Anaerobic digestion (AD) is a sustainable, natural process where microorganisms break down food waste in the absence of oxygen to produce renewable biogas and a nutrient-rich biofertiliser. It is widely recognised as a superior alternative to landfilling or incineration for food waste management.

Key Takeaways

- Anaerobic digestion converts food waste into renewable biogas and nutrient-rich fertilizer, providing a dual-purpose solution to waste management.

- This process can reduce greenhouse gas emissions by up to 95% compared to landfill disposal while creating energy that can power homes and businesses.

- Businesses implementing anaerobic digestion systems can achieve significant cost savings on waste disposal while potentially generating revenue from biogas production.

- The digestate byproduct serves as an organic fertilizer that reduces dependency on chemical alternatives and completes the circular economy model.

- With upcoming UK regulatory changes requiring separate food waste collection by 2025, anaerobic digestion offers a compliant and environmentally responsible solution.

Food waste is one of our most underutilized resources. When sent to landfills, it contributes to greenhouse gas emissions and misses an opportunity to create value. Anaerobic digestion transforms this problem into a sustainable solution by converting organic waste into renewable energy and nutrient-rich fertilizer.

The global food waste crisis is reaching critical levels, with approximately one-third of all food produced worldwide ending up as waste. This represents not only a humanitarian concern but an environmental emergency that demands immediate action. As landfill space decreases and climate change accelerates, finding efficient methods to process organic waste has become imperative for businesses, municipalities, and communities alike.

![]()

“Biogas: Converting Waste to Energy …” from www.eesi.org and used with no modifications.

Food Waste Crisis: Why Anaerobic Digestion Matters Now

Food waste decomposes in landfills under anaerobic conditions, but without the controls that would capture the resulting methane—a greenhouse gas 28 times more potent than carbon dioxide. This uncontrolled process contributes significantly to climate change, with food waste alone accounting for approximately 8-10% of global greenhouse gas emissions. The environmental impact extends beyond emissions to include wasted water, land, and energy used in food production, processing, and transportation.

The regulatory landscape is evolving rapidly. Many regions are implementing food waste bans from landfills, and by 2025, separate collection and treatment of food waste will become mandatory in numerous jurisdictions. These changes are pushing businesses to find alternative solutions for their organic waste streams. Anaerobic digestion presents a timely and comprehensive answer to these challenges, offering environmental benefits alongside economic advantages.

Beyond compliance, modern consumers and investors increasingly demand sustainability commitments from the companies they support. Organizations implementing anaerobic digestion demonstrate environmental leadership while potentially accessing green financing opportunities and improving their ESG (Environmental, Social, and Governance) profiles.

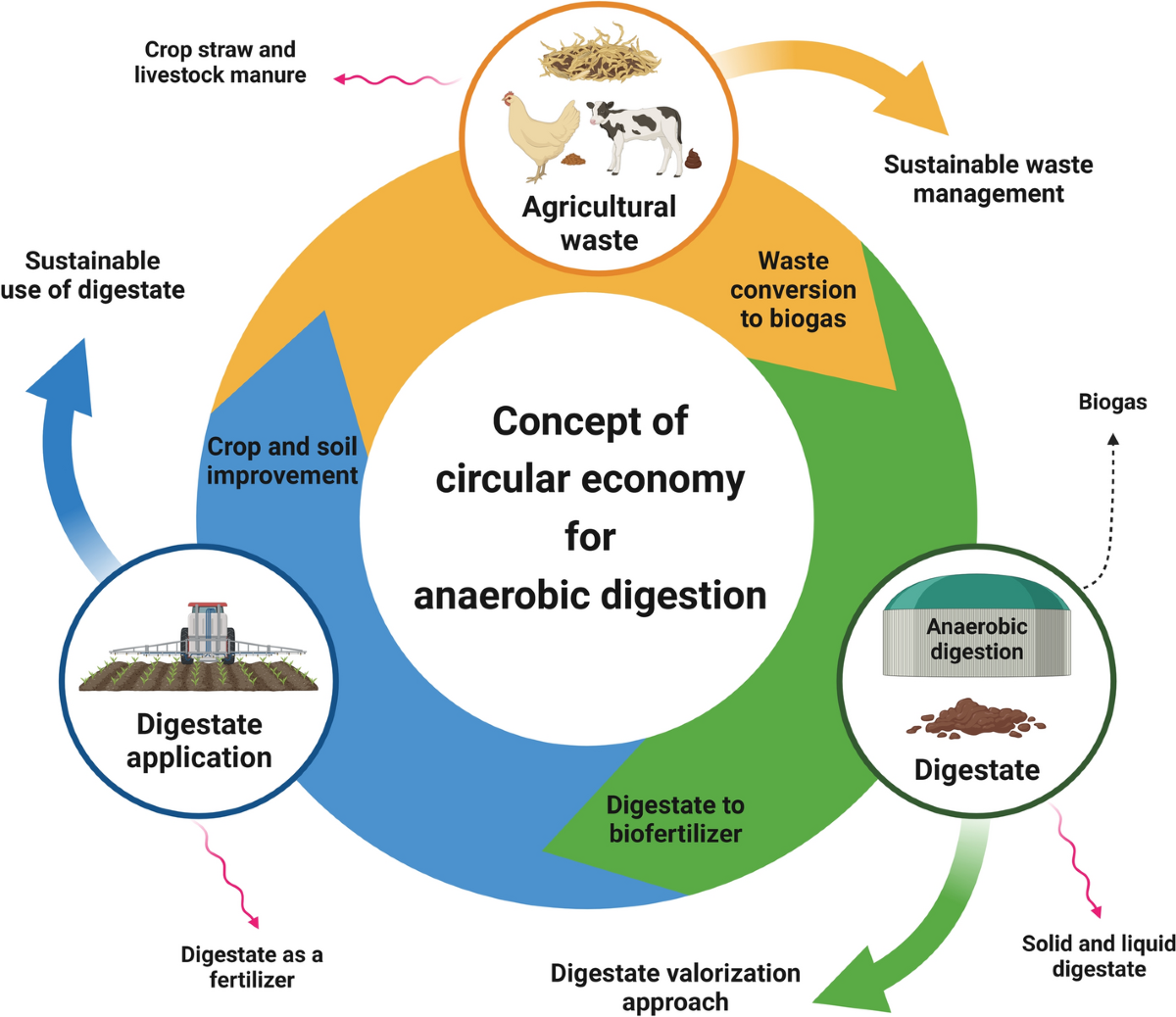

This process represents a perfect example of circular economy principles in action—where waste becomes a resource rather than a liability. Shapiro Environmental has been at the forefront of developing innovative waste management solutions that help businesses achieve sustainability goals while improving their bottom line.

How Anaerobic Digestion Transforms Food Waste

Anaerobic digestion works by harnessing the natural process in which microorganisms break down biodegradable material in the absence of oxygen. Unlike composting, which requires oxygen, anaerobic digestion happens in sealed, oxygen-free tanks called digesters. This controlled environment optimizes the production of biogas while containing odors and emissions that might otherwise be released into the atmosphere.

The Science Behind the Process

At its core, anaerobic digestion mimics and accelerates the same biological processes that occur in natural environments like swamps or in the digestive systems of ruminants. Inside the digester, specialized bacteria consume organic matter and convert it into simpler compounds. This microbial activity produces biogas—primarily a mixture of methane (50-70%) and carbon dioxide (30-50%), along with trace amounts of other gases. The liquid and solid residue that remains after digestion, called digestate, contains valuable nutrients that plants can readily absorb when applied to soil.

Four Stages of Anaerobic Digestion

The anaerobic digestion process unfolds through four distinct biological phases, each facilitated by different groups of microorganisms working in synergy. First is hydrolysis, where complex organic polymers like carbohydrates and proteins are broken down into simpler dissolved compounds. This is followed by acidogenesis, in which acidogenic bacteria convert these simple compounds into volatile fatty acids, alcohols, hydrogen, and carbon dioxide.

The third stage, acetogenesis, sees acetogenic bacteria transforming the products from the previous stage into acetic acid, hydrogen, and carbon dioxide. Finally, during methanogenesis, methanogenic archaea convert these compounds into methane and carbon dioxide, completing the process and producing biogas. This carefully orchestrated microbial symphony requires precise temperature, pH, and nutrient balance to operate efficiently.

Types of Digesters for Different Applications

Anaerobic digestion systems come in various configurations to accommodate different scales and types of food waste. Single-stage systems process all biological steps in one vessel, offering simplicity and lower costs for smaller operations. Multi-stage systems separate the process into different tanks optimized for each biological phase, providing better control and higher biogas yields for larger facilities.

Wet digesters handle pumpable slurries with 10-15% solid content, making them ideal for liquid food waste or mixed food waste that has been preprocessed. Dry digesters can handle material with 25-40% solid content, requiring less water and producing less wastewater but typically generating less biogas per unit of waste. The choice between continuous flow or batch systems depends on the regularity of waste input, available space, and operational preferences. Learn more about anaerobic digestion of food waste.

“Implementing anaerobic digestion isn't just environmentally responsible—it's economically smart. Our clients typically see a 30-50% reduction in waste management costs while generating renewable energy that can be used on-site or sold back to the grid.” – Waste Management Industry Expert

Environmental Benefits That Make a Real Difference

The environmental advantages of anaerobic digestion extend far beyond waste management. This process represents one of the most comprehensive solutions for addressing multiple environmental challenges simultaneously. By capturing methane that would otherwise escape into the atmosphere, anaerobic digestion directly combats one of the most potent greenhouse gases contributing to climate change.

Significant Reduction in Greenhouse Gas Emissions

When food waste decomposes in landfills, it produces methane that typically escapes into the atmosphere. Anaerobic digestion captures this methane in a controlled environment, reducing emissions by up to 95% compared to landfill disposal. The captured methane is then converted into usable energy, creating a double benefit: preventing a harmful greenhouse gas from entering the atmosphere while producing renewable energy that displaces fossil fuels. For every ton of food waste diverted from landfill to anaerobic digestion, approximately 0.5 to 1 metric ton of CO2 equivalent emissions are avoided.

Diversion of Organic Waste From Landfills

Food waste typically comprises 20-30% of what goes into landfills, taking up valuable space and creating environmental hazards. By diverting this waste stream to anaerobic digestion facilities, we extend the lifespan of existing landfills while reducing the need for new ones. This diversion also minimizes leachate production—the toxic liquid that forms as waste breaks down in landfills and can contaminate groundwater and soil. Anaerobic digestion provides a sustainable alternative that transforms what would be a disposal problem into a valuable resource.

Production of Renewable Energy

The biogas produced through anaerobic digestion represents a versatile renewable energy source. After purification, this biogas can be used to generate electricity, provide direct heat for industrial processes, or be upgraded to biomethane for injection into natural gas grids or use as vehicle fuel. A medium-sized anaerobic digestion facility processing 50,000 tons of food waste annually can generate enough electricity to power approximately 2,500 homes year-round. This renewable energy production displaces fossil fuels, further reducing carbon emissions and contributing to energy independence.

The energy produced through this process is notably reliable and consistent compared to intermittent renewables like solar or wind. Digesters operate 24/7, regardless of weather conditions, providing baseload power that complements other renewable energy sources. Many facilities are designed to be energy-positive, producing more energy than they consume for operations.

Creation of Nutrient-Rich Digestate

The digestate byproduct of anaerobic digestion contains valuable nutrients like nitrogen, phosphorus, and potassium that are essential for plant growth. When applied to agricultural land, this digestate serves as an organic fertilizer that improves soil health and structure while reducing reliance on synthetic fertilizers. The nutrients in digestate are in forms that are readily available for plant uptake, making it an efficient fertilizer option. Learn more about the egg-shaped anaerobic digester and its role in optimizing the digestion process.

Unlike raw food waste, properly processed digestate is stabilized, meaning it won't attract pests or produce odors when applied to land. The organic matter in digestate also increases soil carbon content, improving water retention capacity and resilience to drought or flooding. This completes a true circular economy model where nutrients from food are returned to the soil to grow more food.

Water Conservation Advantages

Anaerobic digestion offers significant water conservation benefits that are often overlooked. The process requires substantially less water than alternative waste treatment methods, particularly when compared to technologies that use water for cooling or emissions control. In fact, many anaerobic digestion systems can operate using the natural moisture content already present in food waste, eliminating the need for additional water inputs.

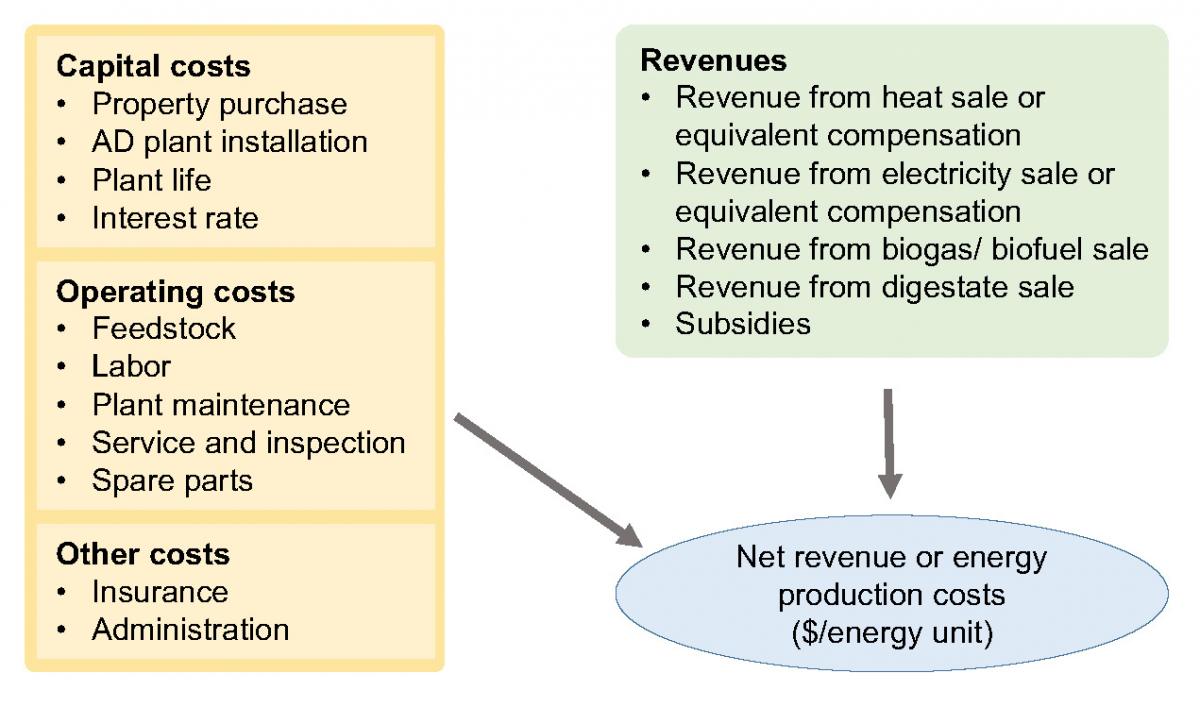

Economic Advantages of Implementing Anaerobic Digestion

Beyond its environmental merits, anaerobic digestion presents compelling economic benefits that make it attractive for businesses and municipalities alike. The financial case for anaerobic digestion has strengthened in recent years as technology costs have decreased while waste disposal costs and energy prices have risen. This convergence has created favorable conditions for investment in these systems, with many projects achieving positive returns on investment within 5-7 years.

“Anaerobic Digestion …” from ohioline.osu.edu and used with no modifications.

Waste Disposal Cost Savings

Waste disposal represents a significant and growing expense for food-related businesses, with landfill tipping fees increasing by an average of 3-5% annually in many regions. By diverting food waste to anaerobic digestion, companies can reduce or eliminate these disposal costs. Many jurisdictions have implemented or are planning to implement landfill taxes or outright bans on organic waste disposal, making traditional disposal increasingly expensive and potentially non-compliant. Organizations that proactively adopt anaerobic digestion solutions position themselves ahead of these regulatory curves while immediately reducing their waste management costs.

Revenue Generation From Biogas

The biogas produced through anaerobic digestion creates multiple revenue streams that can offset implementation costs. When upgraded to biomethane, this gas can be sold to natural gas utilities at premium prices, particularly in regions with renewable natural gas standards or credits. Alternatively, the biogas can be used to generate electricity that powers on-site operations, reducing utility bills, or is sold to the grid, especially where feed-in tariffs for renewable electricity exist.

Many jurisdictions offer renewable energy credits, carbon credits, or other financial incentives specifically for biogas production. These market-based instruments provide additional income streams that improve project economics. For food processors or other businesses with high energy demands, the ability to produce energy on-site from their own waste represents a significant competitive advantage in managing operational costs.

| Biogas Usage Option | Typical Revenue Potential | Additional Benefits |

|---|---|---|

| Electricity Generation | $0.05-0.15 per kWh | Renewable energy credits, on-site use savings |

| Biomethane Grid Injection | $5-25 per MMBtu | Renewable gas credits, carbon reduction credits |

| Vehicle Fuel | $2-4 per gallon equivalent | Low carbon fuel standard credits, fleet fuel savings |

| Combined Heat and Power | Varies by application | Highest overall efficiency, reduced heating costs |

The economics of biogas utilization vary significantly by location, based on local energy prices, incentive structures, and available infrastructure. A comprehensive feasibility study can identify the most profitable pathway for a specific project. Many successful operations implement flexible systems that can switch between different biogas uses depending on market conditions or seasonal demands.

Value of Digestate as Organic Fertilizer

The digestate produced through anaerobic digestion represents a valuable product that can be marketed to agricultural operations or used in landscaping applications. High-quality digestate can command prices ranging from $5-30 per ton depending on nutrient content and local market conditions. The fertilizer value alone can offset a significant portion of operational costs for anaerobic digestion facilities.

Beyond direct sales, some operations create premium soil amendment products by combining digestate with other materials or further processing it into specialized products like potting soil or pelleted fertilizers. These value-added products can achieve significantly higher market prices than raw digestate. For agricultural operations that implement on-site anaerobic digestion, the digestate provides direct savings by reducing or eliminating the need to purchase synthetic fertilizers, which have become increasingly expensive due to rising energy costs.

“Anaerobic digestion of agricultural …” from link.springer.com and used with no modifications.

Real-World Success Stories

Across the globe, organizations of all sizes have successfully implemented anaerobic digestion systems, proving their versatility and effectiveness in diverse contexts. These case studies demonstrate not only the environmental benefits but also the economic viability of this technology. The following examples highlight different approaches and applications that have yielded significant positive outcomes for communities, businesses, and the environment.

Municipal Food Waste Programs

The city of San Jose, California, implemented one of North America's largest municipal food waste digestion programs, processing 90,000 tons of commercial organic waste annually. This initiative diverts approximately 35% of the city's commercial waste stream from landfills while generating enough renewable energy to power 1,200 homes. The program has helped the city achieve 80% waste diversion while creating local jobs and providing stable waste management costs for businesses. Similar programs in European cities like Copenhagen and Milan have achieved even higher diversion rates, demonstrating the scalability of these systems for urban environments.

Industrial Scale Applications

Food and beverage manufacturers have been particularly successful in implementing anaerobic digestion for their high-strength organic waste streams. A major dairy processor in Wisconsin installed an on-site anaerobic digestion system that treats wastewater while capturing biogas for use in plant operations. This system reduced the plant's natural gas consumption by 65% and decreased wastewater treatment costs by 90%, achieving full return on investment in less than four years. The captured biogas now powers boilers that provide steam for pasteurization and cleaning processes, creating a perfect example of circular economy principles in action.

Community-Based Initiatives

- A farming cooperative in Vermont combined manure from five dairy farms with food waste from local processors and restaurants to fuel a centralized digester. This community-scale project generates enough electricity for 400 homes while producing high-quality liquid fertilizer that reduced synthetic fertilizer use across 2,000 acres of farmland.

- An urban community digester in Toronto collects food waste from restaurants, grocery stores, and residential buildings within a 5-mile radius. The facility processes 40,000 tons of food waste annually while providing educational programs on sustainable waste management for local schools and community groups.

- A university campus in Washington state implemented a small-scale digester that processes cafeteria waste and landscaping trimmings, generating biogas used for cooking in campus dining facilities. This closed-loop system serves as a living laboratory for students in environmental science and engineering programs.

These diverse examples demonstrate the adaptability of anaerobic digestion technology to different scales, waste streams, and community needs. What unites these success stories is careful planning, stakeholder engagement, and a commitment to both environmental and economic sustainability. Many successful projects started small and expanded incrementally as they demonstrated value and built community support.

Public-private partnerships have proven particularly effective in developing these facilities, combining municipal waste management goals with private sector expertise and investment capacity. In many cases, grants or incentives for renewable energy production or waste diversion provided the financial boost needed to achieve favorable project economics in the early stages.

Educational components and transparent operations have helped these projects gain community acceptance, addressing potential concerns about odors or truck traffic through proper facility design and operational protocols. The most successful facilities regularly host tours and maintain open communication with neighboring communities.

Perhaps most importantly, these successful projects demonstrate the potential for anaerobic digestion to create multiple forms of value simultaneously—environmental, economic, educational, and social—making them truly sustainable in every sense of the word.

Getting Started With Anaerobic Digestion

Implementing anaerobic digestion doesn't have to be overwhelming. Whether you're a municipality, a business owner, or a community organizer, there are scalable approaches to harness the benefits of this technology. The key is to match the scale and type of system to your specific waste stream, available space, and financial resources. With proper planning and potentially phased implementation, organizations of any size can successfully transition to this sustainable waste management approach.

Small-Scale Solutions for Homes and Communities

For smaller applications, pre-fabricated modular digesters are available that can process from 1 to 10 tons of food waste weekly. These systems require minimal space and can often be installed within existing waste management areas. Community gardens, schools, and small food businesses can utilize these compact systems to process their organic waste on-site, producing biogas for cooking or heating while creating nutrient-rich fertilizer for local use. Initial investments for these small-scale systems typically range from $10,000 to $100,000, with many qualifying for grants or subsidies that significantly reduce out-of-pocket costs.

Medium to Large-Scale Implementation Steps

For commercial and municipal applications, implementation follows a structured approach to ensure system efficiency and economic viability. Begin with a comprehensive waste audit to quantify and characterize your organic waste stream, as this data will inform system design and capacity requirements. Next, conduct a feasibility study that evaluates site constraints, energy needs, digestate utilization options, and regulatory requirements to determine the most appropriate technology configuration.

- Secure necessary permits and approvals from environmental, zoning, and utility authorities

- Develop detailed engineering plans and system specifications

- Establish feedstock supply agreements and end-product utilization pathways

- Create operational protocols and train staff on system management

- Implement comprehensive monitoring and maintenance programs

Construction timelines typically range from 12-24 months for medium to large facilities, with commissioning and optimization requiring an additional 3-6 months. During this critical startup period, the microbial communities essential for efficient digestion are established and stabilized. Many successful projects implement a phased approach, beginning with a pilot system that can be expanded as operational experience grows and additional waste streams are secured.

Integration with existing waste management infrastructure is crucial for operational efficiency. This includes considerations for collection logistics, preprocessing equipment for contamination removal, and digestate processing capabilities. The most successful implementations maintain flexibility in design to accommodate variations in waste volume and composition, as well as potential future expansion or technology upgrades.

Finding Financial Support and Incentives

Numerous financial resources exist to support anaerobic digestion projects, substantially improving their economic feasibility. Federal programs like USDA's Rural Energy for America Program (REAP) and the Environmental Protection Agency's various grant programs offer significant funding opportunities. Many states and local governments provide additional incentives, including investment tax credits, low-interest loans, and expedited permitting for renewable energy projects. Renewable energy credits, carbon offset markets, and specific biogas production incentives create ongoing revenue streams that improve long-term project economics.

Public-private partnerships have proven particularly effective for municipal projects, combining government waste management objectives with private sector financing and operational expertise. Power purchase agreements for the renewable electricity generated can secure predictable revenue streams that satisfy lenders and investors. For food manufacturers and processors, the ability to treat waste on-site while generating energy for operations often presents the most compelling business case, with typical payback periods of 3-7 years depending on waste volumes and energy costs.

Overcoming Common Challenges

While anaerobic digestion offers tremendous benefits, successful implementation requires addressing several common challenges. Contamination in feedstock—particularly plastics, metals, and glass in food waste—can damage equipment and reduce system efficiency, making effective pre-processing and source separation crucial. Biological system stability requires careful monitoring and management of factors like pH, temperature, and loading rates, especially when feedstock composition changes. Community concerns about odors, traffic, or perceived safety issues can be successfully addressed through thoughtful facility design, transparent communication, and community engagement throughout the project development process.

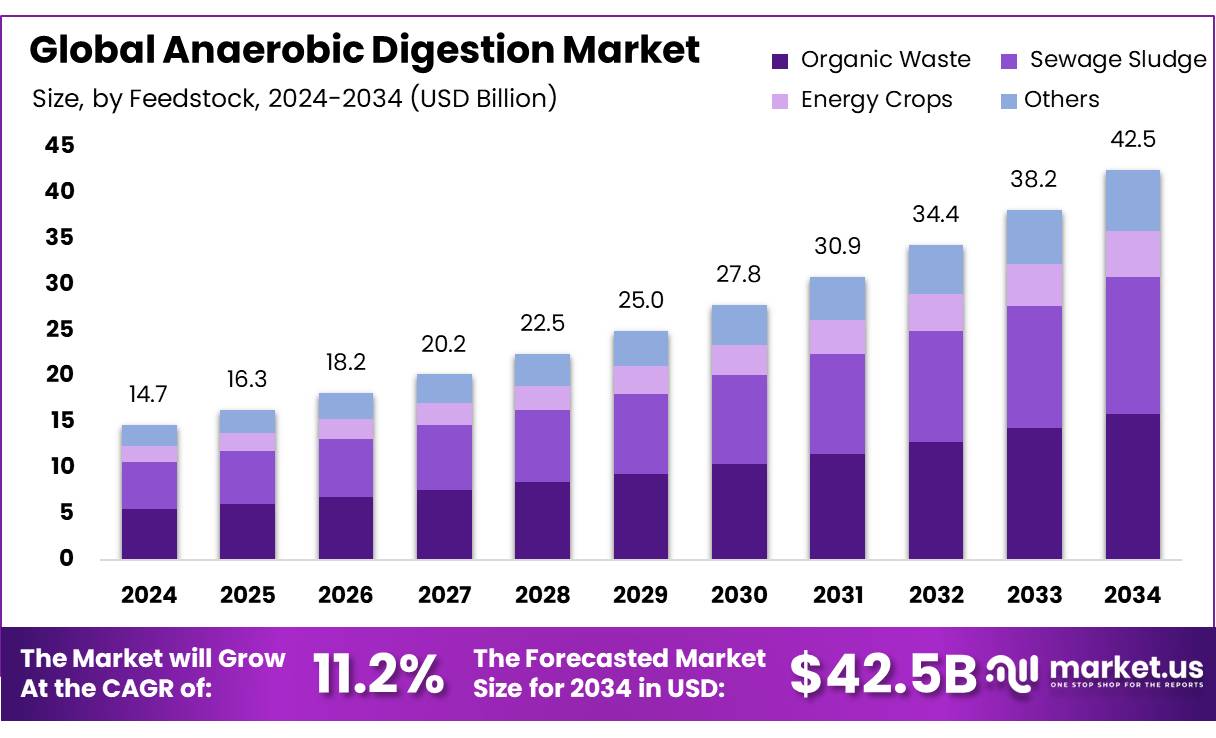

“Anaerobic Digestion Market Size, Share …” from market.us and used with no modifications.

Future of Food Waste Management Through Anaerobic Digestion

The future of anaerobic digestion looks increasingly promising as technology advances and climate imperatives accelerate. Emerging innovations include high-efficiency modular systems that can be deployed quickly in various settings, advanced monitoring technologies using artificial intelligence to optimize process control, and integrated systems that combine anaerobic digestion with other treatment technologies for maximum resource recovery. These developments are making systems more efficient, less expensive, and adaptable to diverse waste streams and operating environments. For example, anaerobic digestion in wastewater treatment is a growing area of focus, providing significant environmental benefits.

Regulatory trends worldwide increasingly favor anaerobic digestion through landfill diversion mandates, renewable energy incentives, and carbon pricing mechanisms. In the United States, states like California, Massachusetts, and Vermont have implemented organic waste disposal bans that effectively mandate solutions like anaerobic digestion. The European Union's Circular Economy Package includes ambitious targets for food waste reduction and recycling that are driving widespread adoption. These policy frameworks, combined with growing corporate sustainability commitments and consumer awareness, are creating a favorable environment for continued expansion of this technology across sectors and regions.

Frequently Asked Questions

As anaerobic digestion becomes more mainstream, potential adopters often have similar questions about implementation, operations, and benefits. The following answers address the most common inquiries we receive from businesses, municipalities, and communities considering this technology.

How much food waste is needed to make anaerobic digestion worthwhile?

The economic viability threshold varies depending on system type, energy prices, and available incentives. Generally, centralized community or commercial digesters become economically viable with consistent access to at least 5-10 tons of food waste daily. Smaller modular systems designed for restaurants or grocery stores can be viable with as little as 500-1,000 pounds daily. Many operations improve economics by combining food waste with other organic materials like manure, yard waste, or food processing byproducts, creating optimal carbon-to-nitrogen ratios while increasing overall volume.

What types of food waste work best in anaerobic digesters?

Most food waste types perform well in anaerobic digesters, though fats, oils, and greases (FOG) typically produce the highest biogas yields, generating up to 1.5 times more methane than other food waste streams. Fruit and vegetable waste digest quickly but produce somewhat lower gas yields, while protein-rich wastes provide excellent nutrient balance. Starchy materials like bread and pasta offer good energy content but may require mixing with higher-moisture materials for optimal processing.

Modern digester designs can accommodate mixed food waste streams, though some materials like eggshells, large bones, and high-lignin waste (like corn cobs or avocado pits) may require pre-processing or longer retention times. Many facilities actually benefit from receiving diverse waste inputs, as this provides better nutrient balance and process stability than single-stream feedstocks. The key is consistent pre-processing to remove contaminants and appropriate blending to maintain optimal digestion conditions.

How does the biogas from anaerobic digestion get used?

Biogas utilization pathways offer flexibility based on local needs and market conditions. In its raw form, biogas can fuel specially designed boilers to generate heat for industrial processes or space heating. When processed through combined heat and power (CHP) systems, it generates both electricity and thermal energy, achieving overall efficiencies of 80-90%. These systems range from small 50kW engines suitable for on-site use to multi-megawatt turbines for large centralized facilities.

Upgrading biogas to biomethane (renewable natural gas) by removing carbon dioxide and impurities creates a product chemically identical to conventional natural gas that can be injected into utility pipelines or compressed for use as vehicle fuel. This purification process typically recovers 95-98% of the methane content while producing a gas that meets strict utility standards. The optimal pathway depends on local energy prices, available infrastructure, and incentive structures, with many facilities maintaining the flexibility to utilize multiple pathways depending on seasonal demands and market conditions.

Are there any odor issues with anaerobic digestion facilities?

Modern anaerobic digestion facilities are designed as fully enclosed systems that effectively contain potential odors. The digestion process itself occurs in sealed, oxygen-free tanks that prevent the escape of odors during normal operation. Potential odor sources like waste receiving areas and digestate handling zones are typically equipped with negative air pressure systems and biofilters that capture and treat any odorous compounds before air is released to the environment.

Well-managed facilities implement comprehensive odor management plans that include regular monitoring, preventative maintenance, and rapid response protocols for any issues that arise. Most facilities maintain buffer zones and strategic site layouts that minimize potential impacts on neighbors. Experience has shown that properly designed and operated anaerobic digestion facilities generate significantly fewer odor complaints than composting operations or traditional waste management facilities processing the same materials.

“Troubleshoot Odour Control Systems …” from https://lastraddie.gumroad.com/l/kujwt and used with no modifications.

How does anaerobic digestion compare to composting for food waste?

While both anaerobic digestion and composting recycle organic matter, they offer different advantages depending on specific goals and circumstances. Anaerobic digestion excels in energy recovery, capturing 70-80% of the potential energy in food waste as biogas while producing liquid fertilizer with readily available nutrients. It requires less land, operates year-round regardless of weather, and fully contains the process, eliminating runoff concerns. The capital costs are typically higher, but operational expenses can be offset by energy and fertilizer revenues.

Composting requires less capital investment initially and handles a wider range of materials, including yard waste and woody debris that don't perform well in digesters. It produces a solid soil amendment that builds long-term soil carbon and structure but captures no energy value and may face challenges with odor management and space requirements. Many advanced waste management systems now implement hybrid approaches that digest high-energy food waste first to capture biogas, then compost the remaining solids with yard waste to produce valuable soil amendments.

- Anaerobic digestion captures energy and nutrients while minimizing emissions

- Composting builds soil structure and requires lower initial investment

- Integrated systems combining both technologies maximize resource recovery

- Local conditions, including climate, available space, and energy prices influence the optimal choice

- Regulatory requirements and available markets for end products should inform technology selection

Understanding the distinct advantages of each technology allows organizations to select the most appropriate solution based on their specific waste characteristics, available space, climate conditions, and desired outcomes. Many regions benefit from having both options available within their waste management infrastructure, directing different organic waste streams to the most appropriate processing technology. For instance, food waste packaging contamination can pose challenges for anaerobic digestion, making it crucial to choose the right processing method.

The anaerobic digestion industry continues to evolve, with technologies becoming more efficient and adaptable to various waste streams and operating environments. What remains constant is the tremendous potential for this process to transform a waste management challenge into an opportunity for renewable energy generation, nutrient recycling, and climate protection. As regulatory pressures increase and technology costs decline, anaerobic digestion is positioned to become a cornerstone of sustainable organic waste management worldwide.

By diverting food waste from landfills to anaerobic digestion systems, we simultaneously address multiple environmental challenges while creating economic opportunities. The process exemplifies circular economy principles by recovering both energy and nutrients from what was once considered merely waste. Whether implemented at household, community, or industrial scale, anaerobic digestion represents a proven, practical solution for sustainable food waste management that benefits both our environment and economy.

For businesses and communities seeking comprehensive waste management solutions that align with sustainability goals while offering tangible economic benefits, anaerobic digestion deserves serious consideration. Shapiro Environmental provides expert consultation on selecting and implementing the right organic waste management system for your specific needs, helping you transform waste challenges into sustainable opportunities.