions, enhance environmental quality, and create more local jobs.

The following is the Press Release from Weltec Biopower, which features their skills in biogas production from sewage sludge.

Increased Energy Production from Sludge Codigestion with Food Waste

There is an additional energy production opportunity to codigest sewage sludge with food waste to create more biogas in the same digesters.

Food waste contains a lot of energy. For example, Christmas food waste is enough to heat 25,000 homes with biogas. WRAP estimates that UK households, hospitality and foodservice, food manufacture, retail and wholesale sectors produce around 10 million tonnes of food waste per year.

According to the Food Recovery Hierarchy developed by the Environmental Protection Agency (EPA), reducing food waste is the highest priority, followed by repurposing surplus food to feed the hungry.

WELTEC BIOPOWER Showcases Solutions for the Energetic Production of Organic Waste and Wastewater

From 14 to 18 May, the globally active biogas plant manufacturer will be present at stand 219 in Hall A4. Visitors are invited to approach the company for all questions concerning its tried-and-tested process technology for the establishment and expansion of anaerobic energy plants. This means promoting sustainable biogas production from WWTW sludge.

Methane gas is particularly important as its high energy content can be used to produce energy. Biomass and biogas are both biofuels; they can be burnt to produce energy.

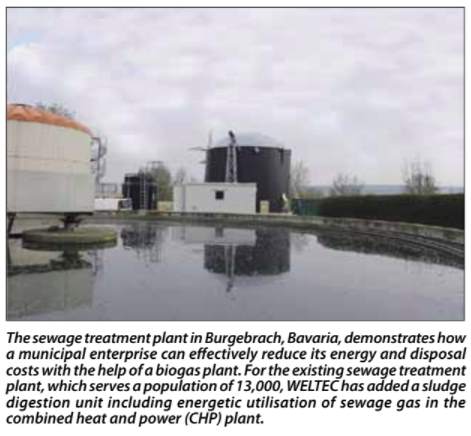

The sewage treatment plant in Burgebrach, Bavaria, demonstrates how a municipal enterprise can effectively reduce its energy and disposal costs with the help of a sewage sludge biogas plant. For the existing sewage treatment plant, which serves a population of 13,000, WELTEC has added a sludge digestion unit including energetic utilisation of sewage gas in the combined heat and power (CHP) plant.

The new biogas from sewage facilities went live in spring 2016. Since then, the sludge has been stabilised with an anaerobic process in the custom-designed stainless-steel tower following the wastewater treatment in a two-stage trickling filter unit.

Thanks to the installation of the digestion unit, the unpleasant odour emissions around the sewage treatment plant have been eliminated. Moreover, the digestion reduces the amount of sludge and enables the energetic utilisation of the digestion gas. The operators gain from the biogas production from sewage sludge. And, also wanted to be able to use all the power and heat generated by the CHP plant for the on-site processes.

“Thanks to our self-supply, we are able to save the electricity costs of about 100,000 kWh/year”

said Arne Nath, Head of Wastewater Treatment at SüdWasser GmbH, the operator that has supported the town of Burgebrach since 2005.

This special plant benefits greatly from the proven technologies of WELTEC BIOPOWER:

- Firstly, the modular structure of the stainless-steel plants enables a customer-specific layout.

- Secondly, such projects draw on the experience that WELTEC has gained in the establishment of more than 300 biogas plants.

More News About Biogas Production from Sewage Sludge

Ofwat offers to boost sewage sludge biogas in UK

April 2018: The following paragraphs described a new opportunity in the UK for private biogas plant operators to bid for utility company sewage sludge which they will treat, and at the same time be able to generate a profit. This could be a new era for biogas production from sewage sludge.

“Where there’s muck there’s brass” is a wise old Yorkshire expression.

Muck and brass is now a focus for Ofwat, which is keen to apply market mechanisms in the water and sewerage sector. Now that the reforms to the water retail market have been completed, with non-household customers able to choose their water and sewerage suppliers, Ofwat’s focus will turn to their upstream reforms. A key element of this is bioresources or sludge.

So, what is the background to the reforms?

The sludge that sewage treatment works produce sludge has historically been treated and disposed of by monopoly water and sewerage service providers, (WASCs). Ofwat’s view is that there has been insufficient competitive pressure on this aspect of the water industry. Their reforms aim to put that right.

The objective is that WASCs find more economic ways of dealing with sludge. As an example, a WASC should explore if it would be cheaper to pass its sludge to another entity to treat as opposed to building additional treatment capacity.

Ofwat’s proposals start with the need to provide information – in very simple terms, Ofwat will require the WASCs to tell us all about their sludge.

WASCs will have to record bids for sludge. Ofwat will then examine how the WASCs are seeking to reduce the costs of sludge treatment, for example by trading. The WASCs’ record of bids will doubtless be an interesting area of focus.

A number of WASCs have been very innovative in linking sludge and energy – one example is Wessex Water. Some suggest that there remains a real opportunity for power generation from sludge. Compared to UK electricity demand the potential output is small. However, energy from gas derived from sludge is predictable, which should be of real value given the extent of intermittent generation. A longstanding aim of UK and EU energy policy is to reward stable and flexible generation.

It follows that power generation is certainly an option to explore. via Ofwat offers boost for sewage sludge biogas

It could also be that biogas production from sewage sludge is just the start of a whole new era of biofuels production from sewage sludge. The following explains how a new discovery may make this a reality:

Sewage Sludge Leads to Biofuels Breakthrough

April 2018: Researchers at the U.S. Department of Energy Joint BioEnergy Institute (JBEI) and Lawrence Berkeley National Laboratory (Berkeley Lab) have discovered a new enzyme that will enable microbial production of a renewable alternative to petroleum-based toluene, a widely used octane booster in gasoline that has a global market of 29 million tons per year.

Results from a study led by Harry Beller, Berkeley Lab senior scientist and scientific lead at JBEI, were published Monday in the journal Nature Chemical Biology. The other lead co-authors are Andria Rodrigues and Kamrun Zargar of JBEI.

A major focus of research at JBEI, and in the broader community of biofuel researchers, is the production of industrially and commercially relevant fuels and chemicals from renewable resources, such as lignocellulosic biomass, rather than from petroleum.

The enzyme discovered in this study will enable the first-time microbial production of bio-based toluene, and in fact, the first microbial production of any aromatic hydrocarbon biofuel. via Sewage Sludge Leads to Biofuels Breakthrough

Biomethane Produced at WWTWs Compared with Natural Gas

If biogas is compressed it can be used as a vehicle fuel. As a replacement for natural gas – if biogas is cleaned up and upgraded to natural gas standards, it's then known as biomethane and can be used in a similar way to methane.

[Fisrt published: April 2018: Updated: February 2022.]

It is amazing people have been making these great digesters out of crappy fitting barrels. Now look. Interesting sewage works have these.

I always thought it was crap! Had to say it… Thank you for posting this helpful information.

Nice piece! I will certainly consider some of the ideas in my project, you’re great.

Do you do online seminars?

I have problem how to discharge my waste sludge from MBR stp system about 800 m3 a day, any suggestions to solve it?.