Solid State Anaerobic Digestion (SSAD) is a cutting-edge technology that is revolutionizing the way we think about waste management and renewable energy production. In this introductory section, we will delve into the world of SSAD, shed light on its significance, and explore how recent engineering advances have transformed the landscape of anaerobic digestion.

Anaerobic digestion has traditionally been limited to liquid, slurry, and semi-solid materials. Recent technological breakthroughs have made it possible to convert dry, stackable materials such as municipal solid waste (MSW), food waste, and yard trash to biogas. “Solid-state digesters” is the name given to these innovative systems.

Unveiling the Concept of SSAD

SSAD: A revolutionary approach to waste conversion

Imagine a world where even dry, stackable materials like municipal solid waste, food waste, and yard waste can be converted into valuable biogas. Traditionally, anaerobic digestion was limited to liquid, slurry, and semi-solid materials, leaving these dry resources untapped. However, recent engineering advancements have given rise to a game-changing process known as Solid-State Anaerobic Digestion (SSAD), also known as Dry Anaerobic Digestion.

[boomdevs_toc]

The Traditional Limitations

Anaerobic Digestion: The age-old method with constraints

Anaerobic digestion, the predecessor to SSAD, had its limitations. It was primarily suitable for liquid and semi-solid materials, rendering dry, stackable resources out of reach. This constraint was a bottleneck in the quest for sustainable waste management and biogas production.

Engineering Advancements

The Turning Point: How engineering changed the game

In recent years, engineering has come to the rescue. Innovations and breakthroughs have shattered the traditional boundaries of anaerobic digestion. This breakthrough now allows us to harness the untapped potential of dry, stackable materials, such as municipal solid waste, food waste, and yard waste, by converting them into biogas. These systems are aptly named “solid-state digesters.”

In the next section, we will take a deeper dive into the SSAD process, unveiling the intricate steps that make this technology a game-changer in the world of waste management and renewable energy production.

Ready to explore the inner workings of Solid State Anaerobic Digestion (SSAD)? In the upcoming section, we will dissect the SSAD process, shedding light on how it transforms organic materials into valuable biogas. Let's embark on this fascinating journey into the heart of SSAD!

The SSAD Process: Unlocking the Power of Anaerobic Digestion

In the realm of waste management and renewable energy production, the Solid State Anaerobic Digestion (SSAD) process stands as a remarkable innovation. In this section, we will dive deep into the heart of SSAD, unravelling the intricate steps that make it a game-changer in converting organic materials into valuable biogas.

Understanding the SSAD Process

SSAD: A Two-Step Marvel

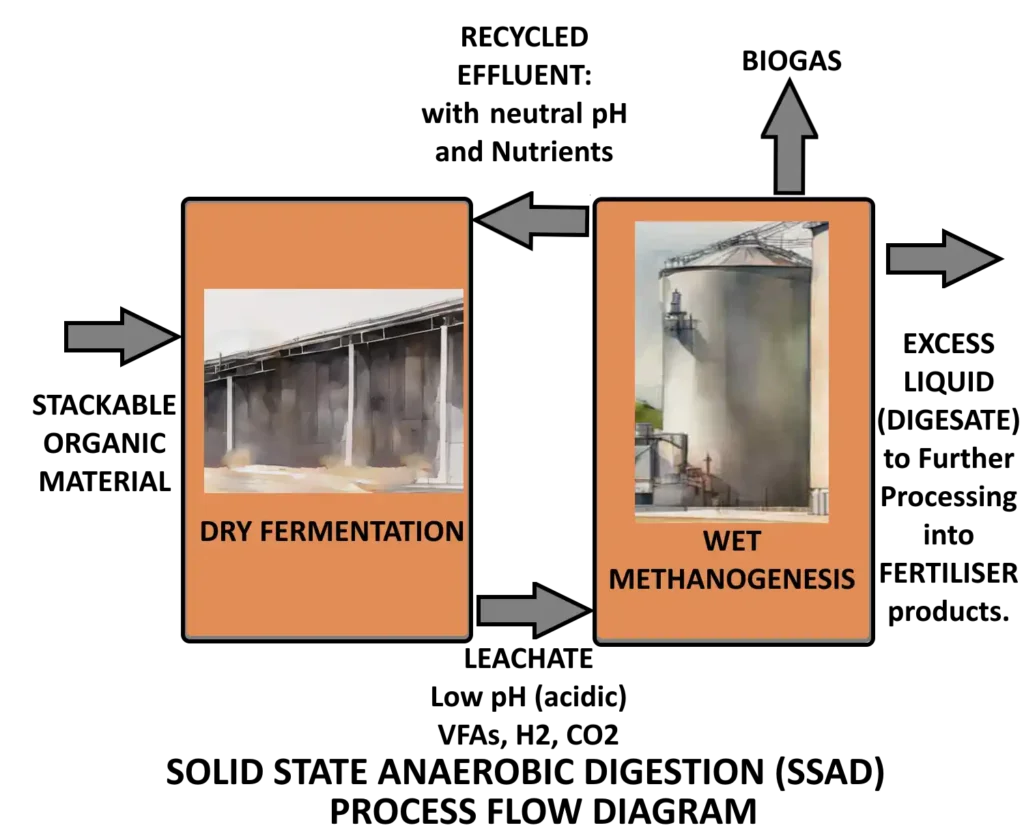

At its core, SSAD is a two-step process that transforms organic materials into methane-rich biogas. These two vital steps are dry fermentation and wet methanogenesis.

Dry Fermentation: The First Step

Liquefying Organic Matter: Unlocking the potential

In the SSAD process, dry fermentation is the initial, crucial step. This is where solid organic matter undergoes a remarkable transformation. During this phase, solid materials such as municipal solid waste, food waste, and yard waste come into play. Fermentation occurs when these materials are exposed to specific conditions.

Fermentation is the liquefaction of solid organic matter into precursor components, namely:

- volatile fatty acids (VFAs),

- hydrogen (H2), and

- carbon dioxide (CO2).

Wet Methanogenesis: The Second Step

The Methane Conversion: Turning precursors into biogas

Methanogenesis is the final step in anaerobic digestion, and in SSAD, it takes centre stage. The precursors made during fermentation (VFA, H2, and CO2) go through an interesting change during wet methanogenesis. They are converted into methane (CH4), the valuable component that makes biogas so appealing.

- This step is where the magic happens, as methane is formed from the conversion of VFA, H2, and CO2.

Separating Fermentation and Methanogenesis

Dry Fermentation: Stacked solids and nutrient-rich effluent

One key innovation of SSAD is the separation of fermentation from methanogenesis. This separation is vital, especially when dealing with lignocellulosic materials like cotton gin trash and municipal solid waste. Fermentation of these materials occurs too slowly in liquid reactors.

- In SSAD, dry fermentation happens as nutrient-rich, neutral pH effluent trickles through stacked solids.

- Liquid is prevented from accumulating during fermentation, giving rise to the term “dry fermentation.”

- The process ensures efficient digestion of materials that might otherwise pose challenges.

A Visual Guide

Figure 1: The basic process of solid-state anaerobic digestion

For a visual reference, refer to Figure 1, which illustrates the fundamental process of SSAD, showcasing the separation of fermentation and methanogenesis.

Moving Forward

As we delve deeper into the world of SSAD, we've uncovered the intricate process that turns waste into valuable biogas. The separation of dry fermentation and wet methanogenesis is a key feature that sets SSAD apart. In the next section, we'll explore the different types of SSAD systems, each with its own unique advantages and configurations, to further enhance our understanding of this transformative technology.

Now that we've grasped the inner workings of the SSAD process, it's time to explore the variety of SSAD systems in the next section. These systems come in different forms, each with its own set of benefits and configurations. Join us as we venture into the world of SSAD systems and discover the versatility of this game-changing technology!

Exploring Different Types of SSAD Systems

In our journey through the world of Solid State Anaerobic Digestion (SSAD), we've uncovered the intriguing process behind this innovative technology. Now, let's delve into the diverse landscape of SSAD systems, each designed with specific configurations and functionalities to maximize its efficiency.

Understanding SSAD Systems

Variety in Design: Different systems for different needs

SSAD systems come in various forms, each tailored to handle specific types of waste and operational requirements. Understanding the types of SSAD systems is essential to appreciate the versatility of this waste-to-biogas technology.

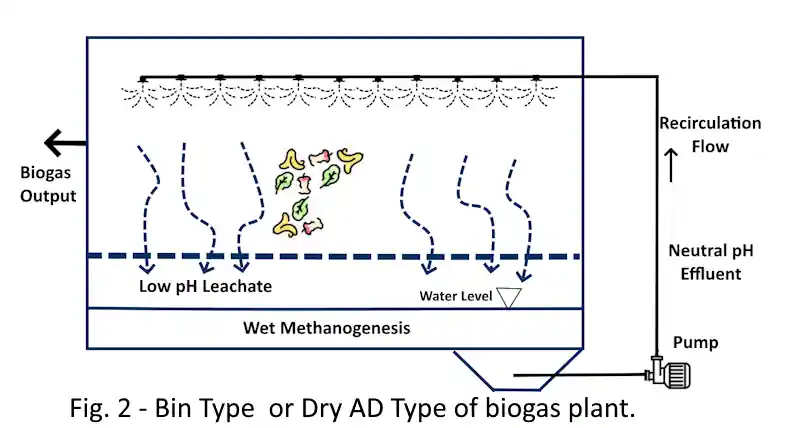

Bin Reactors: Efficiency in a Box

Design and Function: Efficient waste conversion

Bin reactors are essentially boxes with a unique purpose. They serve as the stage for dry fermentation in the SSAD process. Here's a closer look at their design and function:

- Design: Bin reactors feature a box-like structure with false bottoms. These false bottoms are perforated, allowing for the passage of leachate (the liquid produced during fermentation).

- Function: Dry fermentation occurs within the material stacked on top of the perforated floor. As fermentation progresses, leachate percolates through the pile, collecting below the floor.

- Efficiency: Bin reactors are renowned for their efficiency. They make use of a single-phase system, where leachate undergoes methanogenesis as it is collected in the bottom of the bin. This streamlines the process, reducing the need for separate reactors.

- Large-Scale: These reactors are often quite large, sometimes referred to as “Bay Reactors.” Their size allows trucks and loaders to access them, making the stacking and processing of materials a smooth operation.

- Composting: Once the stacked material has been thoroughly fermented, it can be removed as is or composted in place. By blowing air through the false bottom, composting is possible, further improving waste management techniques.

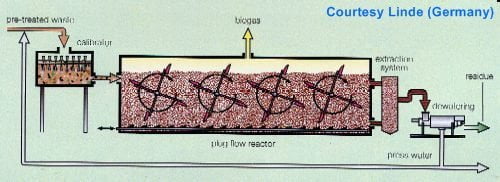

Silo Reactors: Upright Efficiency

Cylindrical Configuration: Maximizing leaching efficiency

Silo reactors offer a different approach to SSAD, utilizing their cylindrical shape to optimize leaching efficiency. Here's what you need to know:

- Design: Silo reactors are large, upright cylinders. Stackable organic material is augered to the top of the silo, ready for digestion. The cylindrical shape allows for efficient leaching throughout the length of the pile.

- Two-Phase Option: Silo reactors can be configured as two-phase systems. In this arrangement, methanogenesis takes place in a separate reactor, and effluent is sprinkled on top of the pile stacked in the silo.

- Single-Phase Variants: Silo reactors also exist in single-phase configurations. Some designs mix incoming dry material with leachate before pumping it to the top of the silo.

The DRANCO Innovation

German Expertise: DRANCO's single-phase silo reactor

In Germany, the DRANCO single-phase silo reactor has gained recognition for its efficiency in digesting solid municipal waste. This innovation is a testament to the international reach of SSAD technology.

What's Next?

Now that we've explored the fascinating world of SSAD systems, we'll journey into the realm of methanogenesis reactors in the next section. These reactors play a pivotal role in converting leachate into valuable biogas, and we'll uncover the various types and efficiencies they bring to the SSAD process.

With a clear understanding of the diverse SSAD systems at our disposal, it's time to delve deeper into the next layer of this transformative technology. In the upcoming section, we will explore the world of methanogenesis reactors, shedding light on the various types and their roles in converting leachate into precious biogas. Join us as we continue our journey through the intricacies of Solid State Anaerobic Digestion!

Methanogenesis Reactors: The Powerhouses of Biogas Production

As we continue our journey through the intricate world of Solid State Anaerobic Digestion (SSAD), it's time to shine a spotlight on the unsung heroes of the process: the methanogenesis reactors. These remarkable reactors play a pivotal role in converting leachate into valuable biogas, and in this section, we'll explore their significance and various types.

The Role of Methanogenesis Reactors

Biogas Generation: Turning leachate into gold

Methanogenesis reactors are the final frontier in the SSAD process. The main job of these reactors is to turn volatile fatty acids (VFA), hydrogen (H2), and carbon dioxide (CO2), which are byproducts of fermentation, into methane (CH4). This conversion is the essence of biogas production.

The Variety of Methanogenesis Reactors

Adapting to Efficiency: Different reactors for different needs

While almost any anaerobic digester can be used for wet methanogenesis, certain types stand out for their high efficiency. Let's delve into some notable examples:

Fixed Film Reactors

Solid Support: Creating an ideal environment

Fixed-film reactors are designed with solid support media where microorganisms responsible for methanogenesis attach and grow. These microorganisms efficiently convert VFA, H2, and CO2 into methane. Key features include:

- Stability: Fixed-film reactors provide a stable environment for the microorganisms, ensuring consistent biogas production.

- High Efficiency: Their design allows for high contact between microorganisms and substrates, enhancing the conversion process.

Upflow Sludge Blanket (UASB) Reactors

Blanket of Efficiency: Efficient sludge management

UASB reactors are known for their ability to separate the solid sludge from the liquid effluent, allowing for efficient treatment of wastewater. In the context of SSAD, these reactors excel in wet methanogenesis due to:

- High-Rate Conversion: UASB reactors achieve high-rate conversion of VFA, H2, and CO2 to methane, making them ideal for biogas production.

- Effective Sludge Management: The separation of sludge from the liquid stream minimizes the risk of clogging and ensures continuous operation.

Anaerobic Sequencing Batch (ASBR) Reactors

Sequential Efficiency: Optimizing the process

ASBR reactors follow a specific sequence of phases, optimizing the methanogenesis process. Their key features include:

- Controlled Phases: ASBR reactors allow for precise control of different phases of anaerobic digestion, enhancing biogas production.

- Flexibility: They can adapt to varying feedstock conditions, making them versatile in SSAD applications.

Further Exploration

For those interested in delving deeper into the world of anaerobic digesters and their applications, additional information on various types of digesters is available through this link.

What Lies Ahead

As we wrap up our exploration of methanogenesis reactors, it's time to turn our attention to the final section of our journey. In the next segment, we will summarize the key takeaways and revisit the significance of SSAD in waste management and biogas production.

Having uncovered the secrets of methanogenesis reactors and their crucial role in biogas production, we now approach the final chapter of our SSAD adventure. In the upcoming section, we will tie together all the knowledge we've gained, emphasizing the potential benefits of SSAD in transforming waste management and harnessing the power of renewable energy. Join us as we conclude our exploration of Solid-State Anaerobic Digestion!

Summary and Conclusion: Unleashing the Potential of Solid-State Anaerobic Digestion

As we conclude our exploration of SSAD, we've journeyed through the intricacies of this innovative waste-to-energy process. In this final section, let's recap the key insights from our journey and emphasize the potential benefits of SSAD in waste management and biogas production.

Recap of Our Journey

Section 1: Introduction

We began our journey by introducing the concept of SSAD. We highlighted the traditional limitations of anaerobic digestion and the recent engineering advances that have ushered in a new era of waste-to-energy conversion. SSAD has emerged as a game-changer, enabling the transformation of dry, stackable materials into valuable biogas.

Section 2: The SSAD Process

In the second section, we delved into the SSAD process itself. We focused on its two crucial steps: dry fermentation and wet methanogenesis. It became clear how important methanogenesis is for turning organic materials into methane, especially lignocellulosic materials. SSAD's unique approach, which separates fermentation from methanogenesis, was illustrated through a helpful diagram.

Section 3: Types of SSAD Systems

Our exploration continued with a discussion of the various types of SSAD systems based on reactor configurations. We explored Bin Reactors, understanding their design, function, and efficiency. Silo Reactors, both single-phase and two-phase, opened new avenues for waste digestion. We even ventured to Germany to witness the DRANCO single-phase silo reactor in action.

Section 4: Methanogenesis Reactors

The unsung heroes of biogas production, methanogenesis reactors, took the spotlight in the fourth section. We uncovered their role in turning leachate into valuable biogas. It was shown that Fixed Film Reactors, Upflow Sludge Blanket (UASB) Reactors, and Anaerobic Sequencing Batch (ASBR) Reactors are all very important to the process. It was also shown that they work well and how flexible they can be.

The Potential Benefits of SSAD

Now, let's emphasize why SSAD is more than just a technological advancement—it's a solution with the potential to revolutionize waste management and renewable energy production.

Waste Management Revolution

SSAD has the power to address the challenges of managing solid waste, food waste, and yard waste. By converting these dry materials into biogas, SSAD reduces landfill waste, minimizes environmental impact, and promotes a circular economy.

Harnessing Renewable Energy

Biogas generated through SSAD is a valuable source of renewable energy. It can be used for electricity generation, heating, and even as a clean fuel for vehicles. SSAD plays a crucial role in diversifying our energy sources and reducing greenhouse gas emissions.

Conclusion

In conclusion, Solid-State Anaerobic Digestion is a groundbreaking technology that offers a sustainable solution to waste management and renewable energy production.

SSAD could change how we deal with waste and use renewable resources by getting around the problems that currently exist with anaerobic digestion and utilizing the power of methanogenesis reactors.

As we've journeyed through the intricacies of SSAD, from its inception to its application in different systems, we've witnessed the promise it holds for a greener, more sustainable future. It's not just a process; it's a pathway to a cleaner, more efficient world.

Thank you for joining us on this exploration. We hope this journey has shed light on the possibilities and potential of SSAD. As we move forward, let's continue to embrace innovative solutions like SSAD to build a brighter and more sustainable tomorrow.