Key Takeaways

- High-rate anaerobic digestion systems can process organic waste up to 10 times faster than conventional digesters while producing valuable biogas for renewable energy.

- The most efficient high-rate systems include UASB reactors, EGSB reactors, fixed-film reactors, anaerobic membrane bioreactors, and two-phase systems.

- Temperature control between 35-55°C and proper pH management (6.8-7.2) are critical factors for optimizing high-rate anaerobic digestion performance.

- Pretreatment methods such as mechanical grinding, thermal hydrolysis, and ultrasonic disruption can significantly increase biogas yields from high-rate digesters.

- Despite higher upfront costs, high-rate anaerobic digestion systems typically offer faster ROI through increased biogas production, smaller footprint requirements, and waste reduction benefits.

Transforming organic waste into renewable energy isn't just environmentally responsible—it's becoming economically essential. High-rate anaerobic digestion stands at the forefront of this transformation, offering faster processing times and greater biogas yields than conventional systems. These advanced biological systems are revolutionizing how industries, municipalities, and agricultural operations manage organic waste while generating clean energy.

Modern high-rate anaerobic digesters can process waste up to ten times faster than traditional systems while maintaining excellent treatment efficiency. This remarkable performance has made them increasingly popular across various sectors seeking sustainable waste management solutions. Paques Global and Clearfleau specializes in implementing these high-performance systems, converting waste streams into valuable biogas while dramatically reducing environmental impact.

![]()

“Clearfleau biogas plant” from www.beveragedaily.com and used with no modifications.

Anaerobic Digestion: Turning Waste into Energy

Anaerobic digestion harnesses the natural biological process where microorganisms break down organic matter in the absence of oxygen. This process converts complex organic compounds into biogas (primarily methane and carbon dioxide), a renewable energy source that can be used for heating, electricity generation, or upgraded to biomethane for vehicle fuel or natural gas grid injection. The remaining digestate serves as a nutrient-rich fertilizer, completing a sustainable cycle that returns valuable nutrients to agricultural soils.

Unlike aerobic treatment methods, anaerobic digestion produces minimal excess biomass (sludge) while generating energy instead of consuming it. This fundamental advantage makes it particularly valuable for treating high-strength organic wastes and wastewaters. The process naturally occurs in oxygen-free environments like marshes and landfills, but engineered digesters optimize conditions to maximize methane production and processing efficiency.

How High-Rate Anaerobic Digestion Works

High-rate anaerobic digestion differs from conventional systems by employing specialized reactor designs that retain microorganisms within the system, effectively uncoupling the hydraulic retention time (HRT) from the solids retention time (SRT). This critical innovation allows wastewater to pass through quickly while maintaining a high concentration of active biomass in the reactor. The result is significantly faster treatment rates—often measured in hours rather than weeks—while maintaining or even improving treatment efficiency and biogas yields.

The Four Key Stages of Anaerobic Digestion

The anaerobic digestion process unfolds through four interconnected biological stages, each performed by specialized microbial communities working in syntrophic relationships. The process begins with hydrolysis, where complex organic polymers (proteins, carbohydrates, lipids) are broken down into simpler monomers like amino acids, sugars, and fatty acids. This critical first step is often rate-limiting, especially when processing difficult substrates like lignocellulosic materials.

Acidogenesis follows, converting these simple compounds into volatile fatty acids (VFAs), alcohols, hydrogen, and carbon dioxide. Next comes acetogenesis, where specialized bacteria transform the products of acidogenesis into acetic acid, hydrogen, and carbon dioxide—the direct precursors for methane production. Finally, methanogenesis occurs as methanogenic archaea convert these intermediates into biogas containing 50-75% methane, along with carbon dioxide and trace gases.

In high-rate systems, these processes occur simultaneously within distinct microbial communities that often form spatially organized structures such as granules or biofilms. This spatial organization enables efficient substrate transfer between different microbial groups and provides protection against environmental stresses, contributing significantly to the stability and efficiency of high-rate processes.

The Four Stages of Anaerobic Digestion

Stage 1: Hydrolysis – Complex polymers → Simple monomers (amino acids, sugars, fatty acids)

Stage 2: Acidogenesis – Simple monomers → Volatile fatty acids, alcohols, H₂, CO₂

Stage 3: Acetogenesis – Acidogenesis products → Acetic acid, H₂, CO₂

Stage 4: Methanogenesis – Acetic acid, H₂, CO₂ → CH₄ (methane) + CO₂

Difference Between Traditional and High-Rate Systems

Traditional anaerobic digesters typically operate as completely mixed or plug-flow reactors with hydraulic retention times ranging from 20-40 days. These systems rely on long retention times to achieve adequate treatment and maintain sufficient active biomass. In contrast, high-rate digesters employ innovative biomass retention mechanisms—including granulation, biofilm formation, or mechanical separation—that allow HRTs as low as 2-12 hours while maintaining SRTs of 50-100 days. This dramatic difference enables high-rate systems to process 10-20 times more organic matter per unit volume than conventional digesters.

Why Processing Speed Matters

Processing speed represents a crucial economic and practical advantage in waste treatment operations. Faster processing translates to smaller reactor volumes, reduced land requirements, lower capital costs, and greater operational flexibility. For facilities facing space constraints or handling large waste volumes, high-rate systems offer the only viable anaerobic treatment option. Additionally, faster startup times (weeks instead of months) and the ability to quickly recover from operational upsets make high-rate systems more resilient and reliable for continuous industrial applications.

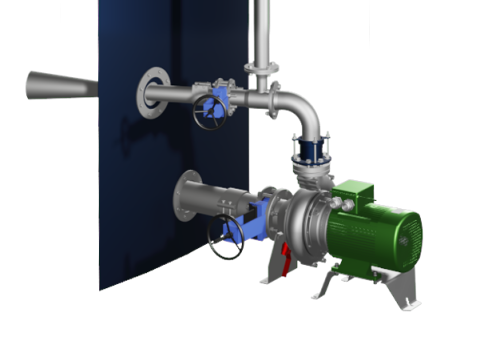

“Superior efficiency BIOPAQ®www.paquesglobal.com and used with no modifications.

5 Top-Performing High-Rate Anaerobic Digestion Systems

The evolution of anaerobic digestion technology has produced several highly efficient reactor designs that address specific operational needs and waste characteristics. Each system offers unique advantages for particular applications, with selection typically based on wastewater characteristics, desired treatment efficiency, space constraints, and budget considerations.

1. Upflow Anaerobic Sludge Blanket (UASB) Reactors

“Upflow Ananerobic Sludge Blanket …” from microbewiki.kenyon.edu and used with no modifications.

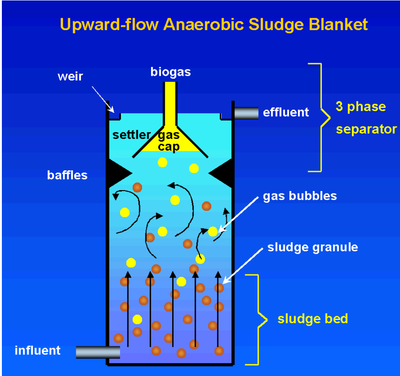

UASB reactors represent the most widely implemented high-rate anaerobic technology globally, with thousands of installations treating industrial wastewaters. The design features an influent distribution system at the reactor bottom, allowing wastewater to flow upward through a dense bed of granular sludge containing the active microorganisms. This granular sludge formation—a self-immobilization of anaerobic bacteria into 1-3mm spherical aggregates—is the key innovation enabling treatment rates up to 15 kg COD/m³·day, far exceeding conventional systems.

The success of UASB technology stems from its elegant three-phase separator design that efficiently divides gas, liquid, and solids within the reactor. Biogas bubbles naturally rise, carrying granules upward until the gas separates at the interface, allowing granules to settle back to the sludge bed. This natural internal recirculation maintains excellent biomass retention while providing gentle mixing. UASB systems excel in treating medium to high-strength soluble wastewaters from food processing, beverage production, and pulp and paper industries.

2. Expanded Granular Sludge Bed (EGSB) Reactors

EGSB reactors evolved from UASB technology to achieve even higher loading rates (up to 30 kg COD/m³·day) and better treatment of low-strength or challenging wastewaters. These systems feature taller reactors with higher height-to-diameter ratios and employ external recirculation to create upflow velocities of 6-10 m/h, significantly exceeding the 1-2 m/h typical in UASB systems. This increased velocity expands the sludge bed, improving wastewater-biomass contact and reducing channeling risks.

The expanded bed configuration enables superior treatment of dilute wastewaters, cold streams (as low as 10°C), and wastewaters containing inhibitory compounds by enhancing mass transfer and diluting toxins. Many EGSB systems incorporate advanced influent distribution systems and sophisticated three-phase separators that further improve treatment efficiency. This technology has proven particularly effective for brewery wastewaters, chemical industry effluents, and pharmaceutical manufacturing wastewaters where conventional UASB systems might struggle.

“The expanded granular sludge bed (EGSB …” from www.researchgate.net and used with no modifications.

3. Fixed-Film Reactors

Fixed-film reactors utilize inert support media that provides surface area for biofilm attachment, eliminating the need for granule formation. These systems—including anaerobic filters, fluidized bed reactors, and moving bed biofilm reactors—offer exceptional biomass retention through immobilization on media surfaces. The attached growth provides significant operational stability and resistance to toxic shock loads, making these systems ideal for variable or challenging waste streams.

Modern fixed-film systems often employ advanced synthetic media with high specific surface areas (up to 600 m²/m³) and optimized designs that prevent clogging while maximizing biomass-substrate contact. These innovations have enabled loading rates comparable to granular sludge systems while offering greater resistance to suspended solids and foaming issues. Fixed-film technology excels in applications where wastewater characteristics make granulation difficult, such as treatment of fatty wastewaters from dairy processing, slaughterhouses, and rendering operations. For more insights on sustainable practices, explore organic waste recycling best practices.

“fixed film anaerobic reactor …” from www.sciencedirect.com and used with no modifications.

4. Anaerobic Membrane Bioreactors (AnMBR)

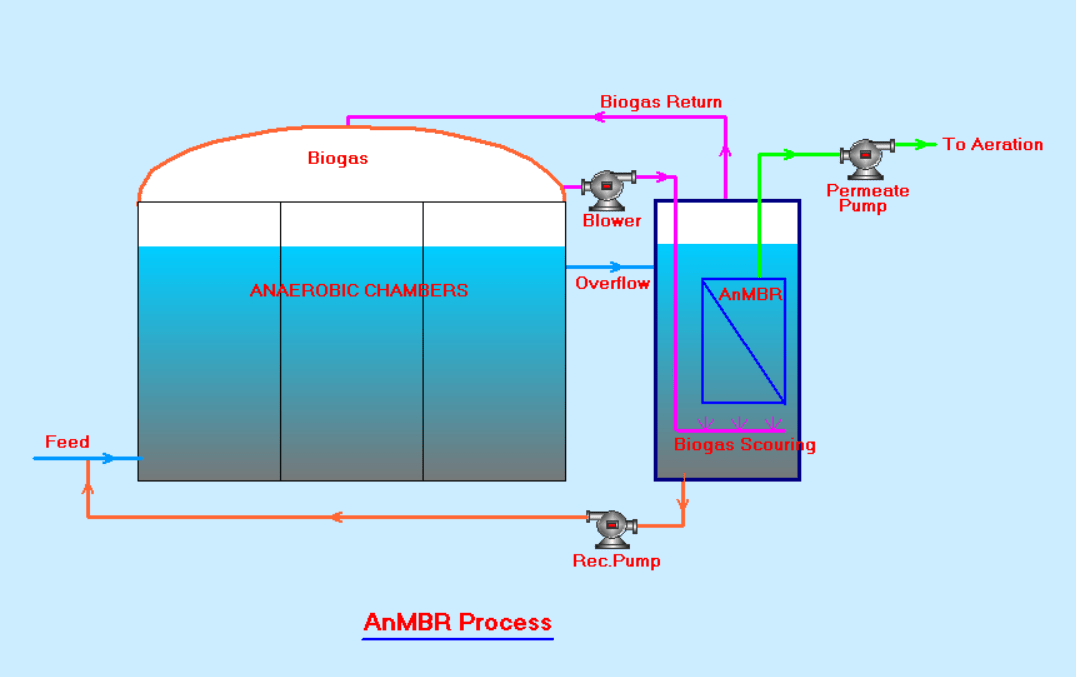

AnMBRs represent the cutting edge of high-rate anaerobic technology, combining biological treatment with membrane filtration to achieve complete biomass retention and exceptional effluent quality. These systems employ ultrafiltration or microfiltration membranes (either submerged or external) to physically separate biomass from treated effluent, enabling infinite SRTs and outstanding treatment efficiency. The membrane barrier allows AnMBRs to treat wastewaters regardless of biomass settleability or granulation potential.

The complete biomass retention in AnMBRs permits treatment of recalcitrant compounds through extended contact time and development of specialized microbial communities. These systems can produce solids-free, high-quality effluent suitable for water reuse applications, offering value beyond biogas production. While membrane fouling remains a challenge, recent advances in anti-fouling strategies, including novel membrane materials, optimized operational protocols, and innovative cleaning methods, have substantially improved long-term performance and reduced energy requirements. For those interested in sustainable waste management, exploring best practices in recycling organic waste can provide additional insights.

“Anaerobic Membrane Bioreactor – Oxy …” from oxymembrane.com and used with no modifications.

5. Two-Phase Anaerobic Digestion Systems

Two-phase (or staged) anaerobic digestion physically separates the acidogenic and methanogenic phases of the process into distinct reactors, optimizing conditions for each microbial group. The first-phase reactor operates at a lower pH (5.5-6.0) and shorter retention time, optimizing hydrolysis and acidogenesis. The second-phase reactor maintains neutral pH and longer retention time, creating ideal conditions for methanogenic archaea to convert acids into methane.

This configuration offers several advantages for complex waste streams, particularly those containing high percentages of particulate or slowly degradable material. The phase separation improves hydrolysis rates, enhances overall process stability, and provides better protection against inhibitory compounds. Two-phase systems have proven particularly effective for treating mixed food waste, agricultural residues, and high-solid industrial wastes where hydrolysis typically limits digestion rates.

“Two-Stage Anaerobic Digestion for Green …” from www.mdpi.com and used with no modifications.

Optimizing High-Rate Digesters for Maximum Output

The exceptional performance of high-rate anaerobic systems depends on maintaining optimal conditions for the diverse microbial communities involved in the digestion process. Careful monitoring and control of key parameters can significantly enhance stability, biogas yields, and treatment efficiency while preventing operational issues.

Temperature Control Strategies

Temperature profoundly impacts anaerobic digestion performance, influencing microbial growth rates, substrate utilization, and biogas production. Most high-rate systems operate in either the mesophilic range (35-38°C) or thermophilic range (50-55°C), with each offering distinct advantages. Mesophilic operation provides greater stability and lower energy requirements, while thermophilic conditions enable faster reaction rates, improved pathogen reduction, and potentially higher loading rates.

Advanced temperature control systems typically employ external heat exchangers, jacketed reactor walls, or internal heating coils to maintain consistent temperatures. Precision is critical—fluctuations exceeding ±2°C can significantly disrupt methanogenic activity, particularly in thermophilic systems. Many modern installations recover heat from combined heat and power (CHP) engines fueled by the produced biogas, creating an efficient circular energy system while minimizing external heating requirements.

“Types of Anaerobic Digesters – Farm Energy” from farm-energy.extension.org and used with no modifications.

pH and Alkalinity Management

Maintaining appropriate pH levels (typically 6.8-7.2) and sufficient alkalinity (2,000-5,000 mg/L as CaCO₃) is essential for high-rate digester stability. Methanogenic archaea are particularly sensitive to pH fluctuations, with activity declining sharply below pH 6.5. Automatic pH control systems using caustic soda, sodium bicarbonate, or lime dosing provide protection against acidification during organic overloads or inhibitory events.

Beyond pH, alkalinity serves as the system's buffer capacity against acid accumulation and provides critical information about digester health. The ratio of intermediate alkalinity (primarily VFAs) to partial alkalinity (primarily bicarbonate) offers an early warning indicator of process imbalance, often revealing issues before pH changes become apparent. Online monitoring systems tracking these parameters allow operators to identify and correct problems before they impact performance. For more insights on anaerobic digestion, explore this comprehensive study.

Mixing Techniques for Better Performance

Effective mixing plays a crucial role in high-rate anaerobic digestion performance, ensuring optimal contact between microorganisms and substrate while preventing temperature gradients, stratification, and dead zones. Unlike conventional digesters that often rely on continuous mechanical mixing, high-rate systems employ more strategic approaches tailored to their specific configurations and biomass retention mechanisms.

In granular sludge-based systems like UASB and EGSB reactors, mixing primarily occurs through the natural hydraulic flow pattern and gas production. The rising biogas bubbles create gentle mixing that helps maintain granule integrity while improving substrate distribution. For fixed-film reactors, recirculation provides the necessary mixing without damaging the attached biofilms, with careful flow rate control to prevent excessive biofilm shearing or media abrasion.

Advanced mixing strategies often combine multiple methods, such as intermittent mechanical mixing during feeding cycles, programmed biogas recirculation, and strategic feed distribution. These hybrid approaches maximize treatment efficiency while minimizing energy consumption and reducing stress on microbial communities. Real-time monitoring of mixing effectiveness using tracer studies or computational fluid dynamics has become increasingly common in optimizing large-scale installations.

“Digester mixing” from www.landiainc.com and used with no modifications.

Pretreatment Methods That Boost Efficiency

Substrate pretreatment represents one of the most effective strategies for enhancing high-rate anaerobic digestion performance, particularly when processing complex or recalcitrant materials. By accelerating the rate-limiting hydrolysis step, these technologies can significantly increase biogas yields, reduce required retention times, and improve overall system stability.

Mechanical pretreatment methods such as grinding, milling, and high-pressure homogenization increase surface area accessibility by reducing particle size and disrupting cellular structures. Thermal hydrolysis processes (THP) apply high temperatures (140-170°C) and pressure to solubilize complex organic matter, particularly effective for waste activated sludge and lignocellulosic materials. Chemical pretreatments using acid, alkali, or oxidative conditions can break recalcitrant bonds in difficult substrates, while enzymatic approaches offer gentler, more selective hydrolysis.

Combined pretreatment approaches often deliver synergistic benefits exceeding what individual methods can achieve. For example, thermo-chemical treatments coupling alkaline conditions with elevated temperatures have proven particularly effective for lignocellulosic agricultural residues. Newer technologies like pulsed electric field (PEF) treatment and ultrasonic disruption offer energy-efficient alternatives that can be integrated directly into feeding systems for continuous operation.

Real-World Applications of High-Rate Systems

High-rate anaerobic digestion technology has been successfully implemented across diverse sectors, demonstrating remarkable versatility in handling various waste streams while delivering significant environmental and economic benefits. These real-world applications showcase the practical advantages of high-rate systems beyond laboratory settings.

Industrial Wastewater Treatment Success Stories

The food and beverage industry has widely embraced high-rate anaerobic technology, with breweries leading adoption through hundreds of successful installations worldwide. A major European brewery implemented an EGSB system handling 5,000 m³/day of wastewater with COD concentrations ranging from 2,000-10,000 mg/L, achieving over 90% COD removal while producing enough biogas to offset 30% of the facility's natural gas consumption. The compact reactor footprint—less than 20% of what an aerobic system would require—proved critical for the space-constrained urban location.

![]()

“Wastewater Treatment for Treating …” from www.yasa.ltd and used with no modifications.

In the pulp and paper sector, a North American packaging manufacturer installed an anaerobic membrane bioreactor to treat high-strength wastewater from recycled paper processing. The system handles extreme COD fluctuations (5,000-25,000 mg/L) while consistently producing high-quality effluent suitable for reuse in less critical manufacturing processes. The technology reduced the facility's freshwater consumption by 40% while generating 2.1 million cubic meters of biogas annually, powering an on-site CHP system that provides both electricity and process steam.

Municipal Waste Processing Plants

Municipalities increasingly adopt high-rate anaerobic digestion for organic fraction municipal solid waste (OFMSW) treatment, often as part of integrated waste management strategies. A pioneering facility in Western Europe processes 40,000 tonnes of source-separated food waste annually using a two-phase thermophilic system. The plant produces 4.8 million cubic meters of biomethane yearly—injected directly into the natural gas grid—while generating high-quality digestate that meets stringent standards for agricultural application, completing a true circular economy model.

For municipal wastewater treatment, several facilities have implemented high-rate anaerobic primary treatment ahead of conventional activated sludge processes. One North American installation uses an AnMBR to treat primary sludge and high-strength sidestreams, reducing overall plant energy consumption by 25% while increasing biogas production by 40%. The approach significantly reduced aeration requirements in downstream biological treatment, demonstrating how strategic implementation of anaerobic technology can transform conventional wastewater treatment plant energy balance.

Agricultural Applications

Agricultural implementations of high-rate anaerobic digestion have evolved from simple manure management tools to sophisticated biorefinery concepts. A large-scale dairy operation in the Midwestern United States installed a modified high-rate system processing manure from 5,000 cows along with local food processing wastes. The two-stage system features a hydrolysis/acidification reactor followed by a high-rate UASB for methanogenesis, achieving exceptional volatile solids destruction while maximizing biogas production. The facility generates 1.2 MW of electrical power while producing liquid and solid fertilizer fractions that have reduced the farm's annual fertilizer expenses by over $200,000.

Innovative agricultural applications increasingly integrate crop residue processing alongside traditional manure digestion. A European cooperative digester serves multiple farms by processing both livestock manures and crop residues using sequential pretreatment and high-rate digestion. The facility employs mechanical steam explosion pretreatment for lignocellulosic materials before feeding into thermophilic high-rate digesters, achieving biomethane yields 30-40% higher than conventional systems processing the same feedstocks. This cooperative model demonstrates how advanced anaerobic technology can operate successfully at community scale.

Common Challenges and How to Overcome Them

Despite their impressive performance capabilities, high-rate anaerobic systems present operational challenges that require thoughtful management strategies. Understanding these common issues and implementing proven solutions can significantly improve long-term system reliability and performance.

Dealing with System Instability

Process instability represents perhaps the most significant operational challenge in high-rate anaerobic digestion. The complex microbial communities—particularly the slow-growing methanogens—can be disrupted by sudden changes in organic loading, temperature fluctuations, or toxic compounds. The classic symptom of instability is volatile fatty acid accumulation coupled with declining alkalinity, ultimately leading to pH drops and inhibited methanogenesis. To address these challenges, it's essential to adopt best practices in recycling organic waste to ensure system stability.

Successful operators implement comprehensive monitoring programs tracking critical parameters including VFA speciation, alkalinity ratios, biogas composition, and microbial activity indices. Early detection systems using online VFA analyzers or advanced biogas composition monitoring provide valuable early warnings before problems escalate. Standardized response protocols for different upset scenarios—such as controlled feeding reductions, alkalinity supplementation, or targeted trace element addition—help minimize recovery times. Many facilities maintain backup granular biomass or specialized bioaugmentation products for rapid recovery following severe upsets.

Advanced control systems employing artificial intelligence and machine learning algorithms increasingly help predict and prevent instability episodes by identifying subtle pattern changes in operating parameters. These systems can automatically adjust feeding rates and operational parameters based on real-time process indicators, significantly enhancing stability in facilities handling variable waste streams.

Managing Inhibitory Compounds

Inhibitory compounds present serious challenges to high-rate anaerobic systems by disrupting microbial metabolism and reducing treatment efficiency. Common inhibitors include ammonia (particularly problematic in protein-rich substrates), sulfides (from sulfate-rich wastewaters), long-chain fatty acids (from lipid hydrolysis), heavy metals, and various industrial chemicals. Each inhibitor affects methanogenic communities through different mechanisms, often at surprisingly low concentrations.

Effective management strategies begin with comprehensive waste characterization and potential inhibitor identification. Dilution using recirculation or co-digestion with complementary waste streams often provides the simplest solution by reducing inhibitor concentrations below threshold levels. Acclimation protocols—gradually increasing exposure to allow microbial adaptation—have proven remarkably effective for many inhibitors, with properly acclimated communities tolerating concentrations that would severely inhibit unadapted systems. For persistent issues, specialized pretreatment technologies such as ammonia stripping, precipitation, or adsorption processes can selectively remove problematic compounds.

Bioaugmentation with specialized microbial consortia has emerged as an effective strategy for addressing inhibition issues. These carefully developed cultures contain microorganisms with enhanced tolerance to specific inhibitors, helping maintain performance when conventional communities would fail. The approach has proven particularly valuable for high-nitrogen wastes, sulfate-rich industrial effluents, and streams containing antimicrobial compounds.

Startup Procedures for New Digesters

Proper startup represents a critical phase determining long-term performance for high-rate anaerobic systems. The process requires careful inoculation, gradual loading increases, and strategic parameter management to develop robust microbial communities with appropriate structural characteristics (granules or biofilms). Rushed startups frequently lead to poor granulation, inadequate biomass retention, or imbalanced microbial populations that limit long-term performance. For more insights on waste management, explore what happens to food waste in landfills.

Best practices include inoculation with high-quality granular sludge (for UASB/EGSB systems) or adapted anaerobic biomass from similar applications. Initial organic loading rates typically begin at 10-20% of design capacity, with gradual increases based on stability indicators rather than fixed schedules. Careful attention to upflow velocity, temperature stability, and feeding patterns during this critical phase promotes proper granule development or biofilm formation. Complete startup periods typically range from 2-4 months for granular systems and 1-3 months for fixed-film reactors, though novel acceleration techniques using specialized carriers or granulation enhancers can reduce these timeframes.

Troubleshooting Poor Biogas Production

Suboptimal biogas production frequently indicates underlying issues requiring systematic investigation and targeted intervention. Declining gas yields may result from inhibition, nutrient deficiencies, inappropriate operating conditions, or physical problems within the reactor. Experienced operators approach troubleshooting methodically, beginning with verification of monitoring system accuracy before proceeding to process evaluation.

Comprehensive troubleshooting typically includes biomass activity testing using batch assays to evaluate specific methanogenic pathways, detailed analysis of microbial community structure, and assessment of biomass retention mechanisms. Micronutrient deficiencies—particularly trace metals like cobalt, nickel, and iron that serve as enzyme cofactors—frequently cause unexplained performance declines in long-running systems. Supplementation strategies using specialized trace element formulations have restored performance in many systems experiencing declining gas yields despite stable operating conditions.

Physical issues such as short-circuiting, poor mixing, temperature gradients, or feeding system malfunctions can significantly impact gas production. Advanced diagnostic approaches including computational fluid dynamics modeling, tracer studies, and thermal imaging have helped identify these less obvious physical limitations in large-scale systems. Regular inspection and maintenance programs focused on critical components like influent distribution systems, gas-liquid-solid separators, and recirculation equipment prevent many common physical problems. For those interested in broader waste management strategies, exploring innovative technologies reducing landfill dependence can provide additional insights.

The Economics of High-Rate Digesters

The economic case for high-rate anaerobic digestion extends far beyond simple waste treatment, encompassing energy production, carbon footprint reduction, and circular economy benefits. Understanding the complete financial picture requires comprehensive analysis of capital costs, operational expenses, revenue streams, and non-monetary benefits.

High-rate anaerobic systems typically involve higher initial capital investment than conventional aerobic treatment but offer substantially lower operational costs and valuable biogas production. The economic equation varies significantly based on waste characteristics, local energy prices, regulatory environments, and available incentives. For many applications, particularly high-strength industrial wastewaters, high-rate anaerobic technology delivers the lowest total cost of ownership among available treatment options.

Beyond direct financial returns, these systems provide significant sustainability benefits including reduced greenhouse gas emissions, lower sludge production, and resource recovery opportunities. As carbon pricing mechanisms and circular economy incentives expand globally, these environmental advantages increasingly translate into quantifiable financial benefits that strengthen the business case for implementation.

- Lower operational costs compared to aerobic treatment (60-80% reduction in energy consumption)

- Valuable biogas production (50-75% methane content suitable for energy generation)

- Reduced sludge handling and disposal expenses (80-90% less excess biomass production)

- Smaller footprint requirements (75-90% less area than conventional systems)

- Potential nutrient recovery from digestate for fertilizer production

- Carbon credit opportunities and renewable energy incentives

A comprehensive economic analysis should include both direct financial impacts and broader sustainability benefits when evaluating high-rate anaerobic technology against alternatives. For many applications, the technology offers compelling advantages that continue improving as energy costs rise and environmental regulations tighten.

Installation and Operating Costs

Capital expenditures for high-rate anaerobic systems typically range from $2,000-5,000 per cubic meter of reactor volume, with economies of scale significantly benefiting larger installations. This initial investment includes the reactor vessel, internal components, pumping systems, biogas handling equipment, and basic control systems. Advanced configurations incorporating sophisticated pretreatment, membrane separation, or biogas upgrading technology may reach $6,000-10,000 per cubic meter but offer enhanced performance and additional value streams.

Operational costs present a major advantage for high-rate anaerobic technology, with typical annual expenses ranging from $1-4 per kg COD removed—substantially lower than the $5-15 per kg COD typical for aerobic systems. This remarkable difference stems primarily from energy requirements: while aerobic systems consume 0.5-2 kWh per kg COD removed, high-rate anaerobic processes require only 0.1-0.3 kWh while simultaneously producing 1-1.5 kWh equivalent in biogas energy. Additional operational advantages include minimal chemical requirements for nutrient supplementation, reduced sludge handling costs, and lower maintenance expenses due to simpler mechanical systems.

Return on Investment Calculations

Return on investment for high-rate anaerobic systems varies substantially based on specific applications, but many industrial installations achieve payback periods of 2-5 years when all benefits are properly valued. Key factors influencing ROI include waste strength (higher COD concentrations improve economics), existing disposal costs, energy prices, and available incentives for renewable energy and carbon reduction. Comprehensive financial analysis should include capital costs, operational expenses, energy production value, avoided disposal fees, and applicable regulatory compliance benefits.

Available Incentives and Grants

Government incentives and grant programs can significantly improve project economics for high-rate anaerobic digestion installations. Many regions offer investment tax credits, accelerated depreciation allowances, or direct grants for renewable energy projects, including biogas production facilities. Feed-in tariffs or renewable energy credits provide premium payments for electricity generated from biogas, while renewable natural gas (RNG) programs offer valuable credits for pipeline-quality biomethane production.

Carbon credit mechanisms increasingly recognize the greenhouse gas reduction benefits of anaerobic digestion, both from avoided methane emissions and displaced fossil fuel consumption. These programs can provide substantial additional revenue streams, particularly for agricultural and food waste digestion projects. Navigating the complex landscape of available incentives often requires specialized expertise, but the financial benefits can reduce payback periods by 30-50% for qualifying projects.

Future of Anaerobic Digestion Technology

The evolution of high-rate anaerobic digestion technology continues to accelerate, driven by increasing focus on renewable energy production, circular economy principles, and sustainable waste management. Current research and development efforts focus on enhancing system performance, expanding applicable waste streams, and integrating anaerobic technology into broader biorefinery concepts.

- Advanced process intensification through novel reactor designs and microbiome engineering

- Integration with complementary technologies including hydrothermal carbonization, pyrolysis, and algae cultivation

- Enhanced resource recovery focusing on nutrients, bioactive compounds, and platform chemicals

- Development of simplified modular systems for decentralized applications

- Implementation of digital twins and advanced control systems for optimal performance

- Innovative biogas upgrading technologies enabling cost-effective biomethane production

These emerging innovations promise to further enhance the economic and environmental benefits of high-rate anaerobic digestion while expanding application possibilities. The continued reduction in implementation barriers through standardized designs, simplified operations, and improved reliability will likely accelerate adoption across diverse sectors. For more information on how to recycle organic waste, check out this waste industry guide.

As the technology matures, high-rate anaerobic digestion increasingly serves as the cornerstone of integrated waste-to-resource systems rather than standalone treatment technology. These comprehensive approaches maximize value extraction from organic waste streams through cascading processes that recover energy, nutrients, and valuable compounds while minimizing environmental impact.

Emerging Innovations in Reactor Design

Next-generation reactor designs focus on addressing limitations in current high-rate systems while further enhancing treatment capacity and operational stability. Novel configurations include staged multi-phase reactors with specialized compartments optimized for different digestion stages, hybrid systems combining multiple retention mechanisms, and intensified designs employing strategic microbial immobilization. These advanced reactors aim to achieve loading rates exceeding 50 kg COD/m³·day—more than double current high-rate systems—while maintaining exceptional stability and treatment efficiency.

Integration with Other Renewable Energy Systems

Integrated Biogas Energy Systems

System Type: Combined Anaerobic Digestion + Solar PV

Key Benefits: Complementary energy production profiles, shared infrastructure, stabilized energy output

Efficiency Gain: 15-25% improved energy return on investment

Application Example: Agricultural digesters with solar arrays on building rooftops and buffer zonesSystem Type: Biogas + Wind Hybrid

Key Benefits: Dispatchable biogas power balancing intermittent wind generation

Efficiency Gain: 20-35% reduction in energy storage requirements

Application Example: Grid-connected installations providing baseload renewable powerSystem Type: Digestion + Electrolysis (Power-to-Gas)

Key Benefits: Hydrogen enrichment of biogas, CO₂ utilization, energy storage capability

Efficiency Gain: 30-45% increased methane output using biomethanation

Application Example: Grid balancing installations leveraging excess renewable electricity

The integration of high-rate anaerobic digestion with other renewable energy technologies creates powerful synergies that enhance overall system performance and resilience. Combined biogas and solar installations leverage complementary production profiles—biogas provides consistent baseload power while solar delivers peak daytime capacity. This integration optimizes infrastructure utilization while providing more reliable renewable energy production.

Power-to-gas concepts represent particularly promising integration strategies, converting excess renewable electricity into storable gas through electrolysis and subsequent biomethanation. These systems utilize hydrogen from electrolysis along with CO₂ from biogas upgrading in a biological methanation process that increases overall biomethane production by 50-70% while creating valuable seasonal energy storage capacity. Early commercial installations in Europe have demonstrated the technical feasibility and economic potential of this approach for balancing intermittent renewable electricity production. For additional insights on waste management, you can explore what happens to food waste in landfills.

Advanced energy management systems enable intelligent coordination between different renewable technologies within integrated installations. These sophisticated platforms optimize resource allocation based on current conditions, market signals, and predictive analytics, significantly improving overall energy value and system economics. The holistic approach represents an important evolution beyond siloed renewable energy projects toward truly integrated clean energy ecosystems.

Frequently Asked Questions

As high-rate anaerobic digestion technology continues gaining adoption across diverse sectors, potential implementers frequently seek clarification on key operational aspects, performance expectations, and implementation considerations. The following questions address common inquiries based on practical implementation experience and technical research.

What types of waste work best for high-rate anaerobic digestion?

High-rate anaerobic systems perform exceptionally well with soluble and readily biodegradable organic wastes containing minimal suspended solids. Ideal candidates include food and beverage processing wastewaters, starch processing effluents, brewery and distillery wastewaters, and high-strength streams from pulp and paper processing. These substrates typically achieve COD removal efficiencies exceeding 90% while producing 0.3-0.4 m³ methane per kg COD removed.

More challenging substrates—including those with high fat content, lignocellulosic material, or protein-rich compositions—can still be effectively processed but may require appropriate pretreatment and careful system design. Many installations successfully treat mixed waste streams or practice co-digestion of complementary materials to optimize performance and balance nutrient content. Recent advances in reactor design and process control have significantly expanded the range of suitable substrates for high-rate treatment.

How much biogas can I expect from a high-rate digester?

Biogas production from high-rate anaerobic systems typically ranges from 0.35-0.50 m³ per kg COD removed, with methane content between 55-75% depending on substrate composition and operating conditions. For carbohydrate-rich wastewaters like those from beverage or starch processing, yields average 0.35-0.40 m³ biogas/kg COD with approximately 60% methane content. Protein-rich substrates generally produce similar volumes but with slightly higher methane percentages (65-70%), while lipid-rich wastes can yield up to 0.75-0.90 m³ biogas/kg COD with 68-73% methane content.

Practical energy value calculations must account for system efficiency, operating temperature, and substrate biodegradability. A typical food processing wastewater with COD concentration of 5,000 mg/L treated in a high-rate EGSB system might generate approximately 1.5-1.8 m³ biogas per cubic meter of wastewater processed. This biogas contains roughly 37,500 kJ of energy, equivalent to approximately 10.5 kWh of thermal energy or 3.5-4.2 kWh of electricity when utilized in a modern CHP system.

What's the typical payback period for investing in high-rate AD technology?

Payback periods for high-rate anaerobic digestion systems typically range from 2-7 years, with significant variation based on application specifics, waste characteristics, existing treatment costs, and energy values. Industrial applications processing high-strength wastewaters (>5,000 mg/L COD) often achieve the fastest returns, with many food and beverage sector installations reporting paybacks under 3 years. These economics primarily derive from avoided aerobic treatment costs, reduced surcharges for municipal discharge, and valuable biogas production.

Several factors can dramatically improve payback periods, including high existing waste disposal costs, elevated energy prices, and available incentives for renewable energy production. Facilities implementing high-rate anaerobic technology as part of comprehensive efficiency upgrades often achieve faster returns by optimizing the entire production process to reduce waste generation while recovering valuable byproducts. Proper system sizing—matching capacity to actual needs rather than theoretical maximums—represents another critical factor in achieving favorable economics.

Can high-rate digesters work in cold climates?

High-rate anaerobic digestion can indeed operate successfully in cold climates with appropriate design considerations and operational strategies. While most systems maintain mesophilic (35-38°C) or thermophilic (50-55°C) internal temperatures regardless of climate, external temperature affects heat loss, insulation requirements, and the energy balance of the overall system. Modern installations in northern regions employ advanced insulation techniques, heat recovery systems, and strategic operational controls to maintain efficient performance despite challenging ambient conditions.

For wastewaters that arrive at low temperatures (below 15°C), additional heating capacity and enhanced heat recovery systems become essential. Innovative approaches for cold-climate operation include subterranean reactor installation to leverage geothermal buffering, advanced heat integration with other facility processes, and specialized low-temperature microbial communities for the initial treatment stages. Several EGSB installations in Scandinavia, Canada, and northern Russia have demonstrated exceptional performance despite extreme climate conditions, achieving standard treatment efficiency while maintaining positive energy balances through sophisticated heat management strategies.

How do I choose the right high-rate digestion system for my needs?

Selecting the optimal high-rate anaerobic technology requires comprehensive assessment of waste characteristics, treatment objectives, space constraints, and operational capabilities. The evaluation should begin with detailed waste characterization including COD fractionation (soluble vs. particulate), biodegradability testing, potential inhibitor identification, and seasonal variation analysis. This foundation enables accurate performance predictions and appropriate technology matching.

For wastewaters with primarily soluble COD and minimal suspended solids (<2,000 mg/L), UASB or EGSB technologies typically offer the most cost-effective solution. Applications involving higher suspended solids concentrations often benefit from fixed-film technologies that resist clogging while maintaining effective biomass retention. Situations requiring exceptional effluent quality or handling inhibitory compounds may justify the higher capital cost of AnMBR technology with its complete biomass retention and superior treatment consistency.

Beyond technical considerations, implementation success depends equally on operational factors, including available expertise, maintenance capabilities, and organizational commitment to proper system management. The most sophisticated technology will underperform without appropriate operational support, while simpler systems often deliver excellent results when well-managed. Many facilities benefit from starting with less complex technology and gaining operational experience before implementing more advanced solutions as part of phased implementation strategies.

High-rate anaerobic digestion technology continues evolving rapidly, offering increasingly powerful tools for sustainable waste management while producing valuable renewable energy. By carefully matching system design to specific application needs and implementing proper operational protocols, these advanced biological systems deliver exceptional performance with attractive economic returns. As global focus on circular economy principles and climate change mitigation intensifies, high-rate anaerobic digestion will undoubtedly play an expanding role in sustainable resource management strategies.

\\\============================

Update to the Original Post published in June 2013 – BioWayste failed as a company in 2014 and was wound up, but the £2 million High Rate Anaerobic Digestion Plant was completed, to Treat Brocklesby Ltd Effluent Streams.

We understand that it continues to operate with an increasing demand for the fuel it produces.

[Article first posted September 2017. Updated January 2022. Rewritten December 2025]

E3 has developed the AGF process that utilizes biogas for the flotation, concentration, and recycle of a concentrated bacterial biomass stream. Consequently, SRT / HRT ratios greater than three are achieved. An SRT / HRT ratio of three means that the digester size can be reduced to one third of the conventional size while achieving the same percentage solids conversion to gas. check out the linked on name above.

If some one wants to be updated with hottest technologies after that he must be pay a quick visit this website and be up to date everyday. https://www.manuremanager.com/beef/canadas-largest-biogas-plant-15093

I don’t do that much of a internet surfing to be

honest but your site is really nice. Keep it up giving us more like this!

I’ll be and bookmarking your website Will come back sometime down the

road. Cheers

Expensive toys for the farm boys! All sounds good but £2 million. That’s an investment.

This whole thing works best when the site has its own waste source to feed the facility with biomass. It should work very well.

Aw, this was a really nice post. Finding the time

and actual effort to make a great article… but what

can I say… I hesitate a lot and never seem to get anything done.

[Supplied link has been deleted as it did not work/ showed a “not found” error.]