In an anaerobic digester, the role of methanogens is to work together with a consortium of other microorganisms to break down organic waste and produce methane. Read on to learn about these fascinating microbes.

Methanogens in Anaerobic Digestion – Key Points

- Methanogens are unique microorganisms that carry out the last essential step in anaerobic digestion, transforming intermediate compounds into methane gas.

- These microbes follow two main pathways: acetoclastic methanogenesis (converting acetate) and hydrogenotrophic methanogenesis (using hydrogen and carbon dioxide).

- Environmental factors like temperature, pH, and trace element availability significantly impact methanogen performance and biogas production efficiency.

- Different methanogen species have varying substrate preferences and resilience levels, with Methanosarcina being notably versatile in biogas systems.

- Optimizing conditions for methanogens can substantially increase biogas yields, offering greater renewable energy production from organic waste materials.

One of the most promising yet often overlooked processes in the search for renewable energy sources occurs on a microscopic scale. Inside anaerobic digesters, tiny organisms known as methanogens work tirelessly to convert organic waste into valuable biogas. These extraordinary microbes represent the final and most critical link in a complex biological chain that converts waste into energy.

Anaerobic digestion is increasingly being recognized as a green waste management solution that also generates renewable energy. We've seen a surge in interest in biogas technologies at Sustainability Directory as companies and communities look for carbon-neutral substitutes to fossil fuels. Methanogens, the biological powerhouses behind this process, are not getting the attention they deserve.

Methanogens are a type of microorganism that falls under the Archaea domain. These ancient lifeforms are different from bacteria and eukaryotes, having evolved more than 3.5 billion years ago. They have unique metabolic abilities that allow them to live in environments without oxygen and produce methane as a metabolic byproduct. When this natural process is controlled in digesters, it becomes a powerful tool for reducing waste and generating clean energy.

“Methanogen – an overview …” from www.sciencedirect.com and used with no modifications.

Uncovering the Unsung Heroes of Biogas Production

In the last step of a four-phase, oxygen-free process that breaks down complex organic materials, methanogens spring into action. After hydrolytic bacteria have turned polymers into monomers, acidogenic bacteria have changed these into volatile fatty acids, and acetogenic bacteria have converted these acids into acetate, hydrogen, and carbon dioxide, it's time for the methanogens to do their thing. Their unique metabolic pathways change these simple compounds into methane gas, which makes up 50-70% of biogas.

Understanding the Function of Methanogens in Anaerobic Digesters

Methanogens are unique microorganisms that perform specific chemical reactions within anaerobic digesters. They are capable of using a limited range of substrates—primarily acetate, hydrogen, carbon dioxide, formate, methanol, and methylamines—to produce methane. This narrow specialization makes them both potent and susceptible, as they rely on other microorganisms to decompose complex organic matter into compounds they can use.

Methanogens are unique in their ability to produce methane through a specialized biochemical process. This process involves the use of enzymes and cofactors that are not found in any other organisms. The enzyme known as methyl-coenzyme M reductase is responsible for catalyzing the final step of methane production. This results in the release of methane gas, which rises and gathers in the headspace of the digester. While this process may seem simple, it is actually a complex metabolic task that requires very specific environmental conditions.

Methanogens are sluggish workers compared to other microorganisms in the digester. Their doubling time can range from a few days to several weeks, depending on the species and conditions. This slow growth rate makes them the bottleneck in the entire anaerobic digestion process. When microbial activity restricts system performance, active biological control becomes necessary. A water treatment service for cooling towers manages microbial fouling that would otherwise reduce heat transfer efficiency and increase operational risk.

If methanogens are inhibited or killed, the entire system gets backed up, leading to an accumulation of acid and potential digester failure.

The Methanogen's Unique Biochemistry

Unlike most organisms that use oxygen as the final electron acceptor in energy generation, methanogens use carbon compounds like CO₂ or acetate. This allows them to produce energy in oxygen-free environments where most life cannot survive. Their unusual metabolism produces methane (CH₄) as a waste product—the very gas that powers our renewable energy systems.

Why These Microbes Are Essential for Renewable Energy

Methanogens transform what would otherwise be pollution into a valuable energy resource. Without their activity, organic wastes would release methane directly to the atmosphere during decomposition—a greenhouse gas 25 times more potent than carbon dioxide. By capturing this process in digesters, we harness this powerful greenhouse gas as renewable energy while preventing its escape to the atmosphere.

The biogas that methanogens produce can be used to generate electricity, provide heating, cook, or be upgraded to biomethane for injection into the natural gas grid or as a vehicle fuel. One ton of food waste can produce about 300-500 cubic meters of biogas through the correct activity of methanogens, which is equivalent to 180-300 liters of diesel fuel. This recovery of energy turns waste management from a cost center into a potential profit center, while also reducing the environmental impact.

Understanding Methanogens: Small Creatures with Big Effects

Old Microbes with Current Uses

Methanogens are some of the oldest creatures on Earth, having evolved in the anaerobic environment of early Earth. These old microbes have stayed mostly the same for billions of years, mastering their unique metabolism before more complex life came about. Nowadays, we're using their ancient skills to tackle current issues of waste management and renewable energy generation.

Methanogens are microorganisms that naturally exist in environments lacking oxygen but abundant in organic matter. These environments include swamps, marshes, lake sediments, animal digestive tracts (especially ruminants like cows), and even human intestines. The methanogens utilized for biogas production are not specifically engineered organisms. Instead, they are natural microbial communities that have adapted to thrive under the controlled conditions of anaerobic digesters. Their widespread distribution in nature makes them easily accessible for biogas applications globally.

Transforming Waste into Energy with Methanogens

Methanogens provide an intriguing case study of chemical change on a microscopic scale. These specialized archaea utilize carbon-containing compounds for both energy and as a terminal electron acceptor— a metabolic strategy that is rare in the biological world. The methane that they produce is rich in energy, with approximately 55 MJ/kg— which is more than coal and similar to natural gas.

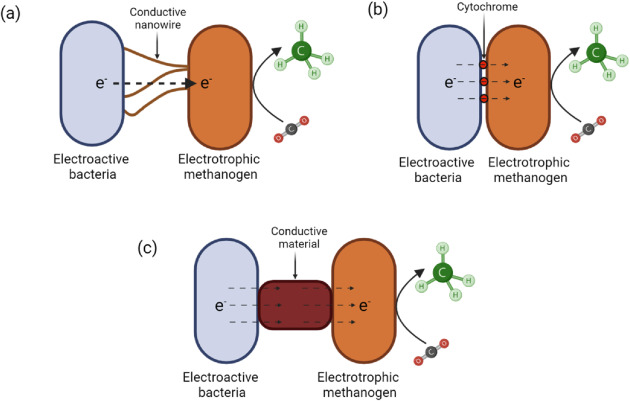

Two Key Methanogenic Pathways

“− The two pathways of methanogenesis …” from www.researchgate.net and used with no modifications.

There are two main metabolic pathways that methanogens use to create methane, and different species with unique substrate preferences use each one. The acetoclastic pathway changes acetate (CH₃COOH) into methane and carbon dioxide. This pathway is responsible for about 70% of methane production in most digesters and is mainly performed by members of the Methanosarcina and Methanosaeta genera.

The hydrogenotrophic pathway, the second major route, uses hydrogen to reduce carbon dioxide to methane. While often contributing less to overall methane output in stable digesters, this pathway becomes critically important during stress conditions when hydrogen levels rise. Genera like Methanoculleus, Methanospirillum, and Methanobacterium specialize in this pathway, serving as “hydrogen sinks” that maintain the thermodynamic favorability of the entire digestion process.

Knowing which process is most active in a digester is essential for understanding the system's health and opportunities for improvement. When the process shifts from acetoclastic to hydrogenotrophic methanogenesis, it often signals stressful conditions like ammonia inhibition or a buildup of volatile fatty acids. Operators can spot potential issues before they impact biogas production by keeping an eye on the balance between these processes through microbial community analysis.

Important Methanogen Species in Biogas Production

In anaerobic digesters, the methanogen community consists of various species that have specialized roles and substrate preferences. The distribution and relative abundance of these species have a significant effect on the efficiency and stability of biogas production. Some methanogen species are particularly useful in industrial biogas applications due to their metabolic versatility or ability to withstand difficult conditions.

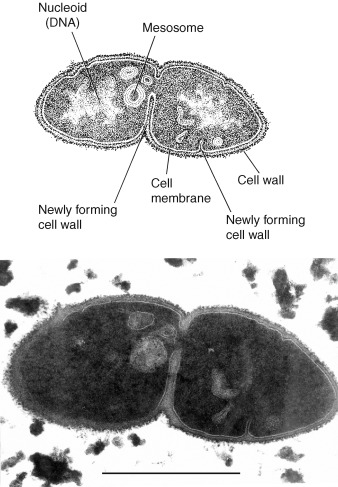

Methanosarcina: The Jack of All Trades

“Methanosarcina – Wikipedia” from en.wikipedia.org and used with no modifications.

Unlike most methanogens, which are specialists, Methanosarcina species are generalists. They can use a variety of methanogenic pathways, converting acetate, methanol, methylamines, and even hydrogen/CO₂ to methane. This metabolic flexibility allows them to adapt to changing conditions in the digester, making them a key player in maintaining system stability.

These critters grow in unique cluster formations that offer some protection against environmental stressors. Their relatively fast growth rate (for methanogens) and ability to withstand moderate levels of toxins like ammonia make them invaluable in industrial biogas applications. Methanosarcina species typically dominate in digesters with higher organic loading rates and shorter retention times, where their versatility provides a competitive advantage.

Methanoculleus: The Dependable Player

“Methanoculleus – an overview …” from www.sciencedirect.com and used with no modifications.

Species of Methanoculleus are experts in hydrogenotrophic methanogenesis, a process that uses hydrogen and carbon dioxide to generate methane. While these organisms are usually less abundant during regular operation, they become vital when stress events occur. Their population usually grows when acetoclastic methanogens are obstructed, offering an alternative methane production route that stops the system from completely breaking down.

They play a crucial role in digesters that process protein-rich substrates such as agricultural waste or food industry byproducts. In high ammonia conditions that stop acetoclastic methanogens, Methanoculleus species keep methane production going through the hydrogenotrophic pathway. This resilience makes them key parts of strong biogas systems built to manage changing or difficult feedstocks.

Other Significant Methanogen Species

Methanosaeta (formerly Methanothrix) species are extremely specialized acetoclastic methanogens that have a high affinity for acetate but grow slowly. They usually dominate in digesters with low acetate concentrations and long retention times, providing stable but slower methane production. Their filamentous growth pattern contributes to granule formation in certain digester types, improving biomass retention.

Commonly found in digesters, Methanobacterium, Methanobrevibacter, and Methanospirillum are additional hydrogenotrophic methanogens. They each have slightly different temperature preferences, growth rates, and tolerance to inhibitory compounds. This diversity provides redundancy in the hydrogenotrophic methanogen community, increasing the system's resilience to environmental fluctuations and stress conditions.

- Acetoclastic specialists: Methanosaeta (has a high affinity for acetate and grows slowly), Methanosarcina (versatile and grows faster)

- Hydrogenotrophic specialists: Methanoculleus, Methanobacterium, Methanospirillum, Methanobrevibacter

- Methylotrophic specialists: Some Methanosarcina species, Methanolobus (can use methanol and methylamines)

- Rare but important: Methanosphaera (uses methanol with hydrogen), Methanomassiliicoccus (uses methanol with hydrogen)

How Methanogens Are Affected by Environmental Factors

Methanogens have stricter requirements than many other microorganisms involved in anaerobic digestion. They are sensitive to changes in their environment, and understanding these sensitivities can help those operating digesters to maintain the best conditions for methanogens. This can help to maximize the production of biogas.

Environmental factors don't just influence the amount of methane produced—they also decide which methanogen species take over. Each species thrives under slightly different conditions, leading to a complex, ever-changing community that adapts to environmental changes. This microbial succession can dramatically affect how well the digester works over time.

How Temperature Impacts Methanogen Communities

There are usually three temperature ranges in which digesters operate, and each of these ranges supports different methanogen communities. Psychrophilic digestion (below 25°C) is a slow process that results in lower biogas yields, but it doesn't require a lot of energy input. Mesophilic digestion (35-42°C) is the most common operating range because it offers a good balance between methane production, energy requirements, and operational stability.

Thermophilic digestion (50-60°C) is the most efficient method for producing methane and reducing pathogens, but it also requires more energy and creates less stable conditions. This is because thermophilic methanogens (like certain Methanothermobacter species) are very sensitive to temperature changes and inhibitory compounds. Even a small change in temperature of 2-3°C can disrupt thermophilic methanogen communities and significantly reduce biogas production.

How pH Levels and Buffering Needs Impact Methanogens

Methanogens are most active in a very specific pH range of 6.8-7.2, which is much narrower than the pH range that acidogenic bacteria can tolerate. Acidogenic bacteria are the first step in the digestion process, and methanogens come after. This difference in pH tolerance can cause problems in the digestion process because acid-producing bacteria can keep working even when the pH drops to levels that stop methanogens from working. If there isn't enough buffering capacity, this can cause a dangerous cycle where the methanogens stop working as much, which lets the acid build up, which makes the methanogens work even less, and this can eventually cause the entire digester to fail.

Importance of Trace Elements

Methanogens need certain trace elements to make the enzymes they need to produce methane. Nickel, cobalt, iron, selenium, molybdenum, and tungsten are especially crucial, acting as cofactors in important methanogenic enzymes. Even if all other conditions are perfect, a lack of these micronutrients can significantly limit the activity of methanogens. To learn more about the role of methanogens in the biogas production process, explore this comprehensive guide.

The enzyme complex methyl-coenzyme M reductase, which is responsible for the final stage of methane production, contains nickel at its active site. Similarly, hydrogenases, which are crucial for hydrogenotrophic methanogenesis, need iron, nickel, and sometimes selenium. Trace element limitations become especially troublesome in digesters that process energy crops or food waste. These often contain lower concentrations of these minerals than manure or sewage sludge.

Methanogens and Their Need for Oxygen-Free Environments

Methanogens are some of the most sensitive organisms to oxygen, and even the smallest amounts can cause irreparable damage to their cell structures and enzymes. For methanogens to survive and be active, it is crucial to maintain strictly anaerobic conditions (redox potential below -300 mV). If oxygen gets in during feeding, maintenance, or sampling, it can temporarily stop methane production and, in the worst cases, it may be necessary to restart the system with a new inoculum.

Overcoming Acid Buildup

If a digester's volatile fatty acids build up and its pH decreases, swift action is required to avoid total methanogen suppression. The initial move is to decrease or stop organic loading to allow methanogens to handle the current acids. Acids can be neutralized and pH levels can be returned to a beneficial state by adding alkaline substances such as sodium bicarbonate, calcium carbonate, or calcium hydroxide.

When things get really bad, you might need to dilute the system with water or active digester content from a healthy system. This can help reduce the concentration of inhibitors and introduce new communities of methanogens. Keep in mind that it can take a while for the system to recover. Methanogens grow slowly compared to the acid-producing bacteria that caused the imbalance in the first place.

Regular testing of pH, alkalinity, volatile fatty acids, and biogas composition is a great way to monitor recovery and get important feedback on the effectiveness of the intervention. If the methane percentage and pH start to gradually increase and the volatile fatty acid concentrations start to decrease, this is a good sign that the methanogen population is recovering successfully. You should only start to reintroduce feedstock in a controlled way after stable conditions have been maintained for a number of days.

Looking Ahead: The Role of Methanogens in Renewable Energy

As we continue to develop biogas technology, we’re moving from simply studying methanogens to using them to improve our production efficiency. Thanks to next-generation sequencing technologies, we now understand that the methanogen communities in digesters are far more diverse and specialized than we once thought. We’re now using this newfound knowledge to optimize the performance of methanogens, which is crucial for the biogas industry.

Scientists are working on creating accelerants that are specific to methanogens, strains that are resistant to inhibitors, and carriers for biofilms that can significantly increase the retention of methanogens in digesters. These developments could potentially decrease the time required for digestion from weeks to just a few days, while also improving the yields of methane from substrates that are difficult, such as biomass that is lignocellulosic and wastes that are high in protein.

- Development of high-throughput screening methods for methanogen activity

- Identification of novel methanogen species with enhanced stress tolerance

- Creation of synthetic microbial consortia with optimized methanogen communities

- Integration of metagenomic and metabolomic data to predict methanogen responses

The integration of artificial intelligence and machine learning with methanogen research presents particularly exciting opportunities. These technologies can analyze complex datasets from thousands of digesters to identify optimal operating conditions for specific feedstocks and methanogen communities. Such predictive models will enable automated process control systems that continuously adjust digester parameters to maximize methanogen activity.

Microbiologists, process engineers, and data scientists working together will fast-track these advancements. As the demand for renewable energy increases and the need to reduce carbon becomes more and more pressing, enhancing the performance of methanogens is a key step to increasing the use of biogas in our energy mix.

Boosting the System: Introducing Specialized Methanogen Communities

One promising avenue for optimizing methanogen communities is bioaugmentation. This is the practice of adding chosen microbial cultures to enhance biological processes. Instead of waiting for nature to take its course and develop ideal methanogen communities, bioaugmentation introduces species or groups that have been pre-adapted for specific capabilities. This can significantly cut down the time it takes to start up new digesters and can help existing systems bounce back from inhibitory events.

There are now commercially available products that contain concentrated methanogen communities that are specific to a substrate. These cultures usually contain not only methanogens but also the syntrophic bacteria that work together to break down complex substrates. Some products are designed to address specific challenges such as high levels of ammonia. These products offer Methanosarcina species that are tolerant to ammonia and can maintain activity under conditions that would inhibit conventional methanogen communities.

- Ammonia-tolerant methanogen consortia for agricultural waste digestion

- Psychrophilic methanogen mixtures for low-temperature applications

- Salt-tolerant communities for marine biomass and industrial wastewater

- Acid-resistant methanogen blends for rapid startup and recovery

Research indicates that bioaugmentation success depends heavily on both the quality of the introduced cultures and the conditions maintained after introduction. The added methanogens must compete with indigenous populations while adapting to the specific chemical environment of the digester. Repeated dosing and careful optimization of conditions to favor the introduced strains significantly improve success rates.

The next step in bioaugmentation technology involves creating methanogen inocula that are tailored to specific sites, feedstocks, and operating conditions. By studying the substrate and the existing microbial community, scientists can determine which species of methanogen would be most beneficial for a particular application.

How Genetic Methods Can Enhance Methane Production

Despite the fact that directly modifying the genetics of methanogens is difficult due to their distinctive biochemistry and rigorous anaerobic needs, there has been substantial advancement in comprehending the genetic foundation of essential methanogenic traits.

Scientists have discovered genes that are responsible for the utilization of substrates, tolerance to stress, and the efficiency of methane production. This discovery paves the way for the selective breeding of high-performing methanogen strains via lab evolution and selective pressure.

More radical approaches involving synthetic biology are also being explored. These include engineering non-methanogenic organisms to express methanogenic pathways, creating hybrid metabolic systems that combine the robustness of conventional bacteria with the methane-producing capabilities of methanogens. Though still largely confined to laboratory research, these approaches could eventually produce designer microbial systems with unprecedented methane production capabilities.

The Importance of Methanogens in a Sustainable Future

Methanogens are much more than just a technical component in digesters. They are a crucial part of our shift towards a circular economy where waste is viewed as a resource. Methanogens convert organic waste into clean energy, helping to complete the material cycle and replace fossil fuels. Every ton of waste that is redirected to anaerobic digestion and processed by methanogens is a step towards reducing emissions and creating renewable energy.

As we grapple with the dual challenges of waste management and the transition to clean energy, methanogens offer a biological solution that tackles both at the same time. These ancient organisms, whose metabolism evolved billions of years before humans came into existence, now provide one of our most promising tools for sustainable development.

By understanding and optimizing methanogen communities in our engineered systems, we are able to harness the power of evolution to address modern challenges. The future of biogas technology, and a significant part of our renewable energy portfolio, relies on these tiny but powerful methane producers.

Commonly Asked Questions

There is a lot of curiosity surrounding anaerobic digestion and methanogen activity, especially from those who are new to the world of biogas technology. The questions below will address common misunderstandings and provide useful knowledge for those who are considering the use of biogas systems or are looking to improve their existing operations. All answers are based on the most recent scientific knowledge of methanogen biology and how they behave in engineered systems.

These questions also emphasize the interdisciplinary nature of anaerobic digestion, which encompasses microbiology, chemistry, engineering, and energy systems. To understand methanogens, it is necessary to combine knowledge from all these fields to get a complete understanding of how these specialized microorganisms work within the larger biogas production process.

Expert Tip: The health of methanogens can be quickly assessed by monitoring biogas composition. A methane content consistently above 50% indicates healthy methanogen activity, while declining methane percentage (especially below 45%) suggests methanogen inhibition requiring immediate attention. Regular biogas analysis provides an early warning system for digester problems.

For further information on optimizing methanogen performance in specific applications, detailed guides on substrate-specific methanogen management are available through our resource center. These materials provide tailored recommendations based on feedstock characteristics and digester configurations.

What is the time frame for methanogens to establish in a new anaerobic digester?

Normally, methanogens need about 3-6 weeks to establish stable populations in new digesters, which is a lot longer than other microbial groups involved in anaerobic digestion. This time frame can be reduced to 1-3 weeks by using high-quality inoculum from another active digester, especially one processing similar substrates.

Factors like temperature, initial pH, and the presence of trace elements have a significant impact on the speed of establishment, with optimal conditions potentially reducing startup time by 30-50%. For more insights on the role of methanogens in the biogas production process, you can explore further resources.

Is it possible for methanogens to thrive in home composting systems?

Traditional home composting systems are not conducive to methanogen activity because they create aerobic (oxygen-rich) conditions, which are lethal to methanogens. Although small anaerobic pockets can develop in poorly managed compost piles, they produce very little methane and are indicative of less than ideal composting conditions.

Proper methanogen cultivation requires sealed, oxygen-free systems specifically designed for anaerobic digestion, like home biogas units that sustain the necessary anaerobic environment.

Which foods or substrates are the most efficient at producing methane in digesters?

Substrates that are rich in fat usually generate the greatest methane yields, with theoretical production getting to 1,014 liters of methane for each kilogram of volatile solids. Used cooking oils, dairy waste, and residues from food processing that have a high fat content are especially efficient. Substrates that are rich in protein, such as waste from slaughterhouses, come next, with theoretical yields of 496 liters per kilogram, although practical yields can be limited by ammonia inhibition.

Materials that are rich in carbohydrates, such as waste from fruits and vegetables, have lower theoretical yields (373 liters per kilogram). However, they often yield better practical results because they degrade quickly and produce fewer inhibitors. To maximize methane production, many commercial digesters use co-digestion. This is a process where complementary substrates are combined to balance nutrient content, degradation rates, and inhibitor dilution. It also supports a diverse community of methanogens.

Do methanogens only exist in digesters or can they be found in the environment?

Methanogens are naturally found in many oxygen-free environments such as wetland sediments, rice paddies, deep sea hydrothermal vents, permafrost, and the digestive tracts of animals (especially ruminants like cattle).

The methanogens used in digesters are not artificially made but are instead concentrated from natural sources and given optimal conditions to maximize their natural ability to produce methane. Different environments have different methanogen communities that are adapted to specific conditions—thermophilic hot springs have heat-loving species like Methanothermobacter, while cold marine sediments have psychrophilic methanogens like Methanococcoides.

Do methanogens contribute to climate change outside of controlled digesters?

Outside controlled environments, methanogens are significant contributors to greenhouse gas emissions through natural and anthropogenic sources. Wetlands represent the largest natural methane source, with methanogen activity releasing approximately 150-225 million tons of methane annually. Human activities like rice cultivation and livestock production dramatically increase methanogen populations and subsequent methane emissions. Cattle alone host trillions of methanogens that produce about 80-100 million tons of methane yearly.

Anaerobic digestion technologies actually help to reduce the effects of climate change by capturing and using the methane that would otherwise be produced by methanogens during natural decomposition processes. Digesters provide a controlled environment that ensures that the methane is collected and used as renewable energy rather than being released into the atmosphere. This dual benefit of preventing methane emissions and producing renewable energy makes anaerobic digestion particularly useful for strategies to mitigate climate change.