Anaerobic Digestion in Wastewater Treatment: Anaerobic digestion (AD) is a wastewater treatment process that uses microorganisms in the absence of oxygen to break down organic matter, producing biogas (primarily methane and carbon dioxide) and a nutrient-rich liquid digestate.

This method is particularly effective for high-organic-load wastewater, like sewage sludge, and transforms waste into valuable resources like renewable energy and fertilizer. AD is more energy-efficient than aerobic treatment and helps reduce greenhouse gas emissions by capturing methane.

Anaerobic Digestion in Wastewater Treatment – Article-At-A-Glance

- Anaerobic digestion transforms wastewater treatment by significantly reducing COD/BOD while producing valuable biogas energy.

- Unfortunately, it does not remove ammonia and is therefore only useful for the treatment of sludge produced by the standard method used for aerobic treatment of sewage across the globe. Nevertheless, the use of Continuously Stirred Tank Reactors (CSTRs) at municipal sewage treatment works is a proven success.

- UASB reactors have proven highly effective for industrial wastewater treatment, with applications spanning Europe, Asia, and the Americas.

- EGSB systems offer superior performance for low-strength wastewaters and can operate effectively at temperatures as low as 10°C.

- Multi-phase anaerobic digestion (staging) can dramatically improve treatment efficiency by separating acidogenesis and methanogenesis processes.

Anaerobic digestion has revolutionized the wastewater treatment industry over the past century, offering sustainable solutions for processing industrial effluents and municipal sewage while recovering valuable energy.

Unlike conventional aerobic treatments that require significant energy input, anaerobic processes produce biogas while effectively reducing contaminants. This biological process works by breaking down organic matter in oxygen-free environments through a complex consortium of microorganisms working in symbiotic harmony.

Wastemaster Technologies has been at the forefront of implementing cutting-edge anaerobic digestion systems for wastewater treatment facilities worldwide, helping operations meet increasingly stringent environmental regulations while reducing operational costs.

Their expertise spans the full range of anaerobic technologies from traditional Upflow Anaerobic Sludge Bed (UASB) systems to advanced Expanded Granular Sludge Bed (EGSB) configurations and optimized staged reactors.

![]()

“Anaerobic Digestion of Wastewater” from water.mecc.edu and used with no modifications.

Anaerobic Digestion: Transforming Wastewater Treatment

Anaerobic digestion represents a paradigm shift in wastewater management, delivering multiple benefits that extend far beyond simple treatment. By harnessing microbial metabolism in oxygen-free environments, these systems convert waste into resources.

The process removes Chemical Oxygen Demand (COD) and Biological Oxygen Demand (BOD) while producing methane-rich biogas that can offset facility energy costs. Additionally, anaerobic systems typically require less space, generate significantly less sludge, and have lower operational requirements than conventional aerobic treatments.

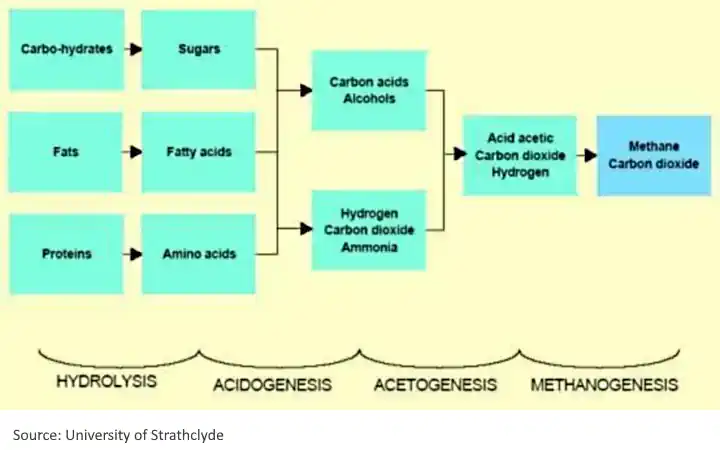

The microbiology behind anaerobic digestion involves four key stages: hydrolysis, acidogenesis, acetogenesis, and methanogenesis. During hydrolysis, complex organic compounds are broken down into simpler molecules by extracellular enzymes.

Acidogenic bacteria then convert these compounds into volatile fatty acids, alcohols, and hydrogen. In acetogenesis, these intermediate products are transformed into acetic acid, hydrogen, and carbon dioxide. Finally, methanogenic archaea convert these compounds into methane and carbon dioxide, completing the biogas formation process.

Over decades of implementation, anaerobic digestion has proven remarkably adaptable to various wastewater streams, from high-strength industrial effluents to dilute municipal sewage.

The technology continues to evolve, with innovations in reactor design, granular sludge development, and process control dramatically expanding its applicability.

Modern systems now operate efficiently in conditions previously considered challenging, including low temperatures and with wastewaters containing complex or inhibitory compounds.

- Reduces COD/BOD while producing renewable energy

- Operates with minimal energy input compared to aerobic processes

- Generates 5-10 times less sludge than aerobic treatments

- Handles high organic loading rates efficiently

- Can treat complex industrial wastewaters containing inhibitory compounds

“Anaerobic Digestion for Sewage Sludge …” from www.cambi.com and used with no modifications.

How Upflow Anaerobic Sludge Bed (UASB) Reactors Have Specific Uses in Wastewater Processing

UASB reactors have established themselves as a cornerstone technology in anaerobic wastewater treatment, particularly for industrial applications. These systems have been successfully implemented across diverse sectors including food and beverage, pulp and paper, textile, and chemical manufacturing.

The popularity of UASB technology stems from its robust performance, relatively simple design, and ability to handle low to moderate strength wastewaters.

Core UASB Operating Principles

The UASB reactor operates on a simple yet ingenious concept: wastewater flows upward through a dense bed of anaerobic granular sludge where biological degradation occurs. As the wastewater rises, it encounters increasingly active microbial communities that break down organic pollutants.

The system's effectiveness hinges on the development of dense, well-settling granular biomass that naturally forms within the reactor under appropriate conditions. These granules contain various microbial populations arranged in layers that facilitate the sequential breakdown of complex organics into methane and carbon dioxide.

The upflow design and specific velocity parameters create hydraulic selection pressure that favors the formation and retention of these high-performance granules while allowing treated water to exit the system.

Optimal Conditions for UASB Performance

UASB reactors perform optimally under specific operational conditions that maximize microbial activity and process stability. Temperature control is critical, with mesophilic conditions (30-38°C) generally preferred for most industrial applications, though thermophilic operation (50-60°C) can accelerate treatment rates for suitable wastewaters.

pH management between 6.8-7.5 prevents inhibition of methanogenic microorganisms, which are particularly sensitive to acidic conditions. Upflow velocity typically ranges from 0.5-1.5 m/h, providing the ideal balance between sufficient mixing and preventing biomass washout. Organic loading rates can reach 10-15 kg COD/m³·day in well-established systems, making UASB reactors remarkably space-efficient compared to conventional technologies.

Continuous Stirred Tank Reactors (CSTRs) for Sewage Sludge Treatment at Municipal (Aerobic) Wastewater Treatment Facilities

Continuous Stirred Tank Reactors (CSTRs) represent the traditional workhorse of municipal wastewater treatment facilities worldwide, particularly for processing sewage sludge generated during aerobic treatment.

These robust systems consist of large, enclosed tanks equipped with mechanical mixing apparatus that maintains homogeneous conditions throughout the digester volume. Unlike the more specialized UASB and EGSB reactors, CSTRs operate with complete mixing, ensuring that all microorganisms have equal access to substrate and preventing stratification within the reactor.

The fundamental operating principle of CSTRs involves maintaining suspended anaerobic biomass in constant contact with incoming waste sludge under carefully controlled conditions. These systems typically operate at mesophilic temperatures (35-38°C), with hydraulic retention times ranging from 15-25 days depending on sludge characteristics and treatment objectives.

While CSTRs don't achieve the high loading rates of granular sludge systems like UASBs, they excel in reliability, operational simplicity, and the ability to handle variable sludge compositions that would challenge more specialized anaerobic technologies.

How CSTRs Reduce and Sanitize Sludge Mass (RAS) for Safe Disposal to Land or Incineration

The primary function of CSTRs in municipal settings is the stabilization and volume reduction of Return Activated Sludge (RAS) and primary sludge. Through the anaerobic digestion process, these reactors achieve 40-60% volatile solids reduction, substantially decreasing the total mass requiring disposal. This transformation is critical for municipalities facing rising disposal costs and diminishing landfill capacity.

The digestion process also naturally inactivates most pathogens, particularly when operated at higher temperatures, helping facilities meet Class B biosolids standards for land application without additional treatment steps.

Beyond volume reduction, CSTRs play a vital role in transforming problematic waste sludge into beneficial biosolids. The process improves dewaterability, reduces odor potential, and creates a more stable end product suitable for agricultural applications.

Anaerobic digestion in CSTRs also significantly reduces greenhouse gas emissions compared to alternative disposal methods, as captured methane is typically utilized for energy production rather than released to the atmosphere. For facilities employing incineration, the volume reduction achieved through digestion translates directly into lower fuel requirements and operating costs.

- Achieves 40-60% reduction in volatile solids content

- Produces Class B biosolids suitable for agricultural use

- Improves sludge dewaterability, reducing subsequent processing costs

- Generates biogas with 60-65% methane content for energy recovery

- Significantly reduces greenhouse gas emissions compared to untreated sludge disposal

Modern CSTR systems incorporate sophisticated monitoring and control systems that optimize the biological process while minimizing operator intervention.

Advanced instrumentation tracks parameters including temperature, pH, volatile acids, alkalinity ratios, and gas production, allowing for real-time adjustments to maintain optimal conditions.

Many facilities now employ co-digestion strategies, adding compatible organic wastes like food processing residuals or FOG (fats, oils, and grease) to increase biogas production while providing additional tipping fee revenue.

Optimal Conditions for CSTR Performance

CSTR performance hinges on maintaining precise environmental conditions that balance the needs of diverse microbial communities.

Optimal operation typically involves temperatures of 35-38°C (mesophilic) or 50-55°C (thermophilic), pH between 7.0-7.8, and volatile acids to alkalinity ratios below 0.3. Loading rates generally range from 1.6-4.8 kg VS/m³·day, with mixing energy inputs of 5-8 W/m³ providing sufficient homogenization without damaging microbial aggregates.

Advanced facilities implement feeding strategies that distribute substrate addition throughout the day rather than batch feeding, reducing the risk of localized overloading and associated pH drops that can inhibit methanogenesis.

Why CSTRs are by Far the Most Popular Choice for Municipal Wastewater Treatment Facilities Globally

CSTRs dominate the municipal sector due to their operational reliability, flexibility in handling variable waste streams, and proven long-term performance.

Unlike more specialized anaerobic systems, CSTRs accommodate fluctuations in sludge quality and quantity without process upset, making them ideally suited to the dynamic conditions typical of municipal operations.

Their relatively simple design translates to lower construction costs, reduced mechanical complexity, and straightforward maintenance requirements that align with the capabilities of typical municipal staff.

Perhaps most importantly, the extensive operational history of CSTRs provides municipalities with performance certainty and regulatory familiarity that newer technologies cannot match, making them the safe choice for risk-averse public utilities balancing treatment requirements with fiscal responsibility.

Staging: Multi-Phase Digestion for Better Results

Staging represents a significant advancement in anaerobic digestion technology, addressing fundamental biological limitations of single-stage systems.

By physically separating the major steps of anaerobic digestion into discrete reactor environments, staged systems optimize conditions for each microbial group, dramatically improving overall process efficiency and stability.

This approach recognizes that the diverse microorganisms involved in anaerobic digestion—hydrolytic bacteria, acidogens, acetogens, and methanogens—have different optimal growth conditions and kinetic requirements that cannot be simultaneously satisfied in a single reactor. For more on how this process impacts waste management, read about anaerobic digestion reducing landfill reliance.

The concept of staging draws inspiration from natural ecosystems where spatial separation of biological processes creates multiple specialized niches. In wastewater treatment, this translates to dedicated reactors for acidification (typically operating at lower pH and shorter retention times) followed by methanogenic reactors (maintained at neutral pH and longer retention times).

This configuration prevents the inhibition of methanogens by transient accumulation of volatile fatty acids during hydrolysis and acidogenesis, a common cause of digester upset in conventional single-stage systems.

Advanced staged configurations may incorporate three or more phases with recirculation streams that optimize treatment while maintaining process stability even under fluctuating loading conditions.

Why Single-Stage Digestion Falls Short

Single-stage digesters inherently force incompatible microbial communities to coexist in a compromised environment that fully satisfies none of them. Acidogenic bacteria thrive at pH 5.5-6.5 and produce volatile fatty acids rapidly, while methanogens require pH 6.8-7.5 and convert these acids more slowly.

This mismatch in optimal conditions and conversion rates creates a perpetual biological bottleneck, limiting overall system performance and creating vulnerability to process upsets. During loading increases, acid production can quickly outpace methane formation, leading to pH drops, methanogenic inhibition, and potential system failure—a scenario that dramatically constrains the practical loading rates of conventional digesters.

Beyond performance limitations, single-stage systems suffer from poor response to transient conditions and offer limited operational control. Operators must maintain conservative loading rates to accommodate worst-case scenarios, sacrificing potential capacity during normal operations.

This conservative approach translates directly into larger required reactor volumes, increased capital costs, and suboptimal biogas production. For wastewaters containing inhibitory compounds or those with particularly high protein or lipid content, the limitations of single-stage systems become even more pronounced, as intermediate breakdown products can accumulate to inhibitory levels before methanogenesis can process them.

Separating Acidogenesis from Methanogenesis

The cornerstone of staged digestion involves creating dedicated environments for acidogenic and methanogenic populations, allowing each to operate under optimal conditions.

First-stage acidogenic reactors typically operate with hydraulic retention times of 12-24 hours, pH between 5.5-6.5, and high mixing intensity to maximize contact between hydrolytic enzymes and particulate substrates.

These conditions accelerate the breakdown of complex organics into simpler molecules and volatile fatty acids, achieving in hours what might take days in a conventional system.

The acidogenic phase also serves as a biological buffer, absorbing loading fluctuations and preventing shock loads from reaching sensitive methanogenic populations in subsequent stages. For more information on the anaerobic digestion process, visit this detailed explanation.

Methanogenic phases in staged systems receive a consistent, partially pre-processed feed stream that allows for stable operation even when the primary input to the system fluctuates significantly.

These reactors maintain strict pH control between 6.8-7.5, operate with longer retention times of 5-15 days, and often employ biomass retention strategies to enrich for slower-growing methanogenic populations.

By receiving a feed already rich in volatile fatty acids and with complex organics already hydrolyzed, methanogenic reactors can achieve consistent, high-rate conversion to biogas without the periodic inhibition events common in single-stage systems.

Research consistently demonstrates that properly designed two-phase systems can achieve 25-50% higher organic loading rates while maintaining equal or better treatment efficiency compared to single-stage alternatives.

This translates directly into smaller required reactor volumes, reduced capital costs, and higher biogas yields per unit of waste processed. Advanced monitoring and control systems further enhance these advantages by allowing real-time adjustment of operating conditions in each phase to maintain optimal biological activity regardless of influent characteristics.

Performance Comparison: Single vs. Two-Phase Digestion

Parameters measured during a 12-month study at a food processing facility:

Performance Metric Single-Phase UASB Two-Phase System Improvement Max. Stable OLR (kg COD/m³·d) 8.5 12.7 +49% COD Removal Efficiency 83% 91% +8% Methane Yield (m³/kg COD removed) 0.31 0.34 +10% System Stability (% time in steady state) 78% 96% +18% Recovery Time After Shock Load (days) 7.2 2.8 -61%

Practical Configurations for Staged Reactors

Staged anaerobic systems have evolved into several proven configurations optimized for different wastewater characteristics and treatment objectives.

The UASB+EGSB combination pairs a robust first-stage UASB handling the bulk of particulate matter with a high-rate EGSB polishing stage for dissolved organics.

AF+AH (Anaerobic Filter + Anaerobic Hybrid) systems excel with wastewaters containing higher suspended solids, utilizing media in both stages to support biomass growth and retention.

For particularly challenging industrial wastewaters, three-phase systems incorporating specialized pre-acidification, main digestion, and polishing stages deliver exceptional performance by creating highly specialized microbial communities adapted to specific substrate fractions and potential inhibitors present in the wastewater stream.

Real-World Performance Metrics and Case Studies

- COD removal efficiencies of 75-95% depending on wastewater characteristics

- Biogas production of 0.25-0.35 m³ CH₄/kg COD removed

- Energy recovery potential of 1.5-2.5 kWh per kg COD removed

- Treatment costs 40-60% lower than conventional aerobic treatments

- Greenhouse gas emissions reduced by 80-90% compared to aerobic alternatives

The theoretical benefits of anaerobic digestion are conclusively validated through hundreds of successful full-scale implementations across diverse industries and geographical regions.

Performance data consistently demonstrates that modern anaerobic systems deliver on their promises of efficient treatment, energy recovery, and operational stability. Treatment facilities report not only meeting discharge requirements but achieving significant operational cost savings through reduced energy consumption, minimal sludge production, and biogas utilization for heat and power generation.

Anaerobic technology has proven particularly transformative for food and beverage processors, where high-strength organic wastewaters once represented a significant disposal challenge and expense.

Breweries, dairy processors, and confectionery manufacturers have reported payback periods of 2-5 years for anaerobic installations, primarily through reduced surcharges for municipal discharge and energy cost savings.

These economic benefits come alongside substantial environmental improvements, with many facilities achieving carbon-neutral or even carbon-negative wastewater treatment through efficient biogas utilization.

Perhaps most impressively, modern anaerobic systems have demonstrated remarkable operational longevity, with many installations continuing to perform at or above design specifications after 15-20 years of continuous operation.

This exceptional service life, combined with minimal maintenance requirements and steady performance, has firmly established anaerobic digestion as not merely an alternative but often the preferred treatment approach for suitable wastewaters.

The technology continues to evolve, with ongoing innovations focused on expanding application ranges, improving energy efficiency, and developing systems capable of recovering nutrients and other valuable resources beyond just energy.

Industrial Wastewater Treatment Success Stories

A beverage manufacturing facility in Brazil implemented a two-stage UASB+EGSB system to treat high-strength wastewater with COD concentrations averaging 12,000 mg/L.

The system consistently achieves 95% COD removal while producing 5,800 m³ of biogas daily, which powers a 600 kW cogeneration system that satisfies 40% of the facility's electricity demands and provides process heating.

The installation eliminated wastewater surcharges exceeding $1.2 million annually and achieved full return on investment within 3.2 years. Particularly noteworthy is the system's resilience to production fluctuations, maintaining stable performance despite seasonal variations in production volumes and product mix that create significant variations in wastewater characteristics.

A pharmaceutical manufacturer in India faced strict discharge requirements while dealing with wastewater containing potentially inhibitory compounds. Their three-phase anaerobic system incorporates specialized pre-treatment, staged digestion, and aerobic polishing to achieve consistent compliance with discharge standards below 50 mg/L BOD.

The anaerobic phases achieve 85% COD reduction despite the challenging wastewater matrix, demonstrating how modern staged systems can successfully treat complex industrial effluents previously considered unsuitable for biological treatment.

Advanced process control and online monitoring have been key to maintaining stable performance with this particularly challenging wastewater stream.

Municipal Applications and Results

The city of Cali, Colombia operates one of the world's largest UASB installations for direct sewage treatment, processing 400,000 m³/day of municipal wastewater.

Despite relatively low influent concentrations (average COD 380 mg/L) and temperature variations, the system consistently achieves 70-80% COD removal while generating sufficient biogas to power all treatment plant operations with excess electricity sold to the grid.

The facility demonstrates that anaerobic technology can effectively treat municipal wastewater at full scale while offering significant energy advantages over conventional activated sludge processes. Particularly in developing regions with warm climates, this approach presents an economically viable pathway to improved sanitation with lower operational costs than traditional aerobic alternatives.

Cold Climate Implementations

Contrary to traditional limitations, innovative anaerobic systems now demonstrate impressive performance even in cold climates.

A food processing facility in northern Europe employs a heated EGSB system that maintains 85% COD removal efficiency while treating wastewater at ambient temperatures as low as 12°C. The installation utilizes recovered biogas for reactor heating, maintaining optimal biological activity year-round without external energy inputs.

Advanced granular sludge with specialized cold-adapted microbial communities provides exceptional treatment capacity despite challenging thermal conditions. The facility's experience demonstrates that with proper design and biomass management, anaerobic treatment remains viable even in regions previously considered unsuitable due to low ambient temperatures. Learn more about maximizing biogas output from food waste in cold climates.

Treatment Efficiency Comparison

When comparing treatment efficiencies across anaerobic technologies, clear patterns emerge that inform selection for specific applications. UASB systems typically achieve 70-85% COD removal at organic loading rates of 5-15 kg COD/m³·day, making them suitable workhorses for various industrial applications.

EGSB reactors push performance boundaries with 80-90% COD removal even at higher loading rates of 15-30 kg COD/m³·day, particularly excelling with soluble substrates. CSTRs, while operating at more modest loading rates of 1-4 kg COD/m³·day, reliably achieve 50-65% COD reduction in difficult-to-digest municipal sludges containing significant particulate matter.

These performance differences directly reflect the specialized biomass retention mechanisms and hydraulic characteristics of each technology.

Energy Recovery Potential

The energy recovery potential from anaerobic digestion represents one of its most compelling advantages over conventional wastewater treatment methods. Modern systems consistently produce 0.25-0.35 m³ of methane per kilogram of COD removed, equivalent to 2.5-3.5 kWh of primary energy.

With efficient combined heat and power (CHP) systems, this translates to approximately 1.0-1.4 kWh of electricity and 1.5-2.0 kWh of thermal energy per kilogram of COD processed—often sufficient to make the treatment process energy positive.

Industrial implementations frequently achieve energy self-sufficiency while generating surplus power for other facility operations. A brewery in Central Europe reports net energy production of 4.8 kWh per cubic meter of wastewater treated through their anaerobic system, completely offsetting the energy requirements of their entire wastewater treatment train.

This energy benefit becomes particularly significant for high-strength wastewaters where conventional aerobic treatment would require substantial electricity input for aeration—typically 0.5-1.0 kWh per kilogram of COD removed with no energy recovery potential.

Beyond direct energy benefits, the carbon footprint reduction achieved through anaerobic treatment can provide additional economic value through carbon credit mechanisms in many jurisdictions.

A comprehensive life cycle assessment of a food processor's transition from aerobic to anaerobic treatment documented a 76% reduction in greenhouse gas emissions, translating to carbon credit values exceeding $180,000 annually at current market rates—a significant secondary revenue stream beyond direct energy savings.

Future Directions: Innovations in Anaerobic Treatment

The field of anaerobic digestion continues to evolve rapidly, with emerging technologies pushing performance boundaries and expanding application ranges. Next-generation systems focus on overcoming traditional limitations while extracting maximum value from wastewater streams.

Key innovation trends include improved biomass retention mechanisms, enhanced process monitoring and control systems, and integration with complementary technologies that transform treatment facilities into resource recovery centers.

These developments collectively promise to further solidify anaerobic digestion's position as the preferred biological treatment approach for a wide spectrum of wastewaters, including those previously considered challenging for biological processes.

Membrane-Coupled Anaerobic Systems

Membrane-coupled anaerobic bioreactors (AnMBRs) represent one of the most promising frontiers in wastewater treatment technology. These systems combine the biological advantages of anaerobic digestion with the physical separation capabilities of membrane filtration, enabling complete biomass retention independent of settling properties.

This configuration allows for unprecedented treatment intensification—with biomass concentrations reaching 30-40 g/L compared to 10-15 g/L in conventional systems—while producing solids-free effluent suitable for direct reuse applications.

AnMBRs overcome the historical challenge of biomass washout during hydraulic fluctuations, maintaining stable performance even during peak flow events.

- Achieve COD removal efficiencies exceeding 95% consistently

- Operate at higher organic loading rates (up to 30 kg COD/m³·day)

- Produce effluent with turbidity <0.5 NTU and TSS <1 mg/L

- Maintain performance during hydraulic and organic load fluctuations

- Enable direct resource recovery from membrane concentrate streams

Recent technological breakthroughs have addressed the historical challenges of membrane fouling in anaerobic environments through innovative module designs and operational strategies.

Dynamic membrane systems utilizing GAC (granular activated carbon) as membrane support material have shown particular promise, significantly reducing energy requirements for fouling control while providing additional adsorptive capacity for trace contaminants.

These systems have demonstrated stable long-term operation treating complex industrial wastewaters with membrane flux rates of 15-25 LMH and cleaning intervals exceeding 90 days—performance metrics previously unattainable in anaerobic membrane applications.

Full-scale AnMBR installations are now operational in food processing, beverage production, and pharmaceutical manufacturing facilities, validating the technology's transition from research to commercial implementation.

These systems consistently achieve effluent quality suitable for water reuse applications, significantly enhancing the value proposition of anaerobic treatment beyond conventional energy recovery. As membrane costs continue to decline and operational experience grows, AnMBRs are positioned to become standard technology for facilities seeking maximum treatment performance with minimal footprint requirements.

Biogas Upgrading Technologies

Significant advances in biogas upgrading technology have dramatically expanded the value potential of anaerobic digestion systems. Modern upgrading systems efficiently convert raw biogas (55-65% methane) into biomethane exceeding 97% purity, suitable for natural gas grid injection or vehicle fuel applications.

Membrane separation, pressure swing adsorption (PSA), and advanced water scrubbing systems now achieve this conversion with energy requirements of just 0.2-0.3 kWh per cubic meter of biomethane produced—a 60% reduction from previous generation technologies.

These efficiency improvements, combined with modular designs scaled for distributed production, make biogas upgrading economically viable even for medium-sized treatment facilities processing 500-1,000 m³ of wastewater daily.

Resource Recovery Beyond Energy

The paradigm of anaerobic treatment is shifting from waste management to resource recovery, with innovative systems designed to extract multiple value streams from wastewater.

Advanced process configurations now enable the selective recovery of nutrients (particularly phosphorus and nitrogen), valuable organic acids, and industrially relevant minerals through side-stream processing of anaerobic effluent.

Struvite precipitation systems integrated with anaerobic digesters recover 85-95% of influent phosphorus as high-purity fertilizer while simultaneously addressing scaling issues that have historically challenged operations.

Similarly, novel ammonia stripping and recovery systems extract nitrogen in concentrated form suitable for fertilizer production, creating additional revenue while improving effluent quality for discharge compliance.

Perhaps most promising is the integration of anaerobic digestion with emerging biorefinery concepts that transform treatment facilities into production centers for high-value biochemicals. Pilot installations have successfully demonstrated the extraction of volatile fatty acids, hydrogen, and precursors for bioplastic production from intermediate digestion streams.

This approach enables facilities to selectively divert carbon flow from methane production to higher-value products based on market conditions, potentially increasing the economic return from organic waste by 300-500% compared to energy recovery alone. These integrated systems represent the future direction of the industry—transforming wastewater from liability to asset while addressing global challenges in resource scarcity.

Frequently Asked Questions About Anaerobic Digestion in Wastewater Treatment

Wastewater treatment professionals frequently encounter common questions when evaluating anaerobic digestion technologies for their specific applications. The following section addresses the most prevalent concerns based on operational experience across hundreds of installations worldwide. These insights provide practical guidance for facilities considering implementation or seeking to optimize existing anaerobic systems.

Proper understanding of startup procedures, limitations, maintenance requirements, and economic considerations is essential for successful project implementation. While anaerobic digestion offers compelling advantages, it remains a sophisticated biological process requiring appropriate expertise for optimal results.

Many performance issues encountered in practice stem from inadequate system selection, improper startup procedures, or operational practices that fail to maintain optimal conditions for the microbial communities that drive the treatment process.

The guidance provided here reflects current best practices derived from both academic research and extensive field experience.

For specific applications, consultation with experienced technology providers remains advisable, as wastewater characteristics can vary significantly even within the same industry sector. Pilot testing often proves valuable for validating performance expectations and identifying potential challenges before full-scale implementation.

- Startup procedures significantly impact long-term performance

- Not all wastewaters are suitable for anaerobic treatment

- Post-treatment may be required for stringent discharge standards

- Proper granular sludge management is critical for high-rate systems

- Economic benefits extend beyond direct energy recovery

UASB for domestic wastewater treatment at University UNITRAR in Lima, Peru (max flow 860 m3 per day) CC BY by Sustainable sanitation

How long does it take to start up a new UASB or EGSB system?

Startup duration for granular sludge systems varies primarily based on seed sludge availability and wastewater characteristics. With high-quality granular inoculum (≥70% VSS as granules) comprising 15-30% of reactor volume, systems can achieve 70-80% of design capacity within 4-6 weeks when treating readily degradable substrates.

This accelerated startup involves gradual loading increases while maintaining strict process parameter controls—particularly pH (6.8-7.2), alkalinity (2,000-3,000 mg/L as CaCO₃), and volatile fatty acids (below 500 mg/L). Without granular inoculum, startup periods extend to 3-6 months as granulation must occur naturally, requiring careful manipulation of hydraulic and organic loading to create selective pressure favoring granule formation.

Modern startup protocols increasingly incorporate specific micronutrient supplementation regimes, particularly for industrial wastewaters that may lack essential trace elements. Controlled additions of iron, nickel, cobalt, and molybdenum during startup have demonstrated 30-50% reductions in acclimation periods while promoting formation of denser, more active granules.

Temperature management proves equally critical, with mesophilic systems (35-37°C) achieving stable performance significantly faster than those operating at lower or higher temperatures. Facilities should budget for reduced treatment capacity during startup and implement comprehensive monitoring protocols to track biomass development and activity indicators throughout the acclimation period.

What types of wastewater are not suitable for anaerobic digestion?

Despite its versatility, anaerobic digestion faces limitations with certain wastewater types that may require pretreatment or alternative approaches. Streams containing high concentrations of sulfates (SO₄²⁻ > 1,000 mg/L) typically prove challenging as sulfate-reducing bacteria compete with methanogens for substrate while producing hydrogen sulfide that inhibits methanogenesis and creates corrosion issues. Similarly, wastewaters with significant concentrations of long-chain fatty acids, certain phenolic compounds, or heavy metals can inhibit anaerobic microorganisms at levels that would not impact aerobic processes. Very dilute wastewaters (COD < 500 mg/L) generally fail to provide sufficient energy benefits to justify anaerobic treatment unless ambient temperatures allow for unheated operation or specialized high-rate technologies like EGSB systems are employed.

Can anaerobic systems meet stringent effluent quality standards?

Anaerobic digestion excels at removing organic carbon but typically requires post-treatment to meet comprehensive discharge standards. While modern high-rate systems achieve 85-95% COD removal, residual levels often range from 50-200 mg/L—potentially exceeding direct discharge limits. More significantly, anaerobic processes provide minimal nitrogen or phosphorus removal, with these nutrients largely conserved or even solubilized during treatment. For facilities facing stringent discharge requirements, anaerobic digestion typically serves as a highly efficient first stage in a treatment train, followed by aerobic polishing, constructed wetlands, or specialized nutrient removal processes depending on specific effluent targets.

This limitation should be viewed in context—the exceptional energy efficiency of anaerobic systems often more than compensates for the additional treatment requirements. Integrated approaches that combine anaerobic pretreatment with targeted post-processing achieve both excellent effluent quality and favorable energy balance. Membrane-coupled anaerobic reactors represent an emerging solution that produces exceptional effluent quality directly, though at higher capital and operational complexity. The optimal approach ultimately depends on specific discharge requirements, available space, and facility priorities regarding energy efficiency versus treatment simplicity.

How do I maintain healthy granular sludge in my reactor?

- Maintain stable pH between 6.8-7.2 and alkalinity >2,000 mg/L as CaCO₃

- Implement consistent organic loading patterns, avoiding sudden increases >25%

- Ensure adequate micronutrient availability, particularly Fe, Ni, Co, Mo, and Se

- Monitor and control calcium levels (200-500 mg/L optimal) to prevent scaling

- Minimize exposure to oxygen during maintenance procedures

Granular sludge health represents the cornerstone of high-rate anaerobic system performance. Regular monitoring should include not only standard parameters (VFAs, alkalinity, biogas composition) but also periodic granule quality assessments. Healthy granules exhibit dark coloration, firm texture, and settling velocities exceeding 30 m/h. Deterioration signs include light coloration, irregular surfaces, or hollow centers, often indicating nutrient limitations or toxicity effects that require prompt intervention.

What is the typical payback period for implementing anaerobic digestion?

Economic performance of anaerobic installations varies considerably based on wastewater characteristics, energy costs, discharge fees, and available incentives. For high-strength industrial applications (COD >3,000 mg/L) with significant discharge costs, payback periods typically range from 2-5 years based primarily on reduced treatment fees and energy production. Food and beverage processors frequently achieve returns at the shorter end of this range, with breweries and dairy processors reporting paybacks as brief as 18-30 months when replacing aerobic systems with high energy consumption. Facilities facing stringent discharge requirements or located in regions with high energy costs naturally experience more favorable economics.

Capital costs for modern anaerobic systems generally range from $3,000-$7,000 per cubic meter of reactor volume, with total installed costs for complete systems including gas handling typically falling between $1.5-$4.0 million for medium-sized installations processing 1,000-2,000 m³/day. These investments deliver operational cost reductions of $0.50-$1.20 per cubic meter treated compared to conventional aerobic alternatives, primarily through energy savings, reduced sludge handling, and lower chemical consumption. Additional value streams from carbon credits, renewable energy certificates, or nutrient recovery can further enhance financial performance, particularly in jurisdictions with supportive regulatory frameworks.