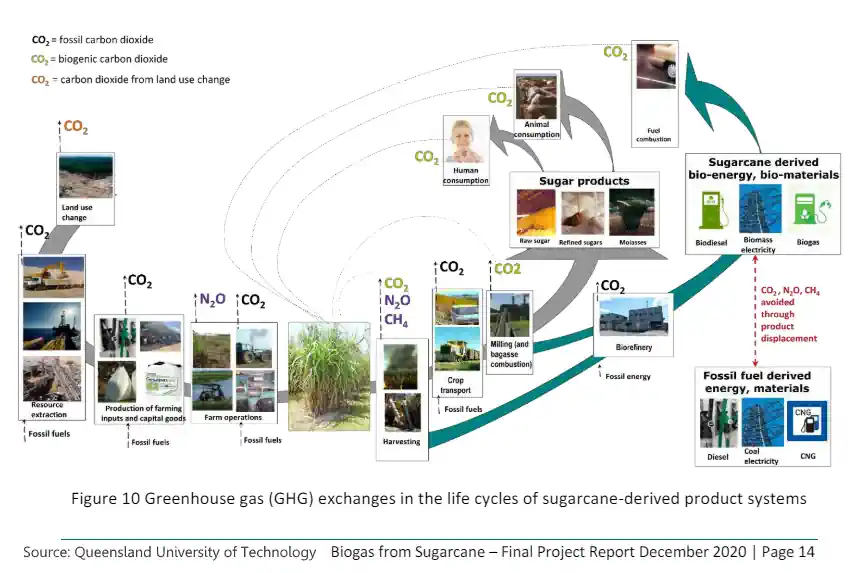

In this article, we discuss unlocking the potential of anaerobic digestion or sugar waste biogas including sugarcane biomass, and sugar beet waste for biogas production not forgetting pre and post-consumer sugary food waste. However, none of this would be possible without reliable and affordable equipment to convey the viscous fibre-filled mash of this biomass through the process equipment, as described in our Borger case study included below.

Sugar waste, in its various forms, presents a unique challenge and opportunity. While excess sugar consumption can lead to weight gain in humans, its inherent energy potential makes it a valuable feedstock for biogas production through anaerobic digestion (AD).

This article explores the potential of utilizing different sugar waste streams – from bagasse in the sugarcane industry to off-spec food products – to generate renewable energy through biogas plants and how users overcome the challenge of pumping it!

Sugar Waste as a Biogas Feedstock

The AD process harnesses the power of microorganisms to break down organic matter in an oxygen-free environment. Sugar, being readily biodegradable, offers a potent energy source for these microbes.

When incorporated into a biogas digester, sugar waste stimulates microbial growth, leading to a significant increase in methane yield – the primary component of biogas used for generating electricity and heat.

This is a wonderful opportunity for society to benefit from what would otherwise be wasted.

Examples of Sugar Waste Streams for AD and Biogas Production

- Sugarcane Bagasse: A fibrous residue left after sugarcane juice extraction, bagasse is a well-established feedstock for biogas production. However, its complex structure can hinder microbial breakdown. Pretreatment methods can enhance digestibility, unlocking its full biogas potential.

- Sugar Beet Waste: As for sugarcane bagasse the waste from sugar beet instead of sugar cane varieties

- Off-Spec Food Products: During food processing and storage, a significant amount of sugary products like syrups, beverages, and bakery items become unfit for human consumption due to minor defects or nearing expiry. While adhering to the waste hierarchy, prioritizing food donation and animal feed options, utilizing unsuitable products for AD offers a sustainable waste management solution while generating valuable biogas.

The Analogy: Sugar for Microbes, Growth for Biogas Plants

Similar to how sugar consumption fuels human growth, incorporating sugar waste into biogas plants acts as a growth stimulant for the resident microbial communities. This enhanced microbial activity translates to a substantial rise in methane production, maximizing the energy output of the biogas plant.

Co-digestion with Existing Feedstocks: A Synergy

The benefits of sugar waste extend beyond dedicated sugar-based AD systems. Co-digesting sugar waste with traditional feedstocks like farm manure or sewage sludge in existing biogas plants can significantly improve overall methane yield.

This approach optimizes biogas production from established infrastructure, leveraging the readily digestible nature of sugar to enhance the breakdown of more complex organic materials present in manure and sludge.

Sweet Success: Borger Pumps Prove Their Worth in the Sugar Industry

Both sugar refineries and waste sugar biogas plants rely on efficient and dependable pumps to keep their operations running smoothly. For one such refinery, the high cost of maintaining their existing pumps and frequent downtime prompted a search for a more reliable solution.

The following press release details their successful transition to Borger pumps, not only in the core sugar production process but also in their innovative application for renewable energy generation.

Press Release June 2024:

“Sugar Sugar” for hard-working Borger Pumps

Following the proven, ongoing performance of three rotary lobe pumps installed in a key process at a sugar refinery, a further two units from Borger are to be installed at the plant.

Two of the existing Borger pumps are utilised for white mass (sugar syrup with crystals), whilst the third pump also runs 24/7 (from August to May), but for a slightly lower grade of sugar. Both applications send the highly viscous solution (50-55% solids) to its final stage, where the syrup is spun off to reveal the end-product of fine white sugar crystals.

Increasingly prohibitive maintenance bills (over £12,000 per overhaul, per pump) and lengthy downtime had prompted the sugar refinery to replace three of its pumps.

To further improve and streamline its pumping operation, the sugar refinery also ensured that the new pumps are all the same size (unlike the previous units), to reduce the cost of required spares.

A further four Borger pumps have also become an integral part of the sugar producer’s AD plant, which uses waste pulp beet as a feedstock for clean renewable energy.

At the AD plant which includes three digesters, receiving around 100,000 tonnes of pressed sugar beet pulp pa, the Borger pumps are utilised for the transfer of digestate.

At a separate sugar-beet processing facility, a Borger BLUEline EL 1000 pump has been installed after an old rotary piston unit failed. The Borger pump conveys massecuite (sugar crystals), with flow rates of 60 – 150 GPM @ 52 psi.

And to complete a hat-trick of new orders in highly viscous and abrasive applications such as the processing of magma, sugar syrup, and liquid sugar, a Borger BLUEline EL 1000 pump has commenced its role in unloading molasses (10,000 cP) from rail tankers.

Borger UK – 01902 798 977 – www.boerger.com

Looking Ahead to a sustainable future for Sugar Waste Biogas

The potential of sugar waste for biogas production is undeniable. However, it's crucial to maintain a responsible approach. Prioritizing food security and ensuring that sugar supplies are directed primarily towards human consumption remains paramount.

Government policies and industry practices should be designed to prevent the diversion of resources away from food production.

The Future is Bright for Sugar Waste Biogas

With proper management and infrastructure development including the prudent choice of specially adapted lobe pumps, sugar waste can significantly contribute to renewable energy generation through biogas.

Research efforts focused on optimizing pretreatment methods for bagasse and exploring co-digestion strategies with various waste streams hold immense promise for maximizing biogas yields.

By harnessing the power of sugar waste, we can move towards a more sustainable future powered by renewable energy sources.

Tags: Anaerobic digestion feedstock, Biogas methane yield, Sugarcane bagasse pretreatment, Sugar beet waste, Co-digestion of sugar waste, Biogas from food waste, Sustainable waste management, Renewable energy from waste.