Did you know that an Anaerobic Membrane Bioreactor (AnMBR) can treat wastewater with 2000 mg/L of N,N-Dimethylformamide (DMF)? It does so with complete degradation efficiency. This shows how AnMBR technology can handle one of the toughest challenges in industrial wastewater treatment.

As industries face the environmental impact of DMF-containing wastewater, AnMBRs are a game-changer. These systems offer top-notch treatment and also allow for energy recovery. This makes them a sustainable option for managing wastewater.

In this article, we'll look at how anaerobic membrane bioreactors are changing the game for DMF-containing wastewater treatment. We'll cover the technology's core parts, its performance, and the many benefits it offers. This includes the chance for carbon neutrality.

Key Takeaways

- AnMBRs can effectively treat high-strength DMF wastewater with complete degradation.

- The technology offers dual benefits of wastewater treatment and energy recovery.

- AnMBRs have demonstrated superior performance compared to traditional treatment methods.

- The process can achieve carbon neutrality through biogas production and energy savings.

- AnMBRs show promise in reducing CO2 emissions by up to 1.45 kg/m³.

Understanding N,N-Dimethylformamide (DMF) and Its Environmental Impact

N,N-Dimethylformamide, or DMF, is a solvent used in many industrial processes. It's great for making polymers and other materials because of its special properties. But, DMF can harm the environment when it ends up in wastewater.

What is DMF and Its Industrial Applications

DMF is a useful chemical in many industries. It's good at dissolving lots of things. It's mainly used for:

- Polymer production

- Pharmaceutical manufacturing

- Petrochemical processing

- Electronic component fabrication

Environmental Challenges of DMF-containing Wastewater

DMF in wastewater is a big problem for the environment. It's made in huge amounts worldwide, affecting water quality. DMF can even cause cancer, making it a serious health risk.

DMF contamination in water bodies primarily stems from industrial wastewater and municipal effluent, with concentrations ranging from nanograms to micrograms per litre.

Current Treatment Methods and Limitations

There are a few ways to clean up DMF in wastewater. The Fenton process and biological treatments are some of them. But, they don't work well for very dirty water.

Aerobic treatment is better than anaerobic for breaking down DMF. But, it needs the right microbes to work. New research has found microbes that can help break down DMF, offering hope for better treatments.

| Treatment Method | Efficiency | Limitations |

|---|---|---|

| Fenton Process | Moderate | High energy consumption |

| Aerobic Degradation | High | Requires specific microbial consortia |

| Anaerobic Degradation | Low | Slow process, limited effectiveness |

Anaerobic Membrane Bioreactors (AnMBR): Technology Overview

Anaerobic Membrane Bioreactors (AnMBRs) have greatly improved wastewater treatment. They mix anaerobic digestion with membrane filtration. This combo treats different wastewater types and saves energy.

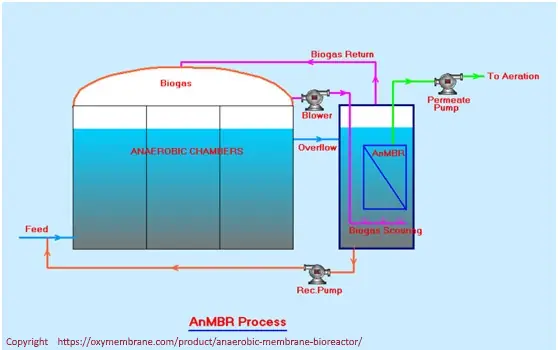

Core Components and Operating Principles

AnMBRs have two key parts: an anaerobic bioreactor and a membrane filtration unit. The bioreactor is where microorganisms break down organic matter without oxygen. This creates biogas full of methane.

The membrane unit separates treated water from the biomass. It uses submerged membranes or external units for this.

Membrane Filtration Process

The membrane filtration in AnMBRs is key for clean effluent. Submerged or external membranes keep treated water and biomass apart. This method captures almost all solids and microorganisms.

Biological Treatment Mechanisms

AnMBRs use anaerobic microbes to break down organic matter. This process goes through several stages: hydrolysis, acidogenesis, acetogenesis, and methanogenesis. Most methane comes from acetic acid decomposition.

The rest is made by bacteria converting CO2 and H2 into methane.

| Parameter | Value |

|---|---|

| COD Removal Efficiency | >99% |

| Organic Loading Rate | Up to 40 kg COD/(m³·d) |

| Energy Consumption Reduction | 10-30% compared to aerobic systems |

| Sludge Production Reduction | Up to 50% |

| Typical Start-up Time | 2-3 months |

AnMBRs face issues like membrane fouling, especially in submerged setups. Yet, they can handle lots of organic matter and produce clean water. This makes them a good choice for green wastewater treatment.

Performance Analysis of AnMBR Systems

Anaerobic Membrane Bioreactors (AnMBRs) are great at treating wastewater with lots of DMF. They can handle up to 2000 mg/L of DMF. This means they can break down all the DMF and also make bio-methane, a clean energy source.

AnMBRs also produce very clean water. They remove about 90% of chemical oxygen demand (COD) at both 35°C and 20°C. This makes them good for many climates, without needing extra heat.

The biogas production in AnMBRs is impressive. They make between 0.25 to 0.35 m³ CH4 per kg COD. This helps the system use energy well and be more sustainable. But, making methane goes down a bit when the temperature drops from 35°C to 20°C.

How well AnMBRs work depends on a few things. The best speed for the agitator is 150 rpm. This stops the membranes from getting clogged. The system can also keep a low pressure for a long time, making it more efficient.

| Parameter | Value |

|---|---|

| COD Removal Efficiency | Up to 90% |

| Biogas Production Rate | 0.25-0.35 m³ CH4/kg COD |

| Optimal Temperature Range | 20-30°C |

| Optimal Stirring Speed | 150 rpm |

AnMBRs are good at removing COD and making biogas. But, they might need extra steps to remove nutrients. The water left over has more nutrients because of the organic matter breakdown. So, more steps are needed to meet the limits for nitrogen and phosphorus.

Energy Recovery and Carbon Neutrality Benefits

AnMBR technology brings big wins in energy recovery and cutting carbon emissions. It's especially good for treating wastewater with n n-dimethylformamide (DMF). This method helps the environment and saves money by making energy.

Bio-methane Production and Utilisation

AnMBR systems are top-notch at making bio-methane from DMF wastewater. They use the energy in the wastewater, which is a lot more than needed to treat it. The biogas made can be used on-site or sold, cutting down costs.

Electricity Generation Potential

AnMBR systems can make a lot of electricity. They can produce up to 3.45 kWh/m3 of bio-energy. This is way better than old methods, which use about 0.6 kWh per m3.

Carbon Emission Reduction Capabilities

AnMBR tech is great at cutting down carbon emissions. It makes clean energy and uses less outside power. With new designs, AnMBRs can even make more energy than they use, making them carbon-neutral or even negative.

| Parameter | Conventional Treatment | AnMBR |

|---|---|---|

| Energy Consumption (kWh/m3) | 0.49 | 0.11 |

| CO2 Emissions (relative) | High | Low |

| Energy Recovery Potential | Limited | High |

AnMBR systems change how we manage wastewater with DMF. They use wastewater's energy, saving money and helping the planet. This is a big step towards a greener, carbon-neutral world.

Operational Considerations and Optimisation

Managing Anaerobic Membrane Bioreactors (AnMBRs) for wastewater with DMF is key. These systems can remove up to 95% of Chemical Oxygen Demand (COD). This makes them a great choice for treating industrial waste.

Membrane Fouling Management

Membrane fouling is a big problem in AnMBR use. It's important to clean the membranes regularly. This keeps the system working well and the water clean. Cleaning methods include backwashing and special chemical treatments.

Process Control Parameters

It's important to set the right parameters for AnMBR to work well. Key factors include:

- Organic loading rate: Effective degradation has been reported at 6.53 COD kg/m3/d

- Hydraulic retention time: Optimal performance observed at 12 hours

- Temperature: Stable operation requires mesophilic conditions around 35°C

Keeping these parameters right helps remove DMF well and makes biogas. Daily methane production can reach up to 2700 Nm³.

System Maintenance Requirements

Keeping the system in good shape is crucial. This includes:

- Routine monitoring of membrane integrity

- Preventive maintenance of pumps and valves

- Regular calibration of sensors and control systems

Following these steps makes AnMBR systems reliable for treating DMF wastewater. They offer environmental benefits and can even produce energy through biogas.

Conclusion

Anaerobic membrane bioreactors (AnMBR) are changing how we treat wastewater. They are efficient and good for the environment. This makes them a key player in sustainable technology.

AnMBRs remove pollutants well. They can cut Chemical Oxygen Demand (COD) by over 99%. This is thanks to managing solid retention time.

External cross-flow membrane treatment also works great. It can reduce biochemical oxygen demand by 85% to 95%. This shows how effective AnMBRs are.

AnMBRs are also good at saving energy. They can get up to 48% methane from wastewater. This makes them a green solution, reducing the energy use of old treatment plants.

| Parameter | Performance |

|---|---|

| COD Removal Efficiency | Over 99% |

| BOD Reduction | 85% to 95% |

| Methane Recovery | Up to 48% |

| Nitrate Removal | 72% |

| Orthophosphate Reduction | 24% to 85% |

More people are studying AnMBR technology. This shows its growing importance in treating industrial wastewater. It's a step towards better water management.

Future research will make AnMBRs even better. They will help us treat wastewater more efficiently and sustainably. This could be a big change for the better.

FAQs

Anaerobic Membrane Bioreactors (AnMBR) are gaining attention in wastewater treatment. They are especially useful for dealing with DMF-containing wastewater. These systems remove over 98% of Chemical Oxygen Demand (COD) in one step.

This high efficiency comes from combining anaerobic digestion with ultrafiltration. It's a powerful method.

Many wonder about the size of AnMBR systems. They can handle a lot of COD, from 10,000 to 70,000 mg/L. This is common in dairy processing. They produce effluent with less than 300 mg/L COD.

This makes them flexible for different industrial needs.

Another question is about energy use. AnMBR technology turns up to 99.5% of biodegradable organics into biogas. This biogas is 50-65% methane and 30-50% carbon dioxide.

In food and beverage production, this biogas can power the whole treatment facility. It makes the process energy neutral.

People also ask about the long-term reliability of AnMBRs. They have a special jet mixing system with no moving parts. This makes them reliable for treating DMF-containing wastewater.

They can handle big changes in organic loading. They can even sit idle during seasonal changes. This makes them a strong choice for wastewater treatment.

FAQ

What are the main advantages of using AnMBR for treating DMF-containing wastewater?

AnMBR is great for treating DMF wastewater. It removes DMF well, saves energy, and makes water cleaner. It's also good for the environment and uses less space and sludge than old methods.

How does AnMBR technology compare to conventional treatment methods for DMF wastewater?

AnMBR beats old methods in treating DMF wastewater. It's better at removing pollutants and saves more energy. It can handle more waste and always produces clean water.

What are the main challenges in implementing AnMBR technology for industrial applications?

Setting up AnMBR systems can be tough. You need to deal with clogged membranes and keep the system running smoothly. It also costs more upfront. But, with the right plan, these problems can be solved.

Can existing wastewater treatment plants be retrofitted with AnMBR technology?

Yes, you can add AnMBR to old plants. It depends on the plant's size and what it already does. You can update it bit by bit, keeping it running.

How scalable are AnMBR systems for different industrial capacities?

AnMBR systems grow with your needs. They fit small or big plants. You can add more parts as needed, making it easy to expand.

What is the typical biogas production rate in AnMBR systems treating DMF wastewater?

Biogas production varies in AnMBR systems. It depends on how much waste you have and the system's design. You usually get 0.2 to 0.5 m³ of biogas per kg of waste treated. This gas can power your site or be sold.

How does the presence of DMF affect the anaerobic digestion process in AnMBR systems?

DMF can slow down the start of AnMBR systems. But, with time, they can break down DMF well. It takes longer to start, but once it does, it works great.

What are the long-term reliability and maintenance requirements of AnMBR systems?

AnMBR systems are reliable with regular care. You need to clean membranes, check the microbes, and look after the equipment. With proper maintenance, they last for years.

Is AnMBR technology cost-effective compared to conventional treatment methods?

AnMBR systems cost more at first but save money later. They use less energy, make less sludge, and can make money from biogas. They're better for big plants and strong wastewaters.

Can AnMBR technology be applied to other types of industrial wastewater besides DMF-containing streams?

Yes, AnMBR works on many types of wastewater. It's good for food, drinks, medicines, and textiles. It's especially useful for strong organic wastewaters where saving energy matters.