In the UK, methane digesters, often referred to as anaerobic digesters, are a rapidly developing technology, especially for waste management and renewable energy.

By using bacteria to break down organic materials, these digesters produce biogas, which is a mixture of carbon dioxide and methane that may be used as fertiliser and to generate energy.

There are close to 700 digesters in operation in the UK (Summer 2025), and many more are in the development phase.

Key Takeaways

- Methane digesters convert organic waste into biogas, providing a dual solution for waste management and renewable energy generation across the UK.

- The UK biogas sector prevents over 1 million tonnes of CO2e annually from entering the atmosphere while diverting substantial organic waste from landfills.

- Government incentives like the Renewable Heat Incentive (RHI) and Green Gas Support Scheme make methane digesters economically viable for farms, businesses, and municipalities.

- ReFood's network of anaerobic digestion plants processes food waste from across Britain, demonstrating large-scale commercial success in the sector.

- Technical innovations in high-temperature digestion and enzyme development are dramatically increasing biogas yields and system efficiency.

The UK's relationship with waste is undergoing a revolutionary transformation. As landfills reach capacity and climate targets loom, methane digesters have emerged as a powerful solution at the intersection of waste management and renewable energy generation.

Across Britain, these remarkable systems are turning everything from farm slurry to food waste into valuable biogas, while simultaneously addressing multiple environmental challenges. Biogas Info, the UK's national anaerobic digestion resource, reports that the technology has seen exponential growth over the past decade, with installations increasing from fewer than 100 in 2011 to over 700 operational plants today.

But what exactly makes these systems so efficient, and why is the UK emerging as a leader in this green technology? Let's explore the science, success stories, and stunning potential of Britain's biogas revolution.

What Are Methane Digesters and Why Do They Matter for the UK?

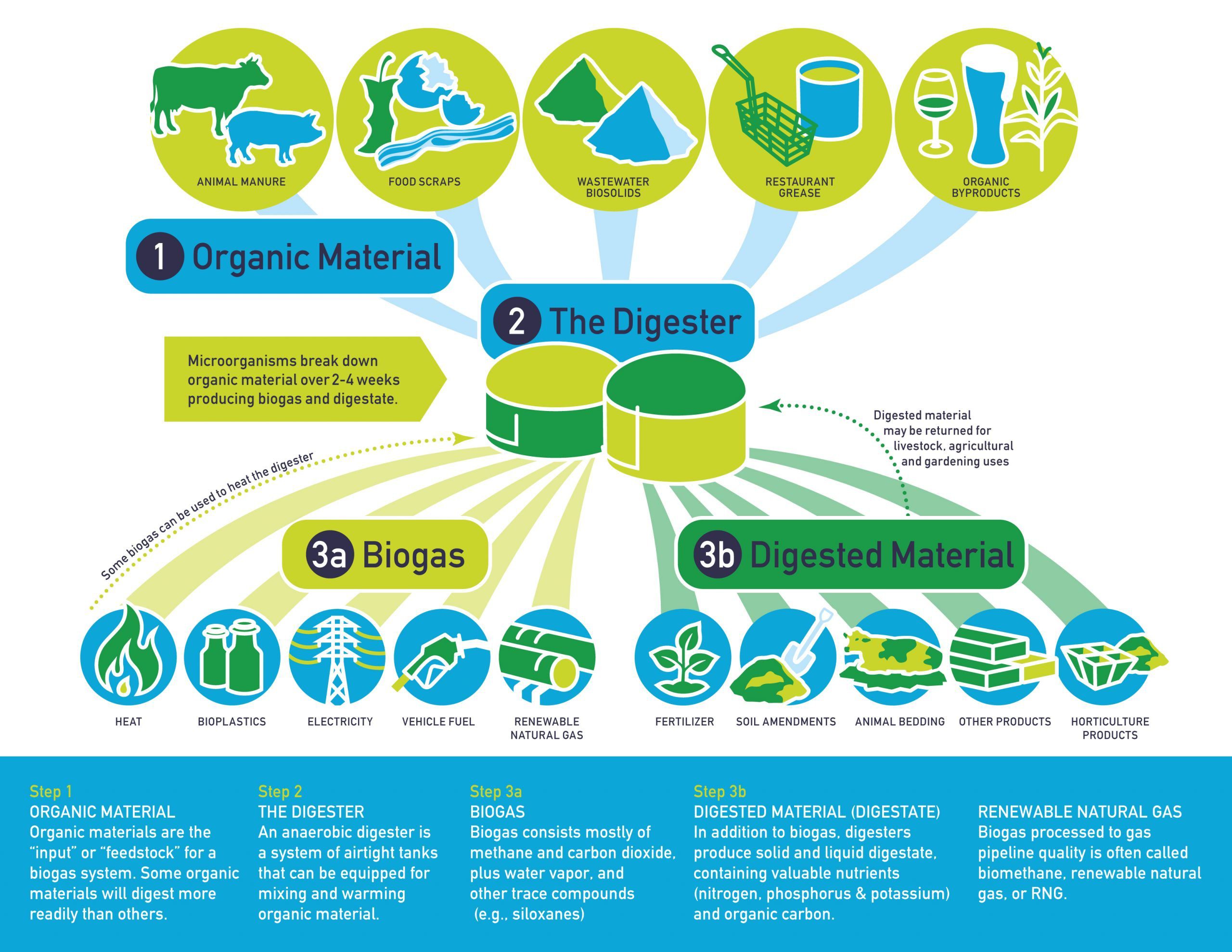

Methane digesters, also known as anaerobic digestion (AD) systems, are specialised facilities that break down organic material in the absence of oxygen to produce biogas.

This technology addresses two critical challenges facing the UK: managing organic waste sustainably and generating renewable energy. With Britain targeting net zero emissions by 2050 and seeking energy independence, these systems represent a practical solution already delivering results nationwide.

![]()

“How do methane digesters work?” from www.findfarmcredit.com and used with no modifications.

The Science Behind Anaerobic Digestion

At its core, anaerobic digestion harnesses a natural biological process. Inside sealed, oxygen-free tanks, specialised microorganisms break down organic matter through a four-stage process: hydrolysis, acidogenesis, acetogenesis, and methanogenesis. During the final stage, methane-producing bacteria convert the intermediate compounds into biogas – typically 50-70% methane, 30-40% carbon dioxide, and trace gases.

This biogas can be combusted to generate electricity and heat or upgraded to biomethane for injection into the national gas grid or use as vehicle fuel. The remaining material, called digestate, serves as a nutrient-rich fertiliser, completing a truly circular system.

Types of Digesters Operating Across Britain

The UK boasts a diverse range of digester configurations tailored to different feedstocks and scales of operation. Farm-based systems primarily process agricultural residues and livestock manures, typically employing continuous stirred-tank reactors (CSTRs) that maintain consistent mixing and biogas production.

Food waste digesters, increasingly common in urban areas, often utilise specialised pre-treatment technologies to handle packaged and contaminated waste streams. Industrial-scale operations may implement two-stage systems that separate the acidification and methanogenesis processes for optimal efficiency. Meanwhile, advanced municipal wastewater treatment plants incorporate anaerobic digestion of sewage sludge, often in egg-shaped digesters that maximise mixing and minimise sediment buildup.

From Farm Waste to Energy: The Basic Process

The journey from waste to energy follows a relatively straightforward path, though the technology behind each step has grown increasingly sophisticated. First, organic materials are collected and prepared, which may involve de-packaging, shredding, screening, or pasteurisation depending on the feedstock. This prepared material enters the digestion tanks where bacterial breakdown occurs over 15-40 days, depending on the system design and operating temperature.

The produced biogas is captured, cleaned of impurities like hydrogen sulfide, and either combusted in a combined heat and power (CHP) engine or upgraded to biomethane. The resulting electricity powers the facility with surplus exported to the grid, while heat is typically used to maintain optimal digester temperatures. The remaining digestate undergoes separation into liquid and solid fractions, both valuable as organic fertilisers.

Real Success Stories: Methane Digesters in Action

The theoretical benefits of anaerobic digestion have been conclusively proven by numerous successful installations across the UK landscape. From small farm operations processing animal waste to industrial-scale plants handling municipal food waste, these systems demonstrate how the technology can be adapted to various settings and requirements.

The diversity of implementation showcases the versatility of methane digesters – they're not just for large corporations or government facilities but can serve communities and businesses of all sizes. Each success story provides valuable lessons on efficiency improvements, operational best practices, and economic viability in the British context.

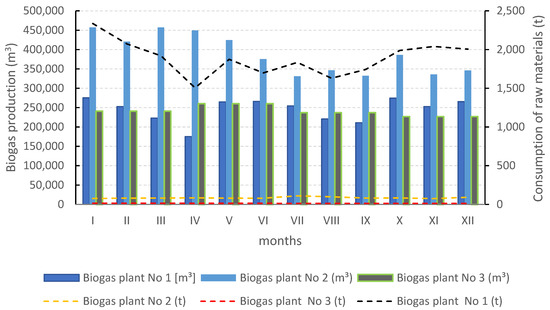

“The Efficiency of the Biogas Plant …” from www.mdpi.com and used with no modifications.

ReFood's Network of Food Waste Processing Plants

ReFood has established itself as a leader in commercial food waste digestion with a network of state-of-the-art facilities across the UK. Their Widnes plant, opened in 2016 with a £32 million investment, processes up to 120,000 tonnes of food waste annually from hotels, restaurants, and supermarkets throughout the Northwest. The facility generates enough electricity to power approximately 10,000 homes while preventing thousands of tonnes of food waste from reaching landfills. Learn more about making biogas from food waste at a commercial scale.

“Our anaerobic digestion network represents one of the most significant commercial investments in UK biogas infrastructure. Each tonne of food waste we process rather than send to landfill prevents 0.5 tonnes of CO2 equivalent from entering the atmosphere – creating a substantial positive environmental impact across our operations.”

– Philip Simpson, Commercial Director, ReFood UK

What makes ReFood's approach particularly efficient is its closed-loop model. They collect food waste from businesses using specialised vehicles, process it at their AD plants, generate renewable energy, and return digestate to agricultural land as biofertilizer – creating a perfect circular economy example. Their de-packaging technology can handle food waste in original packaging, making participation simpler for businesses and improving feedstock quality.

Farm-Based Systems Creating Energy Independence

Copys Green Farm in Norfolk exemplifies how agricultural operations can achieve energy independence through on-site digestion. Farmer Stephen Temple installed a 170kW digester in 2009 that processes slurry from his 100-cow dairy herd alongside locally grown maize. The system generates enough electricity and heat to power farm operations, process milk into award-winning cheese, and still export surplus energy to the grid. This pioneering farm-scale installation paid back its initial investment within seven years and now provides a reliable secondary income stream, insulating the farm business from volatile milk prices.

What's particularly notable is how Temple has integrated the digester into the entire farm ecosystem. The digestate improves soil health and reduces the need for chemical fertilisers, while captured heat from the CHP engine is used in cheese production and to warm farm buildings. This holistic approach demonstrates how agricultural digesters can deliver multiple operational benefits beyond simple energy generation.

“Energy independence – Wikipedia” from en.wikipedia.org and used with no modifications.

Municipal Waste Management Transformations

Milton Keynes has revolutionised its municipal waste management with a sophisticated food waste digestion system. Collecting segregated food waste from over 80,000 households weekly, the city sends approximately 12,000 tonnes annually to a local anaerobic digestion facility. This diversion has reduced landfill costs by over £500,000 per year while generating renewable energy equivalent to the needs of 700 homes. The system has become a model for other local authorities, demonstrating how municipal-scale organic waste can be efficiently converted into energy and fertiliser rather than becoming a costly disposal problem.

The Milton Keynes model is particularly effective because of the closed-loop collection system implemented by the council. Residents receive dedicated food caddies with compostable liners, making participation convenient. The separate collection ensures high-quality feedstock free from contaminants, which maximises biogas yields and digestate quality. This attention to the entire waste journey – from kitchen to energy production – exemplifies best practice in municipal biogas systems. For more insights on how to enhance biogas production, check out strategies for maximising methane production.

The Environmental Impact of UK Biogas Operations

The environmental benefits of methane digesters extend far beyond renewable energy generation. These systems create cascading positive impacts across multiple ecological dimensions, helping the UK address several environmental challenges simultaneously. From greenhouse gas reduction to improved soil health, the environmental case for expanded biogas production continues to strengthen.

Recent research from the Anaerobic Digestion and Bioresources Association (ADBA) indicates that the UK biogas sector already delivers substantial environmental gains, though its potential remains significantly untapped. With supportive policies and continued technological innovation, these benefits could multiply several times over in the coming decade.

Greenhouse Gas Reduction Figures

The UK biogas sector currently prevents over 1 million tonnes of CO2 equivalent (CO2e) from entering the atmosphere annually. This reduction comes from three mechanisms: capturing methane that would otherwise be released from decomposing organic waste, displacing fossil fuels in energy production, and reducing the need for energy-intensive chemical fertilisers.

Given that methane has a global warming potential 25-30 times greater than CO2 over a 100-year period, its capture through digestion represents a particularly significant climate intervention. Analysis by the Committee on Climate Change suggests that with optimal deployment, biogas could contribute up to 8% of the UK's 2050 greenhouse gas emissions reduction target.

“greenhouse gas …” from www.sciencedirect.com and used with no modifications.

Landfill Diversion Achievements

Methane digesters have become critical infrastructure in the UK's strategy to reduce landfill dependence. Currently, anaerobic digestion facilities process approximately 5 million tonnes of organic waste annually that would otherwise likely end up in landfills.

This diversion is particularly important for food waste, which produces substantial methane emissions when decomposing in landfill conditions. The UK's landfill tax escalator – currently set at £98.60 per tonne – has created strong economic incentives for businesses and local authorities to direct organic waste to digestion facilities instead of landfill, driving rapid expansion of food waste processing capacity nationwide.

Creating Circular Economy Solutions

Perhaps the most elegant environmental benefit of methane digesters is their embodiment of circular economy principles. Unlike many waste treatment technologies that merely dispose of materials, anaerobic digestion transforms waste into multiple valuable resources. The biogas provides renewable energy, while digestate returns nutrients to agricultural land, reducing the need for synthetic fertilisers.

This nutrient recycling is increasingly crucial as phosphorus reserves – essential for conventional fertiliser production – face depletion globally. The UK's biogas industry now produces approximately 4 million tonnes of biofertilizer annually, containing roughly 2.7 million kg of nitrogen, 1.35 million kg of phosphate, and 1.8 million kg of potash – nutrients that would otherwise need to be manufactured using energy-intensive processes or mined from finite reserves.

Water Quality Improvements

The contribution of methane digesters to water quality improvement is significant, though often overlooked. By providing a controlled management path for agricultural slurries, food waste, and sewage sludge, digesters help prevent these high-nutrient materials from contaminating waterways through runoff or improper disposal. The digestion process also neutralises up to 99.9% of pathogens present in the original waste, reducing biological contamination risks.

Furthermore, the controlled application of digestate as biofertilizer, compared to raw manure spreading, results in better nutrient uptake by crops and less leaching into groundwater and surface water. Several catchment-sensitive farming initiatives across Britain now incorporate anaerobic digestion as a key strategy for reducing agricultural water pollution while still maintaining productive farming operations.

“Benefits of Biogas | American Biogas …” from americanbiogascouncil.org and used with no modifications.

Economic Benefits Driving Adoption

While environmental benefits make a compelling case for methane digesters, their rapid expansion across the UK has been largely driven by robust economic fundamentals. These systems can transform waste management from a cost centre into a revenue stream, creating multiple income opportunities while hedging against rising energy prices and waste disposal costs.

The business case for biogas has strengthened considerably in recent years as technology costs decrease, operational efficiencies improve, and energy security concerns heighten. For many UK organisations – from farms to food manufacturers – anaerobic digestion now represents not just an environmental choice but a sound financial investment.

Return on Investment Timeframes

Investment recovery periods for UK methane digesters typically range from 3-10 years, depending on scale, feedstock availability, and applicable incentive schemes. Small-scale farm systems processing mainly on-site wastes usually achieve payback within 5-7 years, while larger commercial operations can see returns in as little as 3-4 years when processing gate-fee-generating wastes like food scraps.

The economic modeling has improved significantly as the industry has matured, with more reliable performance data and operational benchmarks available to potential investors. Many systems are now financed through dedicated green investment funds or asset finance arrangements, reflecting the sector's transition from an emerging technology to an established infrastructure class with predictable returns.

Energy Cost Savings for Operators

Operational cost savings from methane digesters provide compelling economic incentives beyond direct revenue streams. A medium-sized farm digester typically generates 500,000-1,000,000 kWh of electricity annually, representing savings of £50,000-£100,000 at current commercial electricity rates.

For food manufacturers and waste management companies, on-site digestion can reduce energy bills by 30-50% while simultaneously eliminating waste disposal costs. During the recent energy price crisis, businesses with digesters reported significant resilience advantages, with some food processing plants avoiding over £250,000 in additional energy costs during 2022 alone through self-generation.

Job Creation in the Biogas Sector

The UK biogas industry has become a notable employment generator, particularly in rural areas where economic opportunities are often limited. According to ADBA, the sector currently supports approximately 3,500 direct jobs and thousands more in the supply chain. These positions range from highly skilled technical roles in plant design and biochemistry to operational staff and logistics specialists handling feedstock and digestate.

The specialization required for efficient digester operation has sparked development of dedicated biogas training programs at several UK agricultural colleges and technical institutes. With the industry projected to triple in size by 2030, workforce development represents both a challenge and an opportunity for continued sector growth.

UK Government Support and Incentives

Government policy has played a pivotal role in establishing the UK's thriving biogas sector. Through a combination of financial incentives, regulatory frameworks, and strategic targets, successive administrations have created conditions favourable to methane digester deployment. While some early incentive schemes have closed to new entrants, the current policy landscape continues to encourage investment in both new and existing biogas facilities.

Renewable Heat Incentive (RHI) Payments

The Renewable Heat Incentive, introduced in 2011 for non-domestic installations, has been instrumental in supporting biogas development focused on heat production. Under this scheme, qualifying biogas plants receive quarterly payments for each kilowatt-hour of renewable heat produced over a 20-year period.

Although the non-domestic RHI closed to new applicants in March 2021, existing participants continue to receive payments that provide long-term revenue certainty. For a typical 1MW thermal biogas plant, RHI payments can generate £400,000-£500,000 annually, representing a critical revenue stream alongside energy savings and potential digestate sales.

Feed-in Tariffs for Electricity Generation

While the original Feed-in Tariff (FiT) scheme closed to new applicants in 2019, existing biogas installations still benefit from guaranteed payments for electricity generated and exported to the grid. These payments, which continue for 20 years from commissioning, provide predictable income streams that have enabled many projects to secure financing.

Newer installations can access the Smart Export Guarantee (SEG), which requires energy suppliers to offer payment for electricity exported to the grid, though typically at lower rates than the original FiT. Combined with significant on-site savings from self-consumption of generated electricity, these export payments enhance the overall economic case for electricity-focused methane digesters.

Green Gas Support Scheme

Launched in November 2021 as a successor to the RHI, the Green Gas Support Scheme (GGSS) specifically targets biomethane injection into the gas grid. The scheme provides quarterly payments over 15 years based on the amount of biomethane produced, with tariff levels designed to support the additional costs of upgrading biogas to grid-standard biomethane.

This incentive has catalysed significant investment in gas upgrading equipment, with several major food waste processors pivoting from electricity generation to biomethane production. The GGSS aims to increase the proportion of green gas in the national network, contributing to the decarbonization of heat and cooking energy while utilising existing gas infrastructure.

Technical Innovations Advancing UK Biogas Production

The evolution of methane digester technology has dramatically improved efficiency, making systems more productive and economically viable. British research institutions and companies have contributed significantly to these advances, positioning the UK as a center of biogas innovation. These technical improvements have collectively increased biogas yields by 30-50% compared to systems from just a decade ago, transforming marginal projects into profitable operations.

High-Temperature Anaerobic Digestion

Thermophilic digestion, which operates at 50-60°C rather than the traditional 35-40°C mesophilic range, represents one of the most significant efficiency improvements in UK biogas production. These high-temperature systems accelerate the digestion process, reducing retention times from 30-40 days to 14-21 days while increasing methane yields by up to 25%. The Severn Trent sewage treatment facility in Birmingham has pioneered large-scale thermophilic digestion, processing 400 tonnes of sewage sludge daily while generating 40% more biogas than their previous mesophilic system. Despite higher energy requirements for maintaining elevated temperatures, the net energy gain makes this approach increasingly popular for new installations, particularly at larger scales where heat management can be optimised.

Enzyme Developments for Enhanced Methane Yield

Enzymatic pre-treatment of feedstocks has emerged as a revolutionary approach to increasing biogas yields from recalcitrant materials like straw, grass, and woody biomass. UK biotech firm Fiberight has developed a proprietary enzymatic process that can increase methane yields from lignocellulosic materials by up to 40% by breaking down complex carbohydrates before digestion. Several commercial-scale plants have now incorporated these pre-treatment systems, enabling them to process previously unsuitable agricultural residues and expand their feedstock options beyond traditional slurries and food wastes. The enzyme technology essentially unlocks the potential of more difficult organic materials, significantly expanding the range of feedstocks that can be efficiently converted to biogas.

Biomethane Grid Injection Technologies

The development of more efficient and cost-effective biogas upgrading systems has revolutionised the UK biomethane sector. Modern membrane separation and pressure swing adsorption technologies can now remove CO2 and impurities from biogas with energy losses of just 3-5%, compared to 15-20% with earlier systems. CNG Services in Gloucestershire has been at the forefront of developing standardised biomethane-to-grid injection units specifically calibrated for UK gas network requirements. These pre-packaged systems have reduced capital costs for grid connection by approximately 40% over the past decade, making biomethane projects viable at smaller scales. As of 2023, over 100 UK biomethane plants now inject renewable gas directly into the national gas network, with a combined capacity to supply over 460,000 homes.

Future of Biogas in Britain's Energy Mix

Methane digesters stand at an inflection point in the UK energy landscape. Having progressed from niche agricultural technology to mainstream renewable energy infrastructure, biogas now faces both expanding opportunities and new challenges. The sector's future trajectory will be shaped by evolving policy frameworks, technological advancements, and integration with broader energy transition strategies. Understanding these emerging trends is essential for current operators and prospective investors alike.

Biogas Contribution to Net Zero Targets

The Climate Change Committee has identified biogas as a critical component in the UK's path to net zero emissions by 2050. Their modelling suggests that optimal deployment could deliver annual carbon savings of 8-10 million tonnes CO2e by 2030, representing approximately 5% of the necessary emissions reductions.

Beyond direct energy production, biogas systems offer one of the few practical methods for reducing agricultural methane emissions from manure management, addressing a particularly challenging sector for decarbonization.

The UK Anaerobic Digestion Strategy targets processing at least 50% of available organic wastes through digestion by 2035, requiring approximately 500 new or expanded facilities beyond the current 700+ operational plants. This expansion represents both an environmental necessity and a significant infrastructure investment opportunity estimated at £5-7 billion.

Integration with Other Renewable Energy Sources

Biogas is increasingly valued for its unique role in a renewable energy portfolio dominated by intermittent sources like wind and solar. Unlike these weather-dependent technologies, biogas provides dispatchable power and heat that can be generated on demand or stored for future use.

This flexibility makes it particularly valuable for balancing grid requirements and providing backup during low wind or solar periods. For more information on how biogas contributes to energy solutions, visit the UK government's guidance on generating energy from waste.

| Renewable Source | Storage Capability | Dispatchability | Generation Consistency |

|---|---|---|---|

| Solar PV | Low (without batteries) | Low | Intermittent (daylight only) |

| Wind Power | Low | Low | Variable (weather dependent) |

| Biogas | High (gas storage) | High | Consistent (24/7 capability) |

| Hydropower | Medium-High | High | Seasonal variation |

Several innovative projects now combine biogas with solar or wind installations in integrated renewable energy parks. The Rainbarrow Farm facility in Dorset pairs an anaerobic digester with a 500kW solar array, using biogas generation to compensate during cloudy periods and maximizing land use efficiency. Similarly, the Future Biogas installation in Lincolnshire incorporates battery storage alongside its digester to provide grid balancing services, generating additional revenue through capacity market payments.

This complementary relationship between biogas and other renewables is likely to become increasingly valuable as the UK progresses toward a zero-carbon electricity system, with biogas potentially commanding premium prices for its dispatchability.

Potential for Transport Fuel Applications

Perhaps the most promising growth area for UK biogas lies in transport applications. Compressed biomethane (Bio-CNG) and liquefied biomethane (Bio-LNG) offer immediate, practical solutions for decarbonising heavy goods vehicles, buses, and agricultural machinery – segments where battery electric technology faces significant limitations. CNG Fuels has established a network of biomethane refuelling stations across Britain's major freight corridors, serving fleet operators including John Lewis, Waitrose, and Hermes who have transitioned to biomethane-powered trucks.

These vehicles typically reduce greenhouse gas emissions by 85-90% compared to diesel equivalents while also delivering significant air quality improvements through lower particulate and NOx emissions. The Department for Transport has signalled strong support for biomethane in its Transport Decarbonisation Plan, potentially creating a market for up to 5TWh of transport biomethane annually by 2030 – equivalent to the output from approximately 150 large-scale digestion plants.

Frequently Asked Questions

For more detailed guidance tailored to specific circumstances, the Anaerobic Digestion and Bioresources Association offers member advisory services and publishes comprehensive technical briefings on various aspects of biogas implementation.

How much does a methane digester cost to install in the UK?

Installation costs for UK methane digesters vary significantly based on scale, feedstock type, and output utilisation. Small farm-scale systems (up to 100kW electrical equivalent) typically require £450,000-£750,000 investment, while medium commercial installations (250-500kW) range from £1.5-3 million.

Large food waste facilities processing 40,000+ tonnes annually can exceed £10 million, particularly when incorporating sophisticated pre-treatment systems and biomethane upgrading equipment. These figures represent total project costs, including digesters, tanks, CHP engines or upgrading equipment, grid connections, buildings, and commissioning.

Most systems achieve lower costs per kW at larger scales due to economies in equipment, engineering, and permitting – with the sweet spot for efficiency typically in the 0.5-2MW range for farm-based systems and 2-5MW for food waste plants.

What types of waste can be processed in a biogas plant?

Modern methane digesters can process virtually any biodegradable organic material, though specific plant designs are optimized for different feedstock types. Common UK digester inputs include cattle and pig slurry, poultry litter, crop residues (particularly maize, grass, and sugar beet), food processing by-products, source-separated food waste, supermarket surplus, brewery and distillery wastes, and sewage sludge. Certain industrial wastes containing high levels of antibiotics, disinfectants, or heavy metals can inhibit the biological process and may be unsuitable without pre-treatment or dilution.

How much energy can a UK farm-scale digester typically produce?

A typical farm-scale digester processing manure from 200 dairy cows (approximately 4,000 tonnes annually) along with 2,000 tonnes of energy crops can generate roughly 100kW of continuous electrical power, equating to 876,000 kWh per year. This output is sufficient to power approximately 250 homes. When operating in CHP mode, the same system would additionally produce around 1 million kWh of thermal energy annually, which can heat farm buildings, grain dryers, or nearby residential properties.