Biochar from Food Waste Digestate: Sustainable Enhanced Waste Management and Carbon Capture Can Bring Advances in the Circular Economy

Recent advancements in biochar production demonstrate significant potential in addressing environmental and economic challenges associated with food waste (FW) management. A pioneering study published in March 2025 has evaluated the techno-economic viability and life-cycle impacts of producing biochar from food-waste digestate through hydrothermal carbonisation (HTC) combined with high-temperature post carbonisation (PC).

This innovation not only presents a sustainable approach to carbon dioxide removal (CDR) but also contributes effectively to the circular economy.

Table of Contents

ToggleKey Takeaways

Biochar from food waste digestate solids offers a sustainable and economically viable waste management solution.

HTC-PC processes efficiently handle high-moisture waste without extensive pre-treatment.

Biochar significantly reduces greenhouse gas emissions through stable carbon sequestration.

Economic viability heavily depends on gate fees for processing food waste digestate.

Implementation could stimulate job creation and enhance local economies.

Background and Context

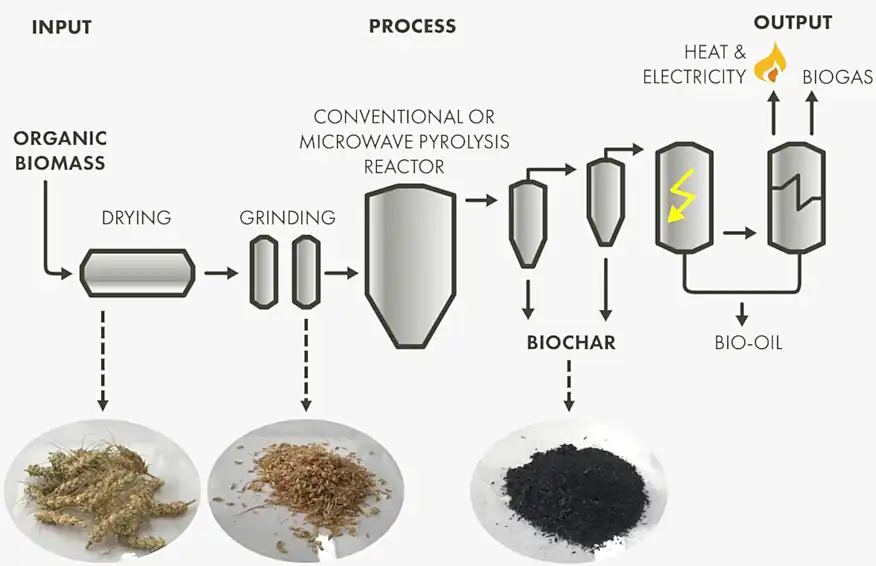

Biochar has historically been produced from biomass through pyrolysis. Previous studies primarily investigated woody biomass and agricultural residues due to their high lignin content and abundant availability.

However, these traditional feedstocks often compete with bioenergy applications and entail significant cultivation costs and associated greenhouse gas (GHG) emissions.

In contrast, the solid portion of food waste digestate emerges as a strategic alternative feedstock, given its abundant availability, minimal competition with other uses, and significant potential for environmental and financial benefits.

Technological Innovations and Advantages

The study highlights the effectiveness of the HTC-PC process in converting high-moisture FW digestate into stable biochar. Traditional pyrolysis methods require extensive drying and high energy inputs, whereas HTC operates efficiently at lower temperatures (150-300°C), significantly reducing pre-treatment energy demands.

The subsequent PC stage further stabilizes the hydrochar, producing biochar with approximately 88% stable carbon fraction, aligning with rigorous standards such as the European Biochar Certificate (EBC).

The HTC-PC process, involving hydrothermal carbonization (HTC) followed by post-carbonization (PC), is a method for producing stable biochar from wet biomass.

HTC converts wet biomass into hydrochar under high temperature and pressure, and PC further converts the hydrochar into a more stable and less degradable biochar. This process is particularly useful for managing wet biowastes and producing biochar with high carbon sequestration potential.

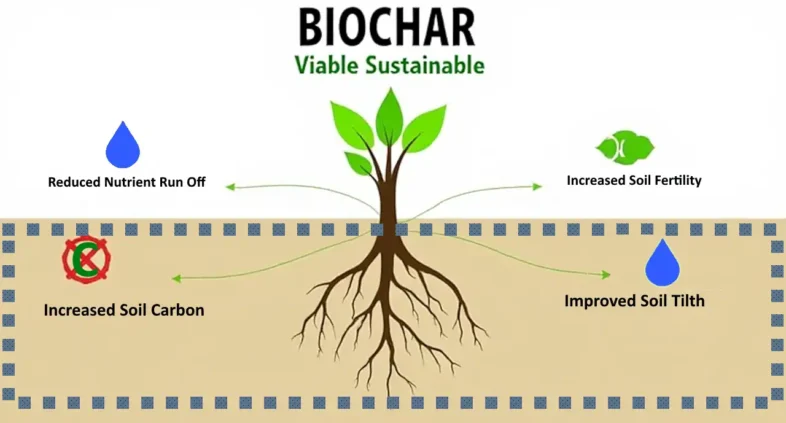

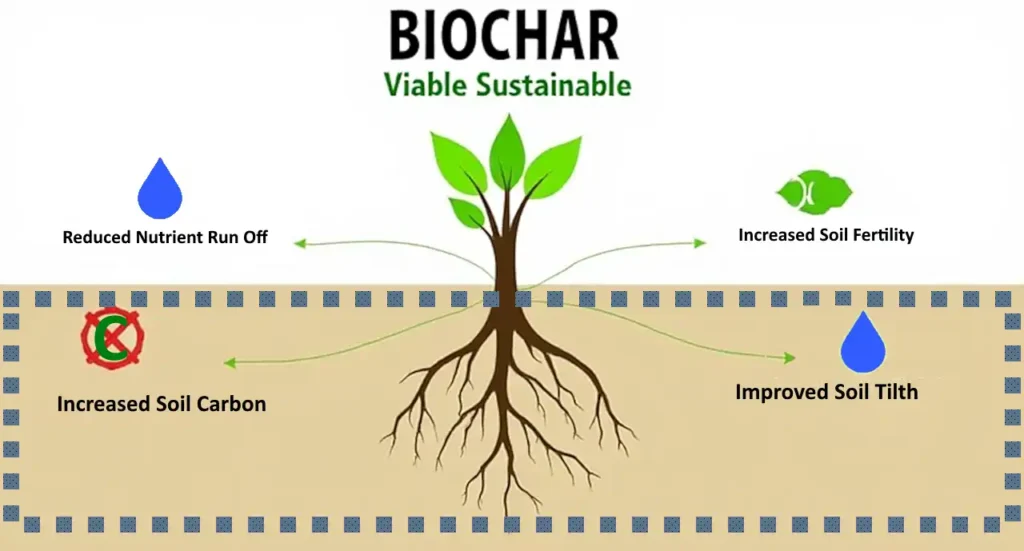

“Use Biochar in Your Garden …” from www.hachettebookgroup.com and used with no modifications.

Economic Viability and Market Potential

Economic viability depends primarily on the gate fees charged for processing FW digestate, with significant potential for profitability when gate fees exceed approximately £74 per tonne. Current waste management methods, such as incineration, carry substantial costs (around £93 per tonne), positioning biochar production as economically attractive. The study indicates that biochar production from digestate could cost as low as £88 per tonne, substantially cheaper than biochar derived from traditional biomass sources.

Environmental Impact and Carbon Sequestration

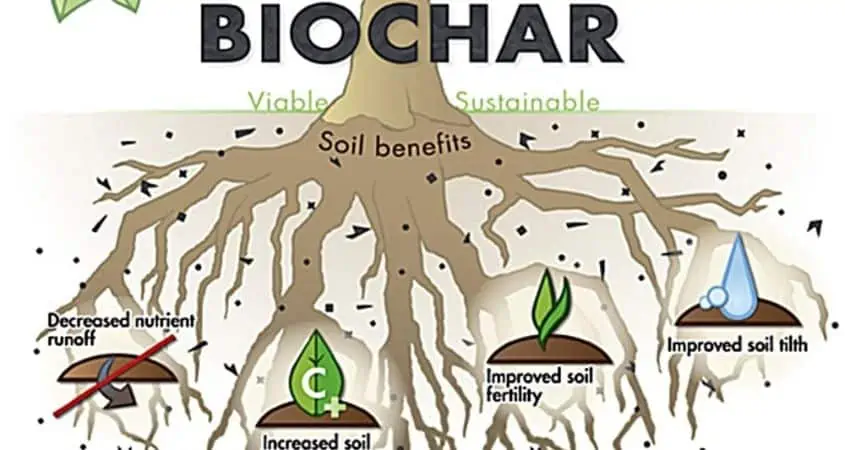

Biochar production from FW digestate yields substantial GHG emission reductions of 1.15 to 1.20 tCO2eq per tonne of biochar. This result arises primarily from biochar’s capability to sequester atmospheric carbon dioxide in a stable form. Additionally, biochar produced this way can potentially offset agricultural fertilizer requirements, providing further environmental benefits by reducing fossil fuel-based fertilizer usage and associated emissions.

“The Basics of Biochar | SpaceBakery” from spacebakery.be and used with no modifications.

Circular Economy and Sustainability

Transforming FW digestate into biochar exemplifies circular economy principles by sustainably and efficiently utilizing waste-derived resources. This method addresses waste management challenges associated with plastic-contaminated digestates, typically expensive to incinerate, thus mitigating disposal costs and environmental burdens. This biochar approach supports UK and global initiatives aimed at diverting food waste from landfills and aligns closely with the Sustainable Development Goals (SDGs).

Employment and Economic Growth

Expanding biochar facilities presents significant opportunities for job creation. Utilizing 50% of the UK's projected FW digestate by 2030 would necessitate approximately 28 biochar production plants, each processing 20 kt per annum. This expansion not only addresses environmental goals but also stimulates local economies by creating jobs in facility operations, transportation, logistics, and agriculture.

Broader Implications and Future Developments

Further advancements in HTC-PC technology and biochar market development could significantly enhance the sustainability and profitability of food waste recycling operations. Research suggests potential improvements in fossil fuel reduction within biochar production processes and greater clarity on biochar’s agricultural benefits could foster broader acceptance and regulatory support, driving greater global implementation.

“The Bountiful Benefits Of Biochar …” from cropnuts.com and used with no modifications.

Hydrothermal Carbonization (HTC) and Post-Carbonization (PC) Explained

1. Hydrothermal Carbonization (HTC):

HTC involves heating wet biomass in a closed system under high pressure and temperature (typically 180-250°C). This process breaks down the biomass, leading to the formation of hydrochar, which is a char-like material. During HTC, a series of reactions like hydrolysis, dehydration, and aromatization occur, increasing the carbon content of the solid matrix.

2. Post-Carbonization (PC):

Post-carbonization is a further step that takes the hydrochar produced from HTC and exposes it to even higher temperatures. This process further stabilizes the hydrochar and reduces its degradability. By increasing the aromaticity and carbon content of the hydrochar, PC transforms it into a more stable and durable biochar.

3. Benefits of HTC-PC:

Stable Biochar: HTC-PC produces biochar with a higher proportion of stable carbon, meaning that the carbon remains locked in the soil for longer periods.

Carbon Sequestration: The stable carbon in biochar contributes to carbon sequestration, effectively removing CO2 from the atmosphere and mitigating climate change.

Wet Biomass Processing:

HTC-PC is particularly effective for processing wet biowastes, such as food waste or sludge, which are difficult to process using traditional pyrolysis methods.

Energy Efficiency: HTC and subsequent PC processes can be energy efficient, especially when integrated with heat recovery systems.

4. Applications of Biochar:

Biochar produced through HTC-PC can be used for various purposes, including soil improvement, water purification, and as a fuel source.

Conclusion

The innovative approach of transforming FW digestate into stable biochar presents an economically attractive, environmentally beneficial, and socially advantageous solution.

Firmly embedding itself within the circular economy framework, this technology offers significant potential for climate change mitigation and represents an exciting frontier for global food waste management.

FAQs

Q1: What is biochar, and why is it important?

A1: Biochar is a carbon-rich product obtained from biomass through thermochemical processes. It helps in carbon sequestration, improves soil fertility, and supports sustainable waste management.

Q2: How does biochar from food waste digestate benefit the environment?

A2: It significantly reduces greenhouse gas emissions by sequestering stable carbon in soils and offsetting fossil fuel-based fertilizer use, thereby lowering the overall environmental impact.

Q3: What makes HTC-PC advantageous for biochar production from food waste digestate?

A3: HTC-PC processes efficiently manage wet waste without extensive drying, significantly reducing energy inputs and costs compared to traditional pyrolysis methods.

Q4: What determines the economic viability of biochar production from food waste digestate?

A4: The gate fee charged for processing digestate strongly influences economic viability, along with production efficiency and operational costs.

Q5: Can biochar production create jobs and stimulate local economies?

A5: Yes, establishing biochar production facilities supports employment in operations, transportation, logistics, and agricultural sectors, positively impacting local economies.

Citation and Source

This summary and analysis are based on the detailed research published in Biochar (2025):

“Biowaste to biochar: a techno-economic and life cycle assessment of biochar production from food-waste digestate and its agricultural field application”, Gamaralalage et al. (2025), Vol 7, Article number 50.